Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Increase dyne value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

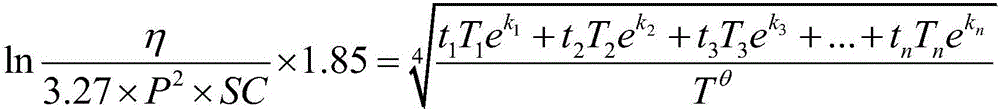

Coating for electronic product shell, and preparation method and application thereof

ActiveCN111560213AImprove the level ofIncrease dyne valueLiquid surface applicatorsPolyurea/polyurethane coatingsDiacetone alcoholMeth-

The invention discloses a coating for an electronic product shell, and a preparation method and application thereof. The coating for the electronic product shell is mainly prepared from the followingeffective raw material components: a component A comprising, by weight, 33-37% of polyester resin, 15-25% of butyl acetate, 13-17% of hydroxy acrylic resin, 4-6% of polycarbonate diol, 4.5-5.5% of anorganic silicon surface additive, 7-13% of methyl isobutyl ketone, 3-7% of diacetone alcohol and 3-7% of ethyl acetate; and a component B being a curing agent HDI tripolymer; and the component B accounts for 8-12% of the total weight of the component A. The coating for the electronic product shell is a two-component spraying oily coating, has the advantages of high light transmittance, adjustablecolor, easiness in processing, boiling resistance and no influence on post-processing procedures, and is particularly suitable for electronic product shells, particularly mobile phone shells and mobile phone battery rear cover plates, and particularly products with embossing texture requirements on mobile phone battery rear covers.

Owner:HUNAN SOKAN NEW MATERIAL

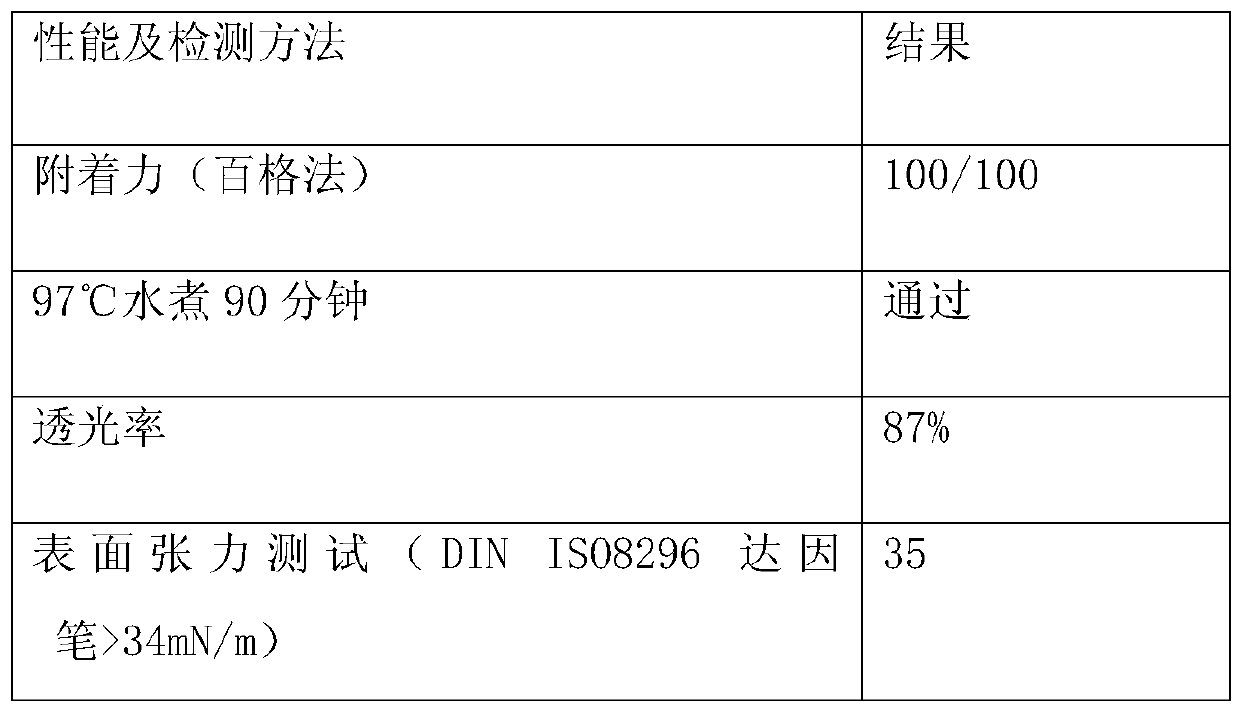

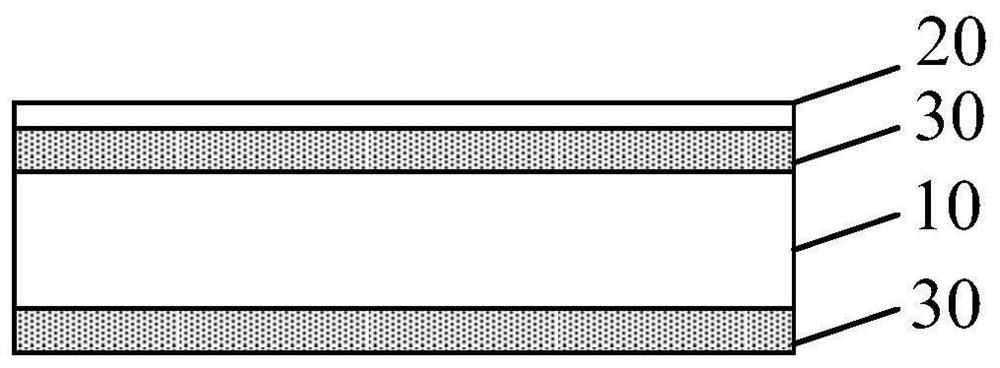

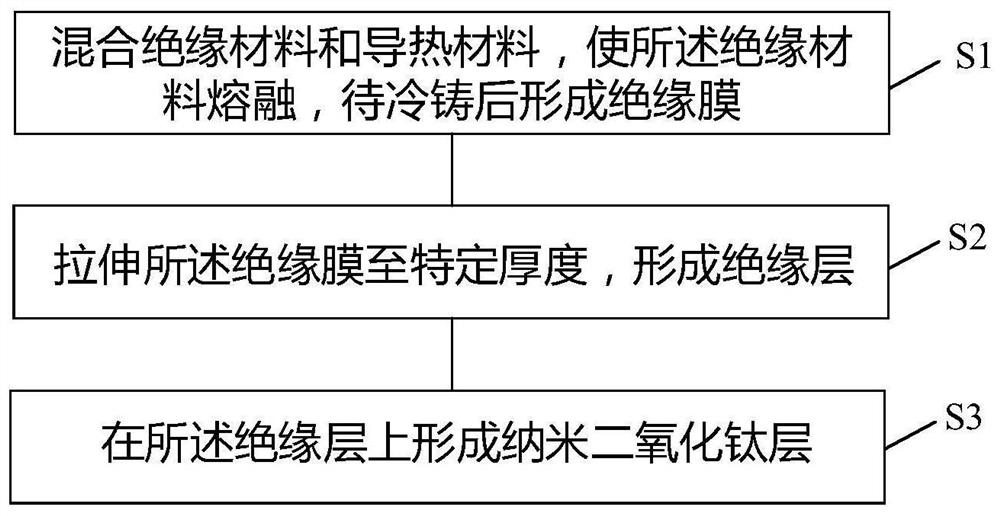

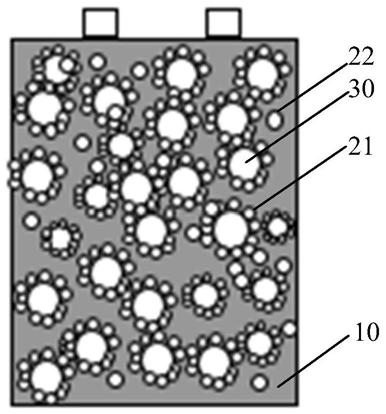

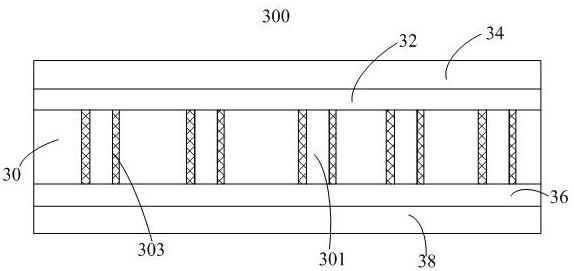

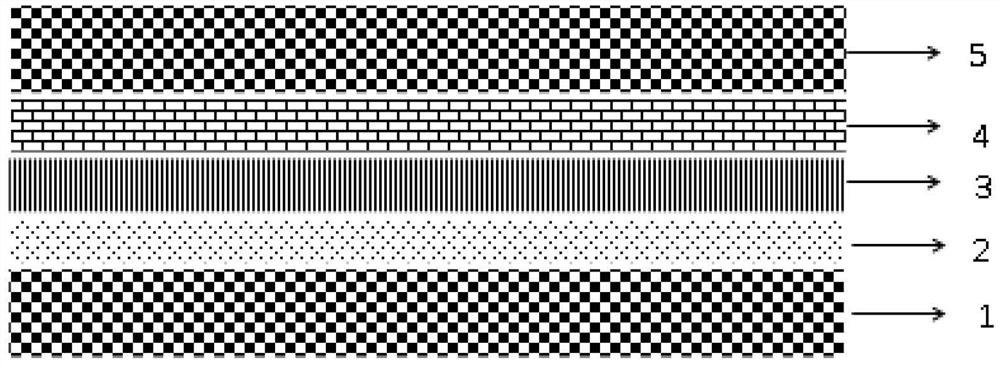

Lithium battery packaging film and preparation method thereof

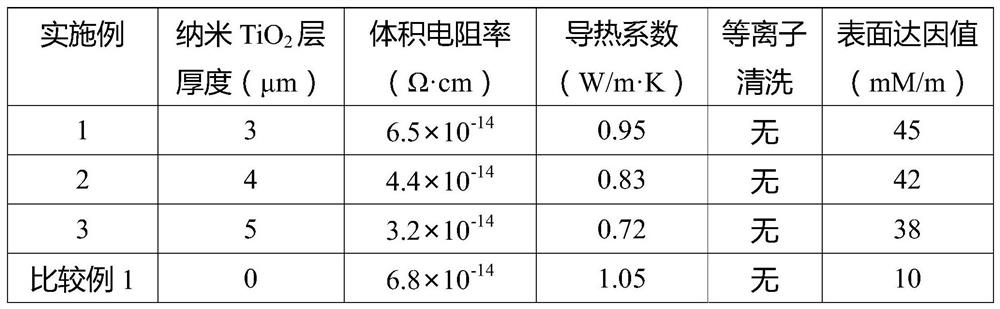

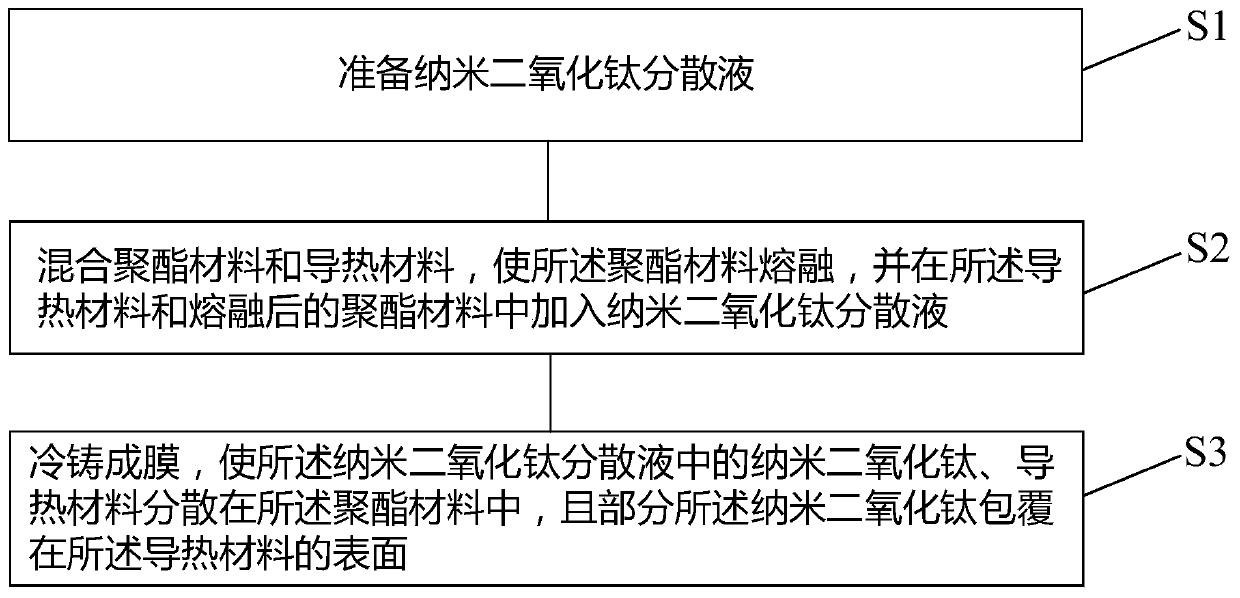

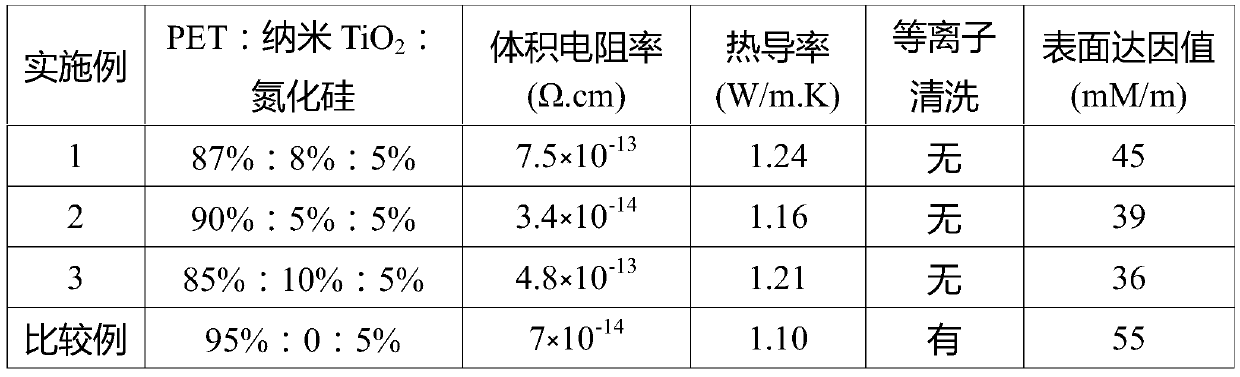

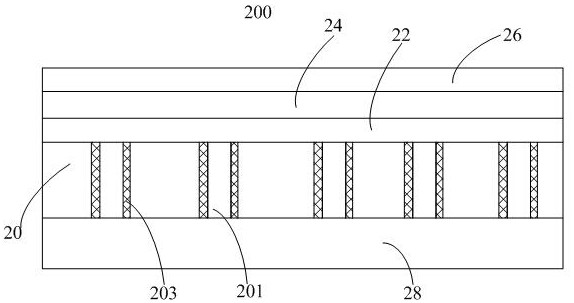

PendingCN111628120AMaintain surface energyWith self-cleaning abilityMaterial nanotechnologyEster polymer adhesivesPolyesterPhysical chemistry

