Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Plasma control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma Controls provides products, research, and services related to devices and processes that utilize plasma. This includes material surface modification through implantation, sputtering, etching, and coating deposition, as well as research into devices related to electric propulsion, including ion sources and ion thrusters.

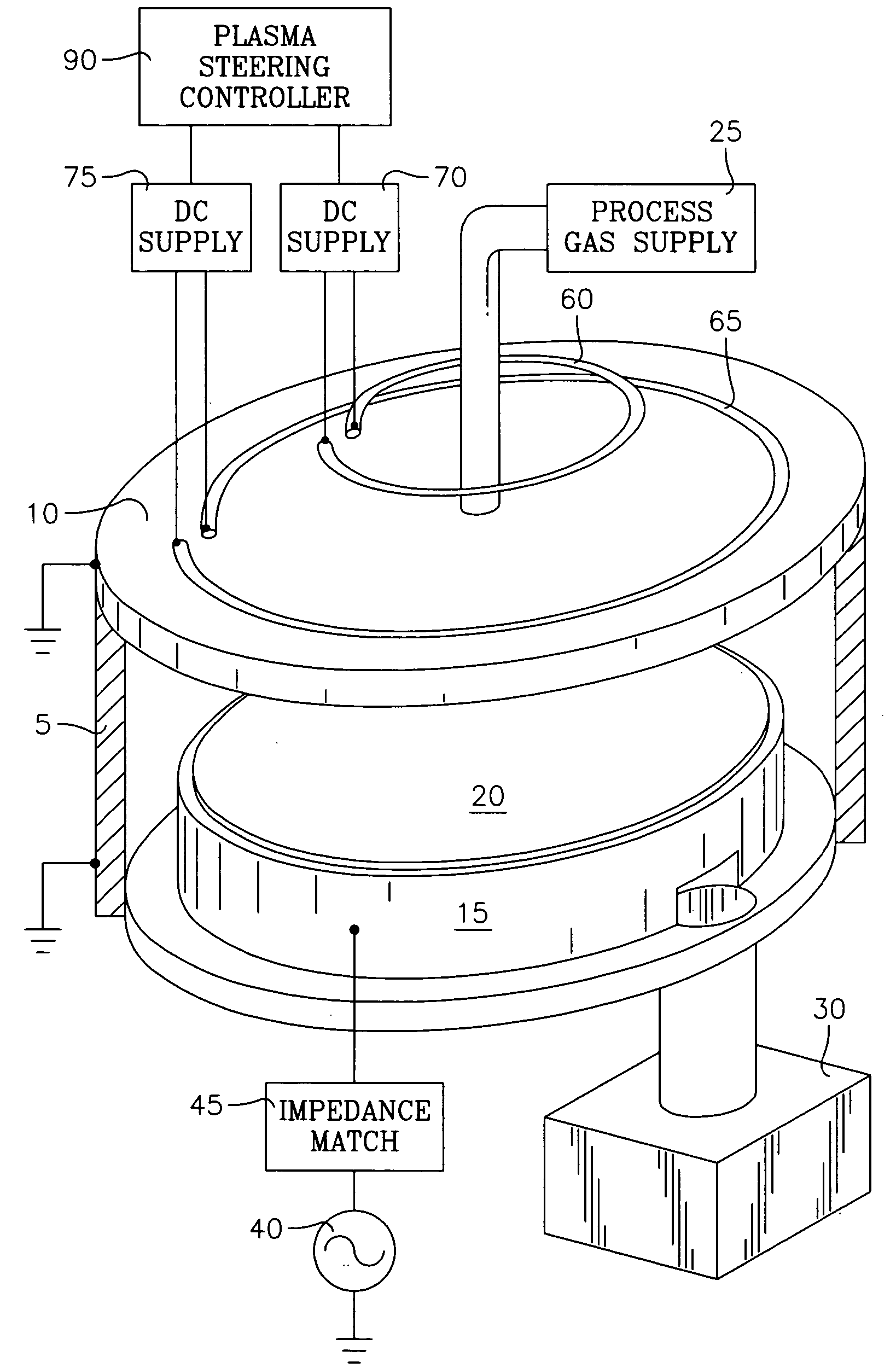

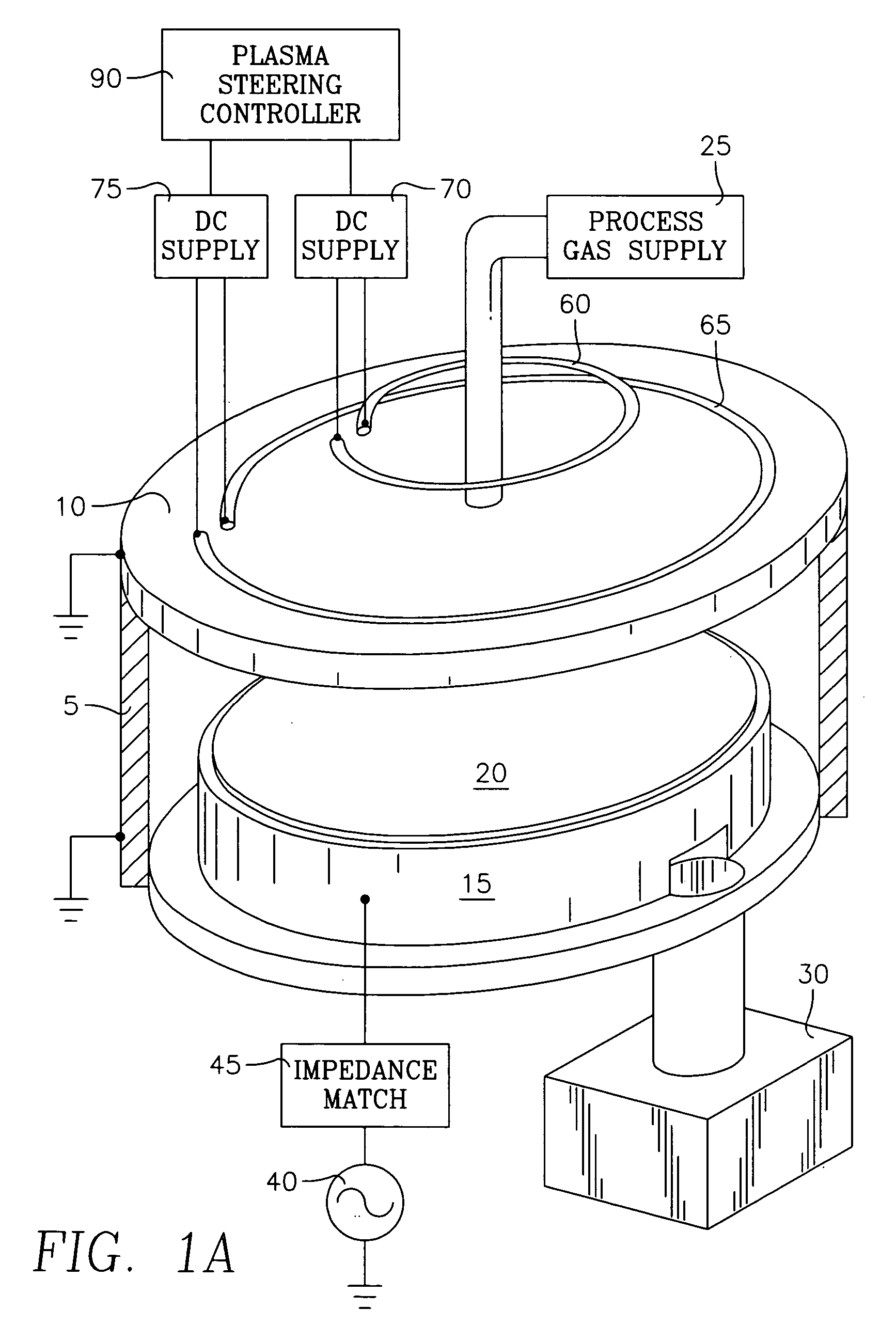

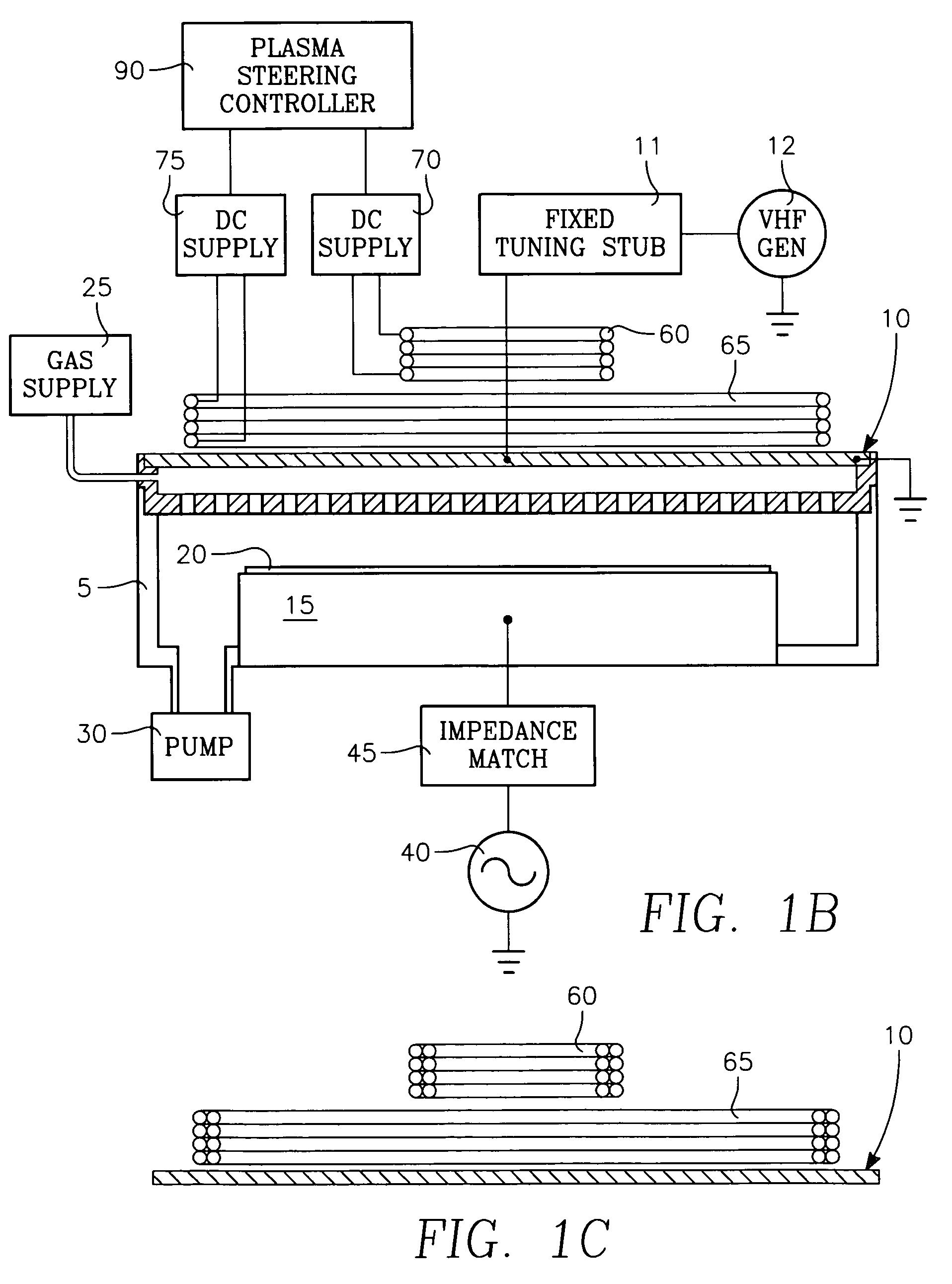

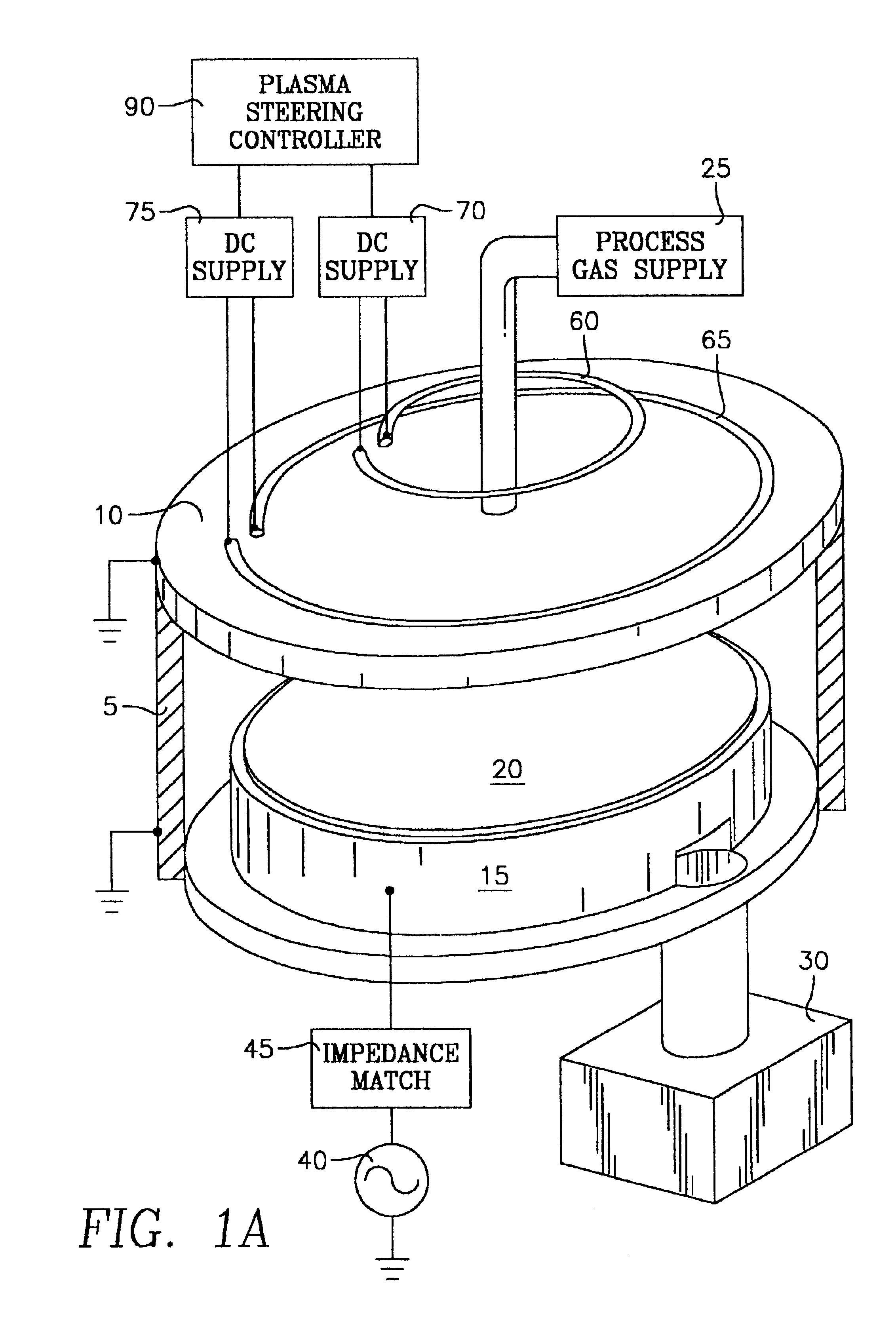

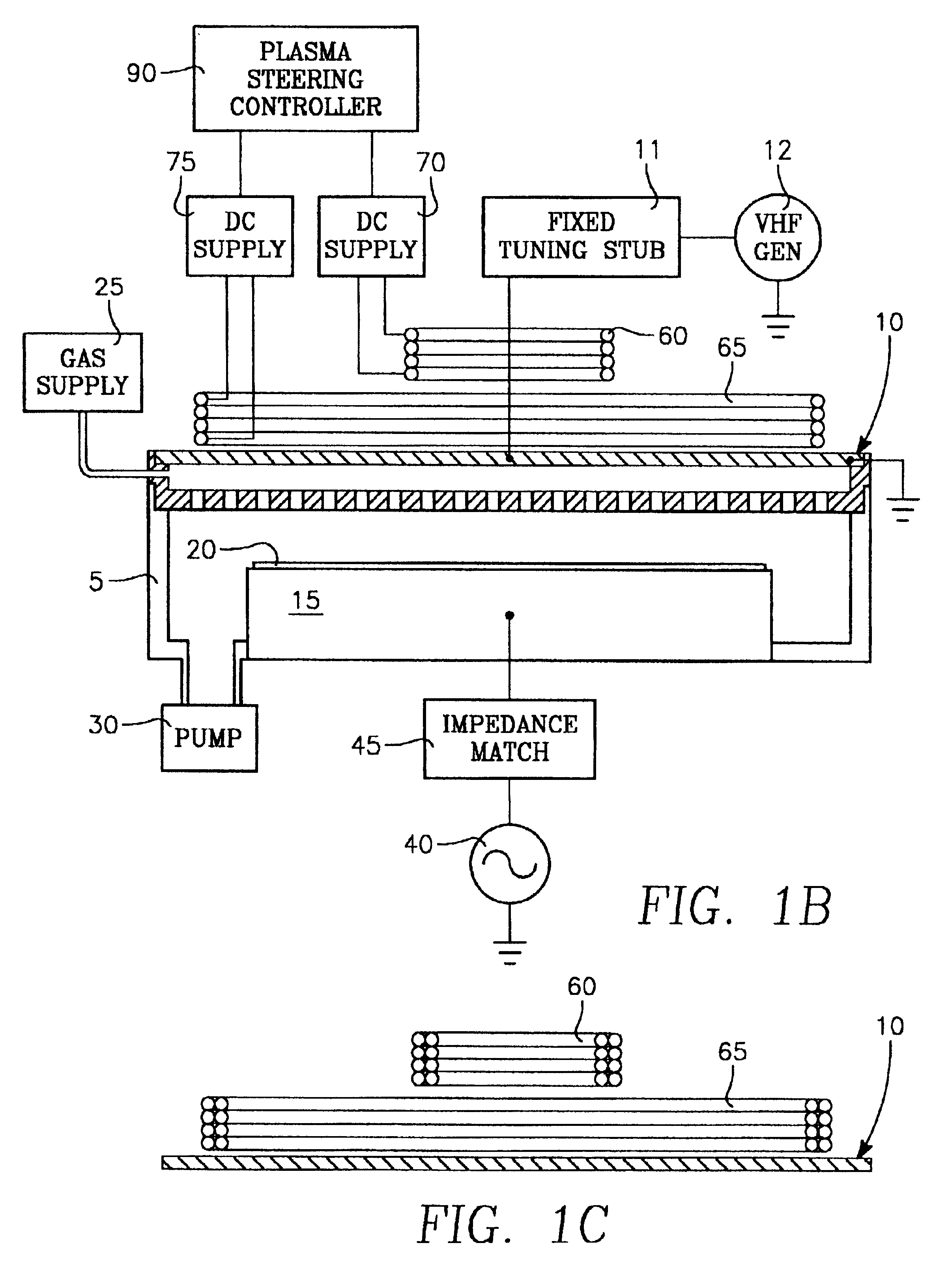

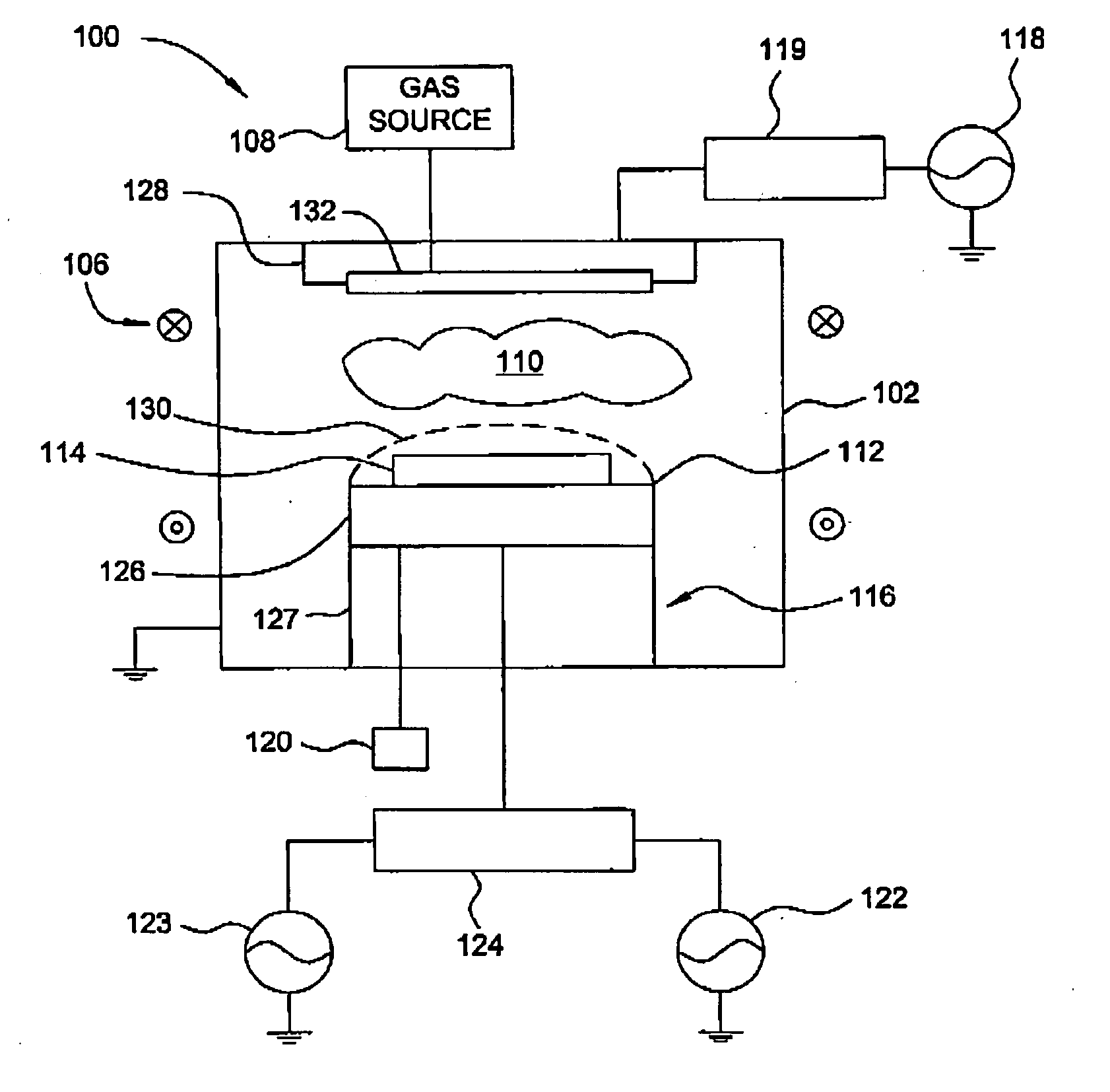

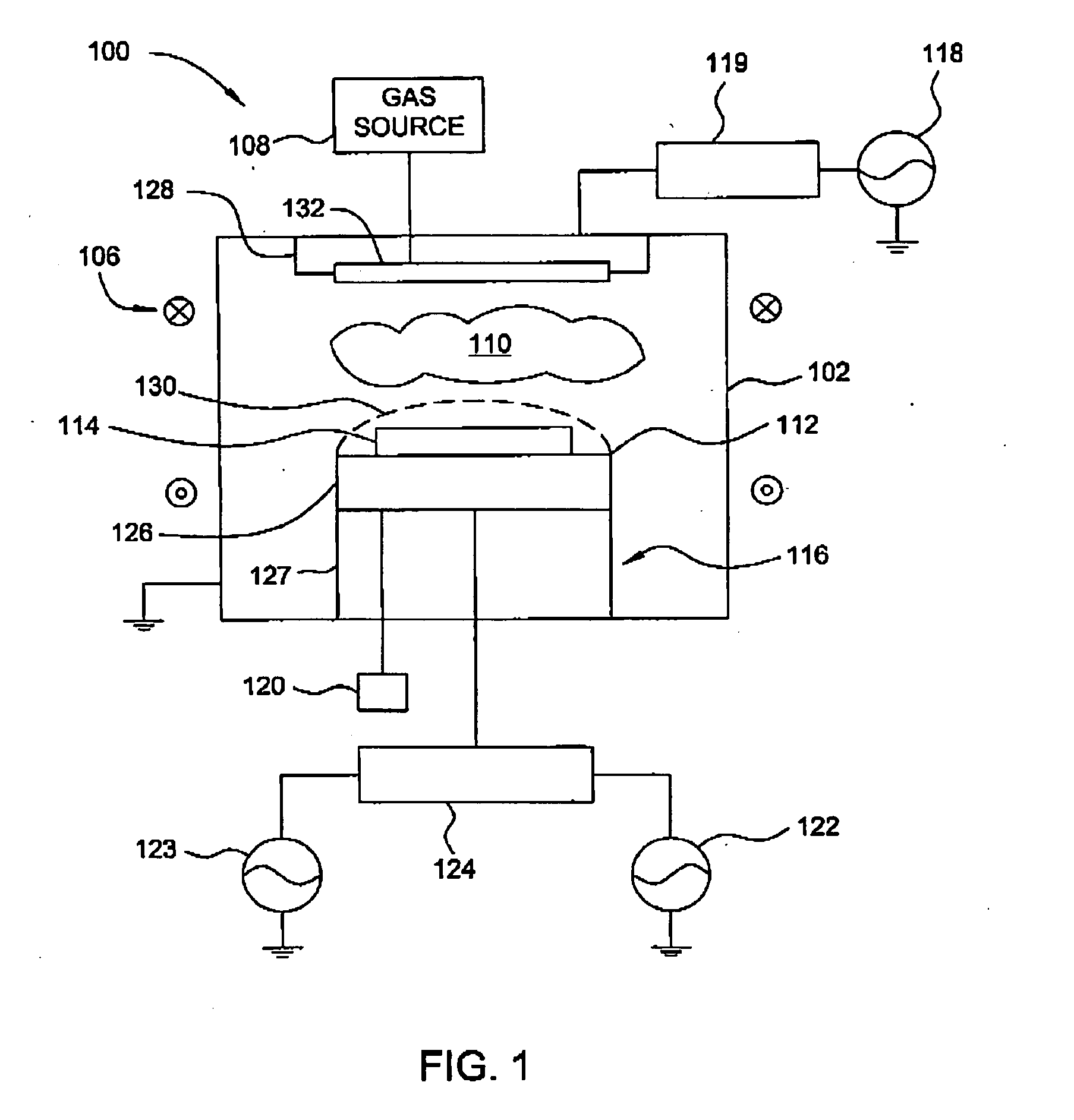

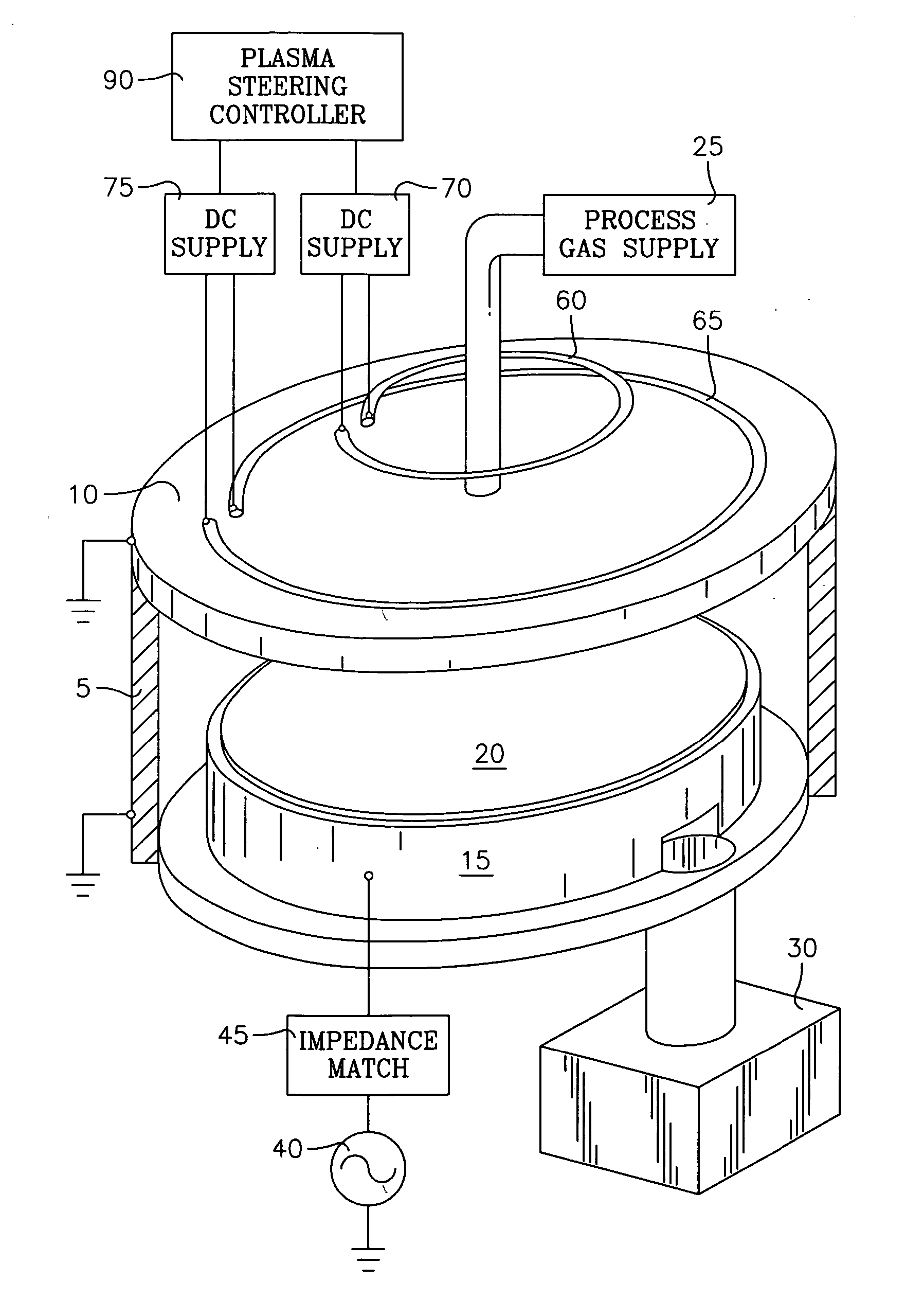

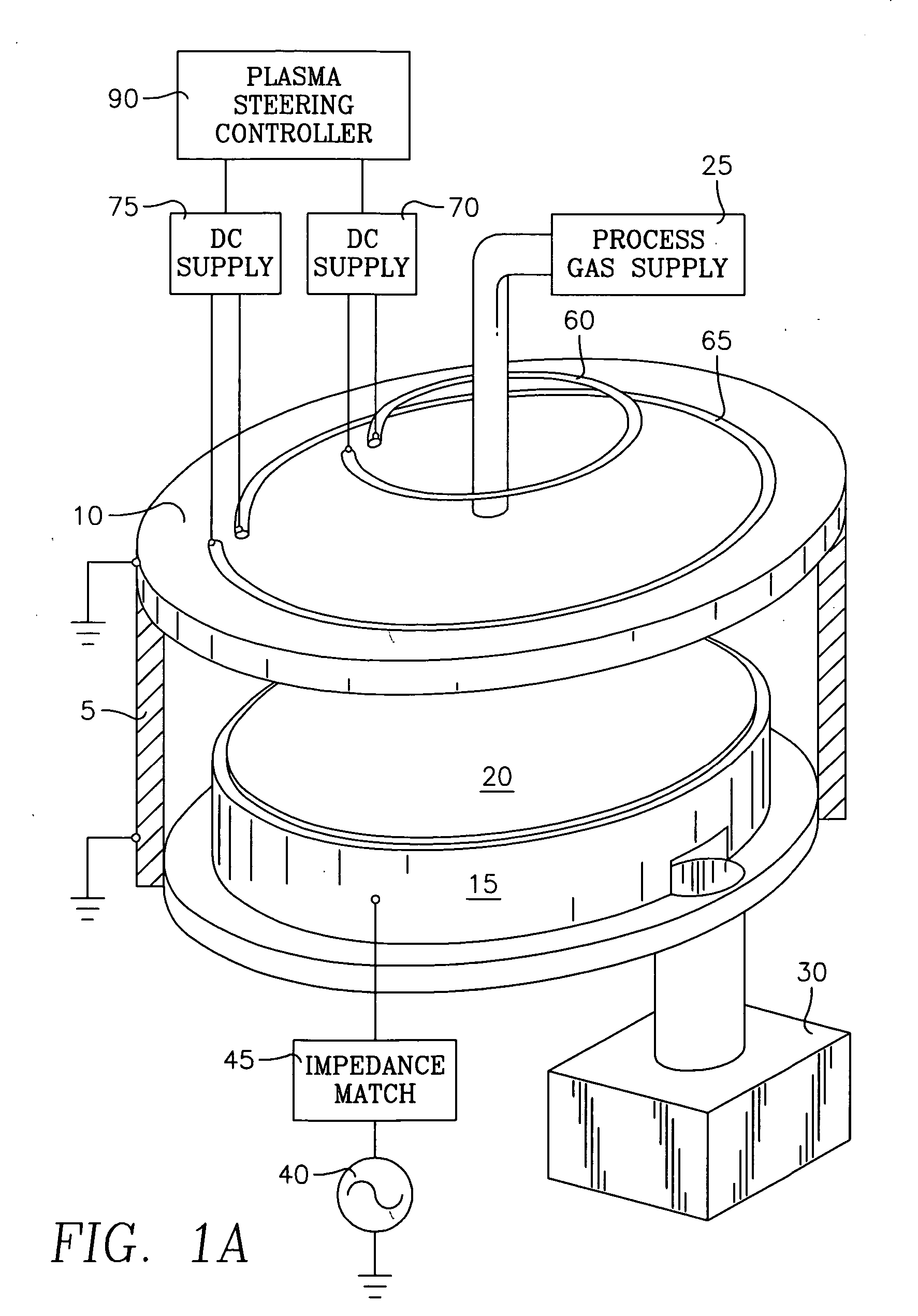

