Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Low moisture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

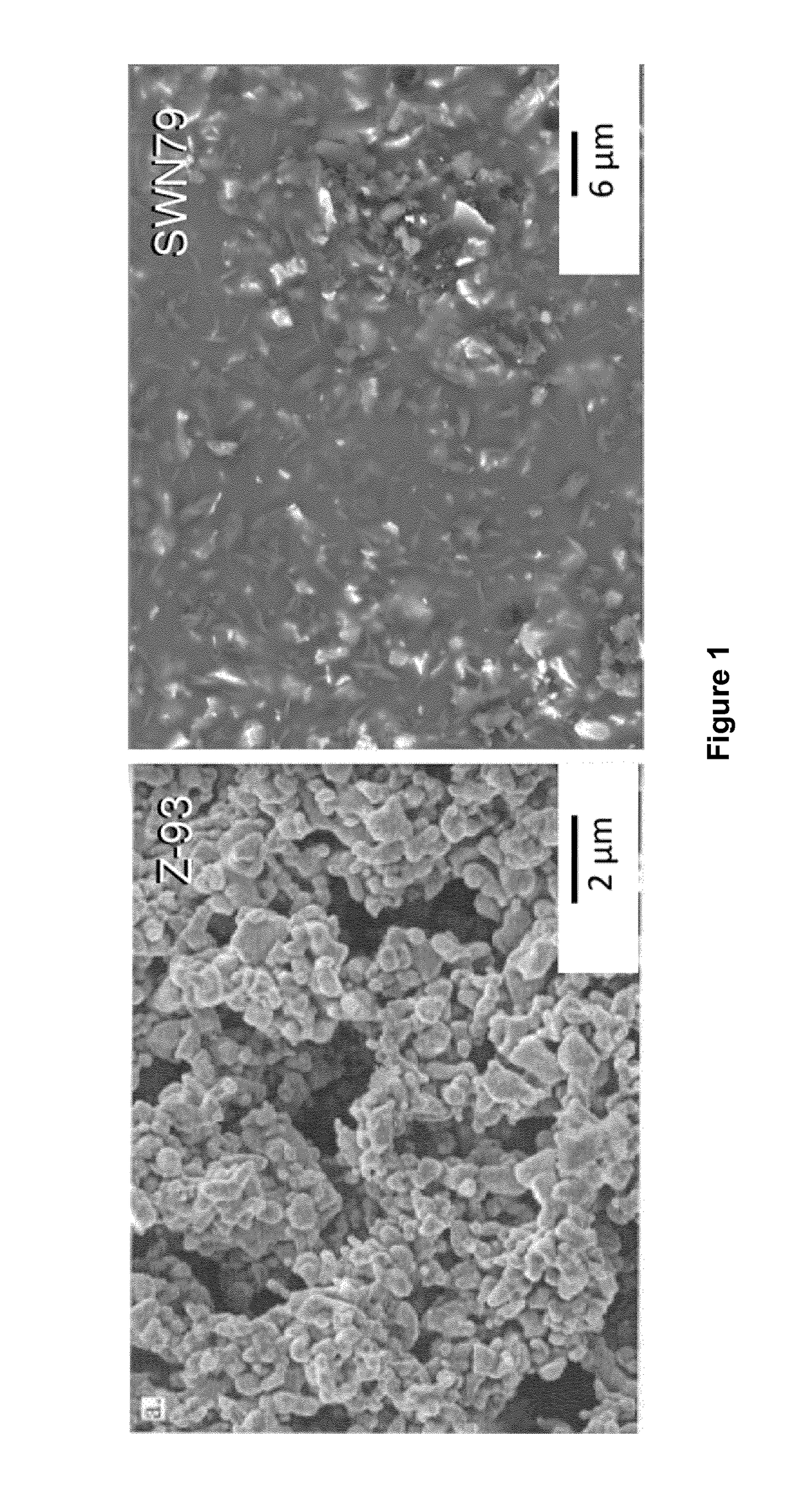

Positive electrode active material for non-aqueous electrolyte secondary battery and method for producing the same

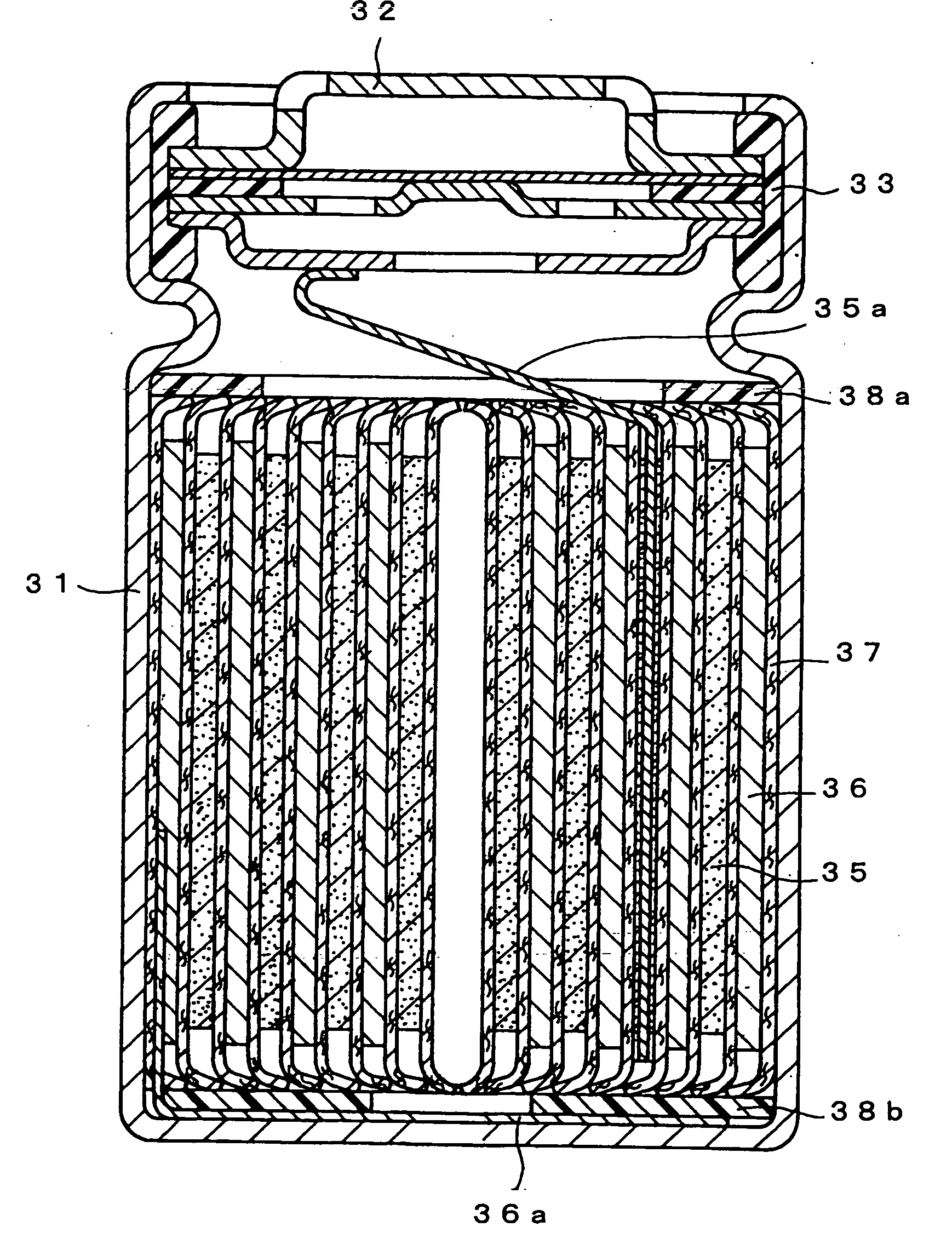

ActiveUS20100112447A1High volume resistivityLow volume resistivityNon-aqueous electrolyte accumulatorsActive material electrodesComposite oxideMaterials science

A positive electrode active material for a non-aqueous electrolyte secondary battery is provided. The positive electrode active material includes a composite oxide containing lithium and metal M other than lithium, and M contains Ni, Mn, and Co. The molar ratio of Ni to the total of Ni, Mn, and Co is from 0.45 to 0.65, and the molar ratio of Mn to the total of Ni, Mn, and Co is from 0.15 to 0.35. The positive electrode active material has a pressed density under a compression of 60 MPa of 3.3 g / cm3 or more and 4.3 g / cm3 or less. The positive electrode active material has a volume resistivity under a compression of 60 MPa of 100 Ω·cm or more and less than 1000 Ω·cm.