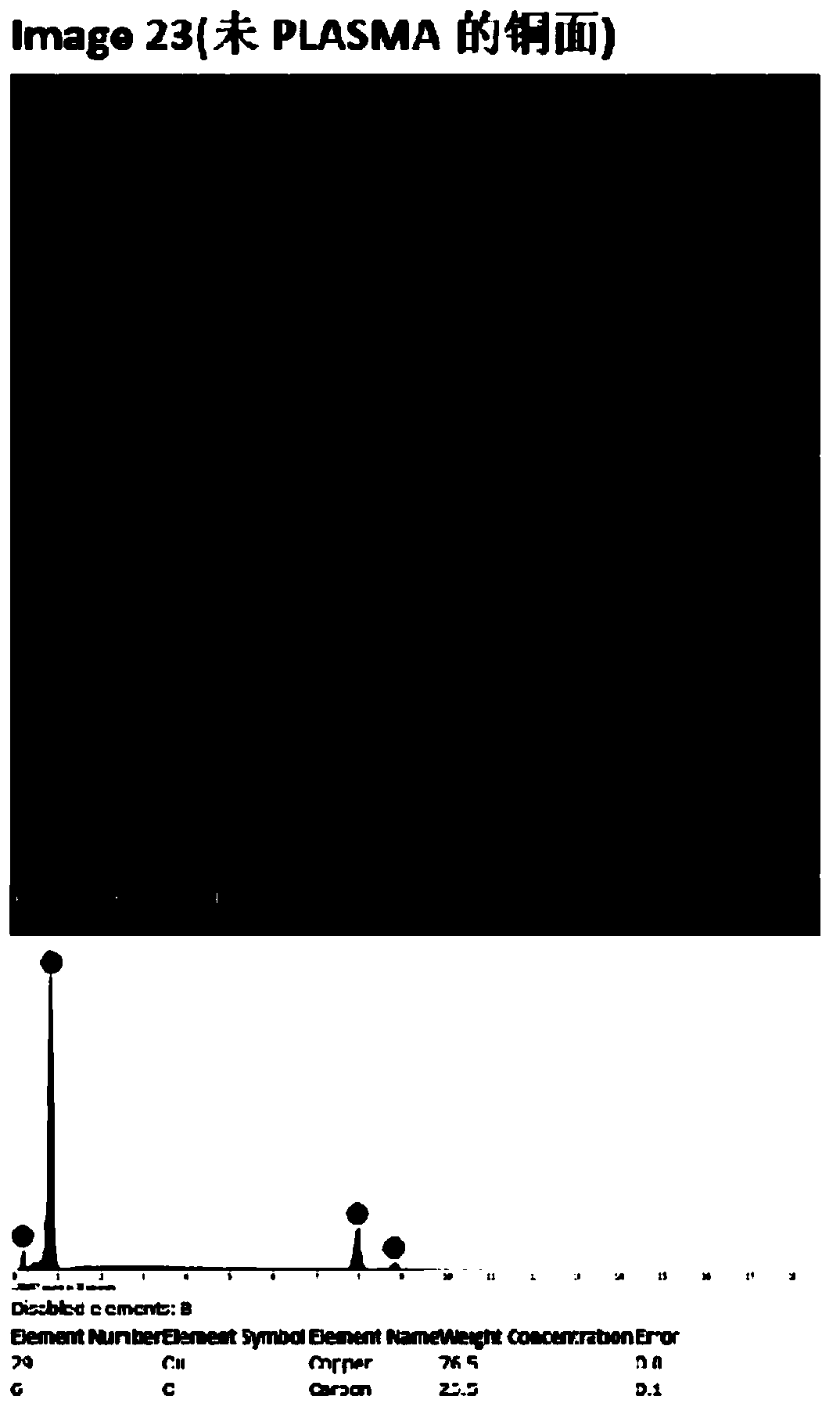

The invention provides a lithium battery packaging film and a preparation method thereof, and the lithium battery packaging film comprises an insulating layer which coats a shell of a lithium battery;and a nanometer titanium dioxide layer, wherein the nanometer titanium dioxide layer is located on the insulating layer. The preparation method comprises the following steps of mixing a polyester material and a heat-conducting material to melt the insulating material, and forming an insulating film after cold casting; stretching the insulating film to a specific thickness to form the insulating layer; and forming the nano titanium dioxide layer on the insulating layer. The nano titanium dioxide layer can enable the surface of the lithium battery packaging film to have self-cleaning capacity,a plasma cleaning procedure can be omitted, the production line efficiency is improved, meanwhile, a plasma cleaning station is prevented from being added, and the production line cost is reduced.

Owner:湖南领湃科技股份有限公司 +4

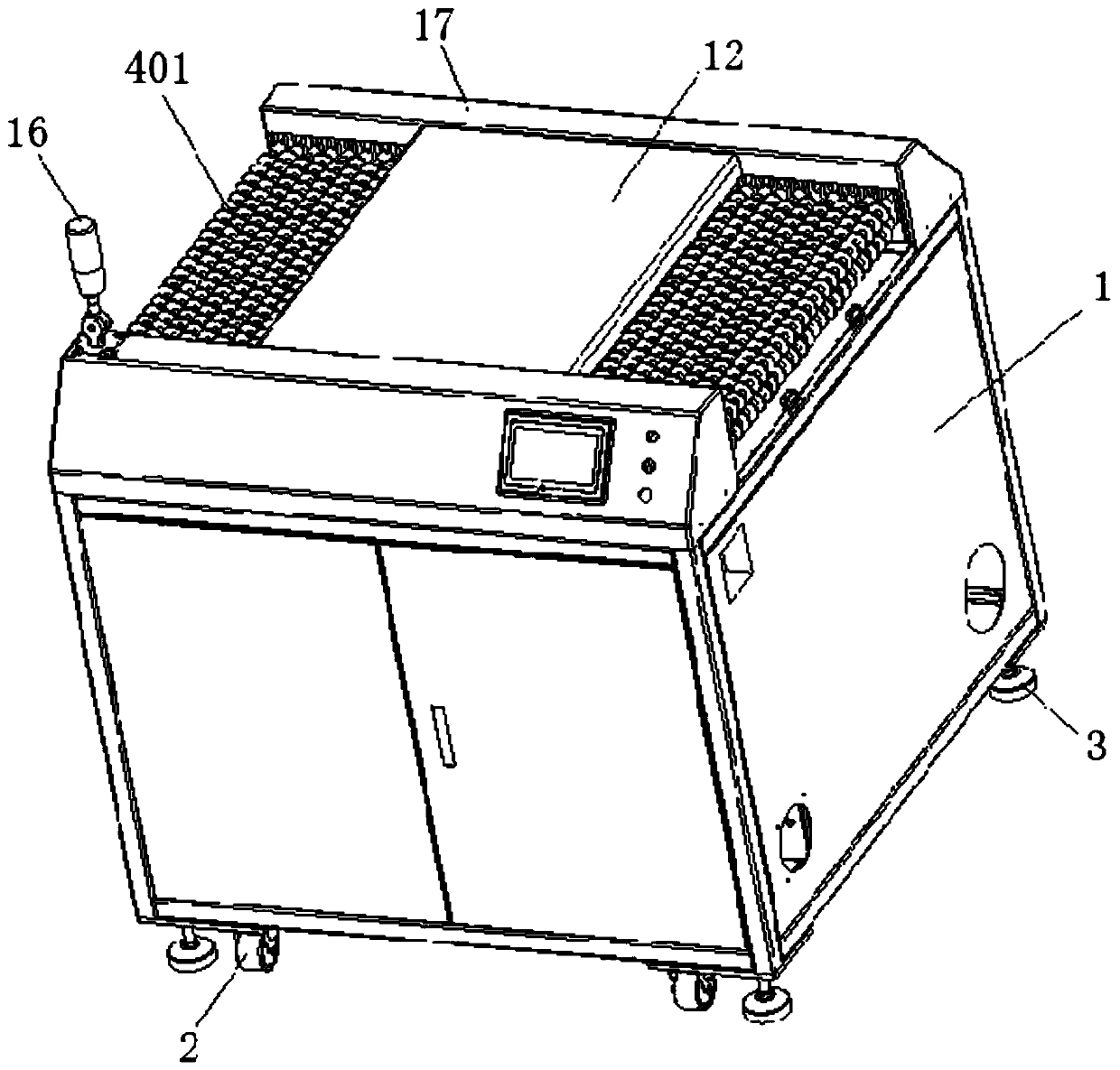

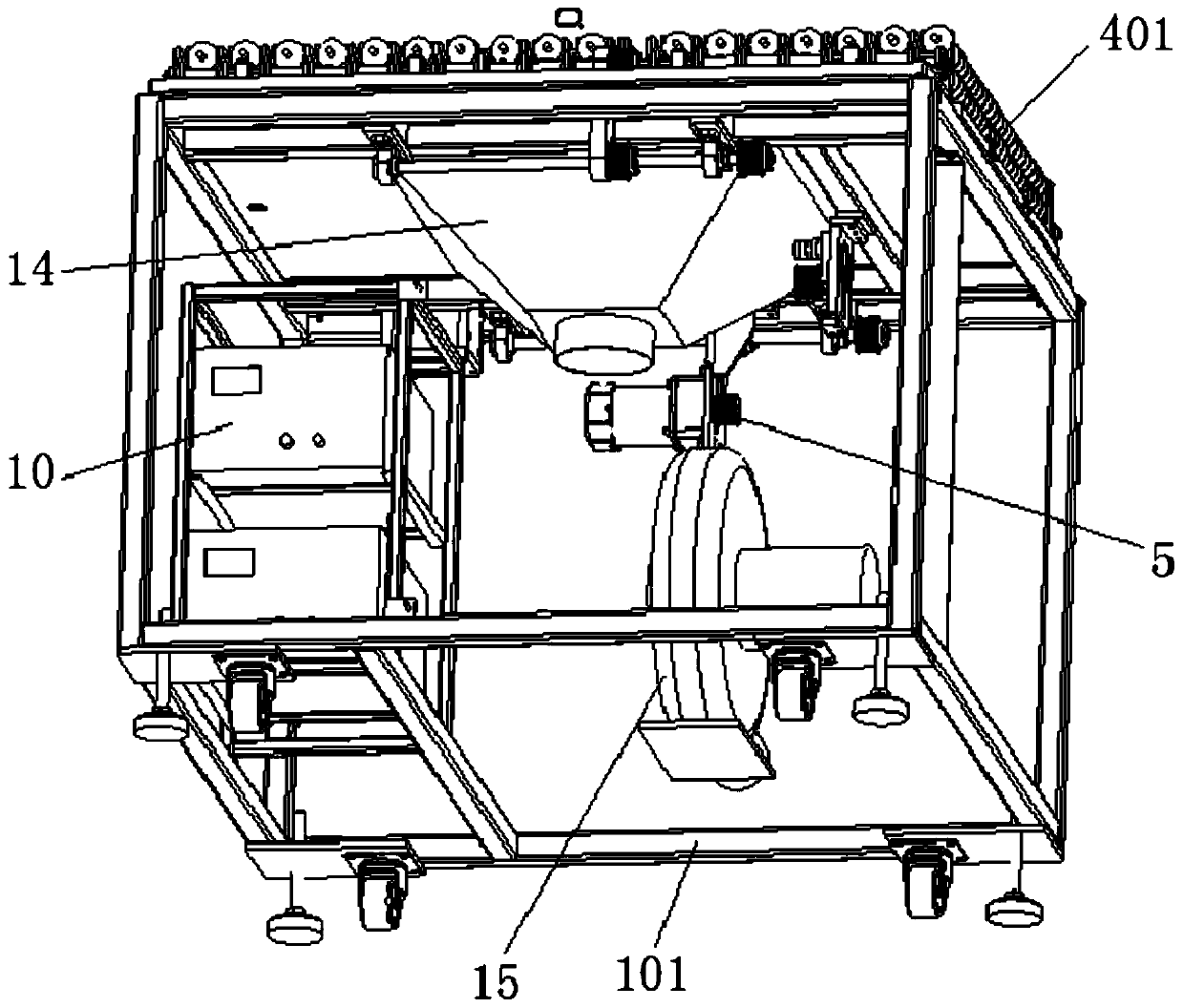

Horizontal line type plasma surface treatment machine

InactiveCN110012583AChange surface tensionIncrease surface polarityConductive pattern polishing/cleaningPlasma techniquePulp and paper industryPulley

The invention discloses a horizontal line type plasma surface treatment machine. The machine comprises a casing, a roller conveying module is mounted in the external top of the casing and connected with a synchronous belt pulley power module, the roller conveying module comprises upper and lower layers of antistatic roller trains, an air-discharge system is arranged under the antistatic roller trains and positioned in the casing, a plasmatron is arranged in the casing and connected with electrode tubes, and the electrode tubes are arranged in the antistatic roller trains correspondingly. The surface tension of a material is changed qualitatively, the dyne value is increased substantially, and the drip angle is changed substantially.