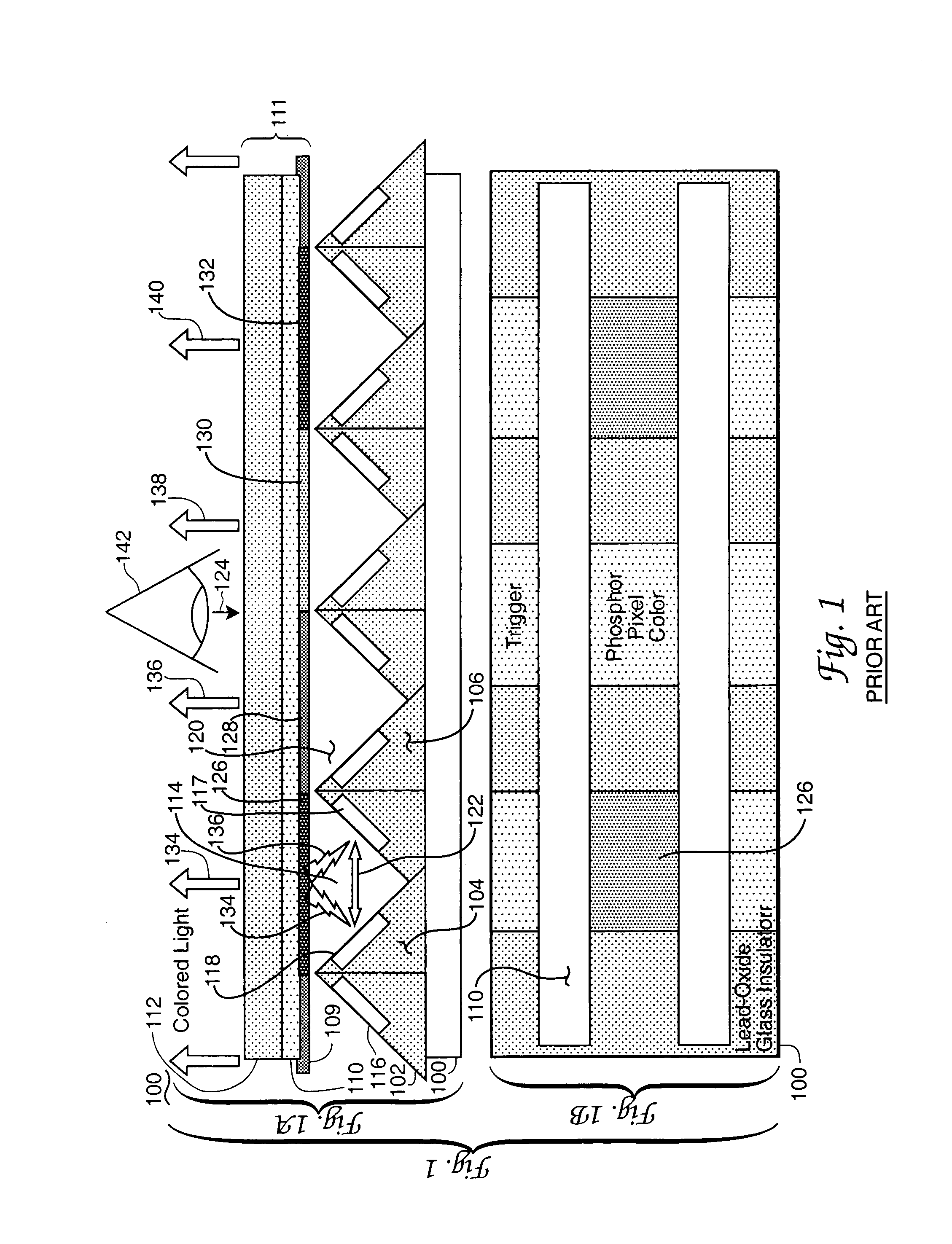

Capacitively coupled plasma reactor with magnetic plasma control

InactiveUS20050001556A1Plasma uniformity can be improvedImprove uniformityElectric discharge tubesElectric arc lampsCapacitanceAxis of symmetry

A plasma reactor includes a vacuum enclosure including a side wall and a ceiling defining a vacuum chamber, and a workpiece support within the chamber and facing the ceiling for supporting a planar workpiece, the workpiece support and the ceiling together defining a processing region between the workpiece support and the ceiling. Process gas inlets furnish a process gas into the chamber. A plasma source power electrode is connected to an RF power generator for capacitively coupling plasma source power into the chamber for maintaining a plasma within the