Owner:PANASONIC CORP

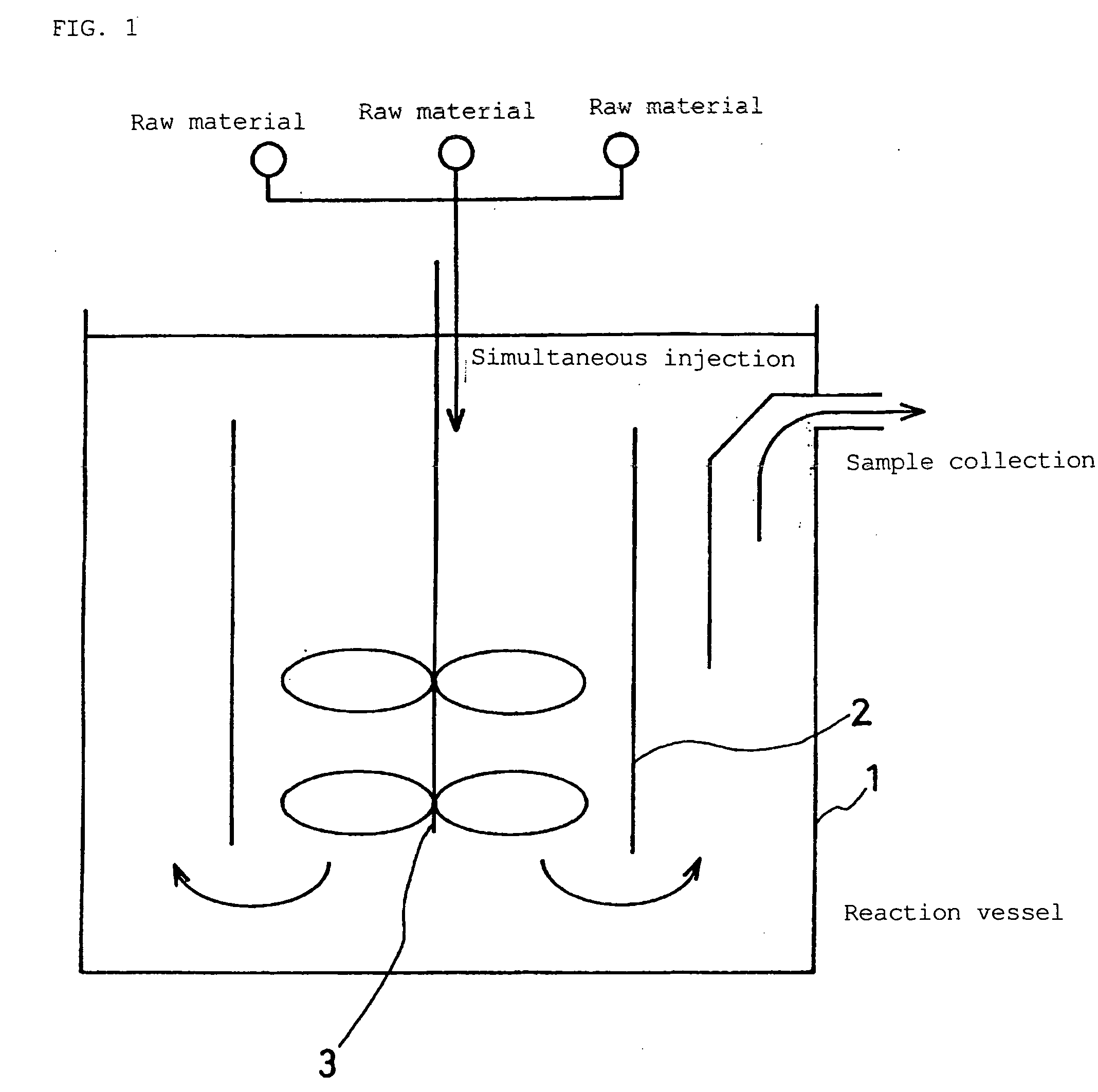

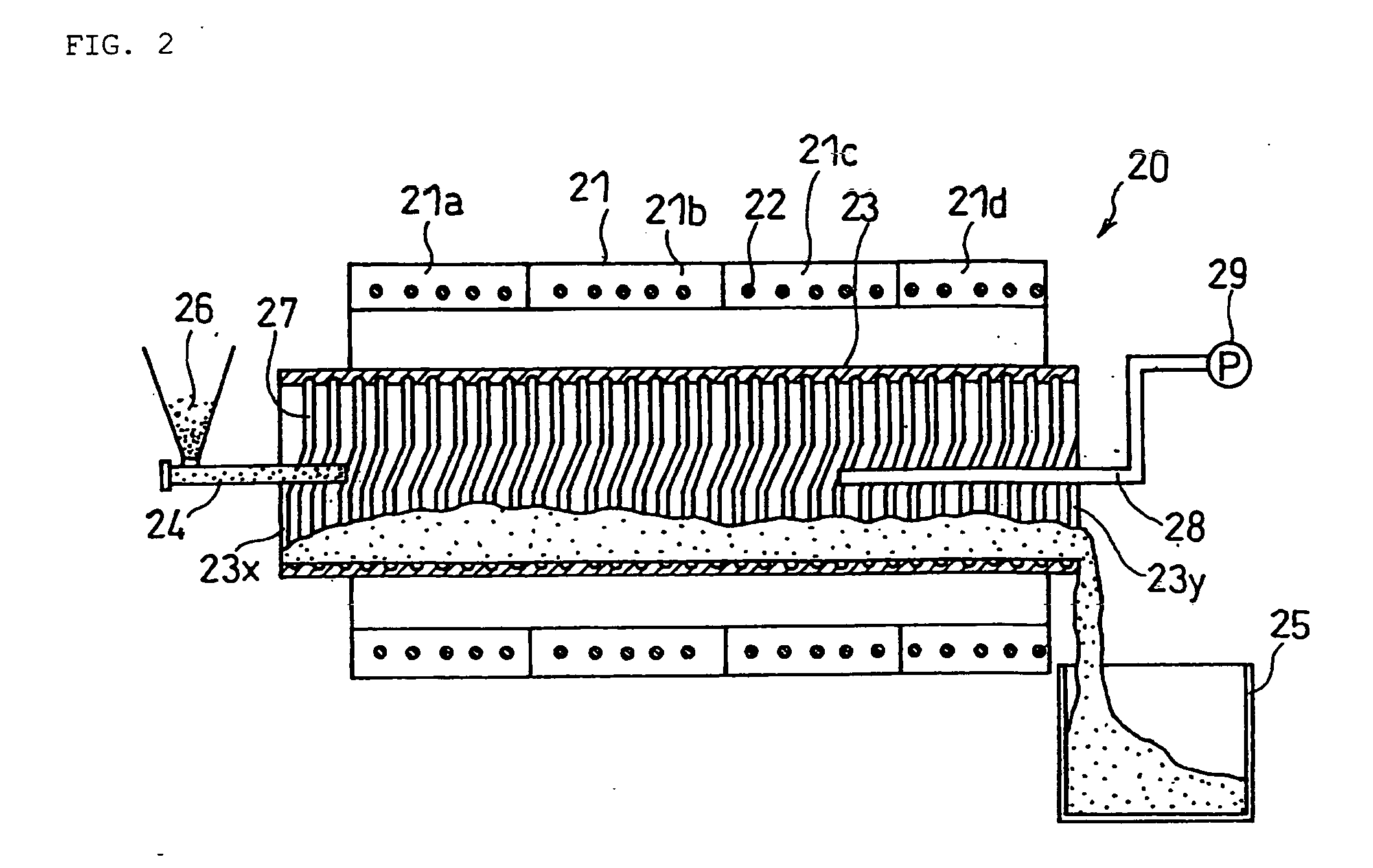

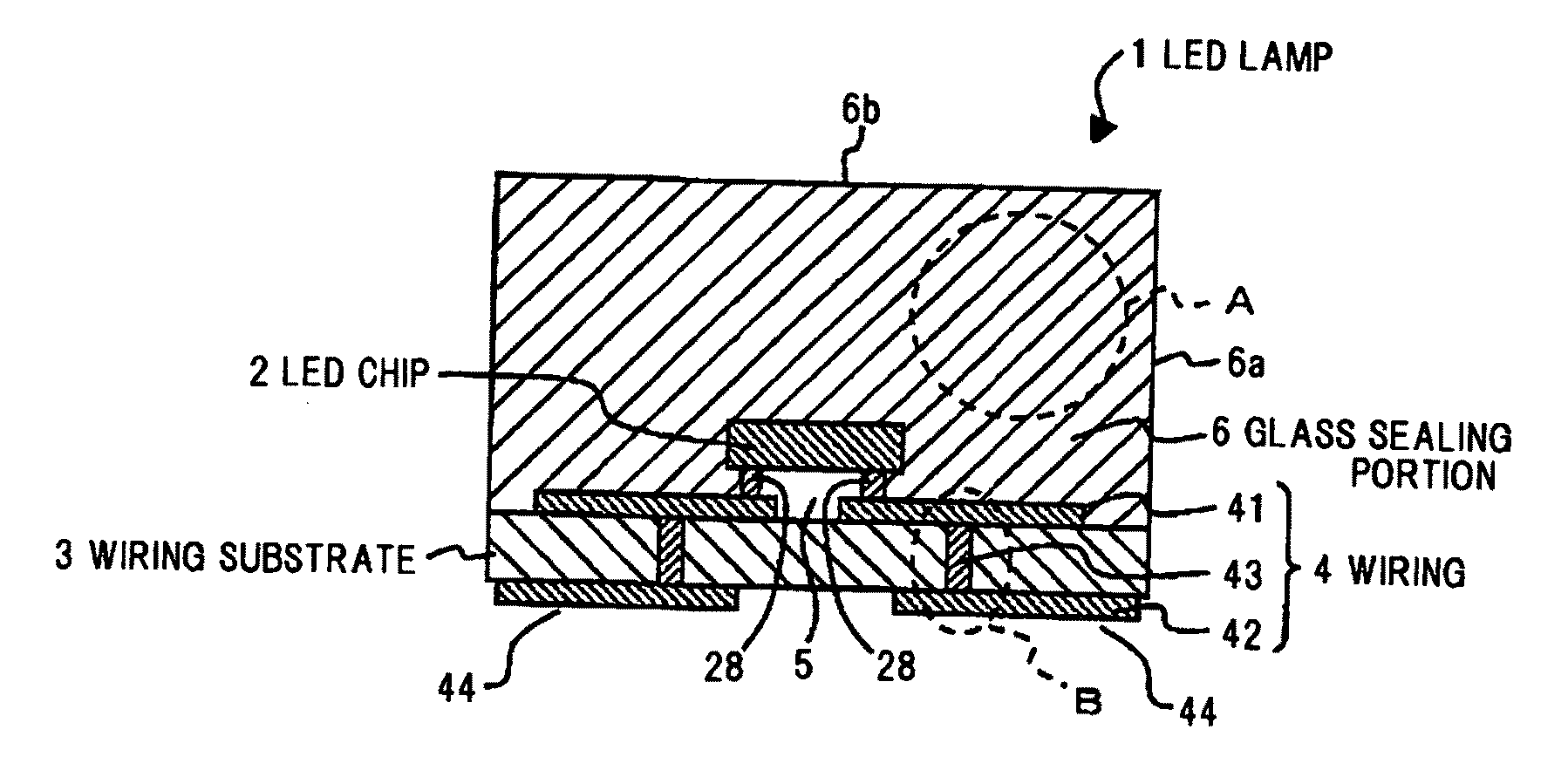

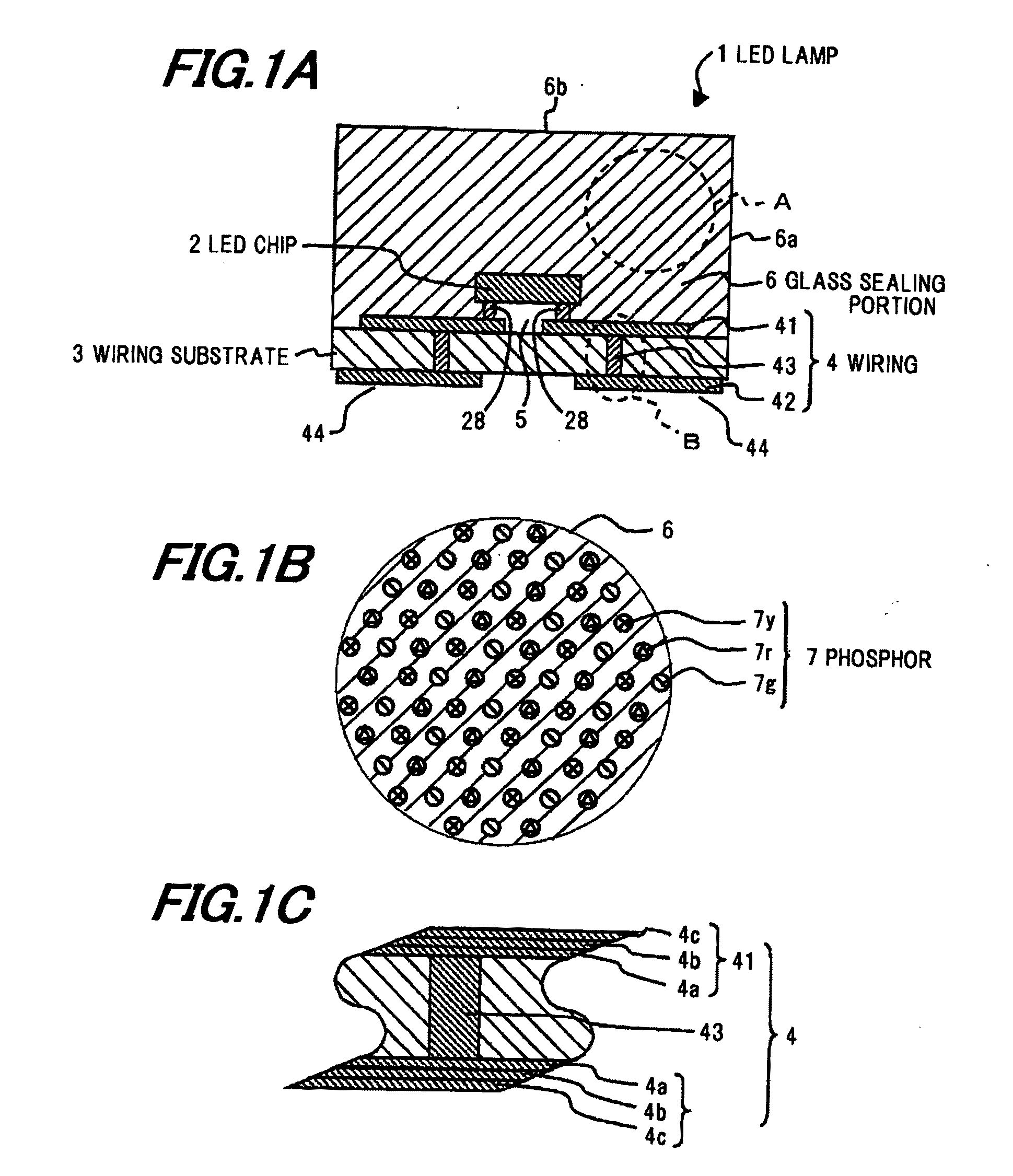

Method of making phosphor containing glass plate, method of making light emitting device

ActiveUS20090186433A1Prevent deteriorationLow moisture resistanceSolid-state devicesGlass drawing apparatusHot pressingPhosphorus

A method of making a light emitting device includes mixing a glass powder with a phosphor powder including at least one of a sulfide phosphor, an aluminate phosphor and a silicate phosphor to produce a mixed powder in which the phosphor powder is dispersed in the glass powder, heating and softening the mixed powder to provide an integrated material, and subsequently solidifying the integrated material to provide a phosphor-dispersed glass, and fusion-bonding the phosphor-dispersed glass onto a mounting portion on which a light emitting element is mounted by hot pressing, and simultaneously sealing the light emitting element with the phosphor-dispersed glass on the mounting portion.

Owner:TOYODA GOSEI CO LTD +1

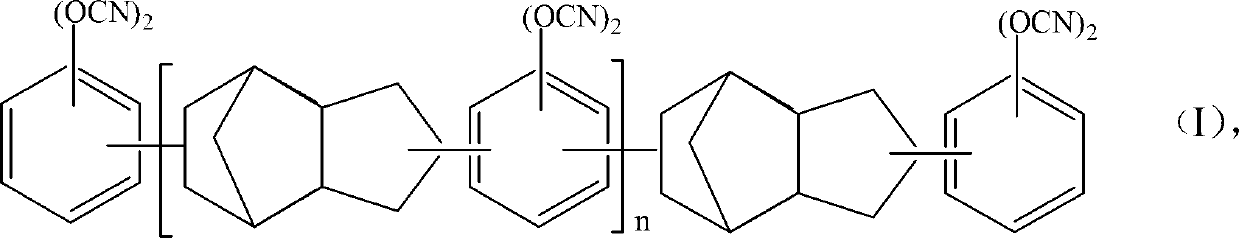

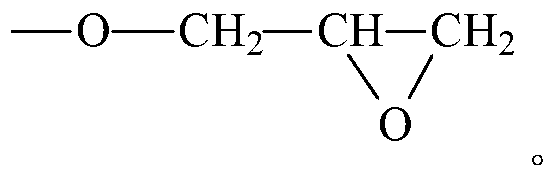

Thermosetting cyanate resin composition and application of thermosetting cyanate resin composition

ActiveCN102942684AOvercome the disadvantage of high water absorptionImprove heat resistanceSynthetic resin layered productsEpoxyCopper coating

The invention relates to a thermosetting cyanate resin composition, which comprises the following components: polyfunctional cyanate, epoxy resin, flame retardant agent and inorganic filler. The thermosetting cyanate resin composition is used for preparing resin substrates, resin compound metal copper foils, prepregs, laminating plates, copper-coating plate laminating plates, printed circuit boards and the like. The thermosetting cyanate resin composition has good heat resistant property, humidity resistant property and flame retardant property and low heat expansion coefficient.

Owner:GUANGDONG SHENGYI SCI TECH

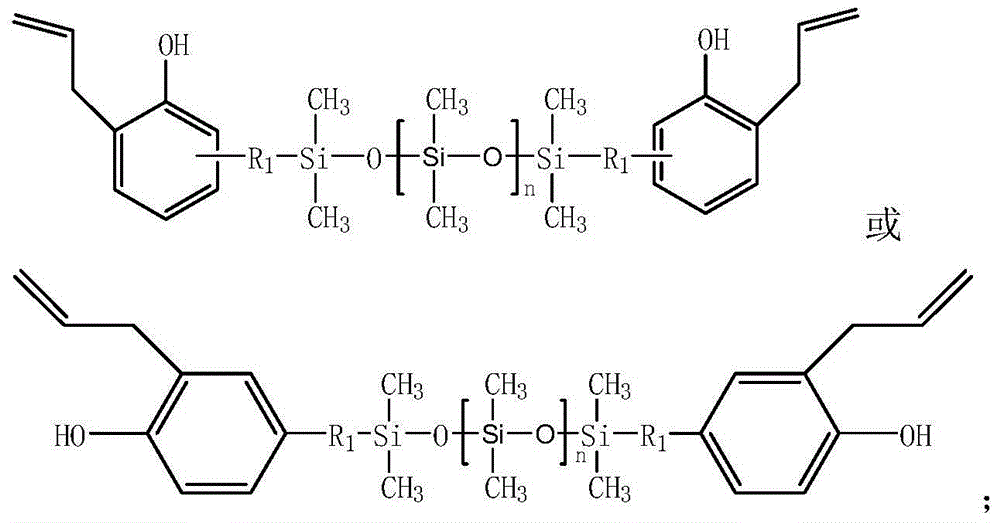

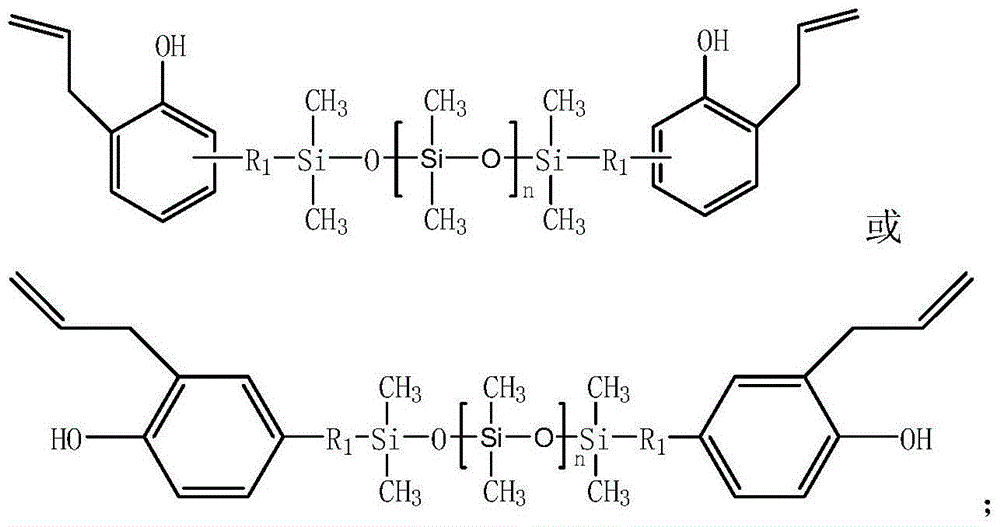

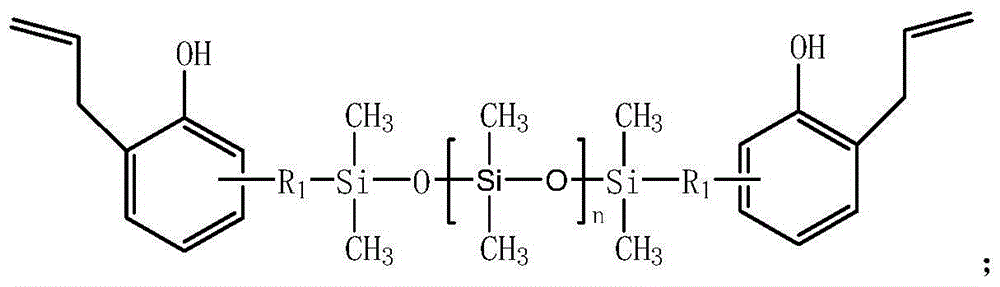

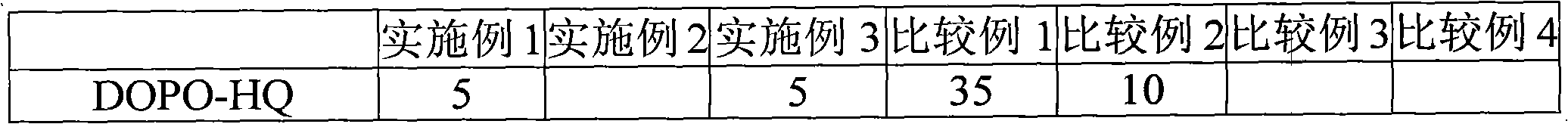

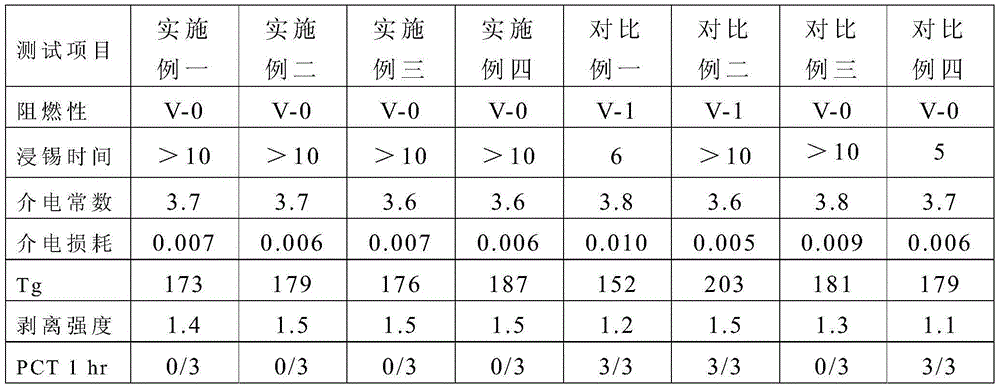

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

Halogen-free thermosetting resin composition, prepreg and metal clad foil laminated plate manufactured by using same

InactiveCN101928444AHeat resistantSolder dip resistantSynthetic resin layered productsMetal layered productsEpoxyHalogen

The invention relates to a halogen-free thermosetting resin composition, and a prepreg and a metal clad foil laminated plate manufactured by using the same. The halogen-free thermosetting resin composition comprises the following components in part by weight: 10 to 70 parts of bifunctional or multi-functional epoxy resin with a halogen-free molecular structure, 10 to 60 parts of styrene-maleic anhydride copolymer and 3 to 20 parts of co-curing agent, wherein the co-curing agent is halogen-free phenolic compound or phenolic resin. The prepreg manufactured by using the halogen-free thermosetting resin composition comprises a base material and the halogen-free thermosetting resin composition attached to the base material after impregnation drying. The metal clad foil laminated plate manufactured by using the halogen-free thermosetting resin composition comprises a plurality of layers of mutually overlapped prepregs and a metal foil pressed on one side or two sides of the overlapped prepregs, wherein each prepreg comprises the base material and the halogen-free thermosetting resin composition attached to the base material after impregnation drying.

Owner:GUANGDONG SHENGYI SCI TECH

Thermosetting resin composition, as well as prepreg and laminated board manufactured by using same

InactiveCN103289283AImprove adhesionImprove thermal stabilitySynthetic resin layered productsMetal layered productsHeat resistanceDielectric loss

The invention discloses a thermosetting resin composition. The thermosetting resin composition comprises the following components in parts by solid weight: (a) 5-80 parts of modified epoxy resin; (b) 5-80 parts of cyanate ester resin; (c) 0-50 parts of fire retardant; (d) 0-100 parts of inorganic filler; and (e) 0-5 parts of curing accelerator. A preparation method of the modified epoxy resin comprises the following steps of: adding one or more of unsaturated monomers which have double bonds and in which an initiator is dissolved into the epoxy resin; heating to 30-60 DEG C and stirring uniformly; and then, heating to 60-150 DEG C, and performing a reaction for 2-8 hours. According to the thermosetting resin composition disclosed by the invention, the unsaturated monomers with double bonds are added into the epoxy resin for modification, therefore, compared with the traditional epoxy resin composition prepared by simple blending, the thermosetting resin composition disclosed by the invention has more excellent cohesiveness, thermal stability and wet and heat resistance; and a laminated board manufactured by using cyanate ester as a curing agent has low dielectric constant, low dielectric loss, high heat resistance and good wet and heat resistance.