Owner:江苏长沐智能装备有限公司

Medicament foil rolling additive composition

The invention discloses a medicament foil rolling additive composition. The composition consists of the following components by weight: (A) 0.04-2.0% of low-temperature antioxidant, (B) 80-95% of fatty acid methyl ester, (C) 0.06-1.0% of phosphide anti-wear agent, (D) 1-15% of polyhydric alcohol and (E) 0.04-2.0% of high-temperature antioxidant, wherein the component (C) phosphide anti-wear agent is one or more of triaryl phosphate, tricresyl phosphate and phosphate amine salt; the component (D) polyhydric alcohol is one or more of trimethylolpropane, pentaerythritol and diethylene glycol. By compounding the carbon chain fatty acid methyl ester, the phosphide anti-wear agent and the polyhydric alcohol, the chemical adsorption capability and the flow cleaning performance are enhanced, the surface residue of a medicament foil product is greatly reduced on the premise of ensuring the lubricating capability, and the dyne value and peeling strength of a medicament foil are effectively improved.

Owner:石家庄新泰特种油有限公司

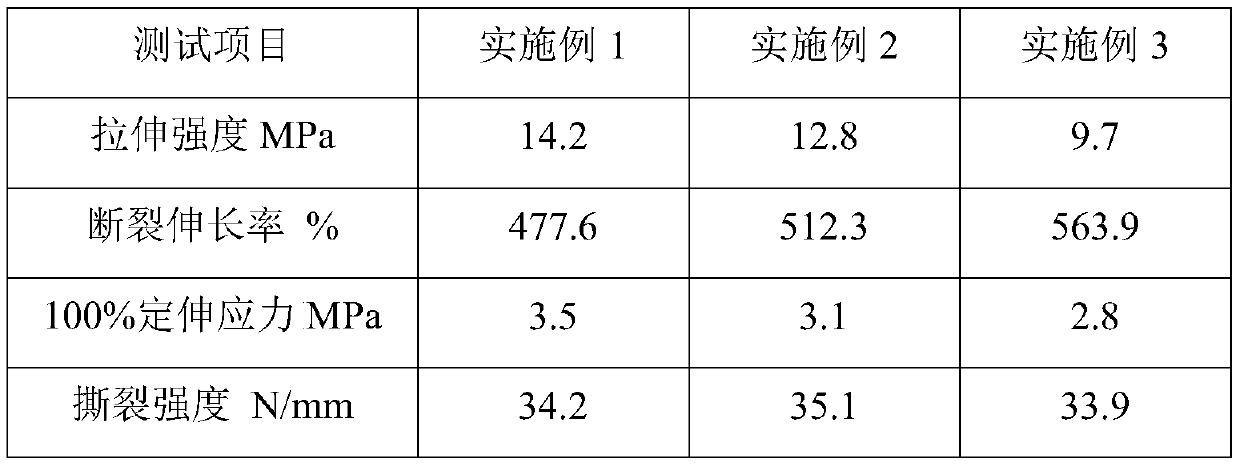

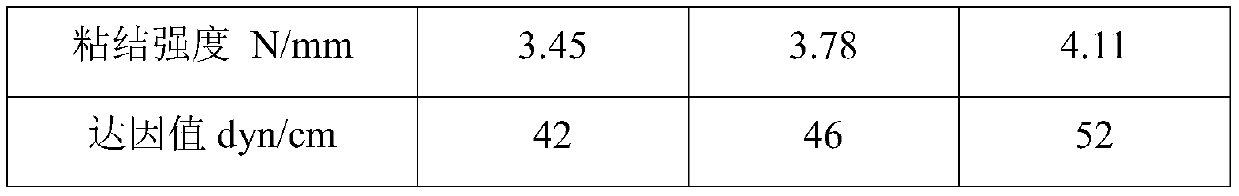

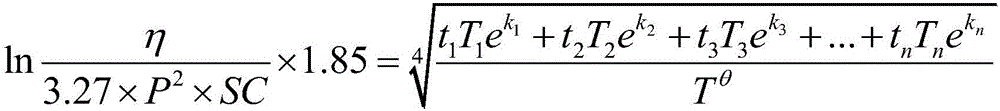

Nano-silica modified high-pressure molding printing ink for two-component plastic

The invention discloses nano-silica modified high-pressure molding printing ink for two-component plastic, belonging to the technical field of printing ink. The nano-silica modified high-pressure molding printing ink comprises, by weight, 40% to 45% of polyester resin, 17.5% to 24% of a solvent, 0.5% to 1.5% of a dispersing agent, 10.0% to 18.7% of pigment, 6% to 7% of a matting agent which includes nano-silica, 1% to 2% of an anti-settling agent, 1% to 2% of a leveling agent, 1% to 2% of a defoaming agent,1% to 3% of an UV aid and 9% to 10% of a curing agent. The nano-silica modified high-pressure molding printing ink for two-component plastic has good hand feeling, excellent fineness, fast curing speed, strong adhesion, high stretchability, soft gloss, excellent resistance to alcohol andwater, high dyne value and good weather resistance.

Owner:深圳市科美达迈斯科技有限公司

High Dyne value and ultraviolet resistant screen printing ink for glass panels

The invention discloses a high Dyne value and ultraviolet resistance screen printing ink for glass panels and a preparation method thereof. The printing ink mainly comprises raw materials in parts byweight: epoxy resin 20-70 parts, mica 3-4 parts, wollastonite 7-8 parts, 783 slow dry water 1-3 parts, adhesion promoter 2-4 parts, Y-Butylactone 22-25 parts, turpentine 25-34 parts, dispersant 3-4 parts, defoamer 4-5 parts, silica 2.5-6 parts, black pigment 4-20 parts, ultraviolet absorber 0.5-2 parts, and bis-sebacate 1-5 parts. The raw materials are put into homogenization equipment, grinding machine and three-roller machine in different sequences to finally obtain printing ink with required fineness. After the invention is applied, the adhesion force, dyne value and ultraviolet light resistance of the printing ink can be improved, thus improving the printing stability of the printing ink.

Owner:北海市龙浩光电科技有限公司

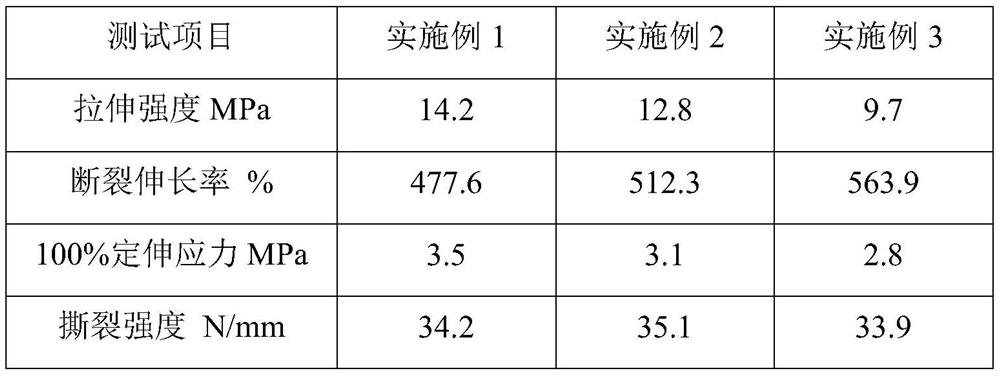

TPV composition and preparation method thereof

ActiveCN111057306AIncrease dyne valueGood adhesive strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceEthylene-propylene-diene-monomer

The invention discloses a TPV composition and a preparation method thereof. The material is prepared from 30-40 parts of polypropylene, 20-30 parts of ethylene propylene diene monomer, 20-30 parts ofa plasticizer, 10-20 parts of a filler, 0.2-1 part of a lubricant, 0.2-1 part of a crosslinking agent, 0.5-2 parts of an assistant crosslinking agent, 0.3-0.5 part of an antioxidant and 1-5 parts of aporous adsorbent. According to the invention, the special auxiliary agent is added into the formula, so that the prepared TPV composition has high encapsulation bonding strength.

Owner:会通新材料(上海)有限公司

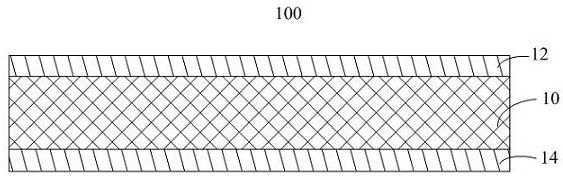

Hard coating film with high dyne value

ActiveCN106634462AIncrease dyne valueGood optical performancePretreated surfacesPolyurea/polyurethane coatingsSolventPhotoinitiator

The invention discloses a hard coating film with a high dyne value, comprising a PET supporter, and a hard coating layer formed by solidifying after coating hard coating layer coating on at least one surface of the PET supporter, wherein the hard coating layer coating has the following components in parts by weight: 15-50 parts of matrix resin, 2-10 parts of oxide particles, 0.05-5.0 parts of surface additive, 0.05-7.0 parts of photoinitiator and 40-80 parts of solvent. The dyne value of the hard coating film provided by the invention can reach 38Dyne-46Dyne, thus being capable of meeting operating requirements of customers on subsequent ITO coating technology and ink printing technology.

Owner:HEFEI LUCKY SCI & TECH IND

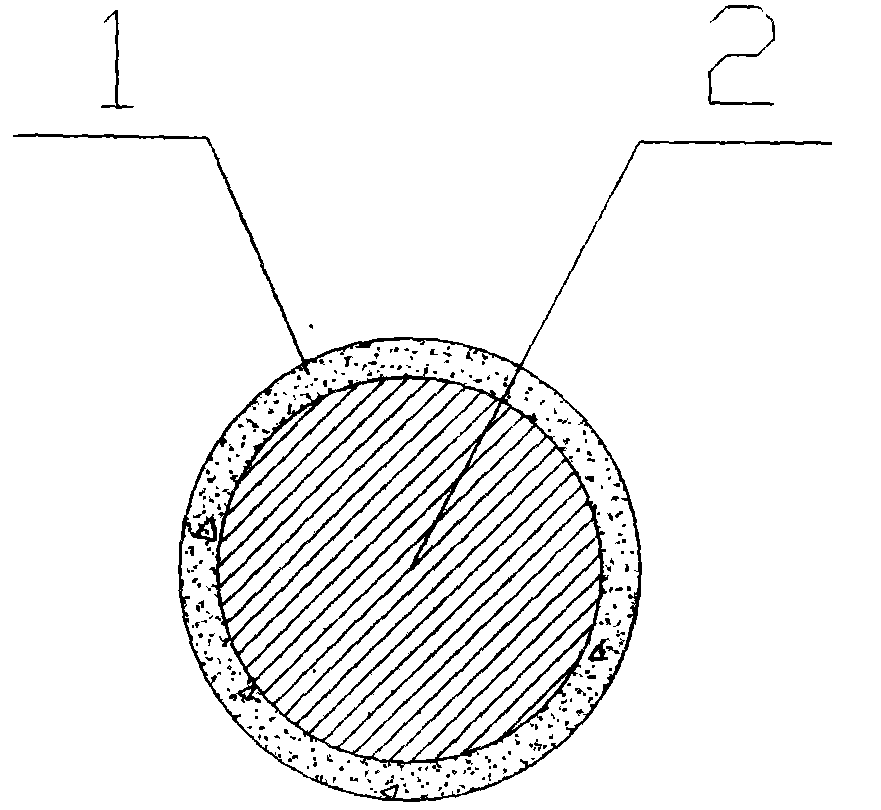

Rubber roller

The invention discloses a rubber roller. The rubber roller comprises a rubber surface layer (1) and an iron core shaft (2), and is characterized in that the rubber surface layer (1) is tightly compounded on the iron core shaft (2); the mesh number of the rubber surface layer (1) is 350, and the hardness is 90A. The rubber roller has the advantages and effects that the polyurethane decorative film produced by the rubber roller is high in dyne value, and is high in adhesive force with a plate.