chamber. The reactor further includes at least a first overhead solenoidal electromagnet adjacent the ceiling, the overhead solenoidal electromagnet, the ceiling, the side wall and the workpiece support being located along a common axis of symmetry. A current source is connected to the first solenoidal electromagnet and furnishes a first electric current in the first solenoidal electromagnet whereby to generate within the chamber a magnetic field which is a function of the first electric current, the first electric current having a value such that the magnetic field increases uniformity of plasma ion density radial distribution about the axis of symmetry near a surface of the workpiece support.

Owner:APPLIED MATERIALS INC

Capacitively coupled plasma reactor with magnetic plasma control

InactiveUS6853141B2Plasma uniformity can be improvedImprove uniformityElectric arc lampsSemiconductor/solid-state device manufacturingCapacitanceAxis of symmetry

A plasma reactor includes a vacuum enclosure including a side wall and a ceiling defining a vacuum chamber, and a workpiece support within the chamber and facing the ceiling for supporting a planar workpiece, the workpiece support and the ceiling together defining a processing region between the workpiece support and the ceiling. Process gas inlets furnish a process gas into the chamber. A plasma source power electrode is connected to an RF power generator for capacitively coupling plasma source power into the chamber for maintaining a plasma within the chamber. The reactor further includes at least a first overhead solenoidal electromagnet adjacent the ceiling, the