Owner:SHENGYI TECH SUZHOU

Gas generating agent and preparing method thereof

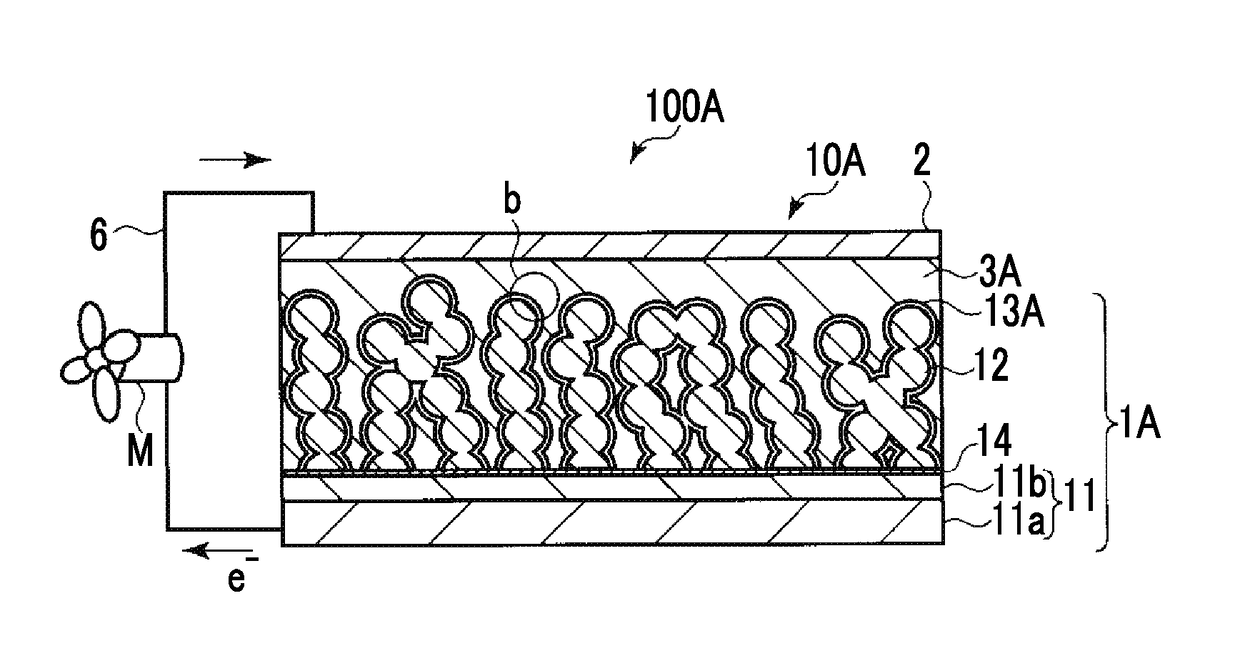

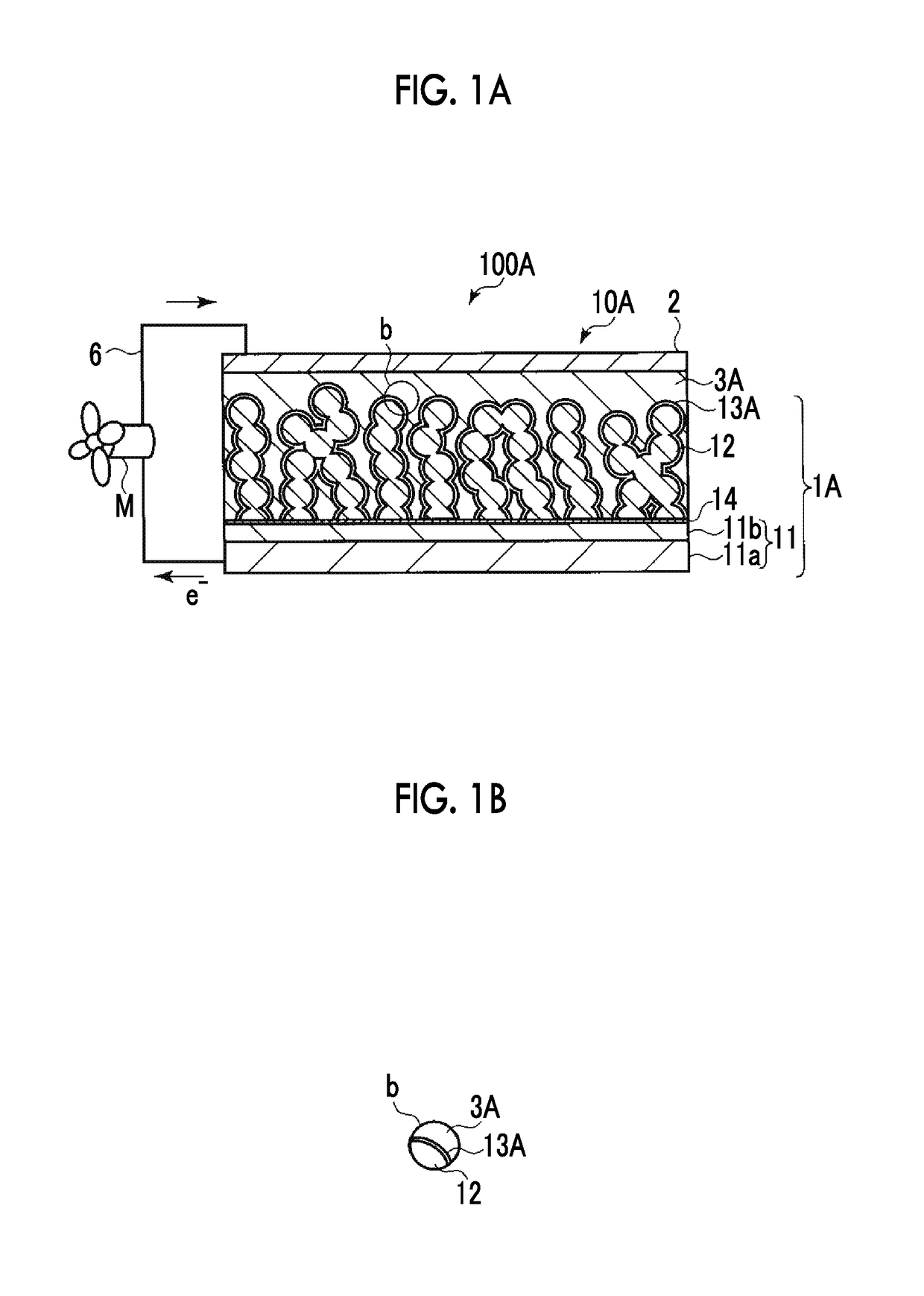

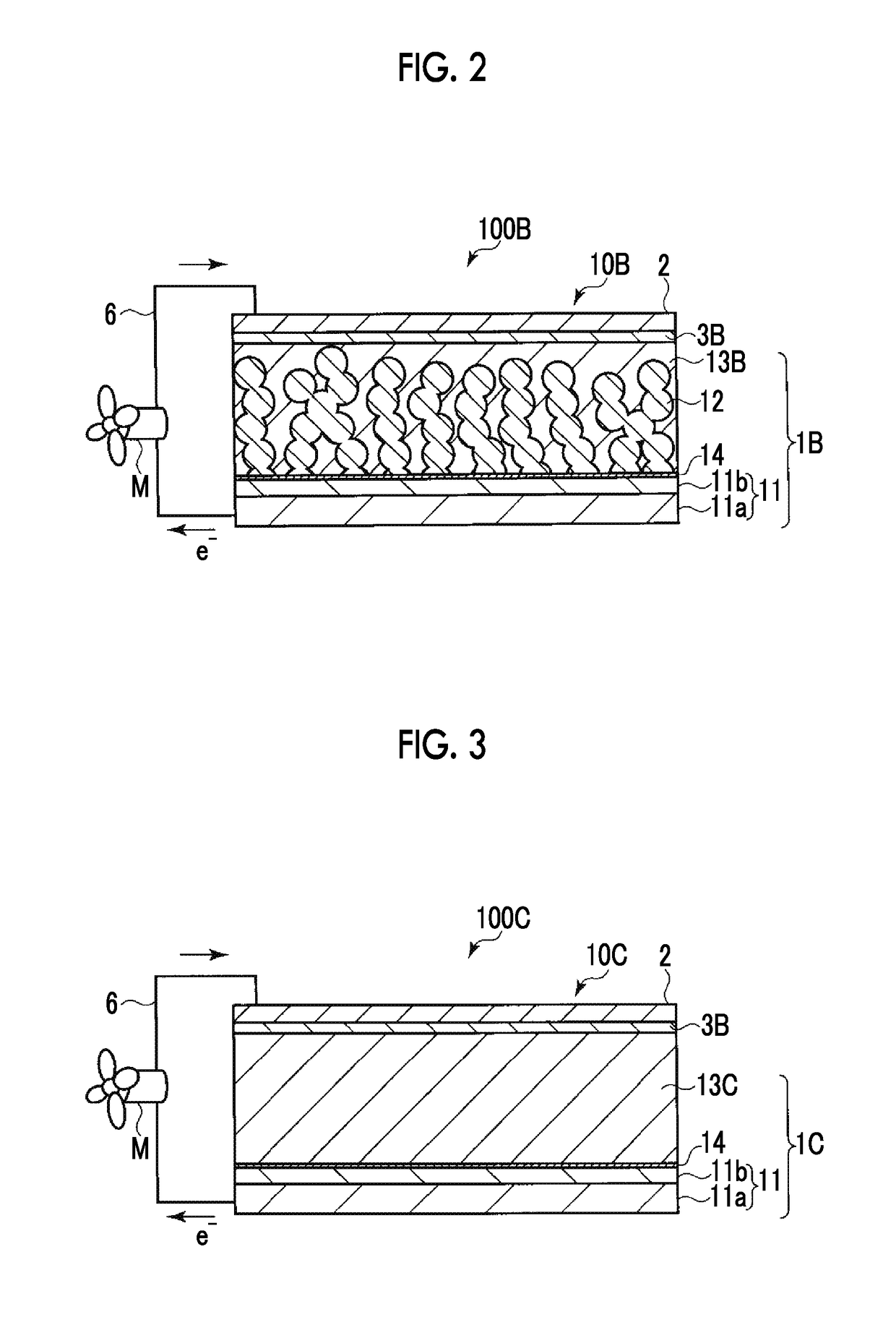

ActiveCN103625413AImprove gas production efficiencyExtended service lifePedestrian/occupant safety arrangementPressure gas generationCombustionProduct gas

The invention provides a gas generating agent and a preparing method of the gas generating agent. The gas generating agent is of an A / B core shell structure. A core A comprises a first combustible agent and a first oxidizing agent, and a shell B comprises a second combustible agent and a second oxidizing agent. The combustion speed of the second combustible agent is lower than that of the first combustible agent, and the gas generating agent not only is adjustable in combustion speed and suitable for gas generators of various gas bags, but also is high in gas generation efficiency, long in service life and little in residue. Meanwhile, a coating structure can enable the gas generator to be longer in acting time and also has a very good moisture proof effect, so that service life of the gas generating agent is greatly prolonged, and using performance is very good. The gas generating agent is simple in technology, easy to prepare, free of harm and pollution and easy to produce in a large-scale mode.

Owner:BYD CO LTD

Rat-proof and ant-proof inflaming-retarding environment-friendly power cable

InactiveCN103985473APrevent immersionNo escapePower cables with screens/conductive layersInsulated cablesPolyesterMica

The invention discloses a rat-proof and ant-proof inflaming-retarding environment-friendly power cable. A cable core of the power cable is formed by twisting a plurality of insulation wire cores. Each insulation wire core is composed of a conductor, an inner mica tape fireproof layer and an insulation layer from inside to outside. Gaps among the wire cores are provided with a packing layer. A lining layer is arranged outside the packing layer. A metal shielding layer is arranged outside the lining layer. A water-blocking polyester band, a waterproof isolation layer, an outer mica tape fireproof layer, an outer band wrapping layer, a restrictive coating, an insulation layer and rat-proof and ant-proof synthesis neoprene tape are arranged outside the metal shielding layer. The rat-proof and ant-proof synthesis neoprene tape is wrapped with an inner rat-proof and ant-proof synthesis neoprene sheath, the inner rat-proof and ant-proof synthesis neoprene sheath is longitudinally wrapped with an embossed alloy aluminum plastic composite belt, and the outmost layer is wrapped with an outer rubber sheath.

Owner:NANAN GUOGAO BUILDING MATERIAL TECH

Manufacturing method of Mo alloy sputtering target materials and sputtering target materials

ActiveCN103173728AStable and cheap to manufactureHigh densityElectric discharge tubesVacuum evaporation coatingElectrical resistance and conductanceHigh density

The invention provides a manufacturing method of a Mo alloy sputtering target material and the sputtering target material. The sputtering target material is low in resistance, excellent in heat resistance, moisture resistance, and closeness with a substrate, high in intensity and purity, and non-magnetic, as well as is suitable for electrodes and wiring films. The manufacturing method of the Mo alloy sputtering target material includes mixing Mo powder with more than one or two Ni alloy powder to satisfy the following combination, and then performing pressure sintering. The combination comprises Ni containing 10-49 atom%, Nb containing 1-20 atom%, the total of Ni and Nb less than 50 atom%, and the balance being Mo and unavoidable impurities.

Owner:HITACHI METALS LTD

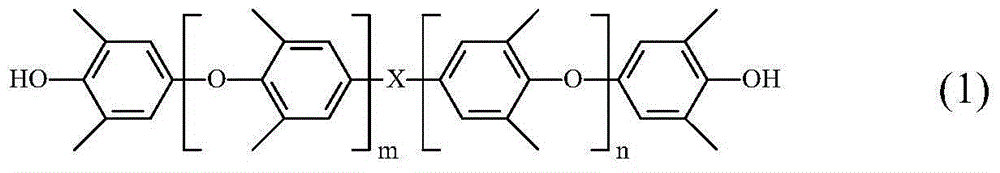

Thermosetting resin composition as well as prepreg and laminated board made from thermosetting resin composition

ActiveCN103554811AImprove adhesionImprove thermal stabilitySynthetic resin layered productsMetal layered productsDouble bondPolyphenyl ether

The invention discloses a thermosetting resin composition, comprising the following components by solid weight: (a) 5-80 parts of modified epoxy resin, (b), 5-80 parts of cyanate ester resin, (c) 5-70 parts of polyphenyl ether resin, (d) 0-50 parts of fire retardant, (e) 0-100 parts of inorganic filler, and (f) 0-5 parts of curing accelerator; the preparation method of the modified epoxy resin comprises the following steps: adding one or a plurality of double bond containing unsaturated monomers in which an initiator is dissolved in the epoxy resin, heating to 30-60 DEG C, uniformly stirring, and then warming to 60-150 DEG C, reacting for 2-8 hours. The modified epoxy resin is used as the main body, the cyanate ester resin and the polyphenyl ether resin are used as a composite curing agent, so that the humidity resistance of the cyanate ester resin and dielectric property of the system are effectively improved, the unexpected effect is obtained, and the prepreg and laminated board with excellent performance are obtained.

Owner:SHENGYI TECH SUZHOU

Firefighter uniform with intelligent heat and humidity transmission adjusting function

InactiveCN105457179AImprove cooling effectImprove practicalityChemical protectionHeat protectionEngineeringDriven element

The invention relates to a firefighter uniform with the intelligent heat and humidity transmission adjusting function. The firefighter uniform comprises a top and / or trousers. An outer layer, a waterproof breathable layer and a comfortable layer are sequentially arranged in the top and / or the trousers from outside to inside. Multiple temperature-sensing drive elements are arranged between the outer layer and the waterproof breathable layer and between the waterproof breathable layer and the comfortable layer. The temperature-sensing drive elements are shape memory springs. According to the firefighter uniform with the intelligent heat and humidity transmission adjusting function, shape memory spring arrays are arranged, and the thickness of the firefighter uniform can be adjusted automatically, so that the heat and humidity transmission adjusting performance is adjusted, wear comfort is achieved, and motion of limbs is not affected.

