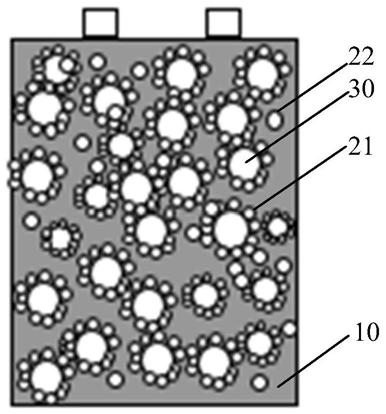

Lithium battery insulating film and preparation method thereof

An insulating film and lithium battery technology, applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of increasing plasma cleaning stations, increasing plasma cleaning processes, and affecting production line efficiency, so as to avoid plasma Cleaning stations, eliminating the need for plasma cleaning processes, and improving production line efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

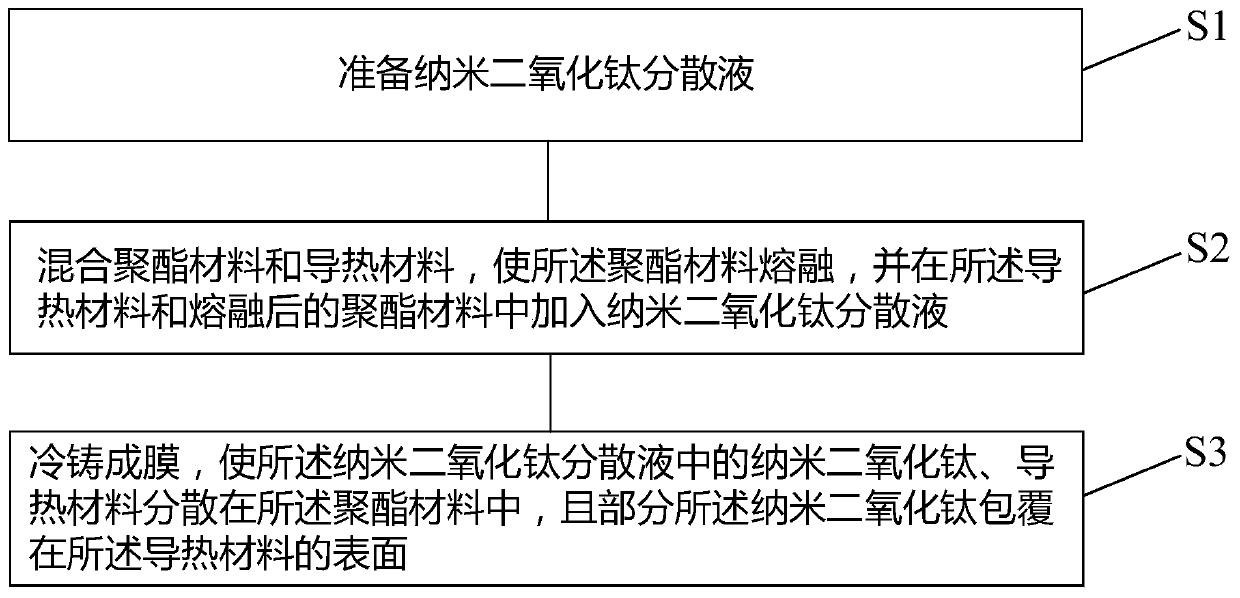

[0035] Based on the lithium battery insulating film, the technical solution of the present application also provides a method for preparing a lithium battery insulating film, including:

[0036] Step S1: preparing nano-titanium dioxide dispersion;

[0037] Step S2: mixing the polyester material and the thermally conductive material, mixing the polyester material and the thermally conductive material, melting the polyester material, and adding nano titanium dioxide dispersion liquid to the thermally conductive material and the melted polyester material;

[0038] Step S3: forming a film by cold casting, so that the nano-titanium dioxide in the nano-titanium dioxide dispersion liquid and the heat-conducting material are dispersed in the polyester material, and part of the nano-titanium dioxide is coated on the surface of the heat-conducting material.

[0039] In step S1, the nano-titanium dioxide dispersion can be self-made or commercially available. The nano-titanium dioxide in...

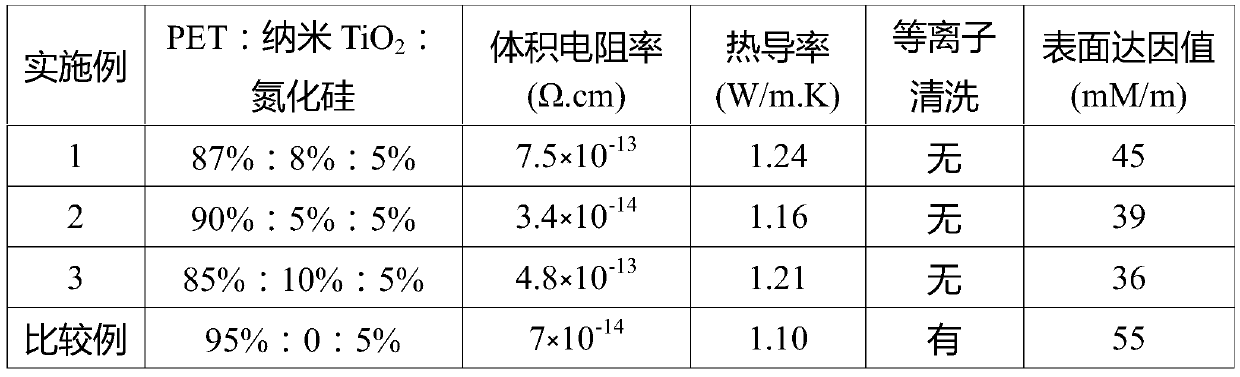

Embodiment 1

[0050] Mix nano-anatase particles, silane coupling agent (model KH-570), and ethylene glycol, and form nano-anatase dispersion liquid after ball milling, stirring and ultrasonic dispersion. Among them, the nano-anatase particles are non-agglomerated, narrow particle size distribution, high crystallinity and isotropic nanoparticles prepared by the hydrothermal method after ion doping modification, and the particle size is 3nm to 50nm.

[0051] Add the dried PET chip or PET base material and silicon nitride thermally conductive filler (particle size 5-30μm) into the high-speed mixer according to the mass ratio, and mix at high speed for 10 minutes. After pre-mixing, pass the mixed material through the blast drying box again Dry in medium for 2h.

[0052] Feed to the twin-screw disperser, control the heating temperature of each zone of the twin-screw between 210°C and 280°C, after the solid PET is gradually melted, add the nano anatase dispersion in two times at the liquid feed p...

Embodiment 2

[0056] The difference from Example 1 is that the mass fraction of PET in Example 2 is 90%, the mass fraction of nano anatase titanium dioxide is 5%, and the mass fraction of silicon nitride thermally conductive filler is 5%. The Tg of PET polyester is 205°C, and the Tm is 236°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com