Owner:宋昊

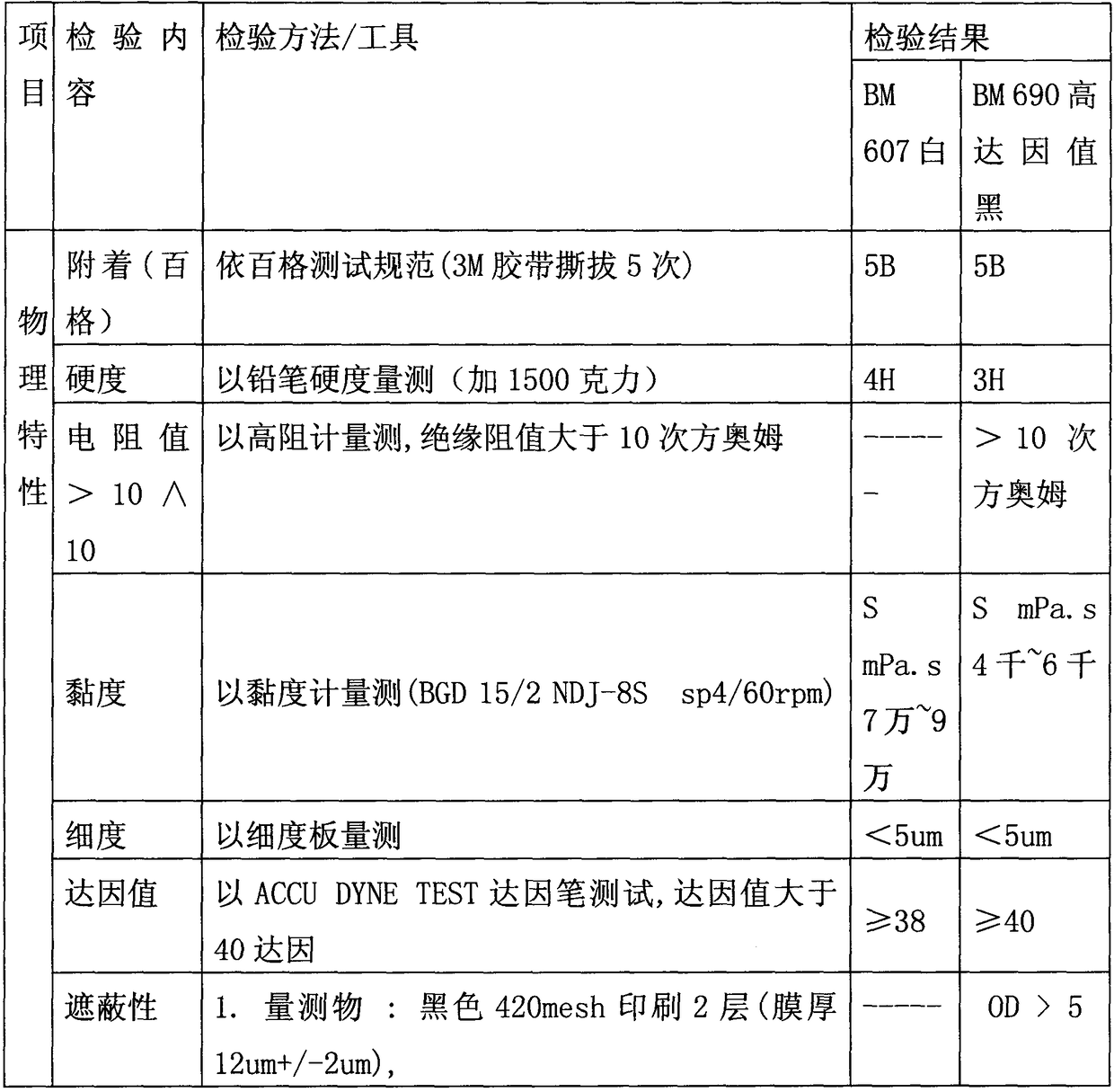

Bi-component modified polyester resin thermosetting ink

The invention discloses bi-component modified polyester resin thermosetting ink which comprises BM 607 white and BM 690 high-dyne-value black. The BM 607 white is mixture comprising, in concentrationrange (percent), 20-50% of polyester resin, 2-10% of propylene glycol methyl ether acetate, 25-35% of isophorone, 40-50% of titanium dioxide and 2-5% of auxiliaries. The BM 690 high-dyne-value black is mixture comprising, in concentration range (percent), 20-50% of polyester resin, 2-10% of propylene glycol methyl ether acetate, 25-35% of isophorone, 20-30% of carbon black and 2-5% of auxiliaries.The ink is high in covering power, good in printability and applicable to printing of a glass cover plate, and a cured ink layer has excellent adherence, chemical resistance and boiling resistance, high surface tension and the like.

Owner:柯伟

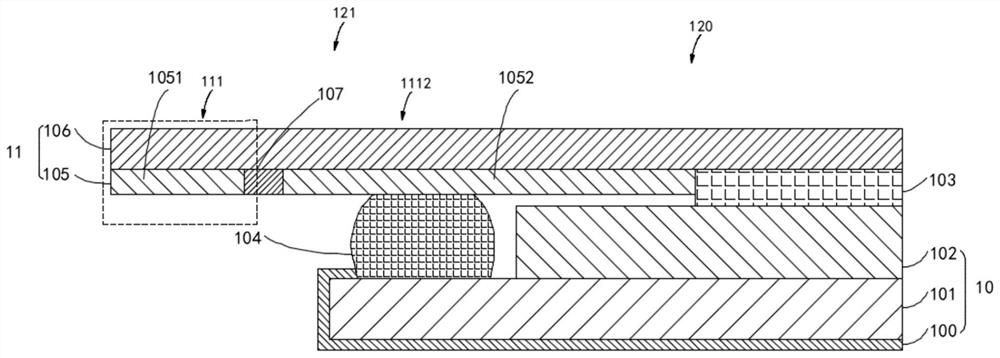

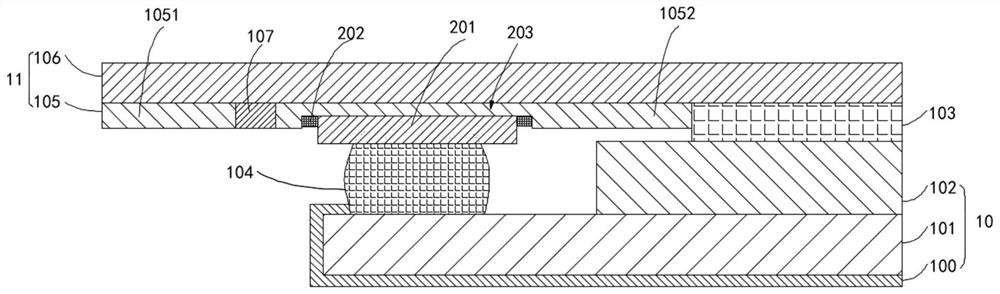

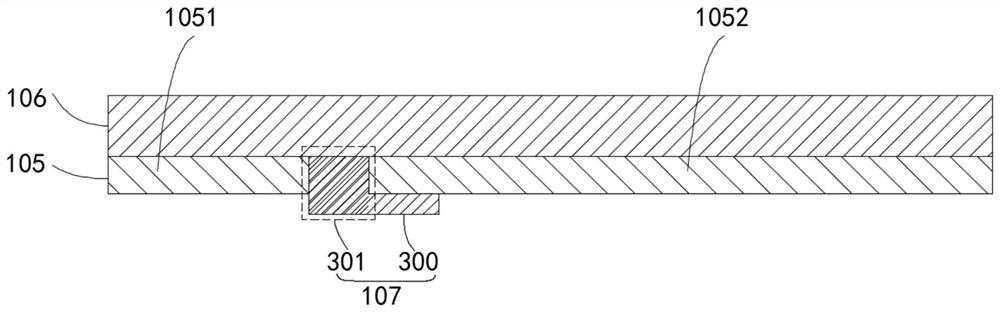

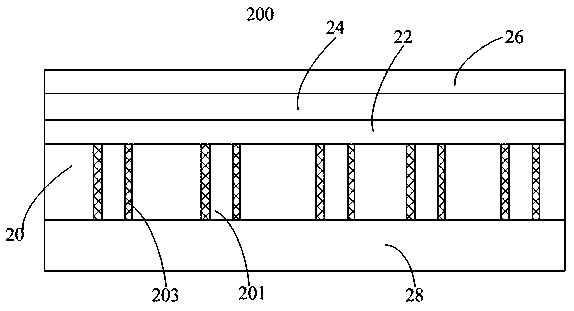

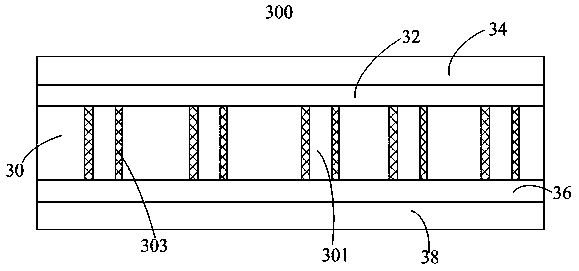

Display device

PendingCN112987371AGuaranteed tightnessGuaranteed Quality and ReliabilityStatic indicating devicesNon-linear opticsPhysicsEngineering

The invention provides a display device which comprises a cover plate, a display panel and a supporting component, the cover plate comprises a light shielding layer and a blocking component, one end of the supporting component is connected with the display panel, the other end of the supporting component is connected with the light shielding layer of the cover plate, the blocking component divides the light shielding layer into a dyne value testing area and a non-testing area, the two areas are not communicated, so that the film layers in the dyne value testing area have good performance, the bonding performance between the film layers is improved, the accuracy of the display panel during dyne value testing and the sealing performance of the display panel are ensured, and the quality of the display panel is effectively improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for processing and increasing printing and packaging dyne value

The invention provides a method for processing and increasing the printing and packaging dyne value and belongs to the technical field of printing and packaging. The method for processing and increasing the printing and packaging dyne value comprises the following steps of forming at least one inflatable sealing structure on the surface of a plastic film to be about to be subjected to corona; andconducting corona treatment on the inflatable plastic film. Through the corona treatment method, air is inflated into the sealing structures, and corona treatment can be conducted better, so that molecular structures on the surface of the plastic film is rearranged to generate more polar parts, so that the dyne value of the surface of the plastic film is increased obviously, and subsequent printing of the plastic film is facilitated.

Owner:WUHAN HONGJINLONG PRINTING

Battery aluminum foil production method capable of increasing surface dyne value

The invention discloses a battery aluminum foil production method capable of increasing the surface dyne value. Battery aluminum foil is produced through smelting, refining, cast rolling, rough rolling, intermediate rolling, finish rolling, corona treatment and heat preservation treatment, rolling oil is used in the rough rolling step, the intermediate rolling step and the finish rolling step, and the rolling oil is obtained by adding an additive and an auxiliary agent into white oil and stirring and mixing evenly. The surface dyne value of the obtained battery aluminum foil is high, and the surface dyne value can keep good stability. The additive is prepared by uniformly mixing n-propyl caprate and lauryl alcohol according to a certain ratio. The auxiliary agent is prepared from the following raw materials of epoxy resin, turpentine, silicon dioxide coated nano aluminum silicate and 1-aminopropyl-3-methylimidazole bis (trifluoromethanesulfonyl) imine salt.

Owner:山东德利铝业科技有限公司

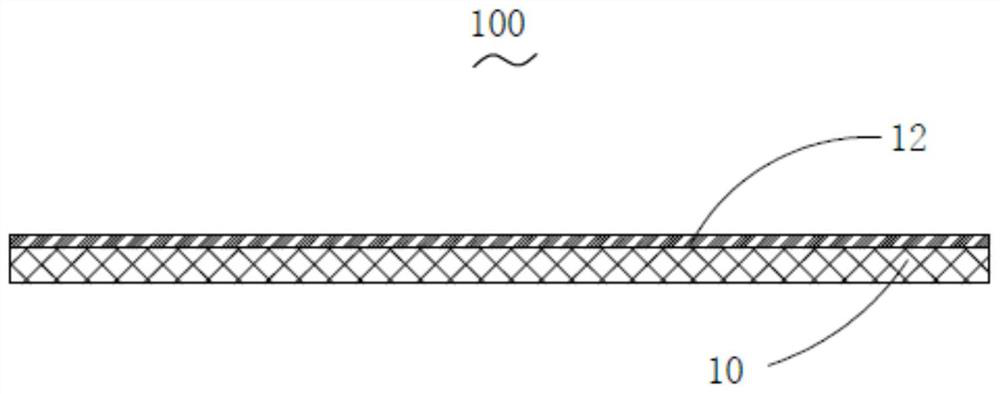

Manufacturing method of flexible ultrathin conductive material

PendingCN112259281AIncrease dyne valueHigh energyConductive layers on insulating-supportsMagnetic/electric field screeningThin membraneConductive materials

The invention discloses a manufacturing method of a flexible ultra-thin conductive material, the flexible ultra-thin conductive material prepared by adopting the manufacturing method and an electronicproduct applying the flexible ultra-thin conductive material. The manufacturing method of the flexible ultra-thin conductive material comprises the following steps of: providing a double-sided non-conducting thin film layer, wherein the thickness of the thin film layer is greater than or equal to 1.0 micron and less than or equal to 6 microns; roughening the thin film layer to enable a dyne valueof the thin film layer to be larger than or equal to 44 and smaller than or equal to 70; and carrying out vapor deposition on the two roughened surfaces, and forming at least one metal shielding layer on each surface, wherein the metal shielding layers on the two surfaces are insulated and isolated by the thin film layer. According to the manufacturing method of the flexible ultra-thin conductivematerial, the flexible ultra-thin conductive material with the two non-conducting sides is very thin.