Owner:SUZHOU UNIV

Heat setting resin compsns. and its use

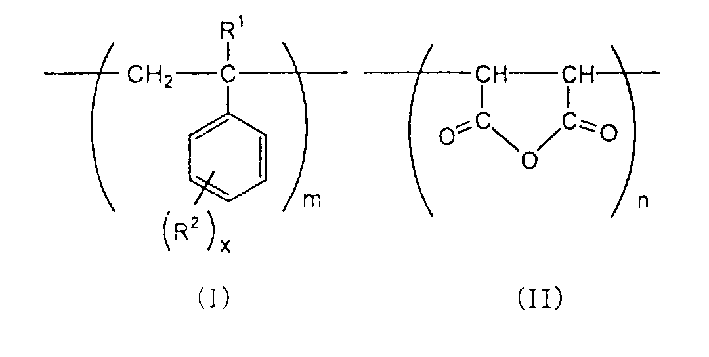

InactiveCN1369521ALow dielectric lossLow heat resistanceSynthetic resin layered productsThin material handlingPolymer scienceDielectric permittivity

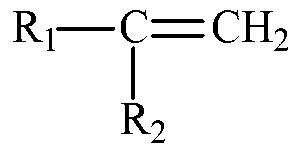

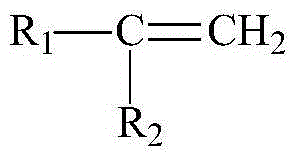

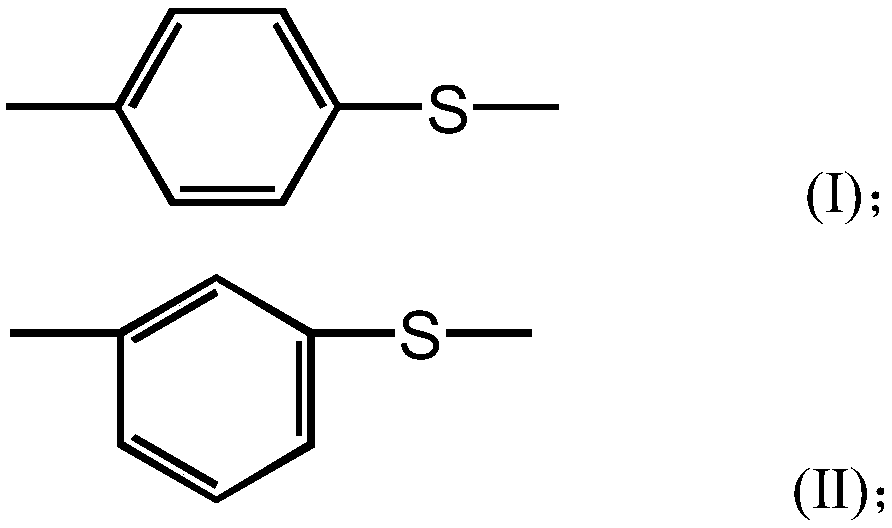

A thermosetting resin composition comprising (1) a copolymer resin comprising (a) a monomer unit and (b) a monomer unit respectively represented by the following general formulae (I) and (II): <CHEM> wherein R<1> represents hydrogen, a halogen, or a C1-C5 hydrocarbon group; R<2> represents a halogen or a C1-C5 hydrocarbon group; x is 0 to 3; and each of m and n is a natural number, and (2) a cyanate resin having at least two cyanate groups per molecule. To provide a printed wiring board material and a printed wiring board for electronic appliance, having a low dielectric constant and a low dielectric dissipation factor as well as improved heat resistance.

Owner:RESONAC CORPORATION

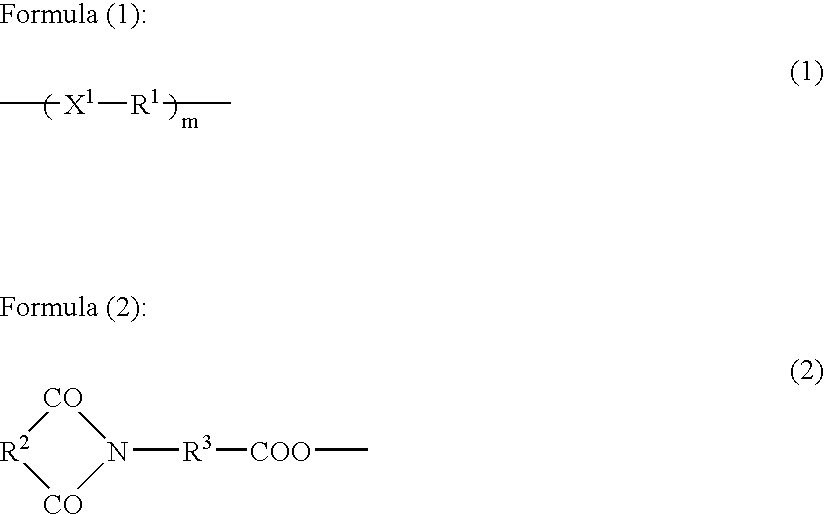

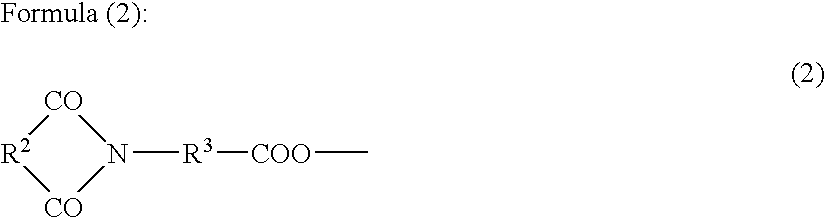

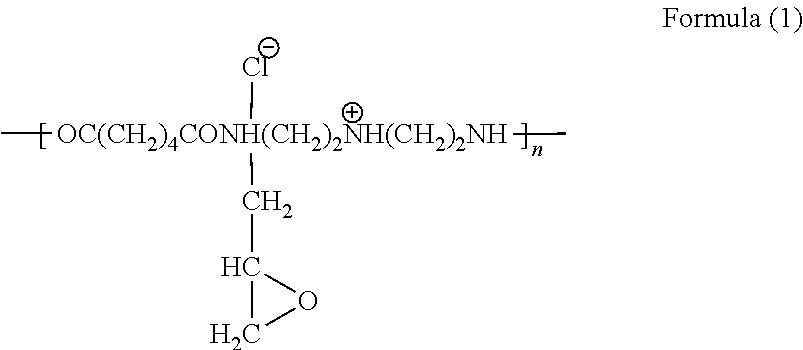

Resin Composition and Semiconductor Device Produced By Using the Same

InactiveUS20070213467A1Improve adhesion strengthImprove reliabilitySemiconductor/solid-state device detailsConductive materialCrack resistanceSemiconductor

A resin composition which is excellent in quick curing and can be used for curing in conventionally used ovens, and a semiconductor device which is excellent in reliability such as solder crack resistance or the like when the resin composition is used as a die attach material for semiconductor. Further preferably, a resin composition which has a sufficient low stress property, good adhesion and excellent bleeding property. A resin composition comprising a filler (A), the compound (B) comprising a structure represented by the formula (1) and a functional group represented by the formula (2) and a thermal radical initiator (C), and substantially not containing a photo polymerization initiator.

Owner:SUMITOMO BAKELITE CO LTD

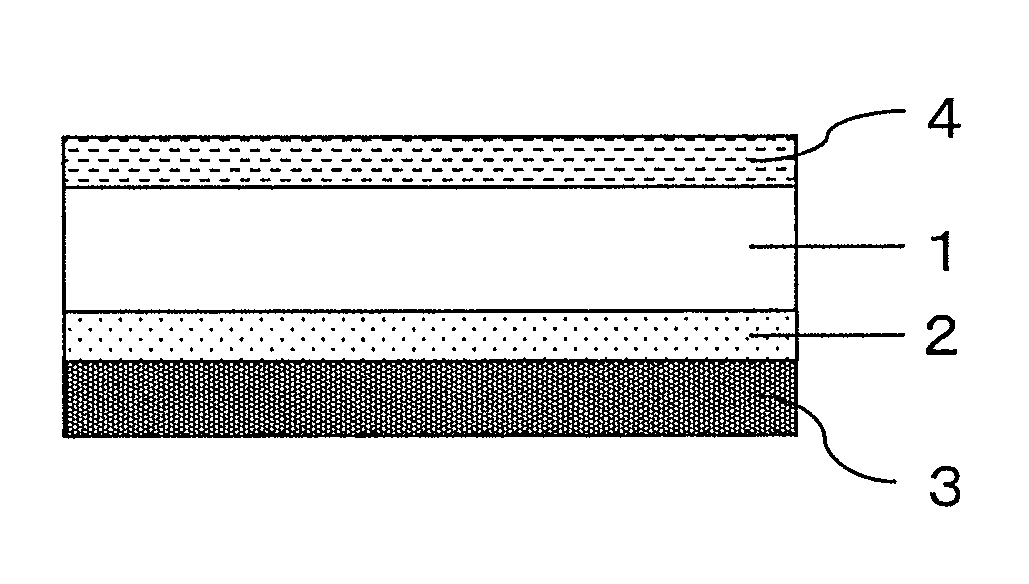

Thermal transfer sheet

ActiveUS20130142969A1High thermal transferImprove cohesionThermographyOther printing apparatusColloidInorganic pigments

A thermal transfer sheet comprising: a substrate; a heat resistant slip layer provided on one side of the substrate; an undercoat layer and a dye layer provided in that order on the other side of the substrate, wherein the undercoat layer is formed by using colloidal inorganic pigment ultrafine particles and a copolymer resin of vinyl pyrrolidone and vinyl acetate as main components.

Owner:DAI NIPPON PRINTING CO LTD

Method and composition for providing repulpable moisture vapor barrier coating for flexible packaging

InactiveUS6150451ALow moisture resistanceImprove impermeabilityOther chemical processesPaper recyclingEmulsionButadiene-styrene rubber

The composition comprises a polymer emulsion containing, for example, polyvinylidene chloride having a particle size distribution finer than 10 mu , and an additive with generally the same size distribution, for example aluminum silicate, calcium carbonate, polyvinyl acetate polystyrene, polyacrylates, carboxylated styrene butadiene, or mixtures thereof in emulsion or powder form which is capable of interstitial combination with the polymer particles. The composition has a critical pH between about 2 and 9. The method of repulping coated packaging is also disclosed.

Owner:RETEC INT INC

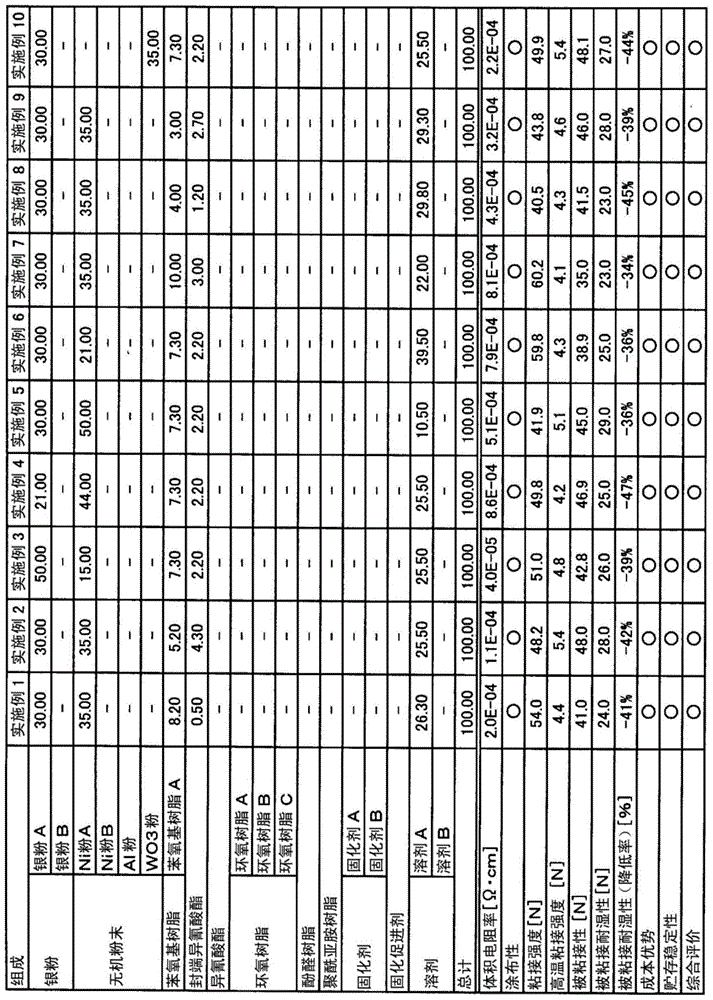

Conductive adhesive composition and electronic element using same

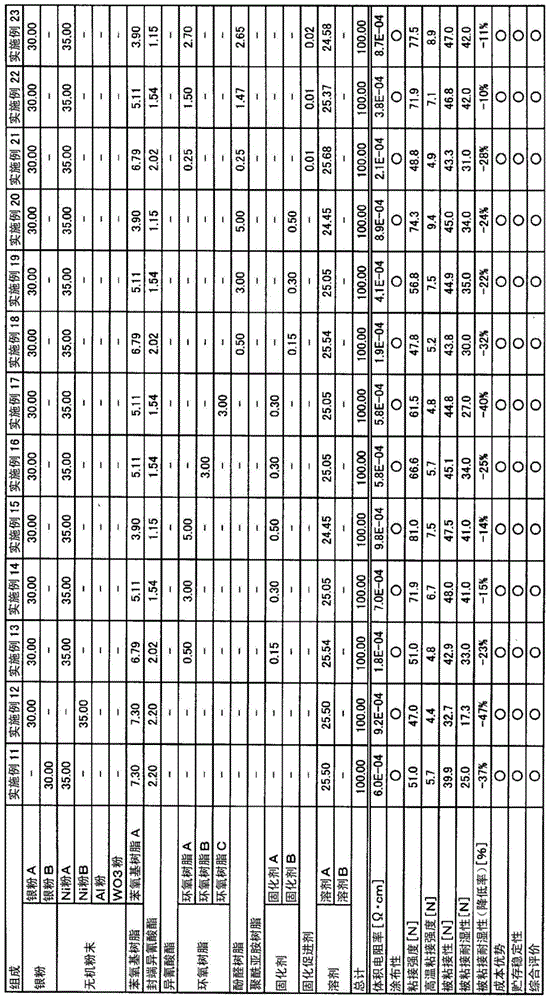

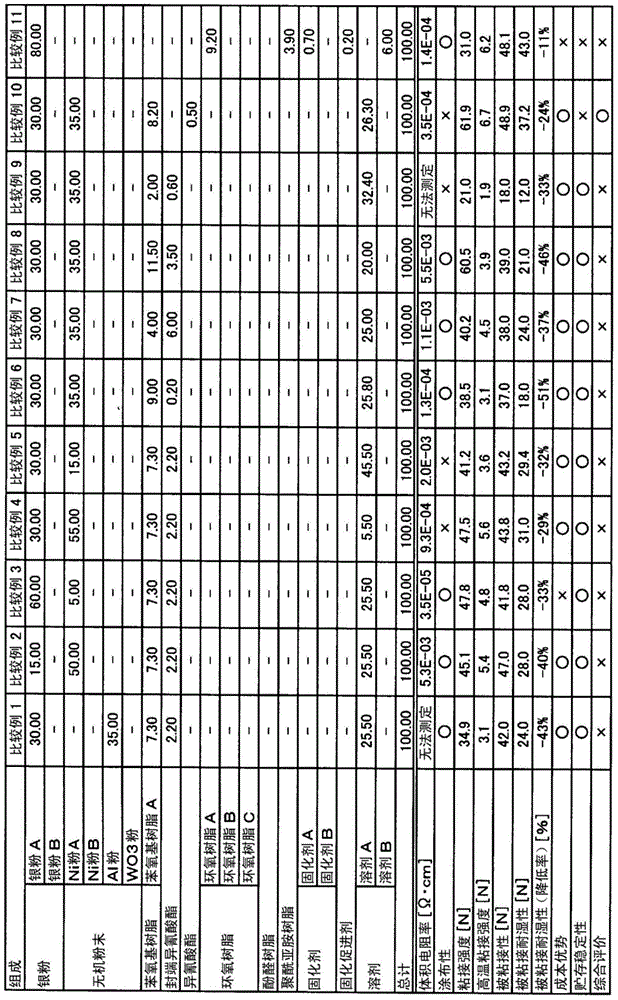

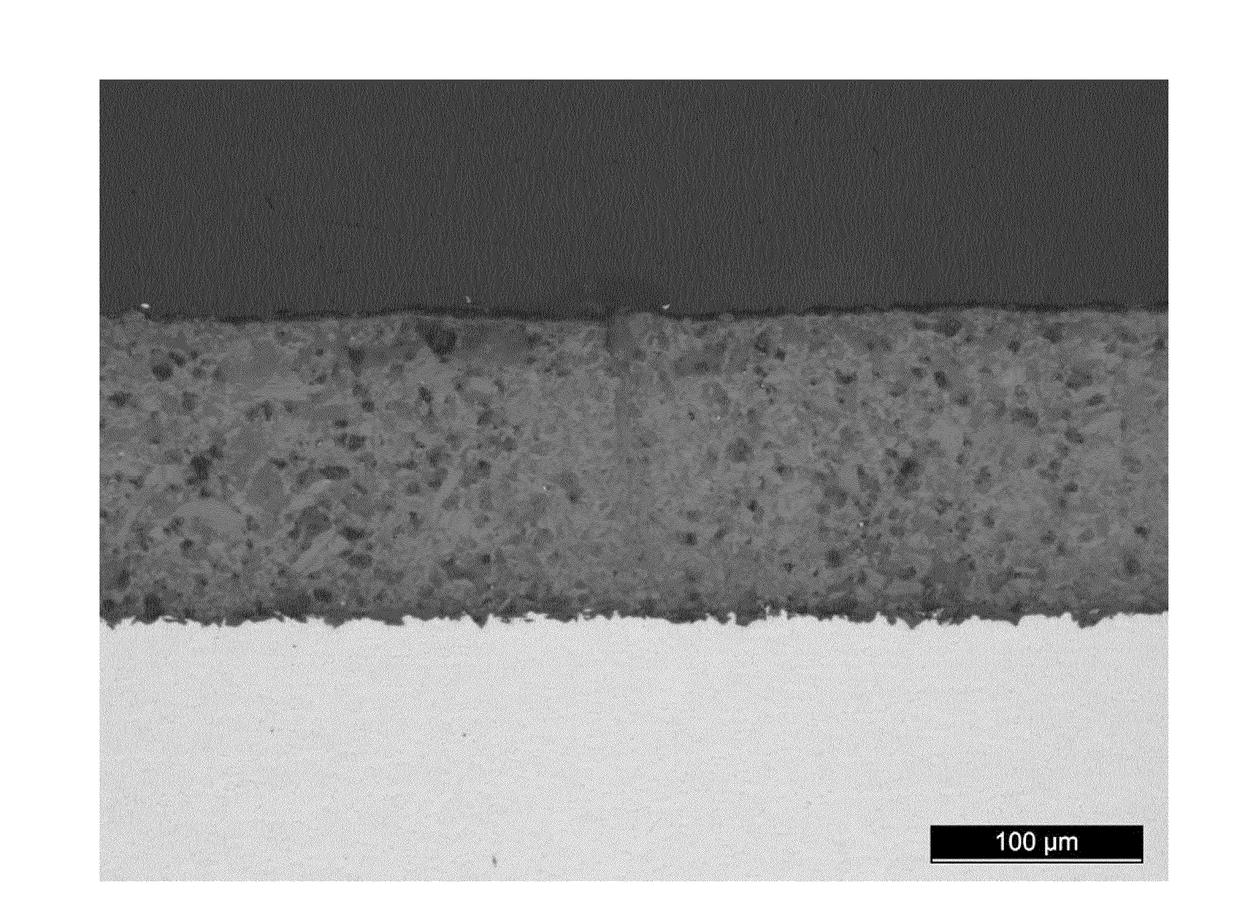

ActiveCN104822789AHigh temperature and humidity resistanceLow silver contentNon-macromolecular adhesive additivesSolid electrolytic capacitorsConductive polymerElectrolytic capacitor

Provided are: a conductive resin paste which has a low silver content and can be cured at a lower temperature in a shorter time than conventional resin pastes, while having a low resistance, high adhesion and excellent storage stability as a material for internal electrodes of solid electrolytic capacitors, conductive aluminum solid electrolytic capacitors and the like; and an electronic element which uses this conductive resin paste. A conductive adhesive composition which contains (A) a silver powder and (B) an inorganic powder filler having a specific gravity of 4 or more as conductive powders, (C) a phenoxy resin and (D) a blocked isocyanate as binder components, and (E) a solvent. This conductive adhesive composition is characterized in that: the silver powder (A) is blended in an amount of 20-50% by weight relative to the total weight; the inorganic powder filler (B) is blended in an amount of 60% by weight or less relative to the total weight; the amount of the blocked isocyanate (D) is 5-90 parts by weight relative to 100 parts by weight of the phenoxy resin (C); and the binder components ((C) + (D)) are contained in an amount of 5-14% by weight relative to the total weight.

