Cleaning coating machine and cleaning coating method

A coating machine and plasma cleaning technology, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of poor hydrophilicity and poor primary adhesion, and achieve good hydrophilicity, good The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

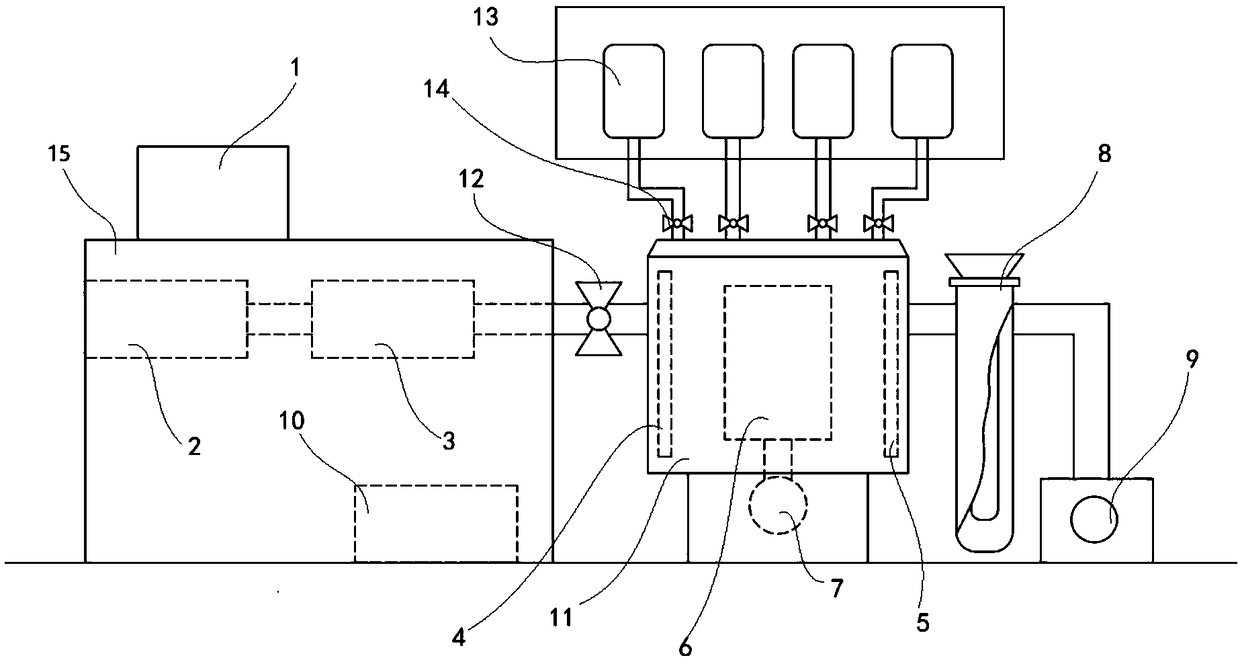

[0023] Such as figure 1 As shown, embodiment 1 discloses a specific embodiment of a cleaning coating machine, which is used to coat a parylene film (i.e. parylene film) on a piece to be coated, which includes: sequentially connected powder gasifiers 2. The high temperature cracking furnace 3, the processing chamber 11, the cold trap 8, the vacuum pump 9, 4 groups of gas tank groups and the central controller 1, wherein the high temperature cracking furnace 3 and the processing chamber 11 are connected through a powder valve 12, and the powder The body valve 12 is a solenoid valve, and the processing chamber 11 is provided with a rotatable bracket assembly and a plasma cleaning assembly for placing the parts to be plated. Each group of gas tank groups includes a gas tank 13 and a gas valve 14. The gas tank 13 The corresponding gas valve 14 communicates with the inside of the processing chamber 11 , and the gas valve 14 is a solenoid valve. Argon, oxygen, hydrogen and nitrogen ...

Embodiment 2

[0032] Such as figure 1 As shown, embodiment 2 discloses a specific embodiment of a cleaning and coating method, which uses the cleaning and coating machine disclosed in embodiment 1, and the method specifically includes the following steps:

[0033] a) Place the piece to be plated on the rotatable bracket assembly of the processing chamber 11, place the coating material in the powder gasification furnace 2, and close the powder valve 12 communicating between the high temperature cracking furnace 3 and the processing chamber 11;

[0034] b) start the cold trap 8 and the vacuum pump 9 to evacuate the processing chamber 11, and the pressure in the processing chamber 11 reaches 15-50 Pa;

[0035] c) Start the plasma cleaning component to clean the parts to be plated in the processing chamber 11, and the cleaning time is 1 to 30 minutes;

[0036] d) After closing the plasma cleaning assembly, open the powder valve 12, and control the pressure in the processing chamber 11 at 5-30P...

