Manufacturing method of electromagnetic shielding material, electromagnetic shielding material and electronic product

A technology of electromagnetic shielding material and manufacturing method, which is applied in the fields of magnetic field/electric field shielding, metal material coating process, electrical components, etc., can solve the problem of long production process flow of conductive cloth, unsatisfactory adhesion of metal layer, and difficulty of accurate conductive cloth. Control and other issues to achieve the effect of improving the use effect and flexibility of use, good coating effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

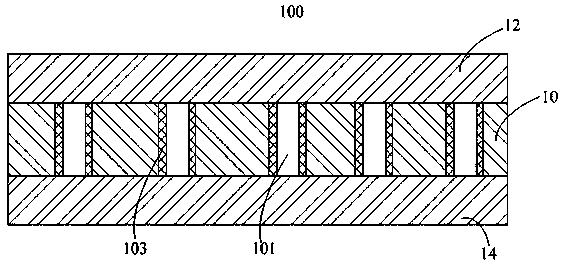

[0065] A polymer film layer is provided, the thickness of the polymer film layer is 1.5 microns, and the material is polyethylene terephthalate.

[0066] The polymer film layer is baked at a temperature of 45 degrees centigrade for 24 hours.

[0067] Laser drilling is performed on the baked polymer film layer to form a plurality of through holes in the polymer film layer, the diameter of the through holes is 0.1 micron, the hole distance is 0.1 micron, and the shape of the several through holes is circular.

[0068] Corona treatment was performed on both surfaces of the perforated polymer film layer, and the corona treatment time was 1 second. The dyne value of both surfaces after corona treatment was 56.

[0069] A layer of metal shielding layer is respectively sputtered on the two surfaces of the polymer film layer after corona treatment and the walls of several through holes, with copper as the target material, and continuous winding coating is adopted. The coating process...

Embodiment 2

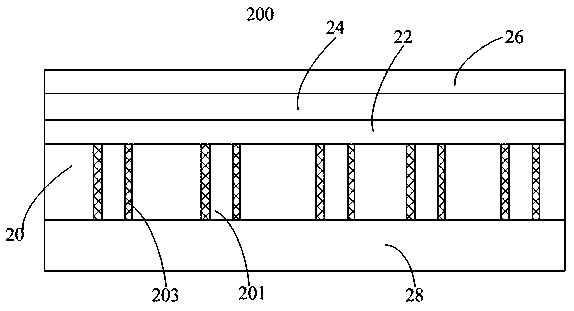

[0072] A polymer film layer is provided, the thickness of the polymer film layer is 6 microns, and the material is polycarbonate.

[0073] The polymer film layer is baked at a temperature of 80 degrees centigrade for 1 hour.

[0074] Laser drilling is performed on the baked polymer film layer to form a plurality of through holes in the polymer film layer, the diameter of the through holes is 100 microns, and the hole distance is 100 microns. The shapes of the through holes are triangles.

[0075] Corona treatment was performed on the two surfaces of the perforated polymer film layer, and the corona treatment time was 10 seconds respectively. The dyne value of both surfaces after corona treatment was 54.

[0076] The first layer of metal shielding layer is sputtered on the two surfaces of the polymer film layer after corona treatment and the hole walls of several through holes, with zinc as the target material, and continuous winding coating is adopted. The coating process co...

Embodiment 3

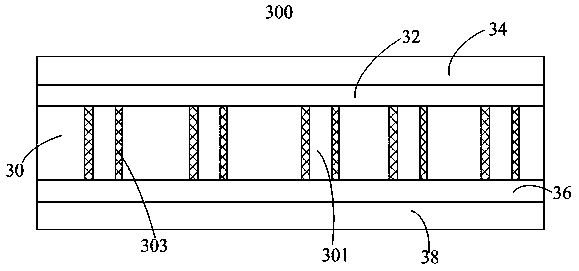

[0079] A polymer film layer is provided, the thickness of the polymer film layer is 2 microns, and the material is polypropylene.

[0080] Laser drilling is performed on the polymer film layer to form a plurality of through holes in the polymer film layer. The diameter of the through holes is 10 microns, the distance between the holes is 10 microns, and the shape of the several through holes is quadrilateral.

[0081] The two surfaces of the polymer film layer were subjected to corona treatment, and the corona treatment time was 5 seconds respectively. The dyne values of the two surfaces after corona treatment were 40 respectively.

[0082] A metal shielding layer is respectively sputtered on the two surfaces of the corona-treated polymer film layer and the walls of several through holes, with titanium as the target material, and continuous winding coating is adopted. The coating process conditions are: vacuum The temperature is 0.2Pa, the continuous winding plating speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com