Owner:SUMITOMO METAL MINING CO LTD

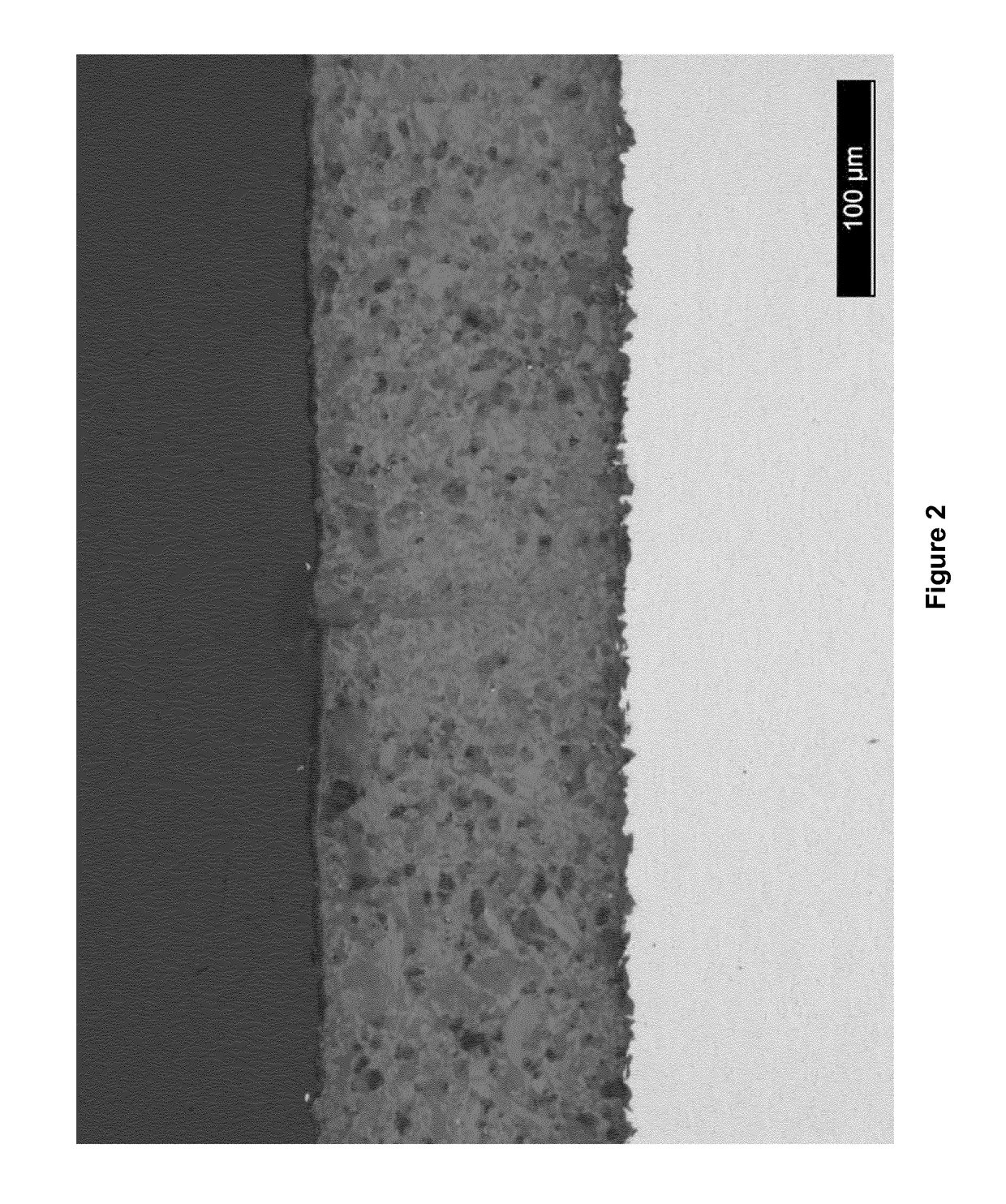

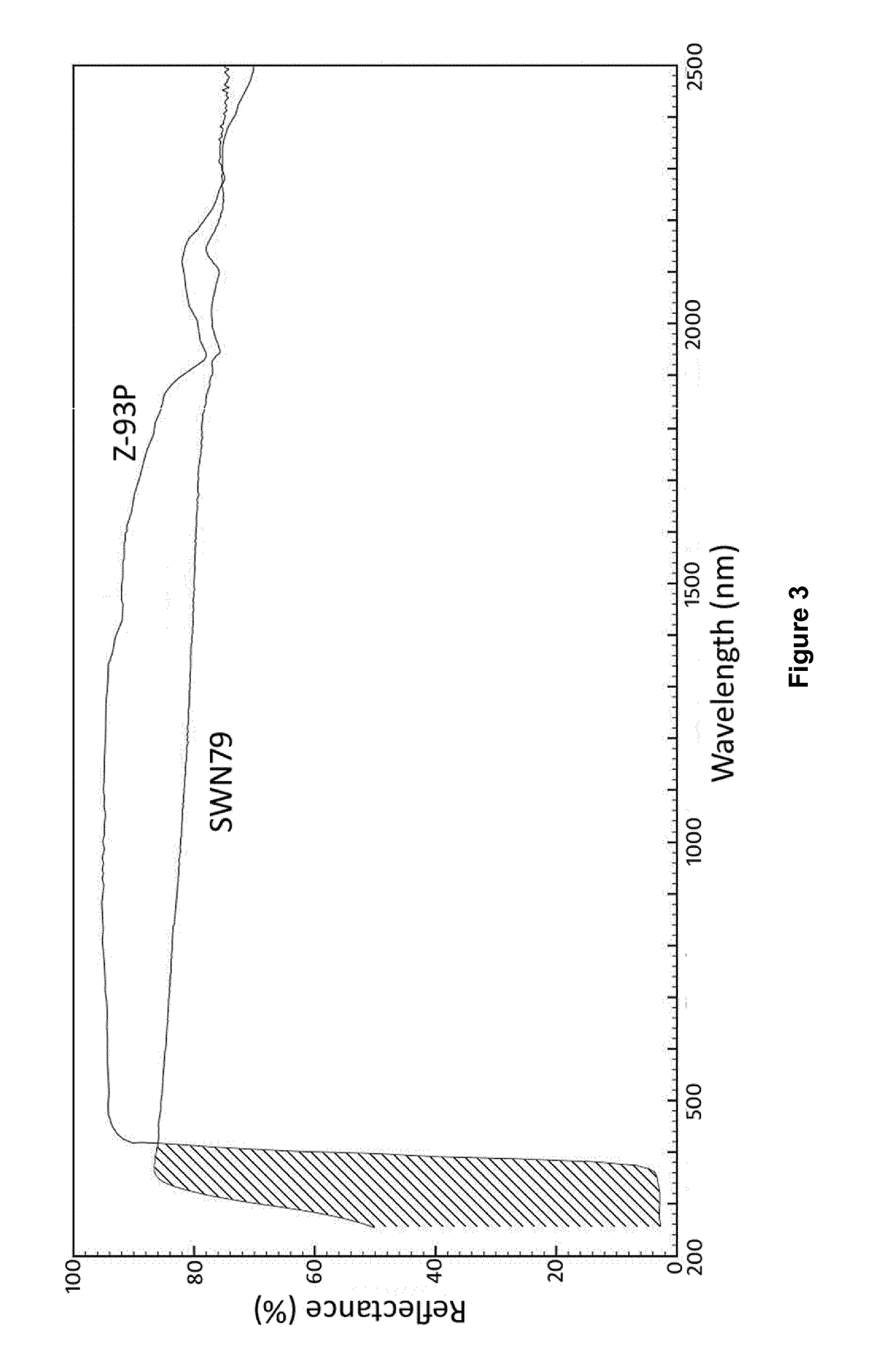

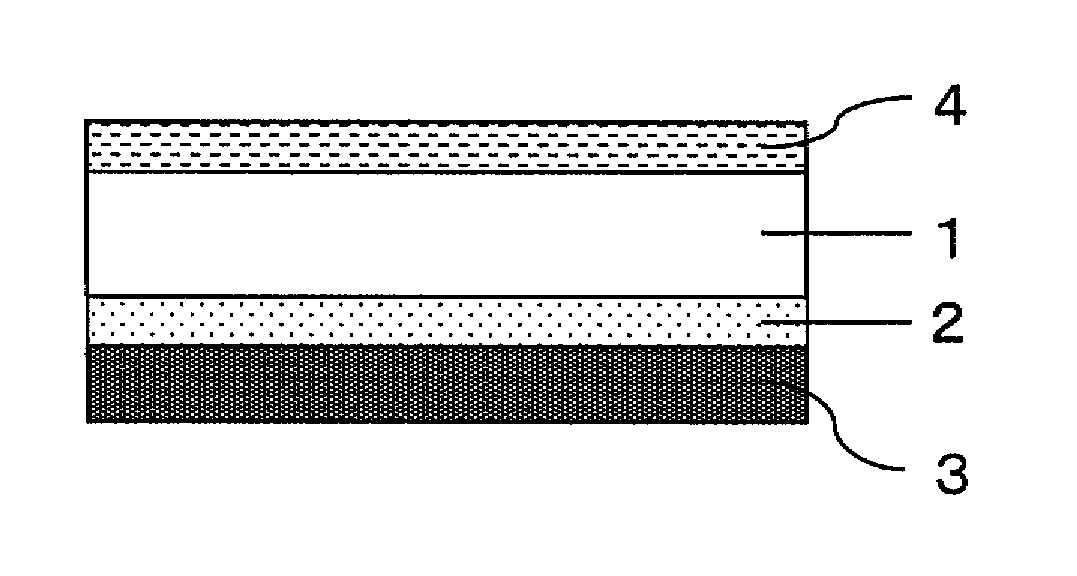

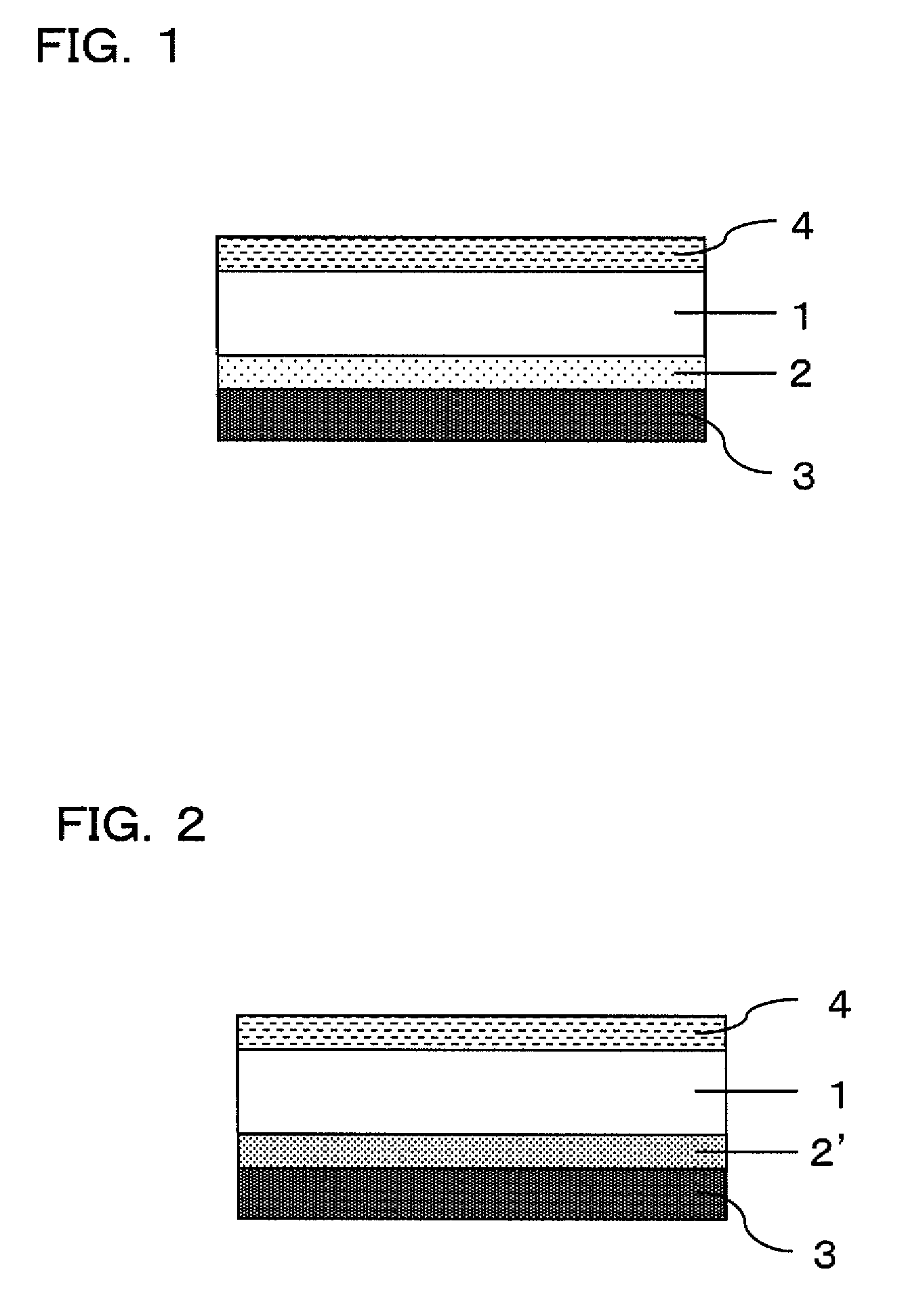

Thermal control coatings

ActiveUS20170204273A1Accelerated degradation of materialDamage to deviceAlkali metal silicate coatingsRadiation-absorbing paintsMagnesium phosphateThermochromism

A curable coating composition comprising: (a) a silicate, such as sodium silicate, potassium silicate or lithium silicate; (b) a phosphate, such calcium phosphate, magnesium phosphate or sodium phosphate; and (c) a metal oxide, such as magnesium oxide, aluminium (III) oxide, scandium (III) oxide, yttrium (III) oxide, or zirconium oxide. Such curable coating compositions may be used as non-thermochromic (tailored based on expected operating environment) thermal control coating compositions for application to spacecraft and components thereof. As an alternative metal oxide component, for use in lower temperature applications, or in applications for which thermochromism at elevated temperatures is not a concern, the metal oxide may comprise zinc oxide. Also provided is a curable coating composition comprising: (a) a silicate (e.g. as above); (b) a phosphate (e.g. as above); and (c) a metal sulphate, such as a barium sulphate. Cured coatings are also provided, as are thermal control coatings, thermal control paints, and processes for making coated substrates.