Embodiment 3~4

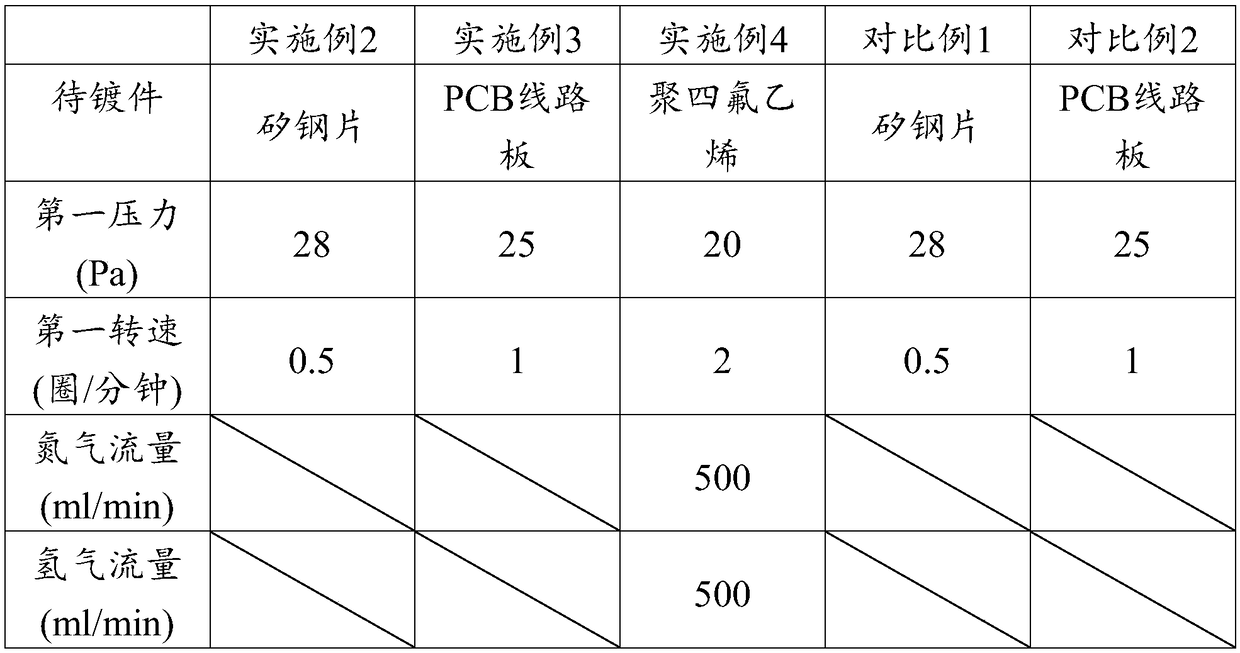

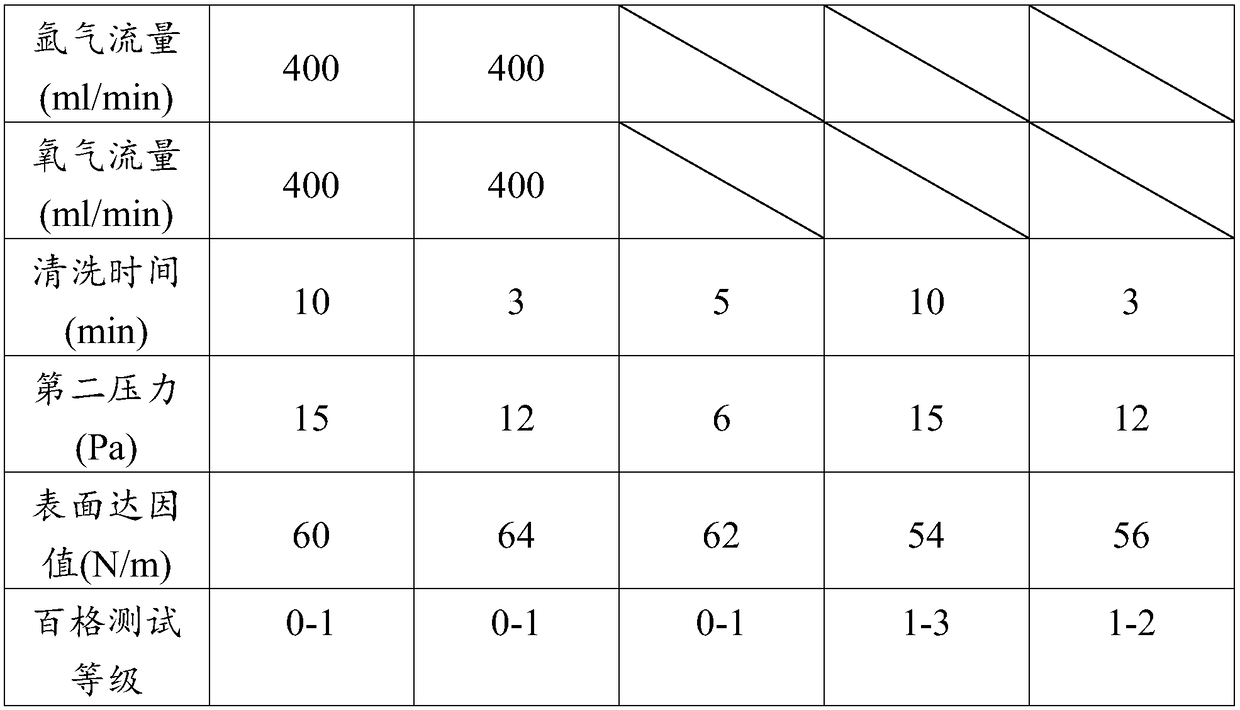

[0048] The cleaning and coating method in embodiment 2 is adopted below to plate parylene coating film on other different materials to be coated, respectively as embodiments 3~4, the experimental parameters of embodiments 3~4, the workpiece to be coated after plasma cleaning The surface dyne values and the properties of the obtained coated products are listed in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com