High performance two-component polyurethane pressure sensitive adhesive and preparation method and application thereof

A two-component polyurethane and pressure-sensitive adhesive technology, applied in the field of pressure-sensitive adhesives, can solve problems such as irritating odors and skin allergies, and achieve good moisture resistance and good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

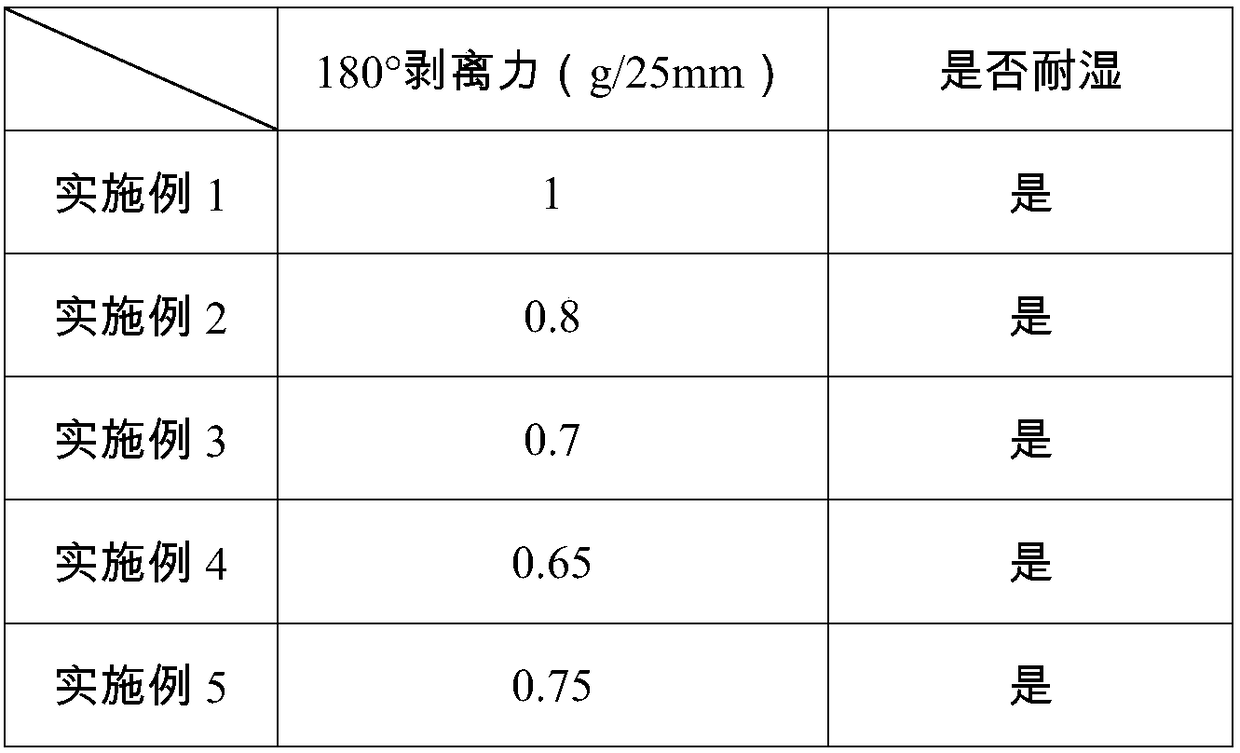

Examples

Embodiment 1

[0034] A pressure-sensitive adhesive made from the following raw materials: 8.5 g of isophorone diisocyanate, 3 g of toluene diisocyanate, 27 g of polytetrahydrofuryl ester diol, 3.4 g of 1,4-butanediol, and 0.1 g of dibutyltin dilaurate , ethyl acetate 29g, toluene 29g, epoxy curing agent L-75.

[0035] The preparation method comprises the following steps:

[0036] (1) Weigh 70% of polytetrahydrofurfuryl ester diol, isophorone diisocyanate, toluene diisocyanate and ethyl acetate and 70% of toluene mass and mix well, pour into the mixture equipped with stirring device, thermometer and condenser tube In the flask, heated to 65°C;

[0037] (2) Add all the catalyst dibutyltin dilaurate into the reaction flask, and raise the temperature to 80°C.

[0038] (3) Pay attention to observe the reaction phenomenon. After the reaction temperature rises to 80°C, keep warm for 4 hours, then add 1,4-butanediol for chain extension reaction, and keep warm for 4 hours;

[0039] (4) Add the re...

Embodiment 2

[0042] A pressure-sensitive adhesive made from the following raw materials: 6.5 g of isophorone diisocyanate, 3.5 g of hexamethylene diisocyanate, 30 g of polyoxypropylene diol, 2.5 g of trimethylolpropane, and dibutyltin dilaurate 0.08g, ethyl acetate 30g, toluene 27.42g, and epoxy curing agent.

[0043] The preparation method comprises the following steps:

[0044] (1) Weigh and mix polyoxypropylene glycol, isophorone diisocyanate, hexamethylene diisocyanate, 90% of total ethyl acetate and 90% of total toluene mass, and pour into a stirring device , thermometer and condenser tube, heated to 65°C;

[0045](2) Add the catalyst dibutyltin dilaurate into the reaction flask, and raise the temperature to 80°C.

[0046] (3) Pay attention to observe the reaction phenomenon. After the reaction temperature is raised to 80° C., keep the temperature for 4 hours, then add trimethylolpropane for chain extension reaction, and keep the temperature for 4 hours.

[0047] (4) Add remaining ...

Embodiment 3

[0050] A pressure-sensitive adhesive made from the following raw materials: 8g of isophorone diisocyanate, 4g of toluene diisocyanate, 24g of polycarbonate diol, 4g of 1,6-hexanediol, 0.12g of dibutyltin dilaurate, acetic acid Ethyl ester 29.88g, toluene 30g, and epoxy curing agent.

[0051] The preparation method comprises the following steps:

[0052] (1) After weighing and mixing 80% of polycarbonate diol, isophorone diisocyanate, toluene diisocyanate and total ethyl acetate and 80% of total toluene mass, pour into a mixture equipped with stirring device, thermometer and In the flask with the condenser tube, heat to 60°C;

[0053] (2) Add the catalyst dibutyltin dilaurate into the reaction flask, and raise the temperature to 80°C.

[0054] (3) Pay attention to observe the reaction phenomenon. After the reaction temperature is raised to 80°C, keep the temperature for 4 hours, then add 1,6 hexanediol for chain extension reaction, and keep the temperature for 4 hours.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com