Owner:深圳市乐工新技术有限公司

Lithium battery insulating film and preparation method thereof

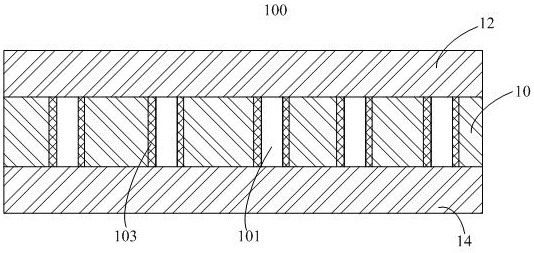

ActiveCN111548614AWith self-cleaning abilityPrevent adhesionMaterial nanotechnologyLi-accumulatorsPolyesterPhysical chemistry

The invention provides a lithium battery insulating film and a preparation method thereof, the lithium battery insulating film comprises a polyester film, which comprises uniformly distributed nano titanium dioxide and a heat conduction material, wherein a part of the nano titanium dioxide coats the surface of the heat conduction material. The preparation method comprises the following steps: preparing a nano titanium dioxide dispersion liquid; mixing a polyester material and a heat-conducting material to melt the polyester material, and adding a nano titanium dioxide dispersion liquid into the heat-conducting material and the molten polyester material; carrying out cold casting to form a film, so that the nano titanium dioxide and the heat conduction material in the nano titanium dioxidedispersion liquid are dispersed in the polyester material, and part of the nano titanium dioxide coats the surface of the heat conduction material. The lithium battery insulating film can prevent short circuit outside the lithium battery shell, has better heat conduction characteristic, can reduce the use of auxiliaries, can shorten the manufacturing process, and improves the production line efficiency.

Owner:湖南领湃达志科技股份有限公司 +4

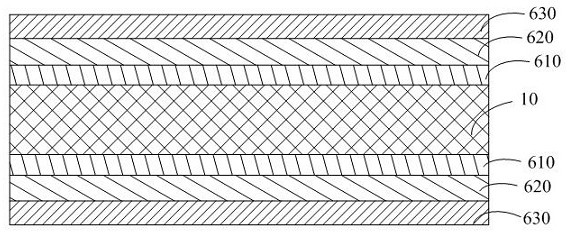

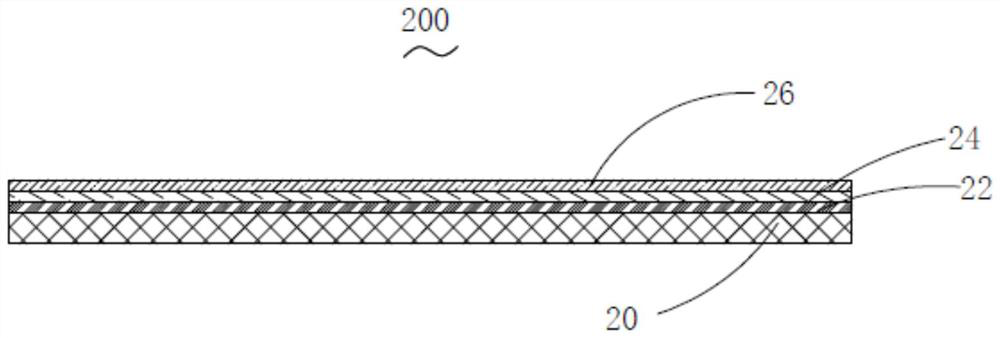

Manufacturing method of electromagnetic shielding material, electromagnetic shielding material and electronic product

PendingCN111621051AHigh energyEasy to acceptMagnetic/electric field screeningVacuum evaporation coatingThin membranePolymer thin films

The invention discloses a manufacturing method of an electromagnetic shielding material, the electromagnetic shielding material prepared by the manufacturing method and an electronic product applyingthe electromagnetic shielding material. The manufacturing method of the electromagnetic shielding material comprises the following steps: a polymer film layer is provided, and the thickness of the polymer film layer is larger than or equal to 1.5 micrometers and smaller than or equal to 6 micrometers; the polymer film layer is punched, so that a plurality of through holes are formed in the polymerfilm layer, the hole diameter of the through holes ranges from 0.1 micrometer to 100 micrometers, and the hole distance ranges from 0.1 micrometer to 100 micrometers; roughening the polymer film layer to enable the dyne value of the polymer film layer to be greater than or equal to 44 and less than or equal to 70; vapor deposition is carried out on the two roughened surfaces respectively, and atleast one metal shielding layer is formed on each surface and the hole walls of the through holes respectively; according to the technical scheme, the electromagnetic shielding material with the two-sided conduction function is very thin and good in flexibility.

Owner:深圳市乐工新技术有限公司

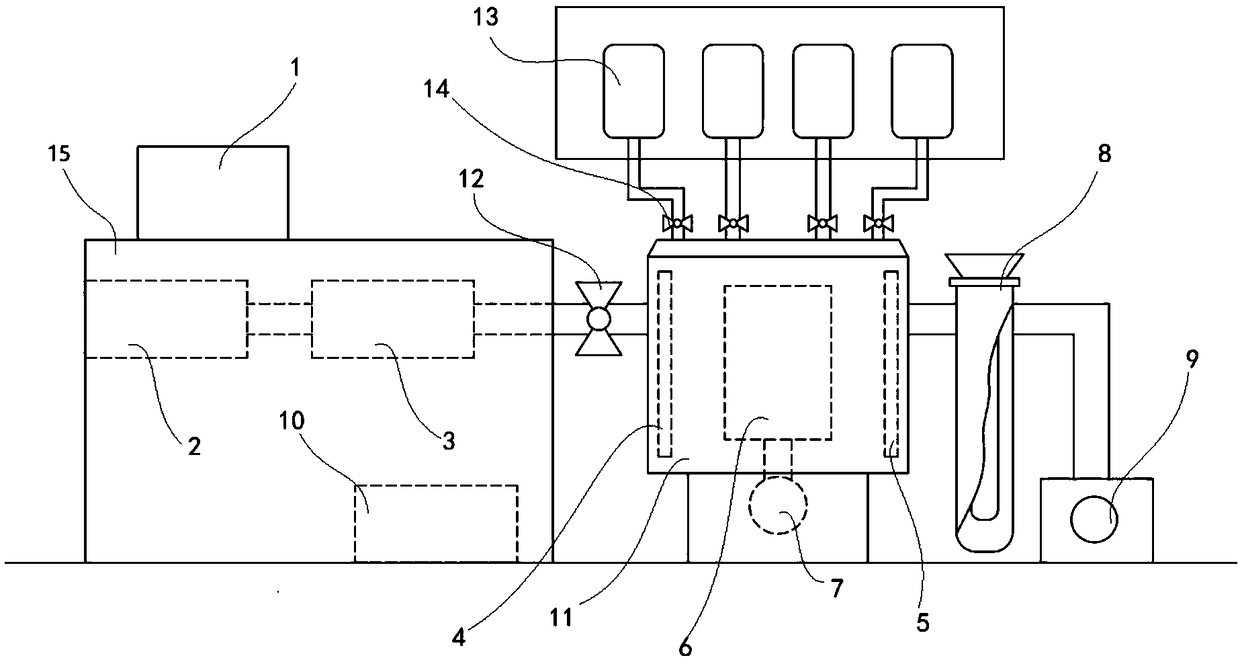

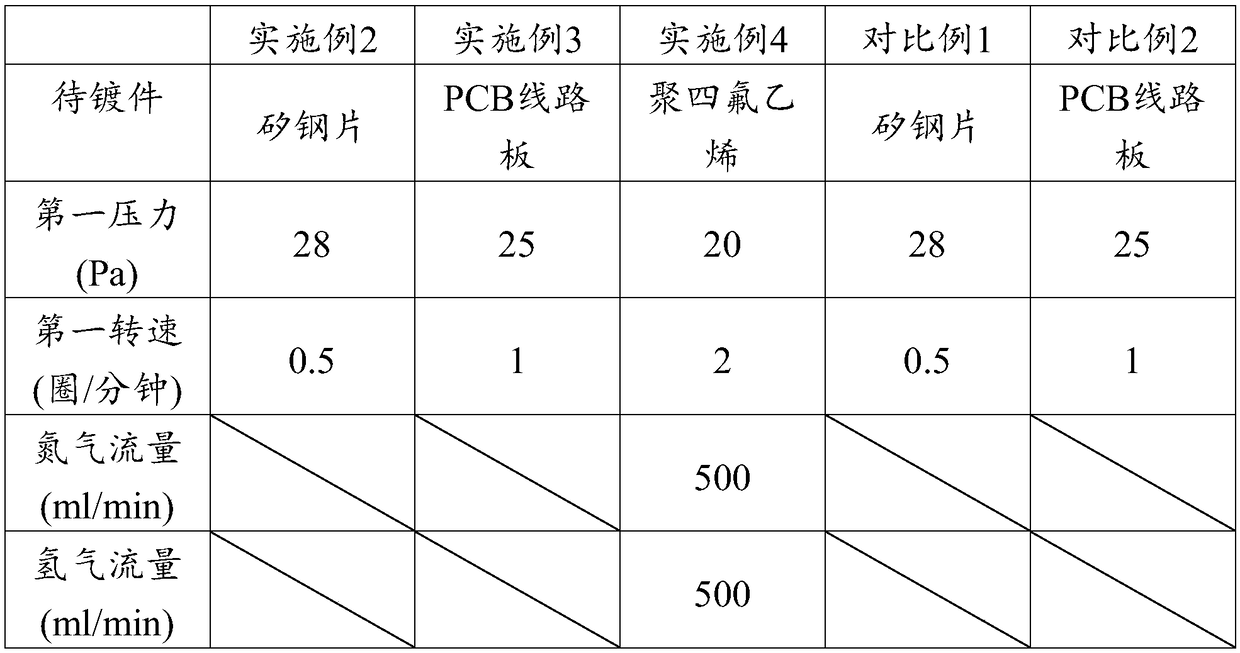

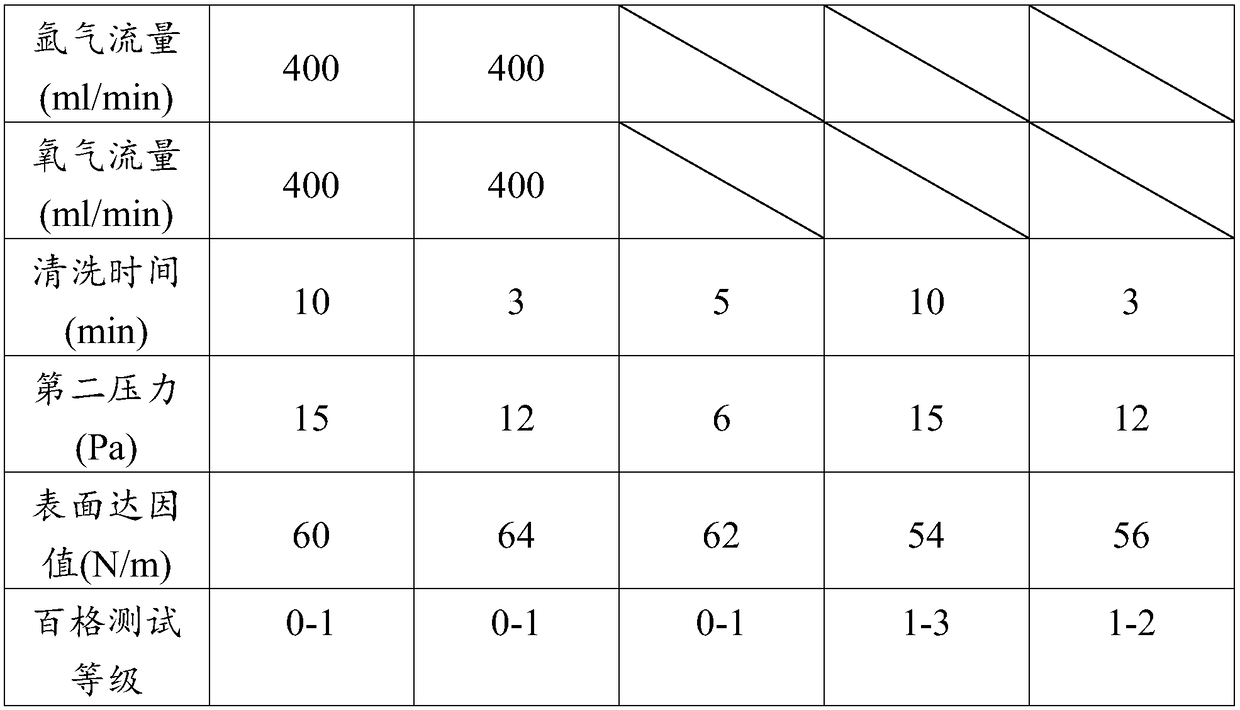

Cleaning coating machine and cleaning coating method

PendingCN109457215AIncrease dyne valueStrong adhesionVacuum evaporation coatingSputtering coatingParylene coatingEngineering

The invention relates to a cleaning coating machine and a cleaning coating method. The cleaning coating machine and the cleaning coating method mainly solves the problem that the surface of a unit tobe plated after plasma cleaning is low in dyne value in the prior art. The cleaning coating machine comprises a powder gasification furnace, a high temperature pyrolysis furnace, a processing chamber,a cold trap, a vacuum pump, a plasma cleaning assembly, gas tank groups and a central controller, wherein each gas tank group is composed of a gas tank and a gas valve, the gas tanks communicate withthe processing chamber through the gas valves, and the central controller is connected with the powder gasification furnace, the high temperature pyrolysis furnace, a powder valve, a rotatable bracket assembly, the cold trap, the vacuum pump and the plasma cleaning assembly. The plasma cleaning assembly comprises a plasma controller, a plasma positive plate and a plasma negative plate, wherein the plasma positive plate and the plasma negative plate are arranged on both sides of the rotatable bracket assembly. The plasma controller is connected with the central controller, the plasma positiveplate, the plasma negative plate and the gas valve. The cleaning coating machine and the cleaning coating method well solve the problems and can be applied to the industrial production of parylene coating.