Owner:UNIV COLLEGE DUBLIN NAT UNIV OF IRELAND DUBLIN

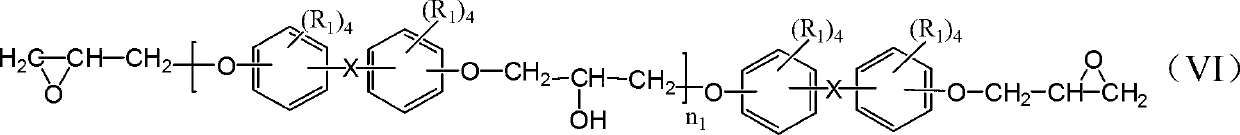

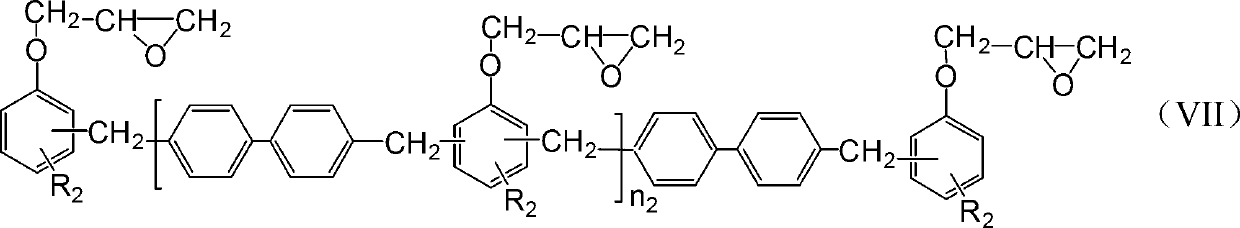

Polyvalent hydroxy resin, epoxy resin, method for producing same, epoxy resin composition and cured product thereof

Provided are an epoxy resin, a polyvalent hydroxy resin and a composition thereof which have excellent curability, which provide cured products with excellent mechanical strength, flame resistance, humidity resistance, low elasticity, etc., and which are suitable for applications such as encapsulation of electronic components, circuit board material, etc. This polyvalent hydroxy resin is an aralkyl denatured polyvalent hydroxy resin which is obtained by reacting a narrow disperse polyvalent hydroxy compound with an aralkylating agent of styrenes, etc., the narrow disperse polyvalent hydroxy compound comprising 15% or less of n=1 component, and 50% or more of a total of n=2 and n=3 components, and having Mw / Mn of 1.2 or less. In addition, the present invention is an epoxy resin obtained by reacting the aralkyl denatured polyvalent hydroxy resin with epichlorohydrin. Furthermore, the present invention is an epoxy resin composition which contains, as an essential component, the aralkyl denatured polyvalent hydroxy resin or the epoxy resin.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

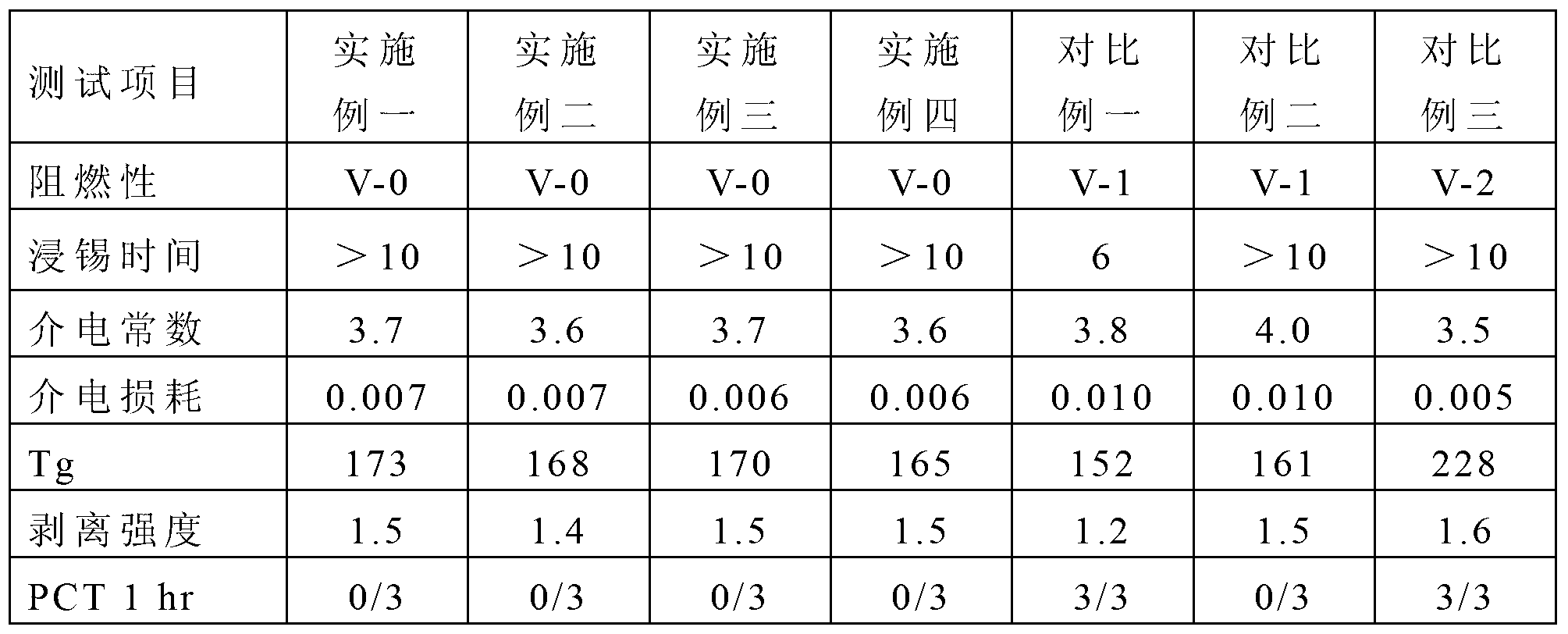

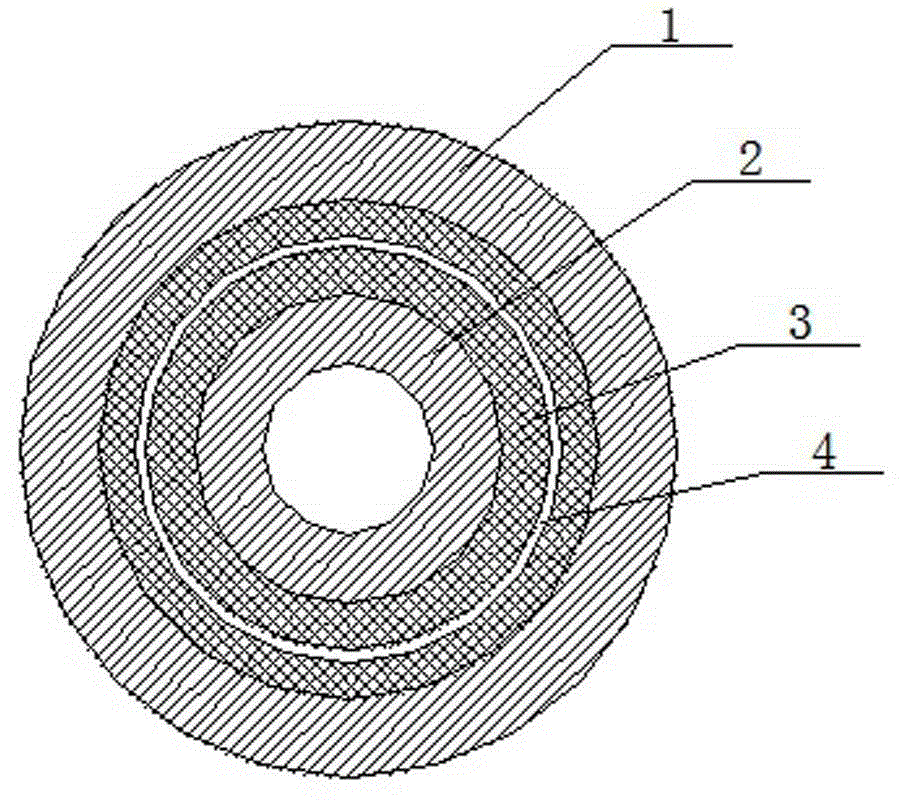

Epoxy resin insulating transformer

InactiveCN102982981AEnhance the effect of curing and formingImprove impact resistancePlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsEpoxyLow voltage

The invention relates to the technical field of electric equipment transformers, in particular to an epoxy resin insulating transformer, which comprises a high-voltage coil and a low-voltage coil arranged coaxially, wherein the high-voltage coil is arranged on the outer side of the low-voltage coil; an epoxy resin insulating layer formed by pouring is formed between the high-voltage coil and the low-voltage coil; and the epoxy resin insulating layer comprises epoxy resin, a filling agent, a curing agent and a toughening agent. Due to the adoption of the formula, the epoxy resin insulating transformer has high heat resistance and high toughness during running, and can run under overload for a long time. Meanwhile, an annular radiating channel is formed in the epoxy resin insulating layer, so that the radiating effect is enhanced, and safety and reliability are realized.

Owner:JIANGSU YAWEI TRANSFORMER

Photoelectric conversion element, and solar cell using the same

InactiveUS20180122587A1Low moisture resistanceImprove moisture resistanceLight-sensitive devicesPhotovoltaic energy generationHalogenOrganic group

Provided is a photoelectric conversion element including a first electrode that includes a photosensitive layer, which includes a light absorbing agent, and a second electrode. The light absorbing agent includes a compound having a perovskite-type crystal structure that includes a cation of a cationic organic group A, a cation of a metal atom M other than the element of Group 1, and an anion of an anionic atom X. A hole transport layer, which includes an organic hole transporting material, is provided between the first electrode and the second electrode. The organic hole transporting material has a molecular weight of 6,000 or less and includes halogen, a halogenated alkyl group, or a group represented by RA—X—*, where X represents S, NRB, or O, RA and RB represent a halogenated alkyl group, and * represents a bonding position.

Owner:FUJIFILM CORP

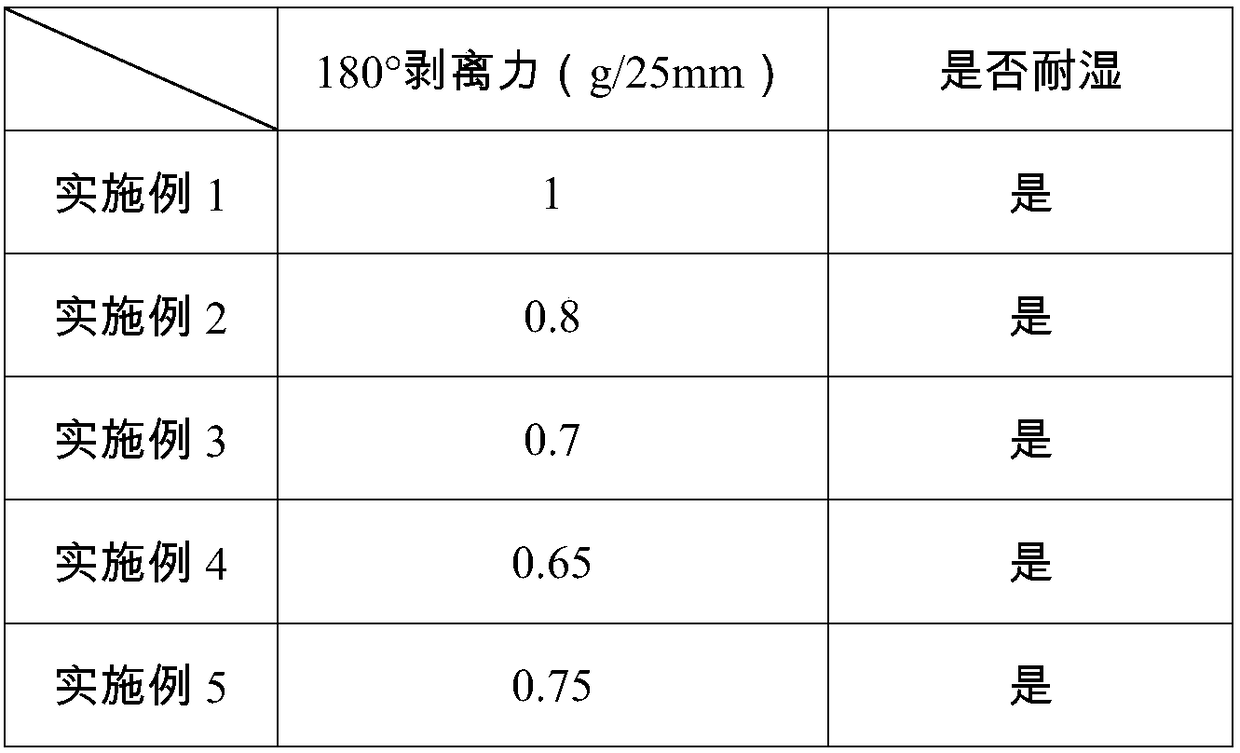

High performance two-component polyurethane pressure sensitive adhesive and preparation method and application thereof

InactiveCN108949088ALow viscositySmall peeling forcePolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesSolventPeel force

The invention discloses a high performance two-component polyurethane pressure sensitive adhesive and a preparation method and application thereof. The high performance two-component polyurethane pressure sensitive adhesive comprises a component (A) and a component (B). The component (A) is a glue liquid prepared from 10-12% by weight of a hard monomer, 24-30% by weight of a soft monomer, 2.5-4% by weight of a chain extender, 0.08-0.12% by weight of an organotin catalyst and 54-60% by weight of a solvent. The component (B) is an epoxy curing agent. The weight of the component (B) is 0.1% thatof the component (A). The high performance two-component polyurethane pressure sensitive adhesive has low adhesion, low peeling force and good moisture resistance.