overhead solenoidal electromagnet, the ceiling, the sidewall and the workpiece support being located along a common axis of symmetry. A current source is connected to the first solenoidal electromagnet and furnishes a first electric current in the first solenoidal electromagnet whereby to generate within the chamber a magnetic field which is a function of the first electric current, the first electric current having a value such that the magnetic field increases uniformity of plasma ion density radial distribution about the axis of symmetry near a surface of the workpiece support.

Owner:APPLIED MATERIALS INC

Alternating asymmetrical plasma generation in a process chamber

InactiveUS20050241762A1Improving uniformity of plasma processImprove uniformityElectric discharge tubesDecorative surface effectsCapacitanceNon symmetric

Embodiments of the invention generally provide etch or CVD plasma processing methods and apparatus used to generate a uniform plasma across the surface of a substrate by modulation pulsing the power delivered to a plurality of plasma controlling devices found in a plasma processing chamber. The plasma generated and / or sustained in the plasma processing chamber is created by the one or more plasma controlling devices that are used to control, generate, enhance, and / or shape the plasma during the plasma processing steps by use of energy delivered from a RF power source. Plasma controlling devices may include, for example, one or more coils (inductively coupled plasma), one or more electrodes (capacitively coupled plasma), and / or any other energy inputting device such as a microwave source.

