Method and device for diaphragm pretreatment

A pretreatment and diaphragm technology, applied in electrical components, circuits, battery pack components, etc., can solve problems such as poor wettability, unpainted, and wavy diaphragms, so as to improve wettability, improve flatness, and improve dyne effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0053] Preparation Example 1: Preparation of Ceramic Slurry

[0054] The composition of the ceramic slurry is deionized water, aluminum oxide, styrene-butadiene rubber, and polyacrylamide, and the ratio is 70%: 27%: 2.7%: 0.3% (weight ratio).

[0055] First, add alumina and styrene-butadiene rubber into deionized water, stir in a planetary ball mill at 30°C, revolution at 20rpm, and rotation at 1200rpm for 2h, then add polyacrylamide, and stir in a planetary ball mill at 30°C, revolution at 20rpm, and rotation at 1200rpm Stir for 0.5h to obtain a ceramic slurry.

Embodiment 1

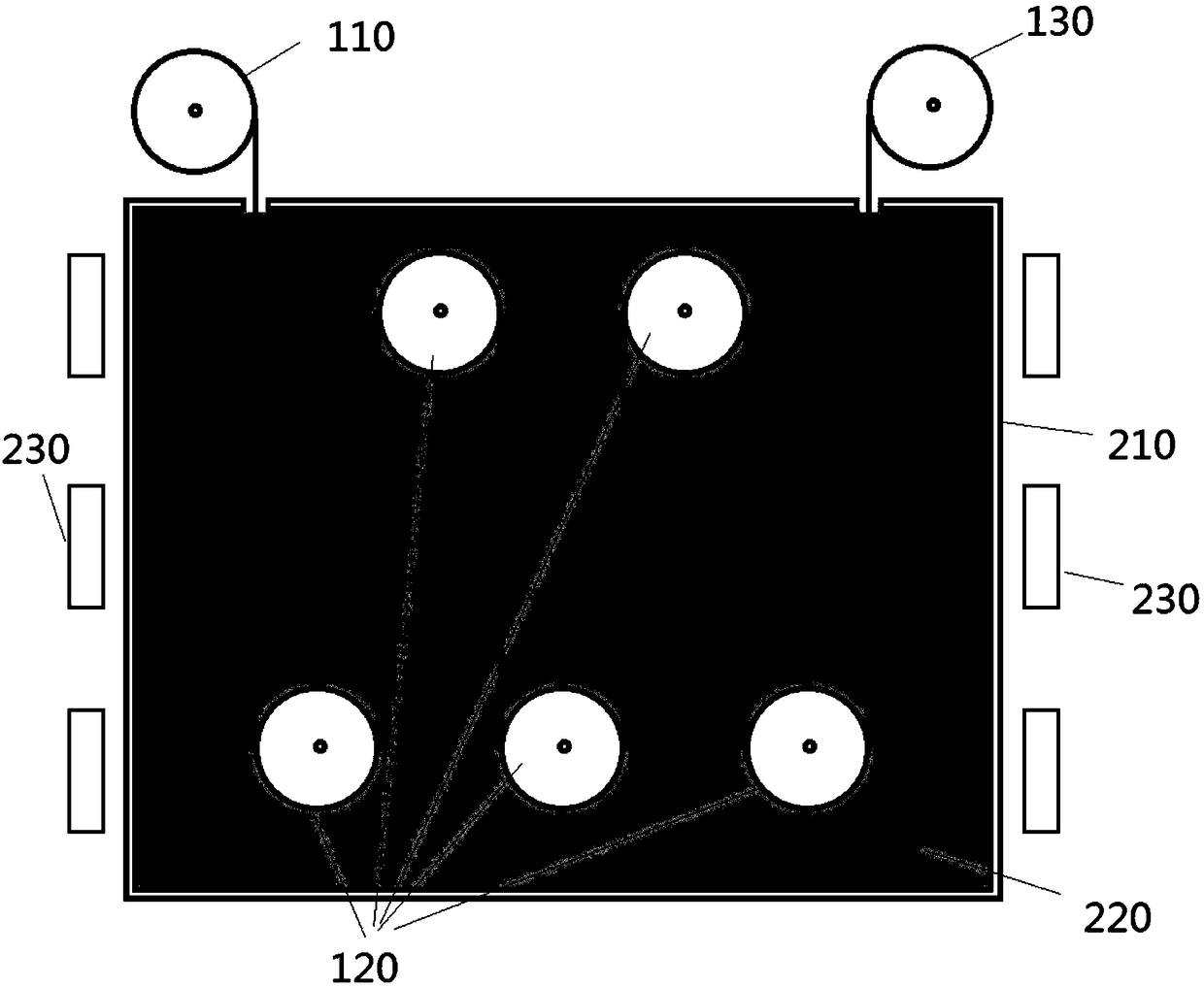

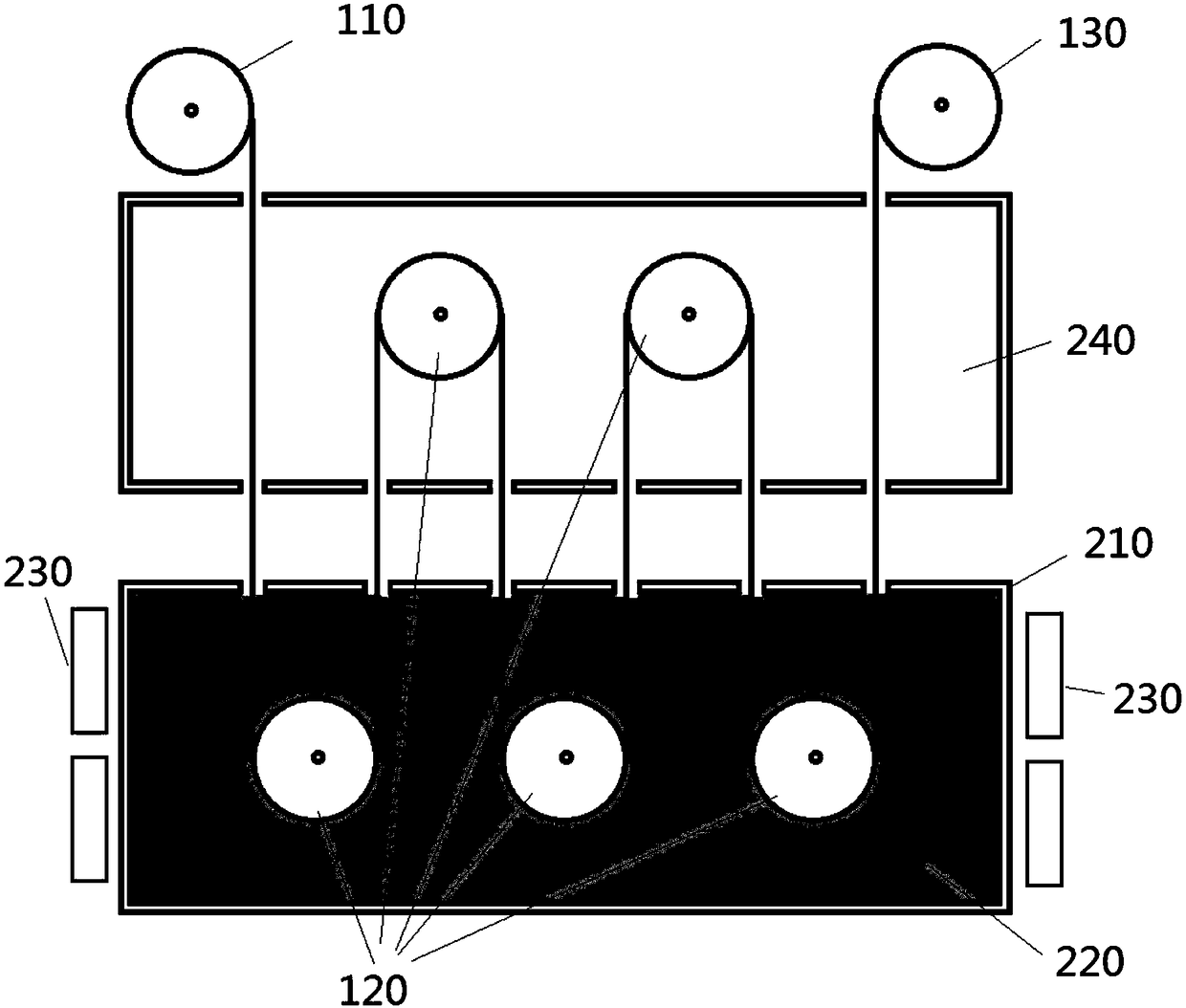

[0057] exist figure 1 The shown membrane pretreatment device is filled with ethanol liquid (solvent), and polyacrylic acid (1% solute concentration) is also added to it, which constitutes a heat transfer medium. A 12 μm thick PE separator purchased from Suzhou Jieli New Energy Materials Co., Ltd. figure 1 In the stretching device, it is unwound through the unwinding roller, and then wound up to the rewinding roller after passing through the middle flattening roller. Heat the heat transfer medium composed of ethanol solution containing 1% polyacrylic acid to 40°C through the heating system, adjust the stretching device so that the tension in the winding and unwinding process is 15N, and the winding and unwinding speed is 30m / min.