Owner:WUXI HAITE NEW MATERIAL RES INST

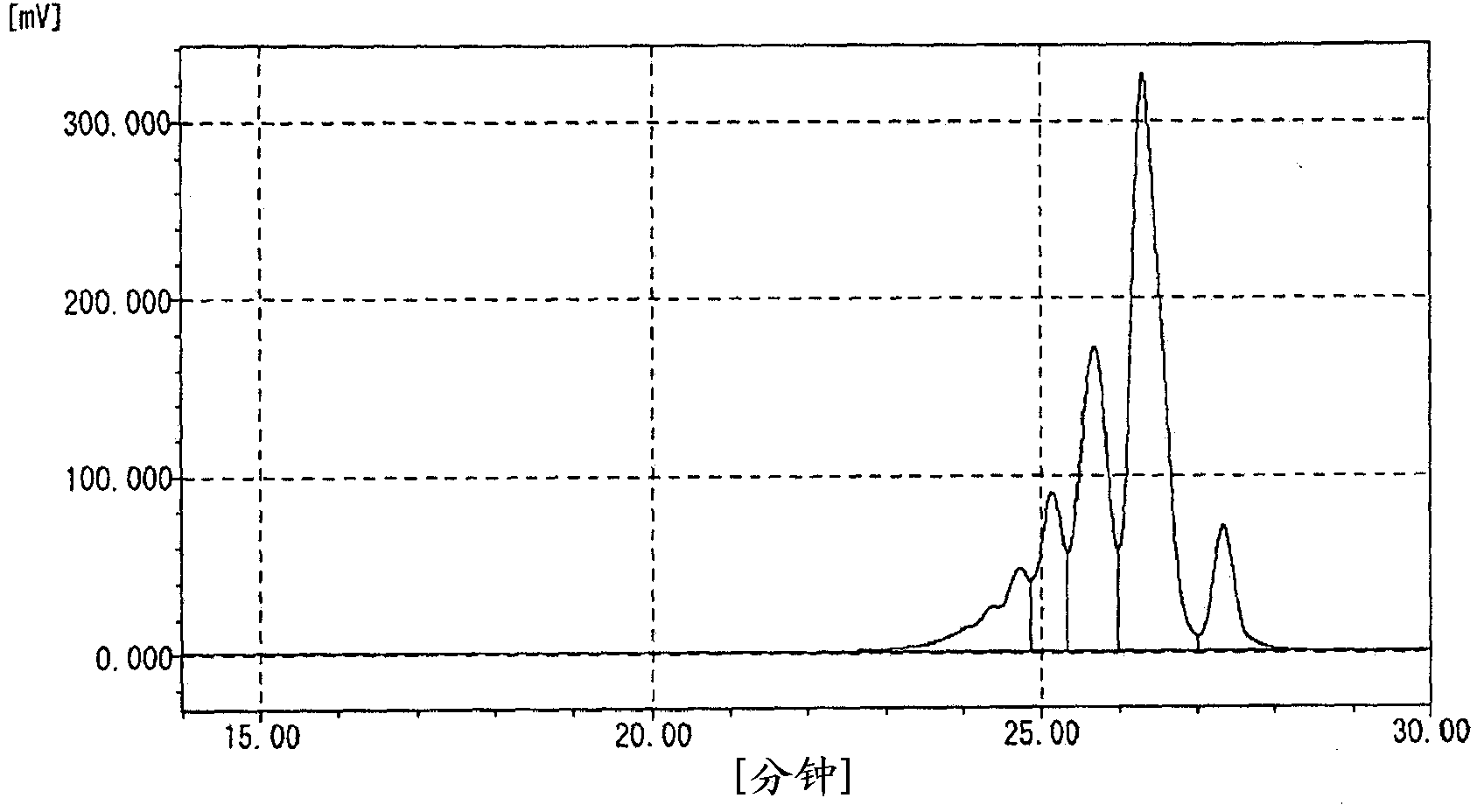

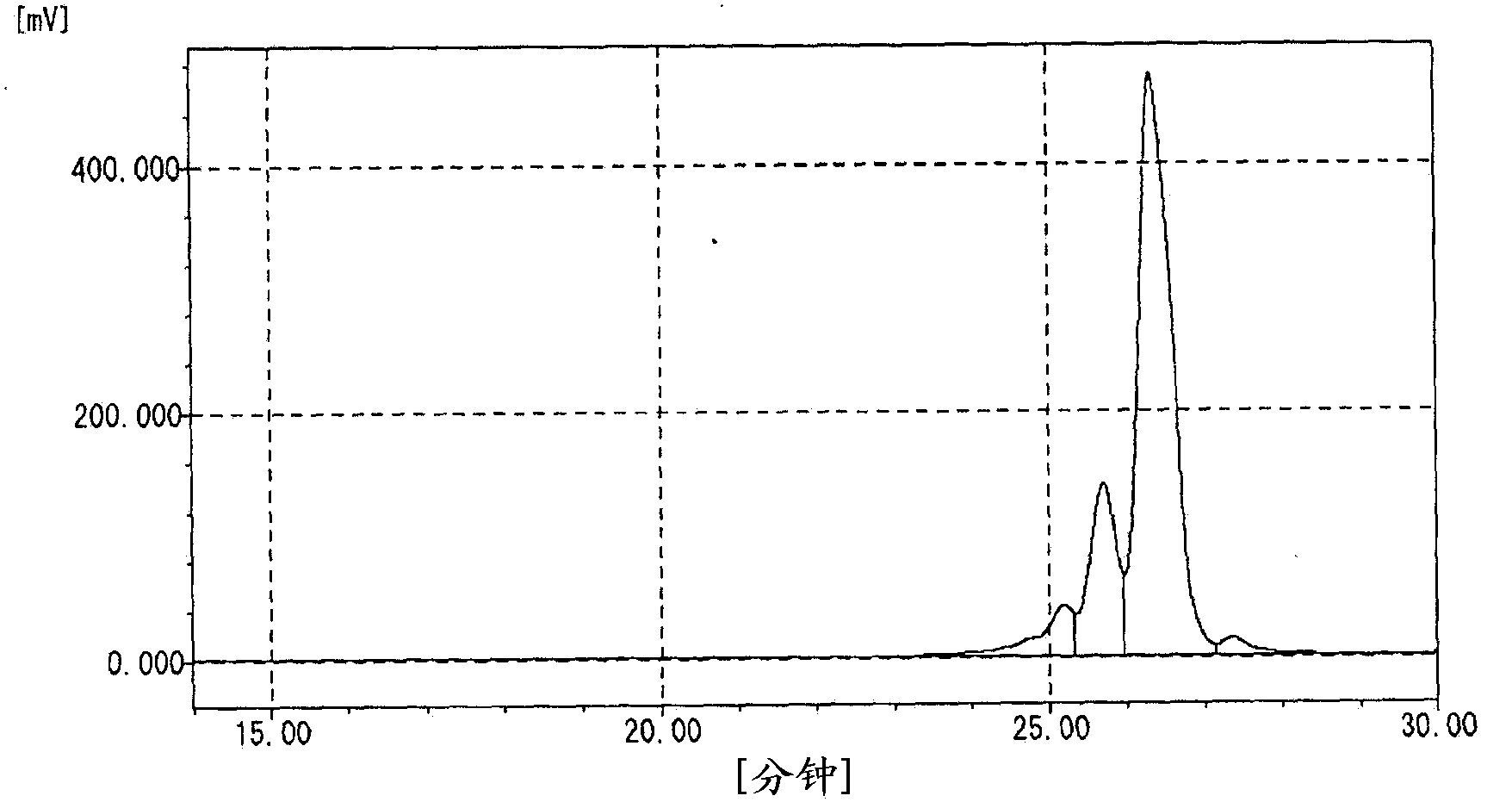

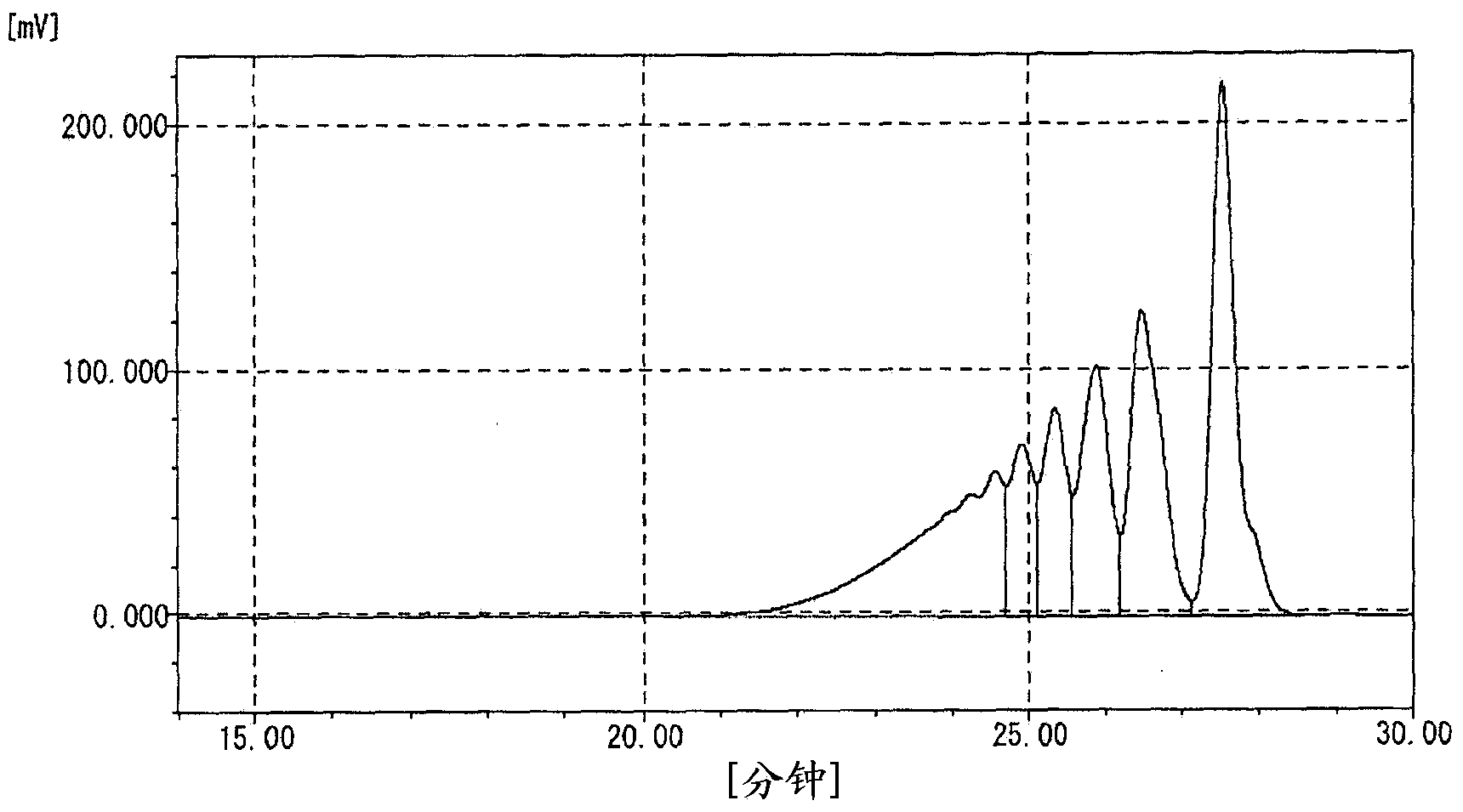

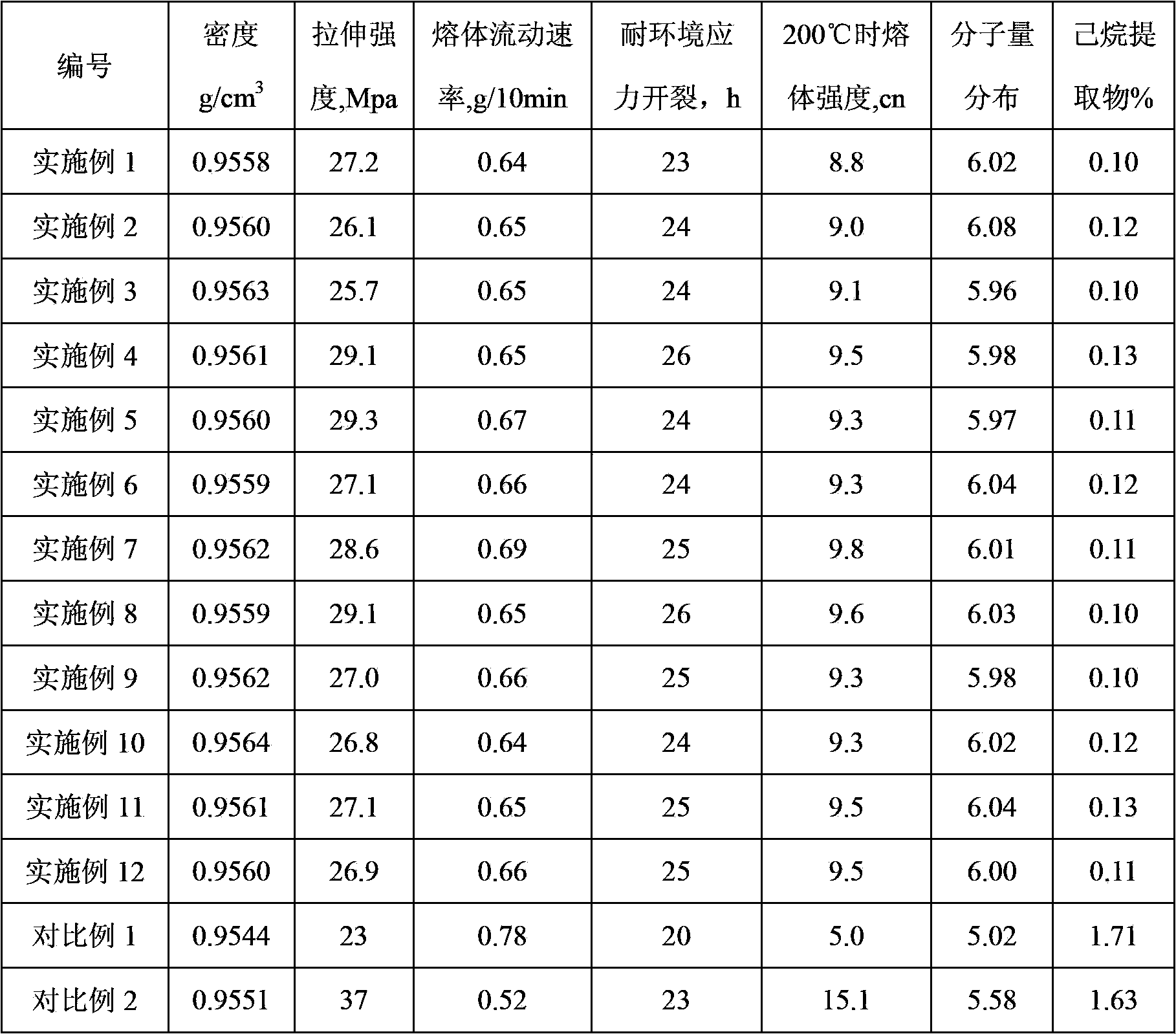

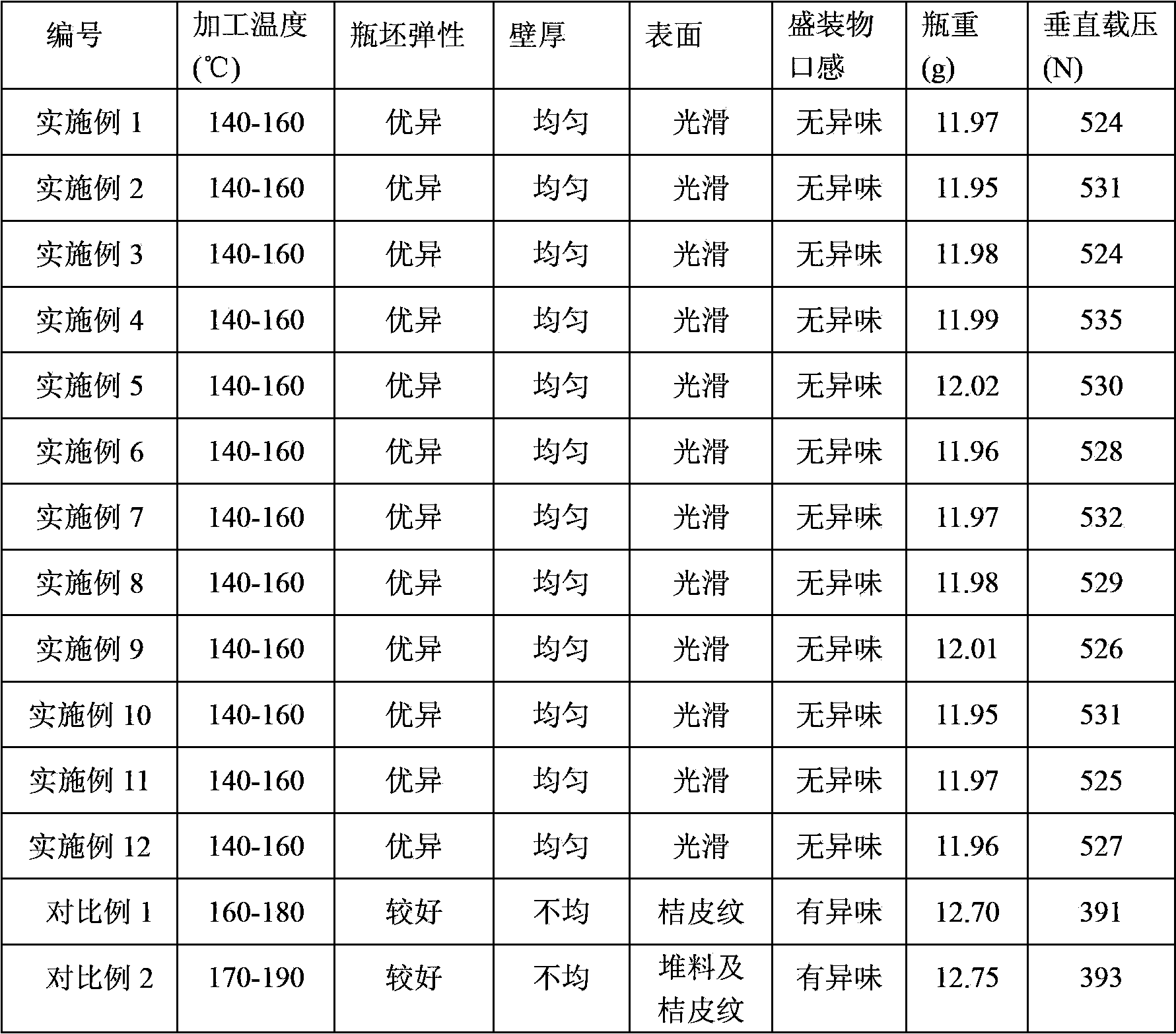

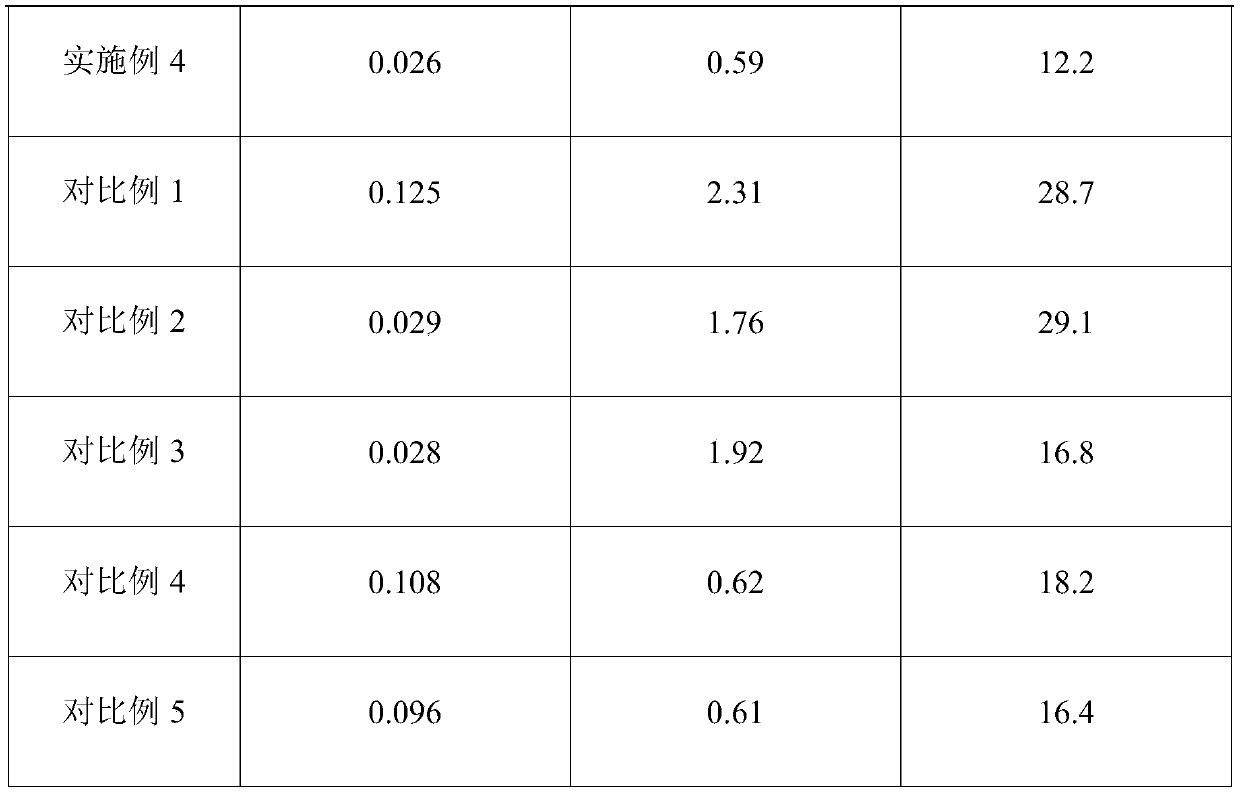

Preparation method of high density polyethylene resin special for abnormal-shape bottles

The invention relates to a preparation method of high density polyethylene resin special for abnormal-shape bottles; in a granulation workshop section of a high density polyethylene device, 0.01-0.8% by mass percentage of a composite processing additive is added for direct preparation of the high density polyethylene resin special for the abnormal-shape bottles; the composite processing additive is prepared from the following substances: by mass, 10-20% of an antioxidant, 35-50% of a lubricant, 20-30% of a fluorine elastomer and 15-20% of oxidized polyethylene wax; the resin has the characteristics of moderate melt strength and wide molecular weight distribution, and the characteristics are necessary for a special material suitable for blowing the abnormal-shape bottles; the resin has excellent processing performances, and solves the problems that: during production of the abnormal-shape bottles by use of blend resin, the produced abnormal-shape bottles have unsmooth surfaces and uneven wall thickness, articles contained in the abnormal-shape bottles may produce peculiar smell, and the like.