Owner:APPLIED MATERIALS INC

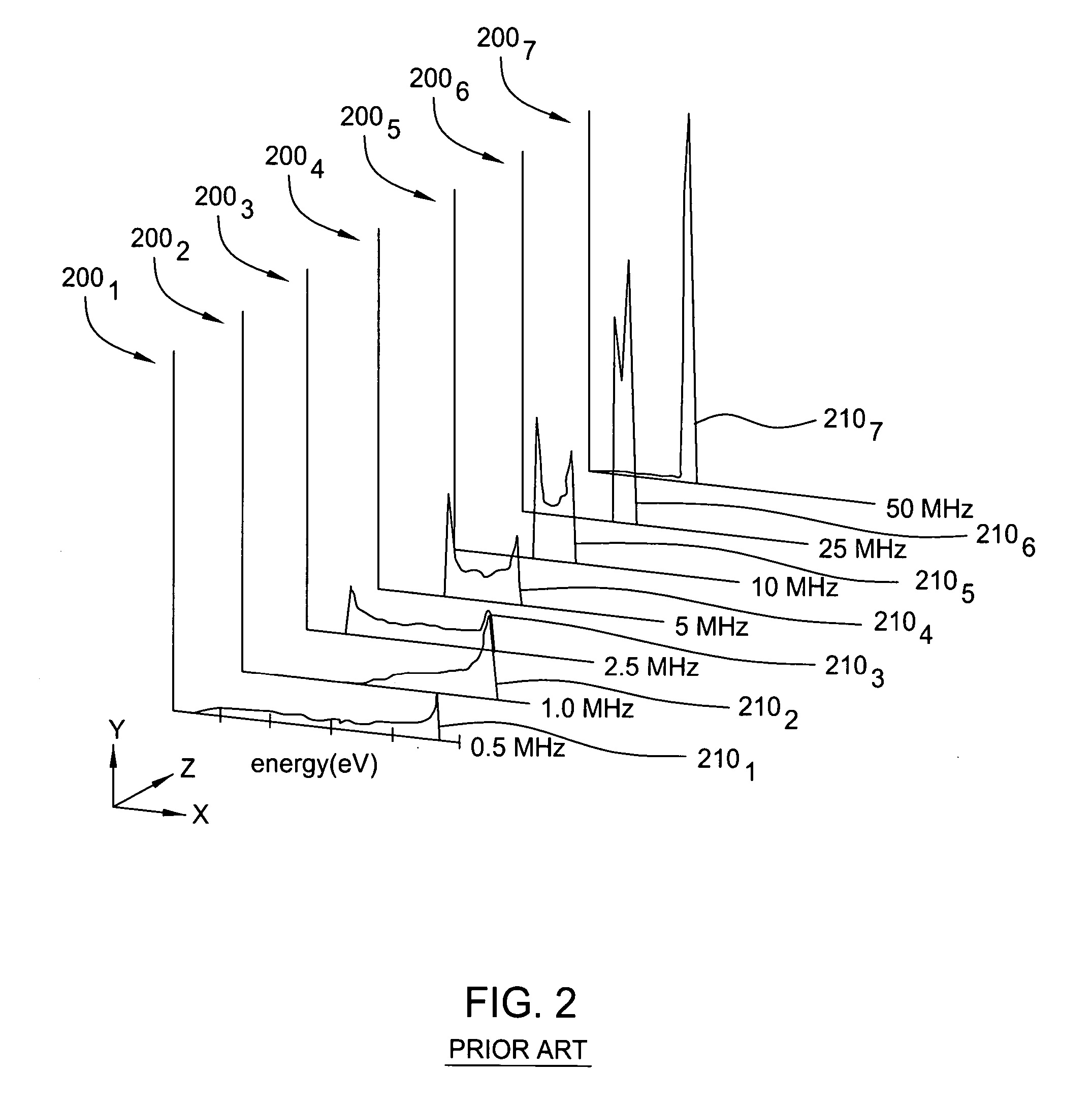

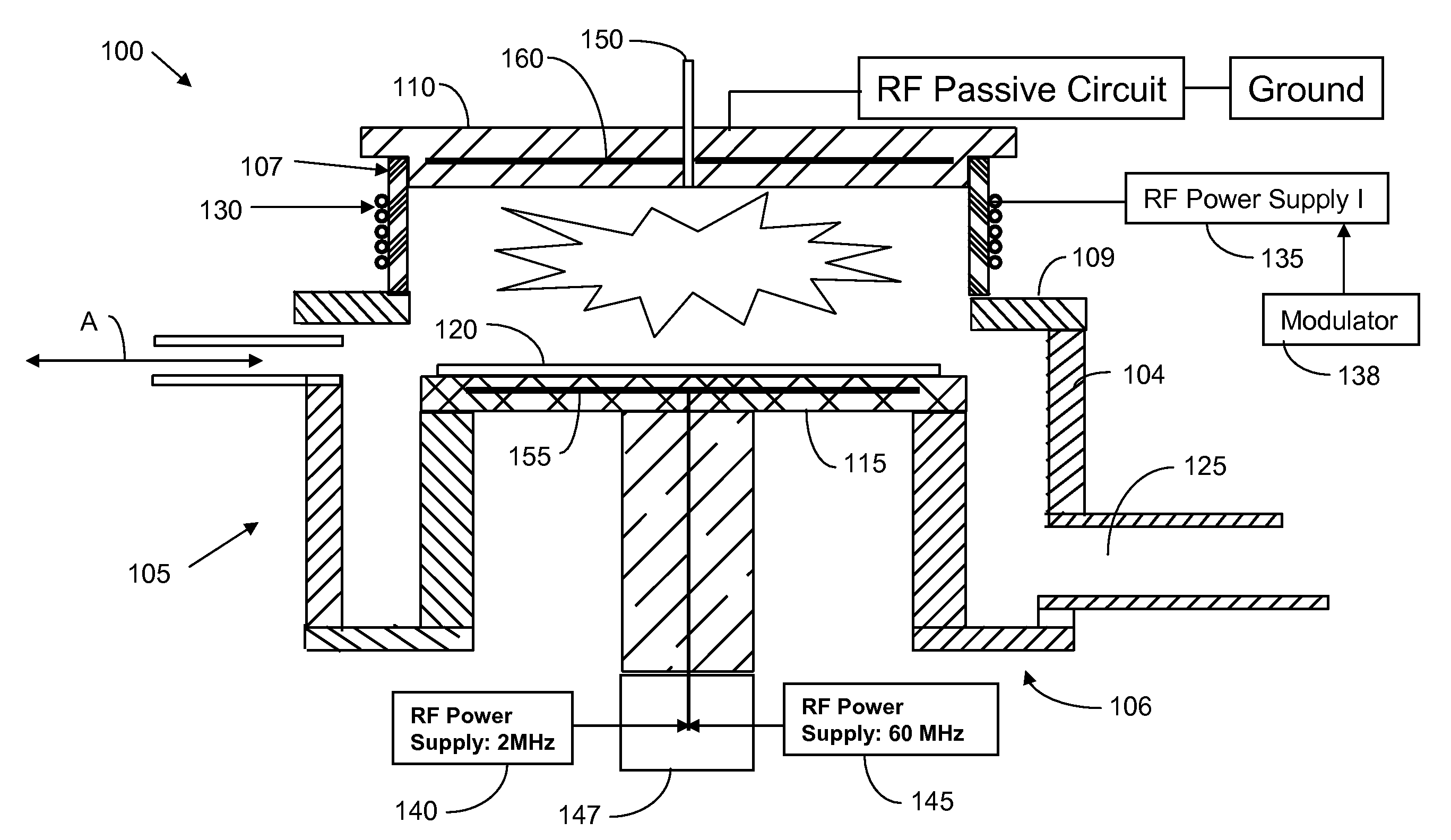

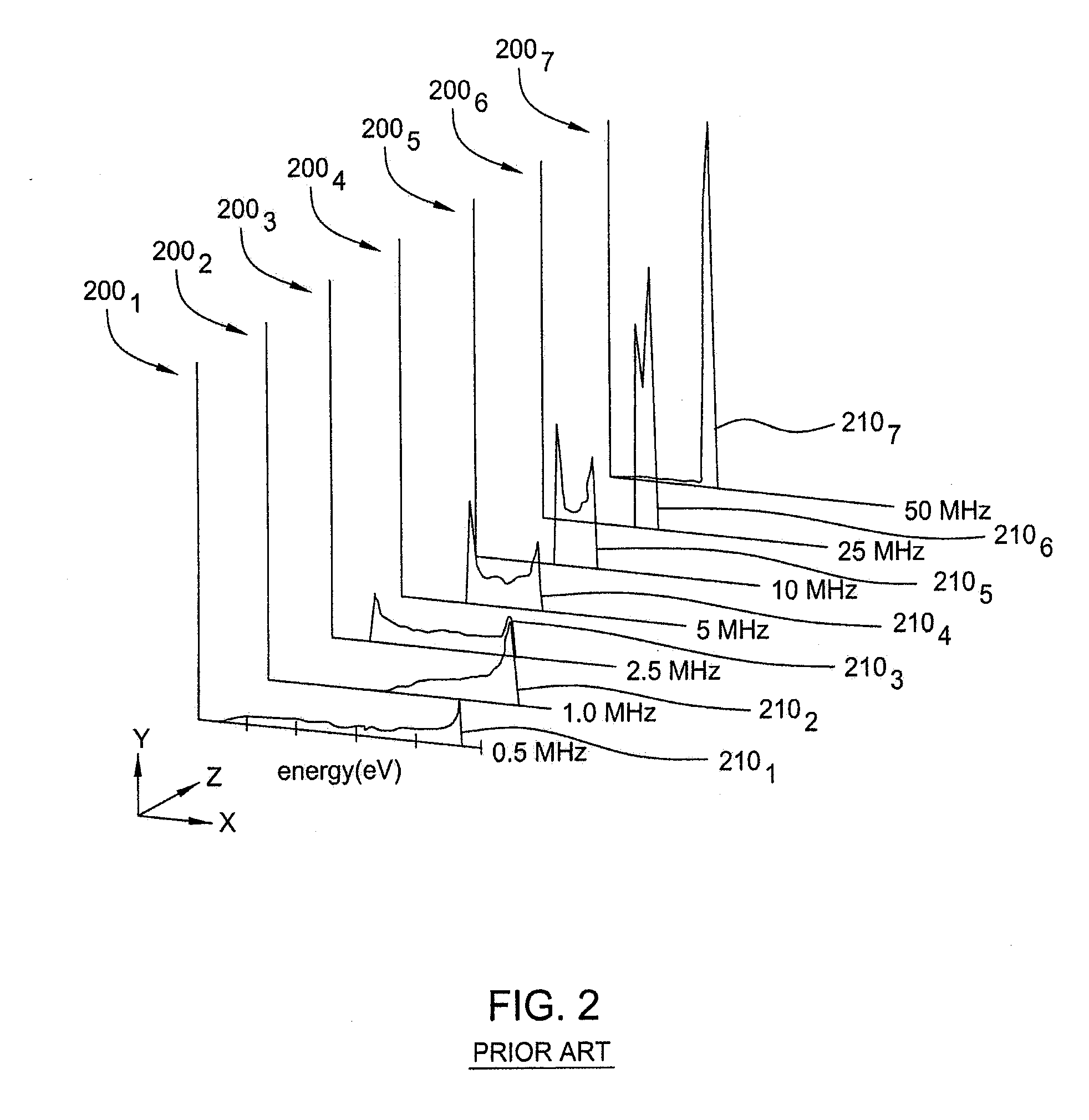

Plasma control using dual cathode frequency mixing

A method and apparatus for controlling characteristics of a plasma in a semiconductor substrate processing chamber using a dual frequency RF source is provided. The method