Manufacturing method of flexible ultrathin conductive material

A technology of conductive materials and production methods, applied in conductive layers, electrical components, magnetic field/electric field shielding and other directions on an insulating carrier, can solve the problems of difficult to thin conductive cloth, high cost, and large environmental pollution, and improve the use of Effects and flexibility of use, increased dyne value, easy to accept effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

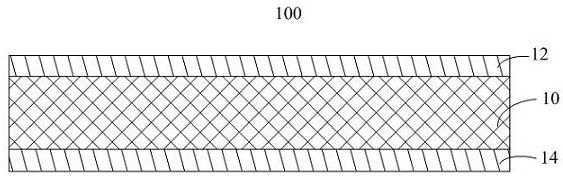

[0061] A film layer 10 is provided, the thickness of the film layer 10 is 1.5 microns, and the material is polyethylene terephthalate.

[0062] The film layer 10 is baked at a temperature of 45 degrees centigrade for 24 hours.

[0063] The two surfaces of the baked film layer 10 are subjected to corona treatment, and the corona treatment time is 1 second. The dyne value of both surfaces after corona treatment was 56.

[0064] A layer of metal shielding layer is sputtered on the two surfaces of the film layer 10 after corona treatment, using copper as the target material, using continuous winding coating, the coating process conditions are: vacuum degree 0.2Pa, continuous winding coating speed It is 15m / min, the coating current is 6A, and the coating voltage is 350V. The metal shielding layer formed on both surfaces of the film layer 10 has a thickness of 0.6 microns.

[0065] The metal shield is subjected to anti-oxidation treatment with a peroxygen protectant.

Embodiment 2

[0067] A thin film layer 10 is provided, the thickness of the thin film layer 10 is 6 microns, and the material is polycarbonate.

[0068] The film layer 10 is baked at a temperature of 80 degrees centigrade for 1 hour.

[0069] Corona treatment is performed on the two surfaces of the baked film layer 10, and the corona treatment time is 10 seconds respectively. The dyne value of both surfaces after corona treatment was 54.

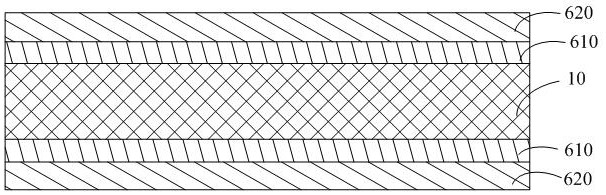

[0070] The first layer of metal shielding layer is sputtered on the two surfaces of the corona-treated film layer 10, using zinc as the target material, and adopts continuous winding coating. The coating process conditions are: vacuum degree 0.02Pa, continuous winding The plating speed is 30m / min, the plating current is 30A, and the plating voltage is 680V. The thickness of the first metal shielding layer formed on the two surfaces of the film layer 10 is 1 micron.

[0071] The second metal shielding layer is sputtered on the surface of the two first m...

Embodiment 3

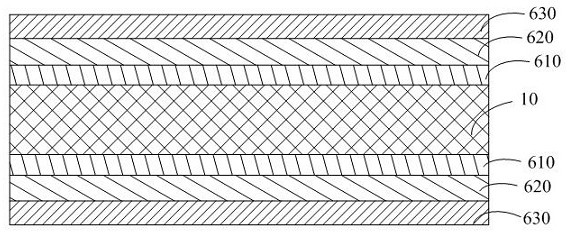

[0073] A film layer 10 is provided, the thickness of the film layer 10 is 2 microns, and the material is polypropylene.

[0074] The two surfaces of the film layer 10 are subjected to corona treatment, and the corona treatment time is 5 seconds respectively. The dyne values of the two surfaces after corona treatment were 40 respectively.

[0075] A layer of metal shielding layer is sputtered on the two surfaces of the thin film layer 10 after corona treatment, with titanium as the target material, continuous winding coating is adopted, the coating process conditions are: vacuum degree 0.2Pa, continuous winding coating The speed is 295m / min, the coating current is 30A, and the coating voltage is 700V. The thickness of each metal shielding layer formed on both surfaces of the film layer 10 is 0.5 micron; or the thickness of one metal shielding layer is 1 micron, and the thickness of the other metal shielding layer is 0.5 micron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com