Plant fiber sun visor and manufacturing process thereof

A plant fiber and manufacturing process technology, applied in the field of plant fiber sun visors and its manufacturing process, can solve the problems of high VOC value, waste of resources, and environmental pollution from leftover waste, and achieve high rigidity and temperature resistance, easy to decompose, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

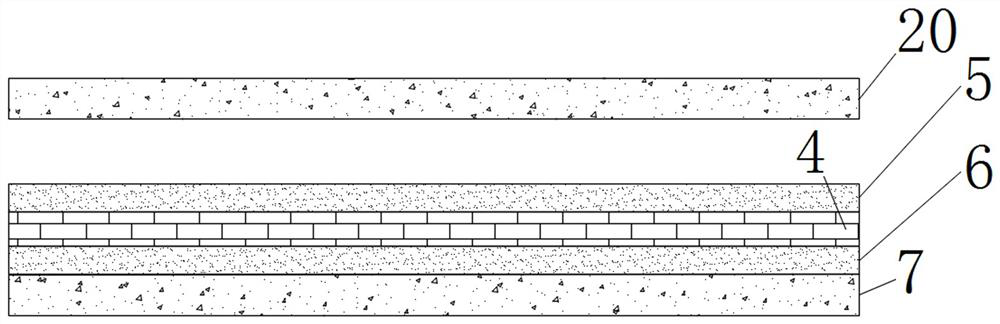

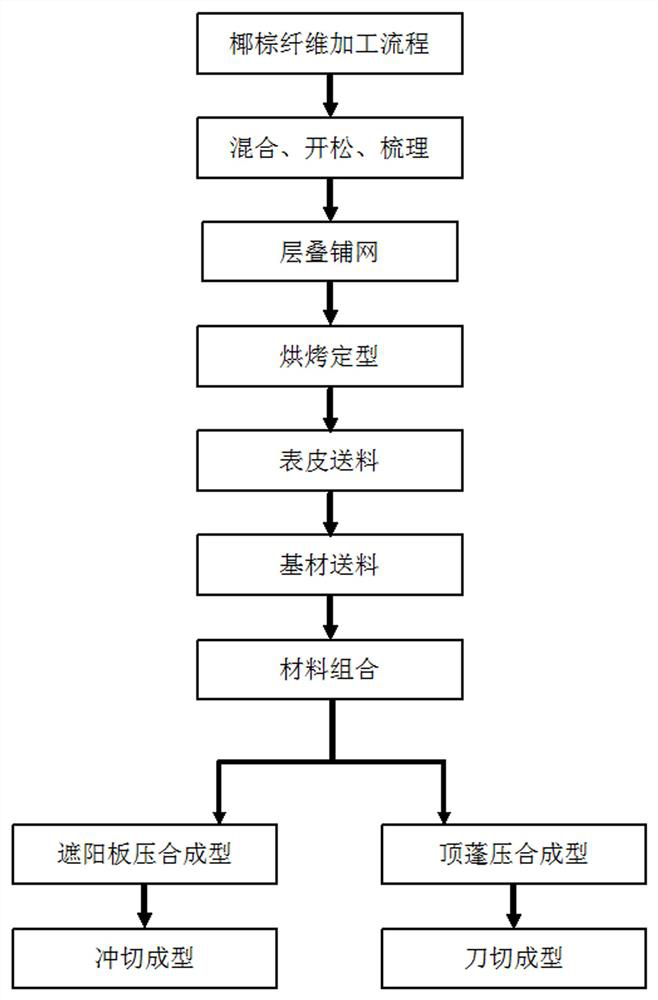

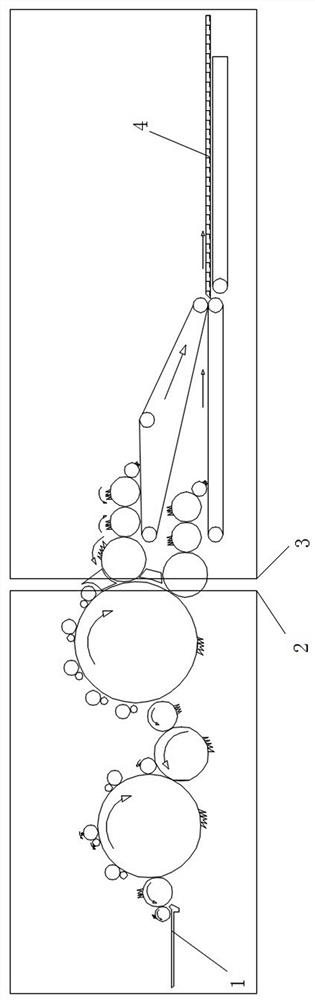

[0038] Such as Figure 1-19 As shown, a plant fiber sun visor: including a fabric layer arranged from top to bottom, a coconut palm fiber silk substrate, both of which are thermocompressed, and the coconut palm fiber silk substrate is arranged from top to bottom The adhesive film, mixed fiber layer, adhesive film and non-woven fabric are formed by hot pressing.

[0039] In this embodiment, the mixed fiber layer is formed by mixing coconut palm fiber: polypropylene fiber = 55% to 65%: 45% to 35%, after opening, carding, laminating, rolling and heating. , the mixed fiber layer has a thickness of 5.25mm~5.5mm and a grammage of 1100~1200g / ㎡ after being heated and shaped by rolling.

[0040] In this embodiment, the adhesive film is made of PE material with a melting point of 180-200°C, the non-woven fabric is black-gray fabric for light protection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com