Owner:苏州凯瑞纳米科技有限公司

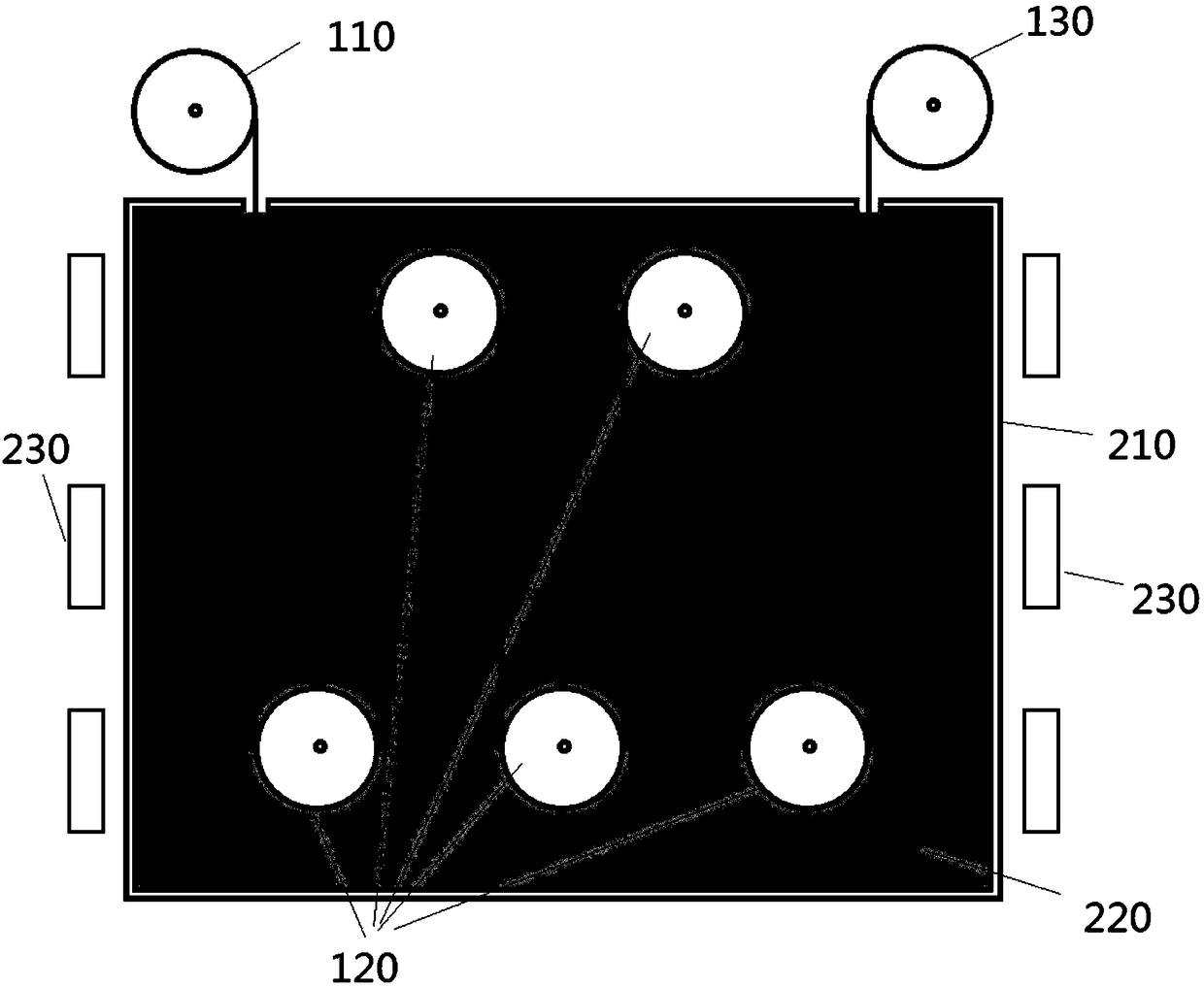

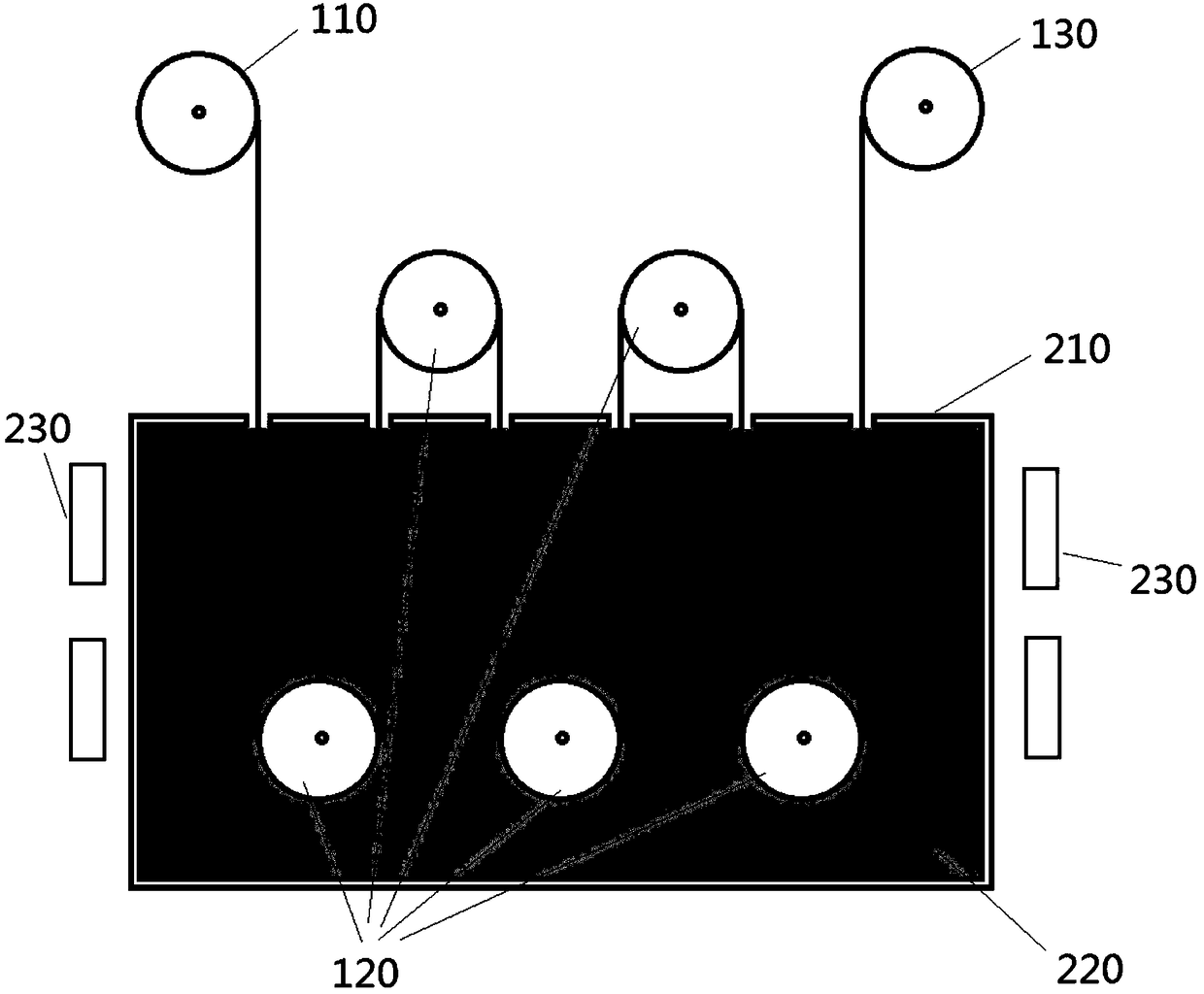

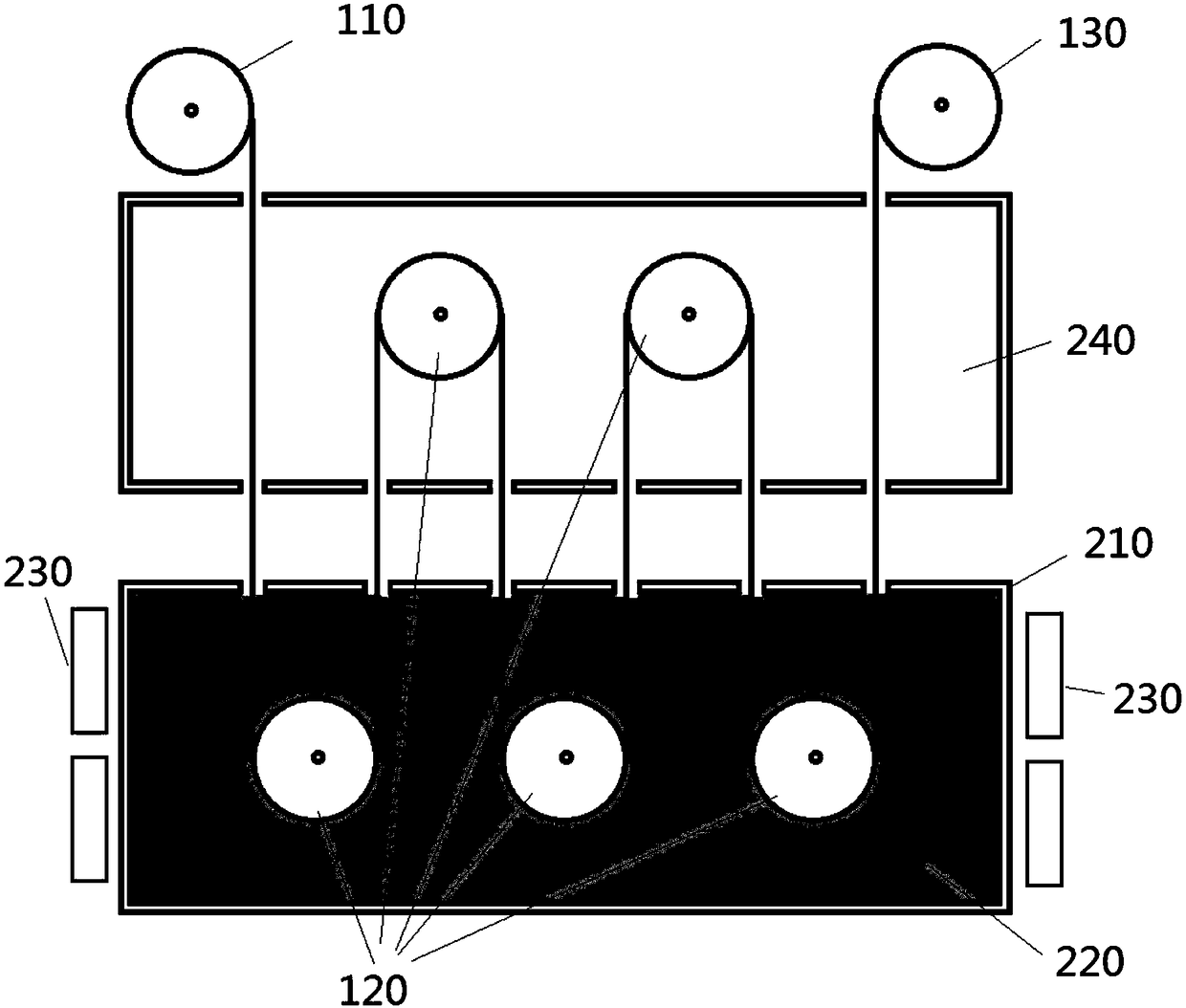

Method and device for diaphragm pretreatment

PendingCN108574080AImprove flatnessIncrease dyne valueCell component detailsPropanolPretreatment method

The invention relates to a method and device for diaphragm pretreatment. The method comprises: a) unwinding a substrate diaphragm from a discharge roller, b) making the discharged substrate diaphragmto pass through an intermediate flattening roller under action of a liquid heat transfer medium, and c) winding the substrate diaphragm treated by the liquid heat transfer medium to a receiving roller, wherein the liquid heat transfer medium is least one of deionized water, ethanol, propanol, butanol, N-methylpyrrolidone, dimethylacetamide, N, N-dimethylformamide and dimethyl sulfoxide and has a temperature of 20 to 80 DEG C. The diaphragm is pretreated by the liquid heat transfer medium so that the flatness of the diaphragm is improved at a relatively low temperature. The diaphragm is subjected to surface modification under the action of the liquid heat transfer medium so that the Dyne value of the diaphragm is improved, the wettability of the diaphragm to the later coating is improved and the good coating effects are obtained.

