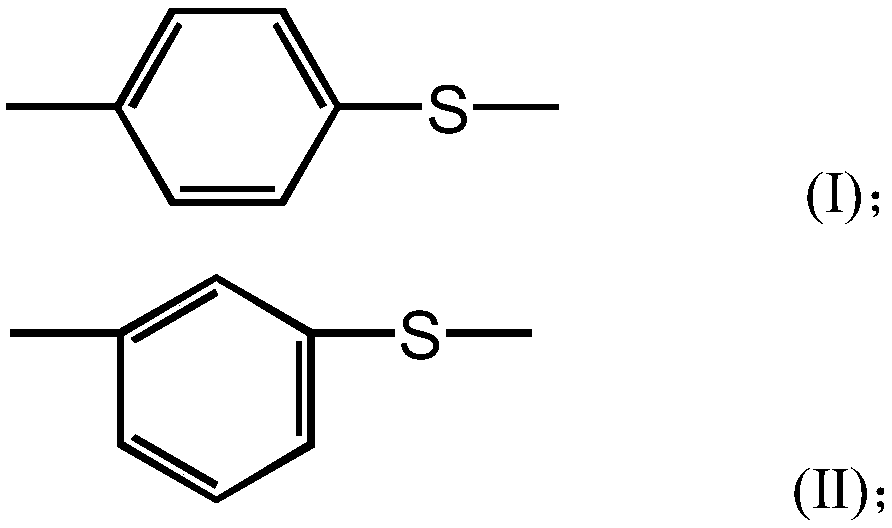

Polyphenylene sulfide resin composition and molded product thereof

A technology of polyphenylene sulfide resin and poly-p-phenylene sulfide, which is applied in the field of polymer materials and can solve the problems of poor film-making stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

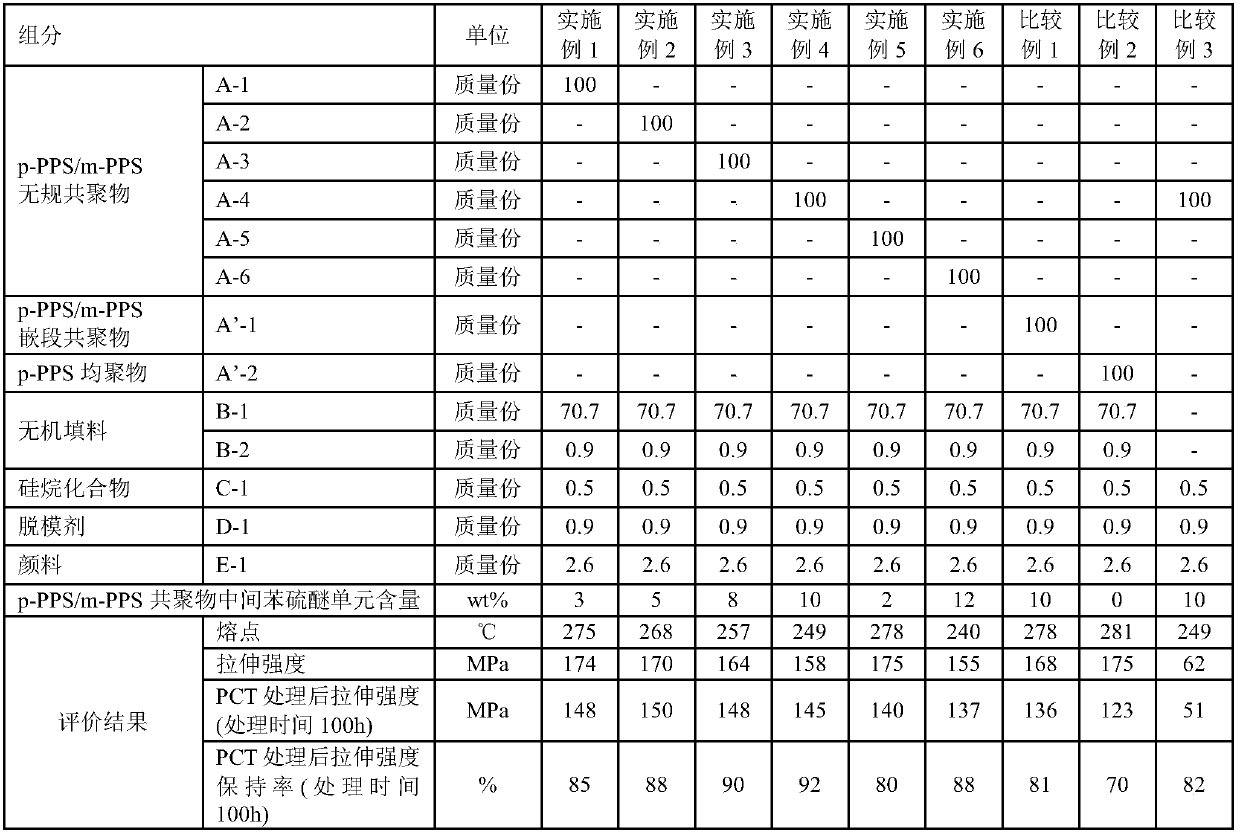

Embodiment 1-6

[0085] The raw materials are as shown in Table 1. The TEX30α twin-screw extruder (L / D=45.5) manufactured by Japan Steel Corporation is used for granulation. The extruder has 13 heating zones and two sets of feeding devices with measuring instruments. And with vacuum exhaust equipment. Except for glass fiber, after mixing other raw materials, add it from the main feed port of the extruder, and add glass fiber from the side feed port of the extruder. The temperature of the extruder is set to 200℃-330℃, after melting and extruding , Cooling and pelletizing to obtain a pelletized polyphenylene sulfide resin composition; after drying the pellets in an oven at 130°C for 3 hours, use the NEX50 injection molding machine manufactured by Nissei Plastic Industry Co., Ltd. to mold at a molding temperature of 330°C and a mold temperature of 130°C The conditions of injection molding into ISO standard sample (the size of the sample mould is 10mm wide×4mm thick), and the performance test is ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com