Owner:PETROCHINA CO LTD

Ultraviolet-absorbing coating composition having enhanced abrasion resistance

InactiveUS20170166761A1Improved ultraviolet absorptionIncreased durabilityRadiation-absorbing paintsOrganic solventWhitening Agents

Disclosed is a coating composition for wet coating to block ultraviolet light radiation as being applied on a vehicle glass. The composition comprises: a binder including an amount of about 15 to 20% by weight of tetraethoxysilane (TEOS) and an amount of about 10 to 15% by weight of glycidoxypropyltrimethoxysilane (GPTS), an amount of about 20 to 35% by weight of an organic solvent, an amount of about 0.5 to 2% by weight of a curing agent, an amount of about 0.1 to 0.5% by weight of a leveling agent, an amount of about 10 to 40% by weight of a hydrophobically surface-treated inorganic nanosol, an amount of about 8 to 12% by weight of an inorganic ultraviolet blocking agent and an amount of about 1 to 3% by weight of a fluorescent whitening agent, all these % by weights based on the total weight of the coating composition.Accordingly, the coating composition may be used as a vehicle glass coating agent due to substantially improved abrasion resistance and durability.

Owner:HYUNDAI MOTOR CO LTD

Production process of knitted sportswear fabric

InactiveCN106400357AAdapt to market demandSimple processSucessive textile treatmentsWeft knittingWater vapor permeabilityEconomic benefits

The invention discloses a production process of a knitted sportswear fabric. The production process comprises a step of selecting and pretreating the knitted sportswear fabric, a step of preparing a waterproof auxiliary agent, a step of soaking the knitted sportswear fabric with the waterproof auxiliary agent, a step of leaching the soaked knitted sportswear fabric through a padder, a step of drying the leached knitted sportswear fabric in a drying oven and a step of baking the dried knitted sportswear fabric in a sizing machine. On the basis of the knitted sportswear fabric, the knitted sportswear fabric is endowed with high waterproofness, ventilation performance and water vapor permeability; the waterproofness is at the level of 4 to 5; and the permeation volume is greater than 1200, and the wet resistance value is less than 1.5 m<2>.Pa / W. The production process can fill the blank that nearly no knitwear is sold on the Sports and Outdoor market and the waterproof, breathable and permeable fabric market, can meet the market requirement and is high in economic benefit.

Owner:NANTONG ZHONGBANG TEXTILE CO LTD

Damp-proof heat preservation layer material for floor, and preparation method of damp-proof heat preservation layer material

The invention discloses a damp-proof heat preservation layer material for a floor. The material is prepared from the following raw materials in parts by weight: 70 to 85 parts of an ethylene-vinyl acetate copolymer, 14 to 19 parts of methyl vinyl phenyl silicone rubber, 18 to 23 parts of an elastomer, 6 to 9 parts of a dimethyl siloxane-ethylene oxide copolymer, 4 to 7 parts of expanded perlite powder, 2 to 4 parts of aluminum silicate fibers, 1.7 to 2.4 parts of a foaming agent, 0.6 to 0.8 part of an auxiliary foaming agent and 4 to 6 parts of other auxiliary agents. The damp-proof heat preservation layer material for the floor is an EVA foaming material, has a low heat conductivity coefficient and is good in heat preservation effect, low in water absorption rate, good in damp-proof effect, light in weight, high in elasticity, small in permanent compression deformation, and durable in use.

Owner:ZHEJIANG XINHENGTAI ADVANCED MATERIAL

Thermal control coatings

ActiveUS10100203B2More resistant to moistureLow curing temperatureAlkali metal silicate coatingsRadiation-absorbing paintsMagnesium phosphateThermochromism

A curable coating composition comprising: (a) a silicate, such as sodium silicate, potassium silicate or lithium silicate; (b) a phosphate, such calcium phosphate, magnesium phosphate or sodium phosphate; and (c) a metal oxide, such as magnesium oxide, aluminum (III) oxide, scandium (III) oxide, yttrium (III) oxide, or zirconium oxide. Such curable coating compositions may be used as non-thermochromic (tailored based on expected operating environment) thermal control coating compositions for application to spacecraft and components thereof. As an alternative metal oxide component, for use in lower temperature applications, or in applications for which thermochromism at elevated temperatures is not a concern, the metal oxide may comprise zinc oxide. Also provided is a curable coating composition comprising: (a) a silicate (e.g. as above); (b) a phosphate (e.g. as above); and (c) a metal sulphate, such as a barium sulphate. Cured coatings are also provided, as are thermal control coatings, thermal control paints, and processes for making coated substrates.

Owner:UNIV COLLEGE DUBLIN NAT UNIV OF IRELAND DUBLIN

Thermal transfer sheet

ActiveUS8343889B2High thermal transferImprove cohesionAblative recordingThermographyCross-linkEngineering

It is an object of the present invention to provide a thermal transfer sheet which has a high transfer sensitivity in thermal transfer printing to obtain a high density print, has a high sharpness of thermal transfer images, can prevent an abnormal transfer in printing even after being stored at high temperature and high humidity, and can provide a sufficiently satisfactory printed matter.The above object is achieved by a thermal transfer sheet comprising: a substrate; a heat resistant slip layer provided on one side of the substrate; an undercoat layer and a dye layer provided in that order on the other side of the substrate, wherein the undercoat layer is formed by applying and drying a coating liquid which contains, as main components, a water soluble self cross-linking resin and colloidal inorganic pigment ultrafine particles, and cross-linking polymerizing the water soluble self cross-linking resin, or wherein the undercoat layer is formed by using colloidal inorganic pigment ultrafine particles and a copolymer resin of vinyl pyrrolidone and vinyl acetate as main components.

Owner:DAI NIPPON PRINTING CO LTD

Novel plastic steel door-window sectional material

The invention relates to a novel plastic steel door-window sectional material comprising the following raw materials by weight: 70-80kg of resin, 20-26kg of rock powder, 3-4kg of titanium pigment, 3-4kg of precipitant, 8-9kg of chlorinated polyethylene, 0.4-0.8kg of modified resin, 10-14g of ultramarine, 10-14g of whitening agent, 40-60g of polyethylene wax, 70-90g of stearic acid and 10-12g of ammonium polyphosphate. According to the novel plastic steel door-window sectional material, the resin is used as the main raw material, the rock powder for reducing the product cost as well as the titanium pigment, whitening agent and ultramarine achieving a whitening effect are added to ensure that the product can not turn yellow when used for a long time, and chlorinated polyethylene with impact resistance as well as PE wax and stearic acid for lubrication are added at the same time. The plastic steel door-window sectional material disclosed by the invention has relatively strong corrosion resistance, ultraviolet resistance, fire resistance, insulating property and the like, and is high in safety factor, low in cost and suitable for the level of mass consumption.

Owner:江苏荣光塑料科技发展有限公司

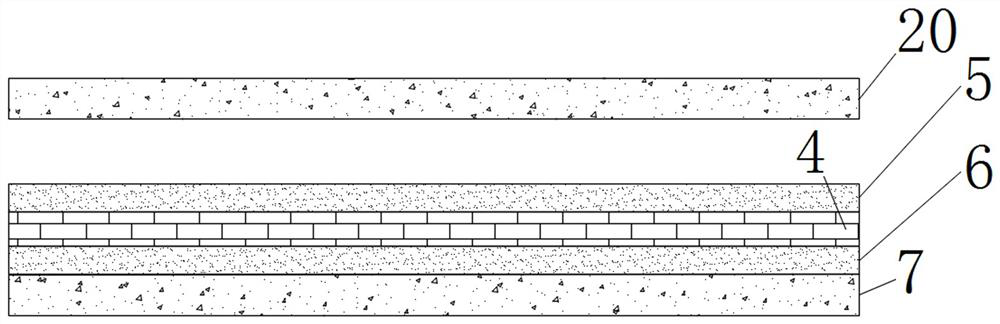

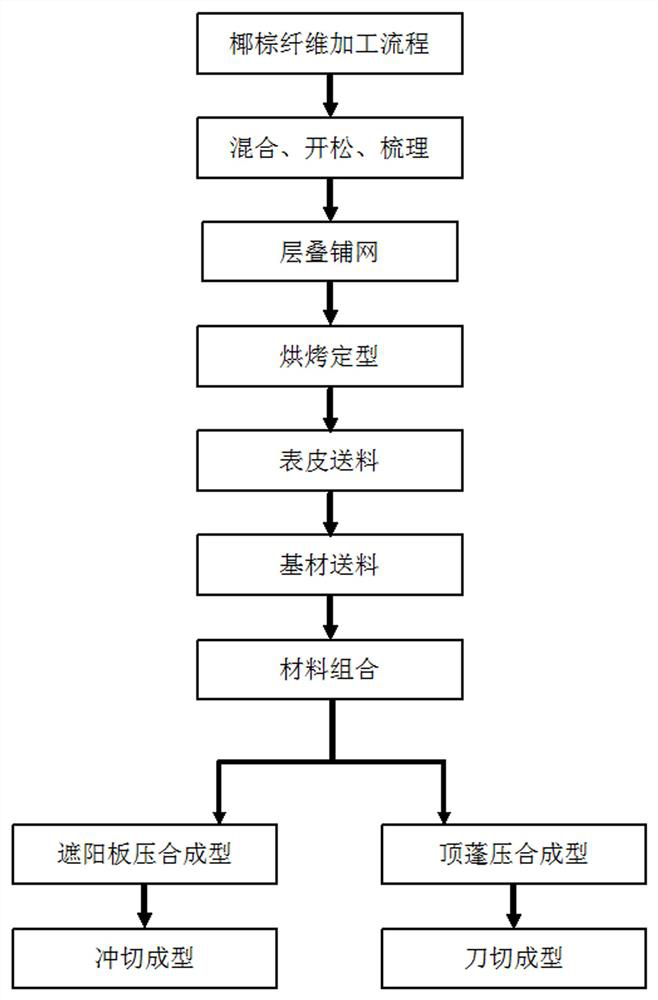

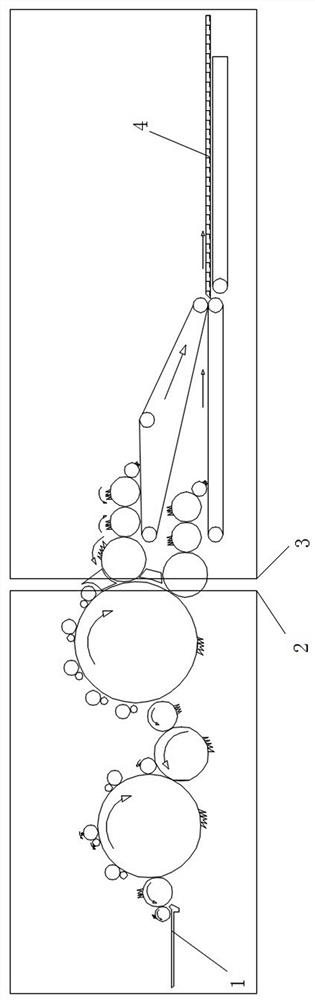

Plant fiber sun visor and manufacturing process thereof

PendingCN112692953AImprove rigidityImprove temperature resistanceLamination ancillary operationsSynthetic resin layered productsGlass fiberPlant fibre

The invention relates to a plant fiber sun visor and a manufacturing process thereof. The plant fiber sun visor comprises a fabric layer and a coconut fiber filament base material which are arranged from top to bottom, the fabric layer and the coconut fiber filament base material are subjected to hot press molding, and the coconut fiber filament base material is formed by hot press molding of an adhesive film, a mixed fiber layer, an adhesive film and non-woven fabric which are arranged from top to bottom. The mixed fiber layer is formed by mixing coconut fibers and polypropylene fibers according to the ratio of 55%-65%: 45%-35%, and conducting opening, carding, stacking and lapping, and rolling, heating and shaping, a coconut fiber and PP material combined plate is adopted for replacing an existing glass fiber material plate, the design is reasonable, the formed sun visor and ceiling have high rigidity and temperature resistance, waste can be recycled, and is easy to decompose, and the sun visor has the effects of high toughness, low VOC (Volatile Organic Compounds), bacterium resistance and moisture resistance, and is environmentally friendly and healthy.

Owner:FUZHOU LIANHONG MOTOR PARTS

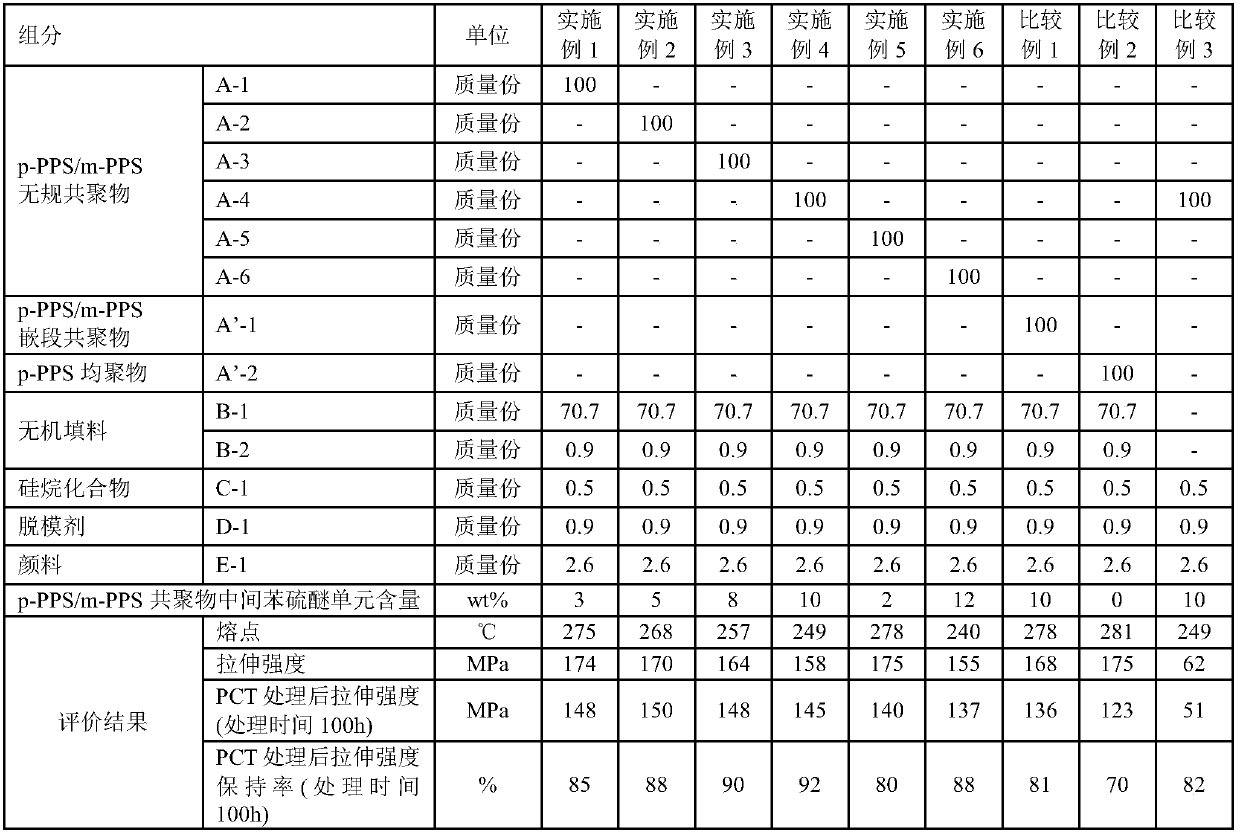

Polyphenylene sulfide resin composition and molded product thereof

The present invention relates to a polyphenylene sulfide resin composition comprising 5-150 parts by mass of an inorganic filler with relative to 100 parts by mass of a polyphenylene sulfide-m-phenylene sulfide random copolymer. The composition has excellent heat and humidity resistance, can maintain very high mechanical strength under the condition of long-term contact with water, and thus, is especially suitable for injection molding of cooling water, anti-freezing solution circulation systems and other products in long-term contact with water and other liquids of automobiles and the like.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com