Owner:JIANGSU ADVANCED MATERIAL TECH CO LTD

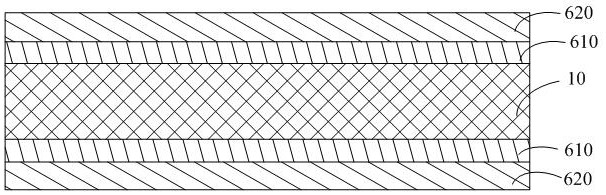

Low-climbing high-dyne-value polyurethane protective film and preparation method thereof

ActiveCN113462302AImprove stabilityIncrease exhaustPolyureas/polyurethane adhesivesWind energy generationAdhesive cementPolymer science

The invention discloses a low-climbing high-dyne-value polyurethane protective film and a preparation method thereof. The low-climbing high-dyne-value polyurethane protective film is characterized in that the low-climbing high-dyne-value polyurethane protective film is formed by sequentially compounding a PET thin film layer, a bottom coating layer, a polyurethane adhesive layer, a release layer and a PET thin film layer. The preparation method comprises the following steps: mixing polyurethane prepolymer, an isocyanate curing agent, a temperature-resistant hardening agent, a retarder and an organic solvent to prepare the polyurethane adhesive; coating the single surface of the PET film layer with bottom coating liquid, and drying to form the bottom coating layer; and coating the polyurethane adhesive on the bottom coating layer, drying through a drying tunnel with the temperature of 65-130 DEG C and the total length of 24-45m at the linear speed of 10-35m / min, compounding with a single-sided release PET film, and curing to obtain the low-climbing high-dyne-value polyurethane protective film. The low-climbing high-dyne polyurethane protective film disclosed by the invention is suitable for protecting the copper foil surface of the copper foil adhesive tape in the transportation, storage and manufacturing processes of the copper foil adhesive tape, and is good in performance and high in practicability.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Drug Foil Rolling Additive Composition

Owner:石家庄新泰特种油有限公司

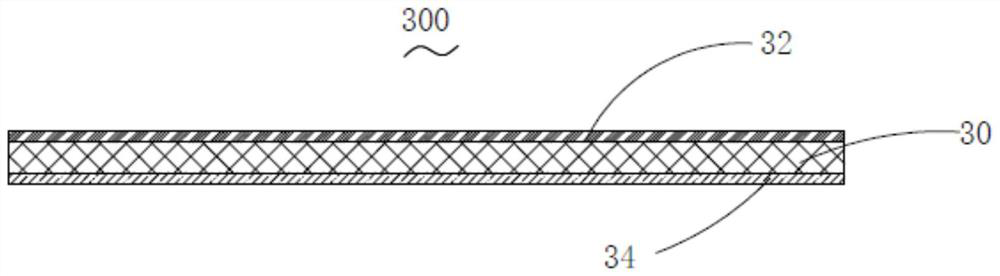

Manufacturing method of electromagnetic shielding material, electromagnetic shielding material and electronic product

PendingCN113186488AEasy to acceptOvercoming Poor PlatingMagnetic/electric field screeningVacuum evaporation coatingThin membranePolymer thin films

The invention discloses a manufacturing method of an electromagnetic shielding material, the electromagnetic shielding material manufactured by the manufacturing method and an electronic product applying the electromagnetic shielding material. The manufacturing method of the electromagnetic shielding material comprises the following steps that a polymer film layer is provided, and the thickness of the polymer film layer is larger than or equal to 1.5 microns and smaller than or equal to 6 microns; at least one surface of a polymer film is subjected to roughening treatment, so that the dyne value of the at least one surface is larger than or equal to 44 and smaller than or equal to 70; and at least one metal shielding layer is deposited on the roughened surfaces. According to the manufacturing method of the electromagnetic shielding material, the thickness of the polymer film layer can be reduced by 75% to the maximum extent, the flexibility of the electromagnetic shielding material is better, the using effect is better, and the product cost is lower.

Owner:深圳市乐工新技术有限公司

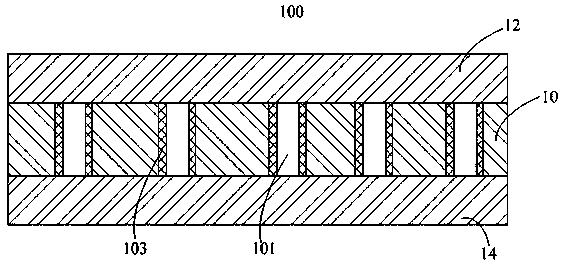

Manufacturing method of electromagnetic shielding material, electromagnetic shielding material and electronic product

PendingCN111484640AIncrease dyne valueHigh energyMagnetic/electric field screeningVacuum evaporation coatingThin membranePolymer thin films

The invention discloses a manufacturing method of an electromagnetic shielding material, the electromagnetic shielding material prepared by the manufacturing method and an electronic product applyingthe electromagnetic shielding material. The manufacturing method of the electromagnetic shielding material comprises the following steps: providing a polymer film layer of which two sides are conducted, wherein the thickness of the polymer film layer is greater than or equal to 0.8 micron and less than or equal to 12 microns; roughening the polymer film layer to enable the dyne value of the polymer film layer to be greater than or equal to 44 and less than or equal to 70; performing vapor deposition on the two roughened surfaces, forming at least one metal shielding layer on each surface, andperforming the metal shielding layers on the two surfaces through the polymer film layer; according to the technical scheme, the electromagnetic shielding material which is very thin and is conductedon two sides is provided.

Owner:深圳市乐工新技术有限公司

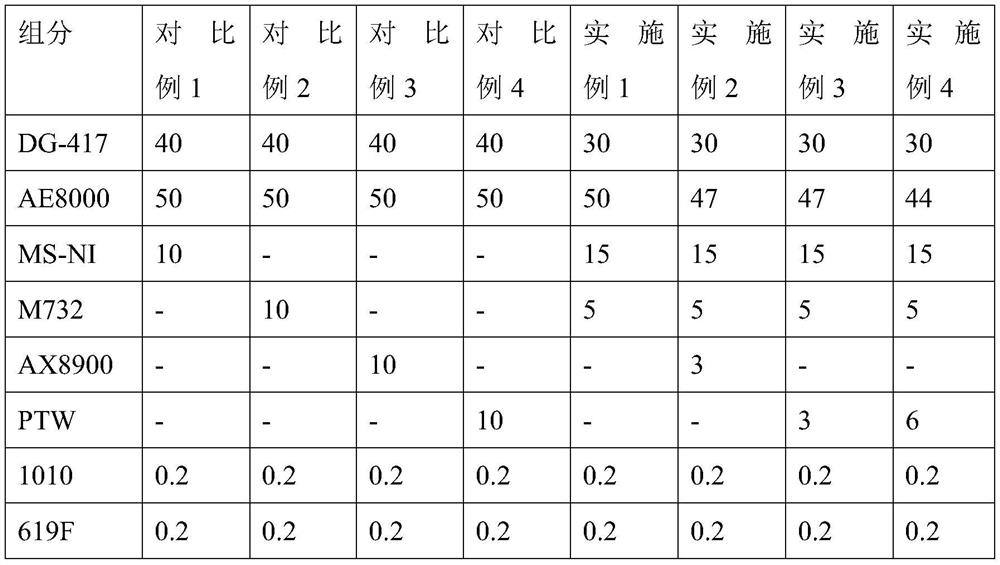

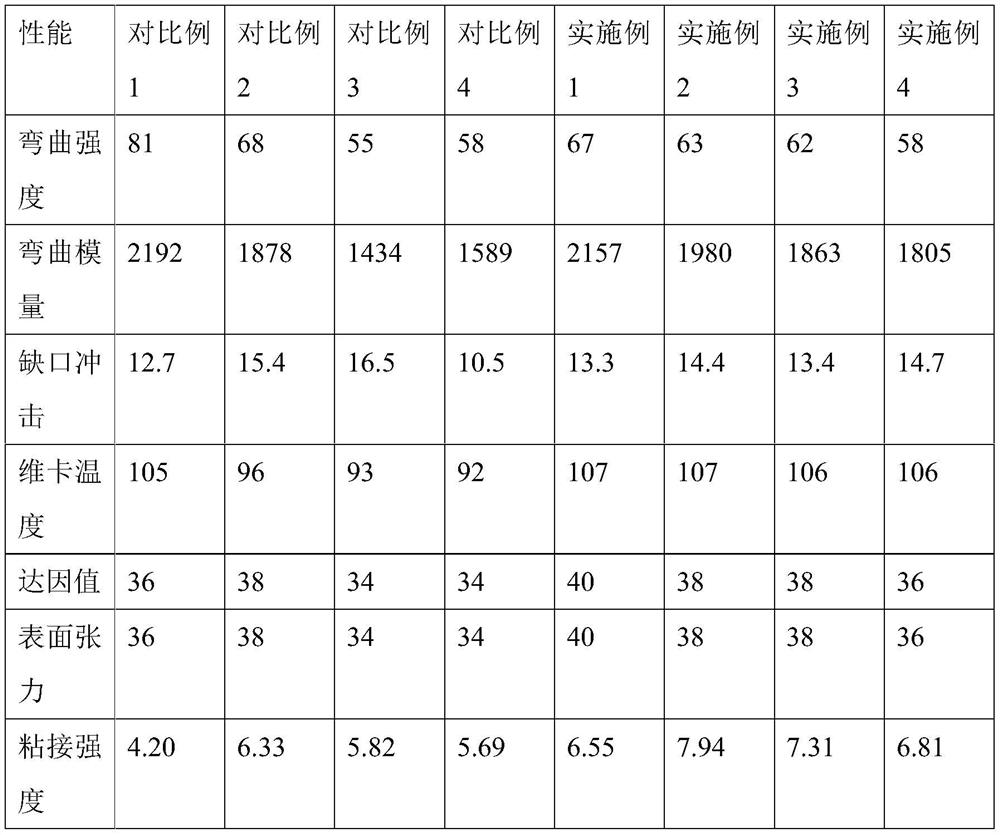

High-heat-resistance modified ABS (Acrylonitrile Butadiene Styrene) material with strong adhesion with PUR (Polyurethane) and preparation method thereof

The invention discloses a high-heat-resistance ABS (Acrylonitrile Butadiene Styrene) material with strong adhesion with PUR (Polyurethane) and a preparation method thereof. The material comprises the following components in percentage by weight: 65-80% of ABS resin, 10-25% of a heat-resistant agent, 3-10% of a toughening agent, 0-10% of a reaction type compatilizer and 0.4% of an antioxidant. Compared with the prior art, the selected MS-NI heat-resistant agent has high glass transition temperature so as to improve heat resistance, and contains imide groups so as to improve polarity; the introduced MBS flexibilizer endows the material with high elasticity, and the surface dyne value and the initial adhesion are also improved; the reactive compatibilizer has poor compatibility and is intensively distributed on the surface, the active GMA group can form chemical bonds with hydroxyl and amino in moisture-cured polyurethane, and the strong bonding effect enables the moisture-cured polyurethane to have high and low temperature resistance and damp-heat aging resistance, and the moisture-cured polyurethane can be used for interior and exterior trim parts of automobiles.

Owner:ZHEJIANG PRET NEW MATERIALS

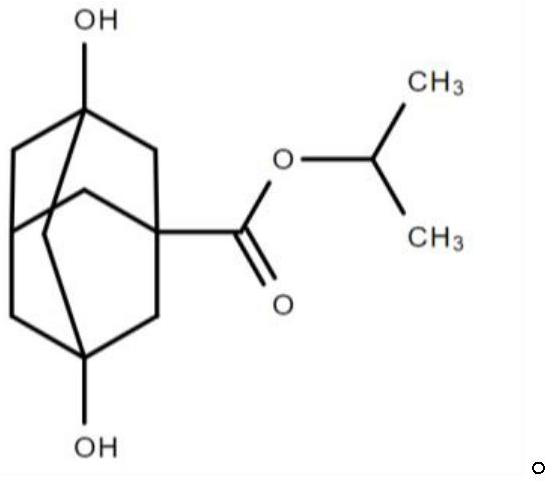

Battery foil rolling additive and preparation method and application thereof

ActiveCN113444559AImprove surface qualityIncrease surface dyne valueAdditivesAl powderIsopropyl formate

The invention provides a battery foil rolling additive as well as a preparation method and application thereof. The battery foil rolling additive comprises the following components in percentage by mass: 10-20% of fatty acid ester, 15-30% of fatty alcohol, 45-65% of an adamantane compound and 0.1-5% of an extreme pressure additive, wherein the mass percentage content of dihydroxy adamantane isopropyl formate in the adamantane compound is 50 to 100 percent. According to the battery foil rolling additive, through matching of the components, especially the use of the adamantane compound with a specific molecular structure, the battery foil rolling additive has excellent lubricating performance, the surface quality of a rolled battery foil can be improved, the surface dyne value of the battery foil is increased, and the cost of a corona process is reduced; and meanwhile, the use of the battery foil rolling additive is beneficial to improving the dispersing performance and filtering efficiency of aluminum powder and improving the cleaning performance of a rolling mill.

Owner:QUAKER CHEM CHINA

Aqueous medium coating formula and preparation method thereof

The invention relates to an aqueous medium coating formula coated on a cold revolving membrane. The formula comprises the following components in percentage by weight: 10-18 percent of styrene monomer, 10-15 percent of acrylic monomer, 2-10 percent of butyl acrylate, 30-40 percent of water, 20-30 percent of alcohol, 0.1-0.2 percent of polydimethylsiloxane and 0.1-0.3 percent of carboxylate anion active agent. The preparation method includes the following two steps: firstly, according to the formula, sequentially adding the alcohol and the water to a stirring drum and stirring for 5-10min at the constant temperature of 25-30 DEG C; and secondly, according to the formula, adding the styrene monomer, the acrylic monomer, the butyl acrylate and the polydimethylsiloxane to the stirring drum and finally wholly stirring evenly for 10-15min. After use, the aqueous medium coating formula leads to high adherence degree between a UV glue layer and an aluminum coated layer, and the content of volatile organic compounds (VOC) in a finished thin membrane reaches the standard.

Owner:DONGGUAN K LASER TECH

A kind of TPV composition and preparation method thereof

ActiveCN111057306BIncrease dyne valueGood adhesive strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePlasticizer

The invention discloses a TPV composition and a preparation method thereof, which consists of 30-40 parts of polypropylene, 20-30 parts of EPDM rubber, 20-30 parts of plasticizer, 10-20 parts of filler, lubricating 0.2-1 part of agent, 0.2-1 part of cross-linking agent, 0.5-2 part of auxiliary cross-linking agent, 0.3-0.5 part of antioxidant and 1-5 parts of porous adsorbent. In the present invention, special additives are added to the formulation, so that the prepared TPV composition has high encapsulation bonding strength.