Embodiment 2

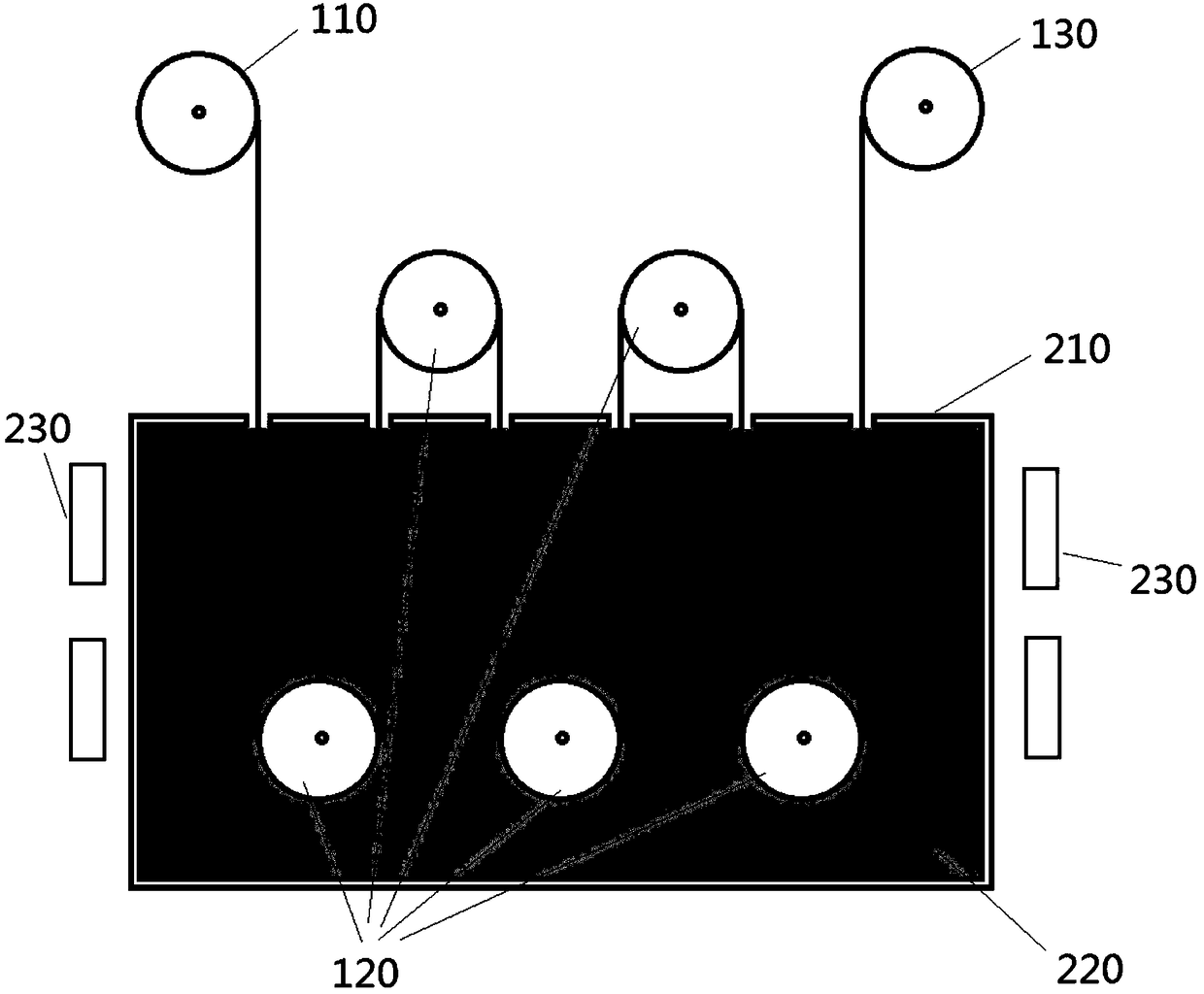

[0059] The diaphragm was pretreated in the same manner as described in Example 1, except that the device described in Example 2 was used to fill the diaphragm pretreatment device with ethanol+polyvinyl alcohol solution.

[0060] The treated separator was then coated with the ceramic slurry described in Preparation Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com