Owner:会通新材料(上海)有限公司

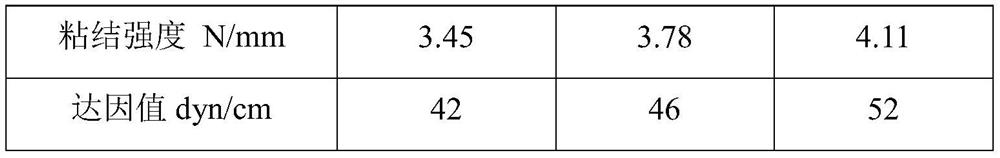

High-purity aluminum foil as well as preparation method and application thereof

ActiveCN114798770AIncrease dyne valueImprove adhesionWork cleaning devicesMetal rolling arrangementsMetallurgyAluminum foil

According to the preparation method, the step that cleaning liquid is placed in a material groove of a micro-concave roller to conduct micro-concave cleaning on the aluminum foil is added, the dyne value of the aluminum foil is greatly increased, the dyne value is increased to 60 dyn from original 30 dyn, and the technical blank of the high-grade aluminum foil is filled up; and the micro-concave roller is used for cleaning, so that the production rate is greatly improved. According to the method, the amount of the used cleaning liquid is small, and the amount of the cleaning liquid is accurately controlled by adjusting the mesh number of the micro-concave roller. The method is obvious in deoiling effect, does not generate harmful gas in the use process, and has the characteristics of environmental protection and no pollution. By adopting the method disclosed by the invention, the binding power of the aluminum foil can be remarkably improved, no side effect is caused to the mechanical property of the aluminum foil, the dyne value of the obtained aluminum foil is kept stable, and the attenuation change is basically avoided in the production process. And the application of the obtained aluminum foil in the lithium ion battery is further ensured.

Owner:HANGZHOU FIVE STAR ALUMINUM

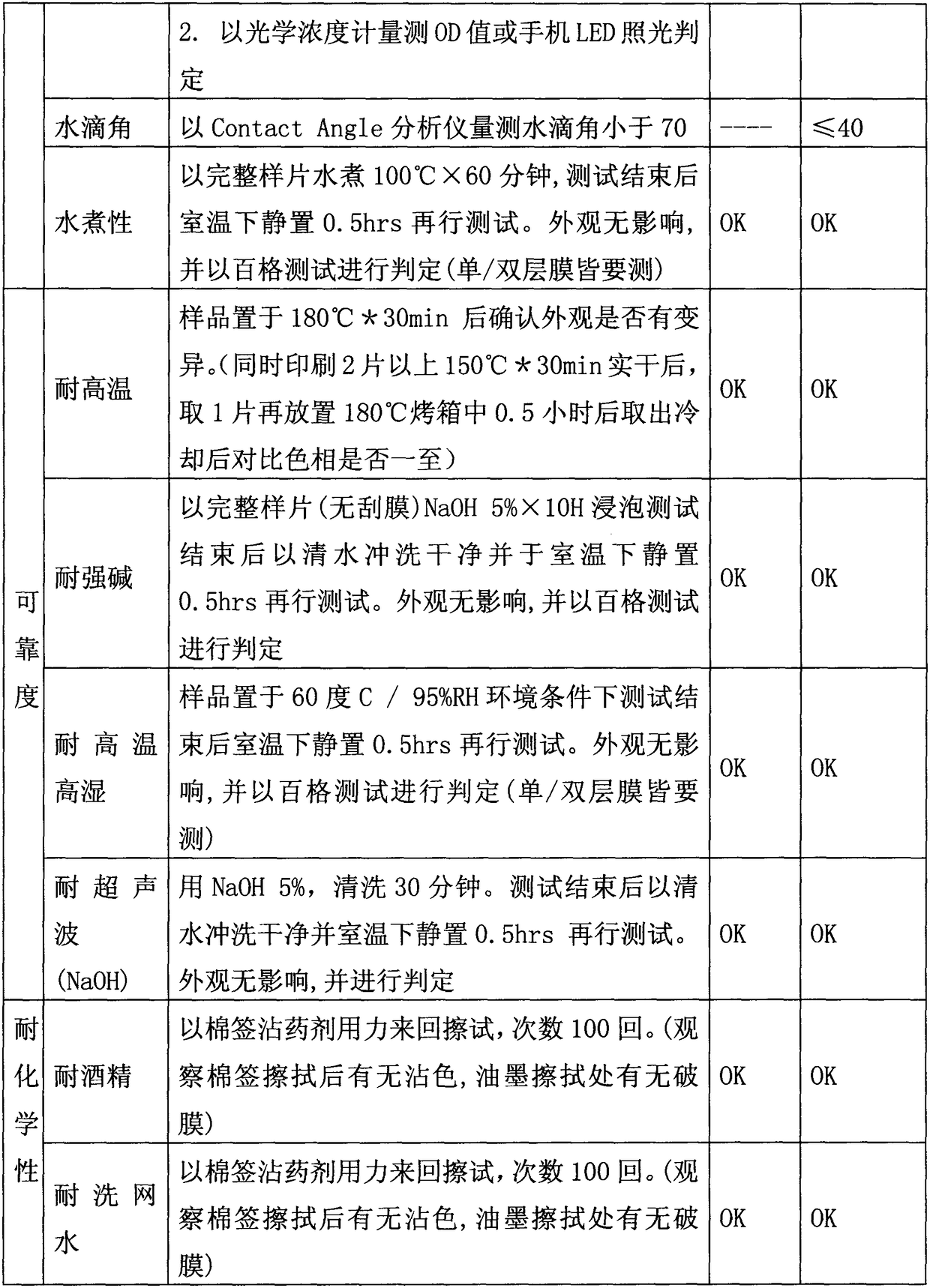

Photovoltaic cable with high factor value and production process thereof

PendingCN114883036AReduce manufacturing costProduction environmental protectionClimate change adaptationInsulated cablesPolyolefinElectrical conductor

The invention discloses a photovoltaic cable with a high dyne value and a production process thereof, the photovoltaic cable comprises a conductor, an insulator wrapping the conductor and a sheath wrapping the insulator, and the sheath is made of an improved irradiation crosslinking low-smoke polyolefin material containing a lubricant with ultra-high molecular weight. The surface of the cable subjected to sheath extrusion shows uniform roughness, and the dyne value of the cable subjected to sheath extrusion after irradiation is greater than or equal to 36. According to the photovoltaic cable and the production process thereof provided by the invention, the sheath adopts the improved irradiation cross-linked polyolefin, so that the surface of the product has the characteristics of uniform roughness, good surface tension performance and the like, and the product has good adhesiveness with glue during subsequent production, so that the adhesiveness between the cable and a connector is stronger, and the service life of the cable is prolonged. The service life of the assembly is prolonged, so that the market competitiveness of the assembly is improved; the manufacturing cost is low, and the production process is more environment-friendly.

Owner:SUZHOU BAOXING WIRE & CABLE

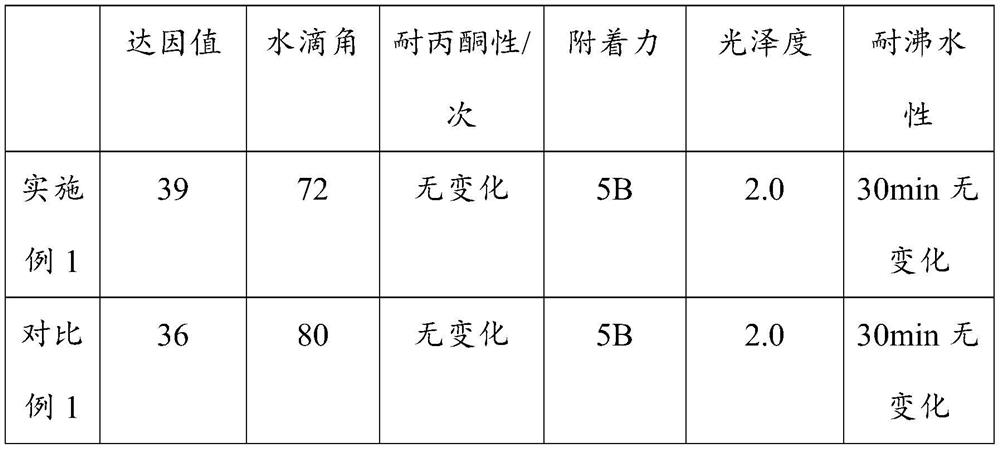

Matt ink suitable for OGS full lamination process and preparation method thereof

The invention relates to matte ink (IPC classification number: C09D11 / 10), in particular to matte ink suitable for an OGS (One Glass Solution) full lamination process and a preparation method of the matte ink. Raw materials at least comprise the following components in parts by weight: 30-45 parts of a resin binder, 8-12 parts of a filler, 12-18 parts of matting powder, 1-2 parts of an organosilicon-free defoaming agent, 10-15 parts of an isophorone solvent, 8-12 parts of ethylene glycol butyl ether and 10-15 parts of carbon black. The dyne value of the matte ink suitable for the OGS full lamination process is larger than 38, the water drop angle can range from 70 degrees to 75 degrees, the fastness of OCA rubberizing is greatly improved, the probability that bubbles are generated during lamination is reduced, meanwhile, the matte ink prepared through the method has good pain and wiping resistance, and even if hydrophilic matte powder is added, the matte ink can still be used for a long time. And the coating also can pass a water boiling resistance test, and has good water resistance.

Owner:惠州市百时达化工有限公司

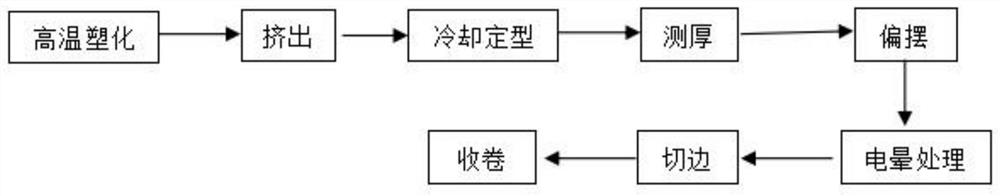

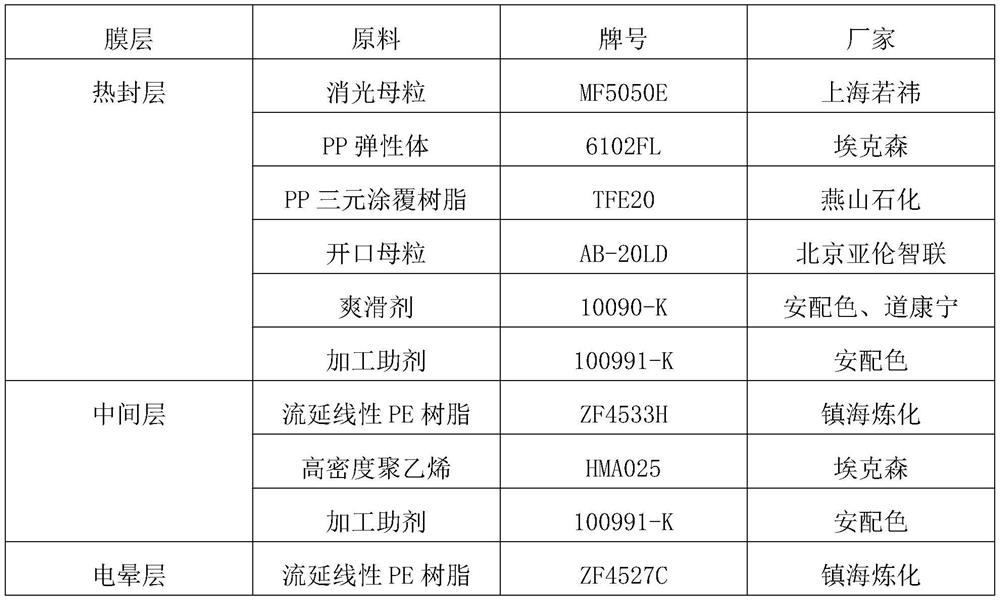

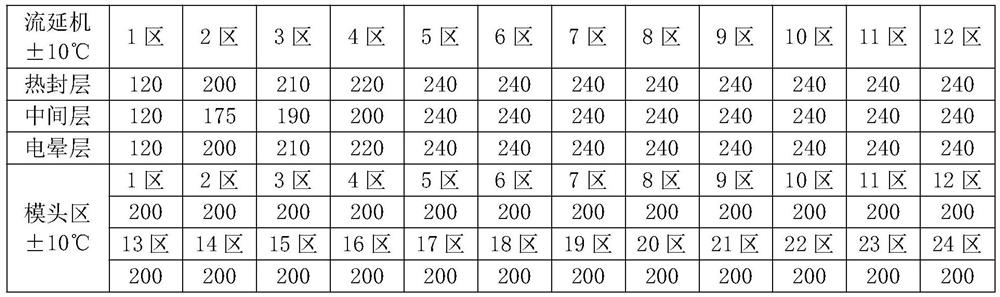

A kind of matting cast PE film and its production process

ActiveCN110305402BSpecular Scatter ScaleGood heat sealing performanceSynthetic resin layered productsFlat articlesElastomerPolymer science

The invention relates to a matting cast PE film and a production process thereof. The matting cast PE film includes a heat-sealing layer, an intermediate layer and a corona layer; the heat-sealing layer includes matting masterbatches, PP elastomers, PP ternary coating resins, opening masterbatches, slip agents and processing aids; The layers include cast linear PE resin, high density polyethylene and processing aids; the corona layer includes cast linear PE resin. The matte cast PE film prepared by the above formula is suitable for the requirements of printing equipment: excellent thickness uniformity, stable friction coefficient, high 10% tensile strength, large tensile breaking force, low surface gloss on the matte surface, The overall haze of the film is high, and the appearance of the film surface is delicate, which can adapt to high-speed gravure and flexographic printing, and the color registration is accurate during gravure multi-color printing without deviation.

Owner:HUANGSHAN NOVEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com