comprises supplying a first RF signal to a first electrode disposed in a processing chamber, and supplying a second RF signal to the first electrode, wherein an interaction between the first and second RF signals is used to control at least one characteristic of a plasma formed in the processing chamber.

Owner:APPLIED MATERIALS INC

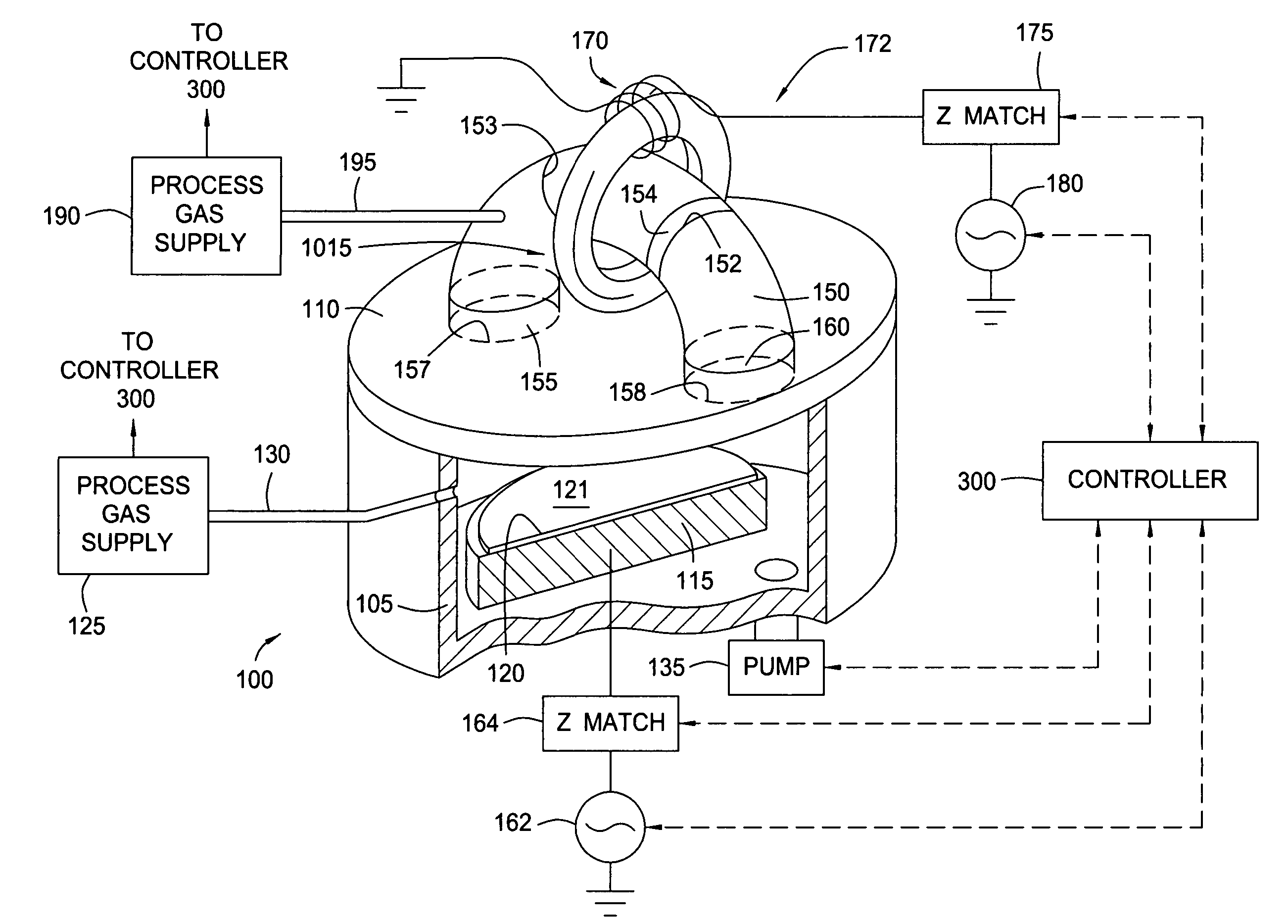

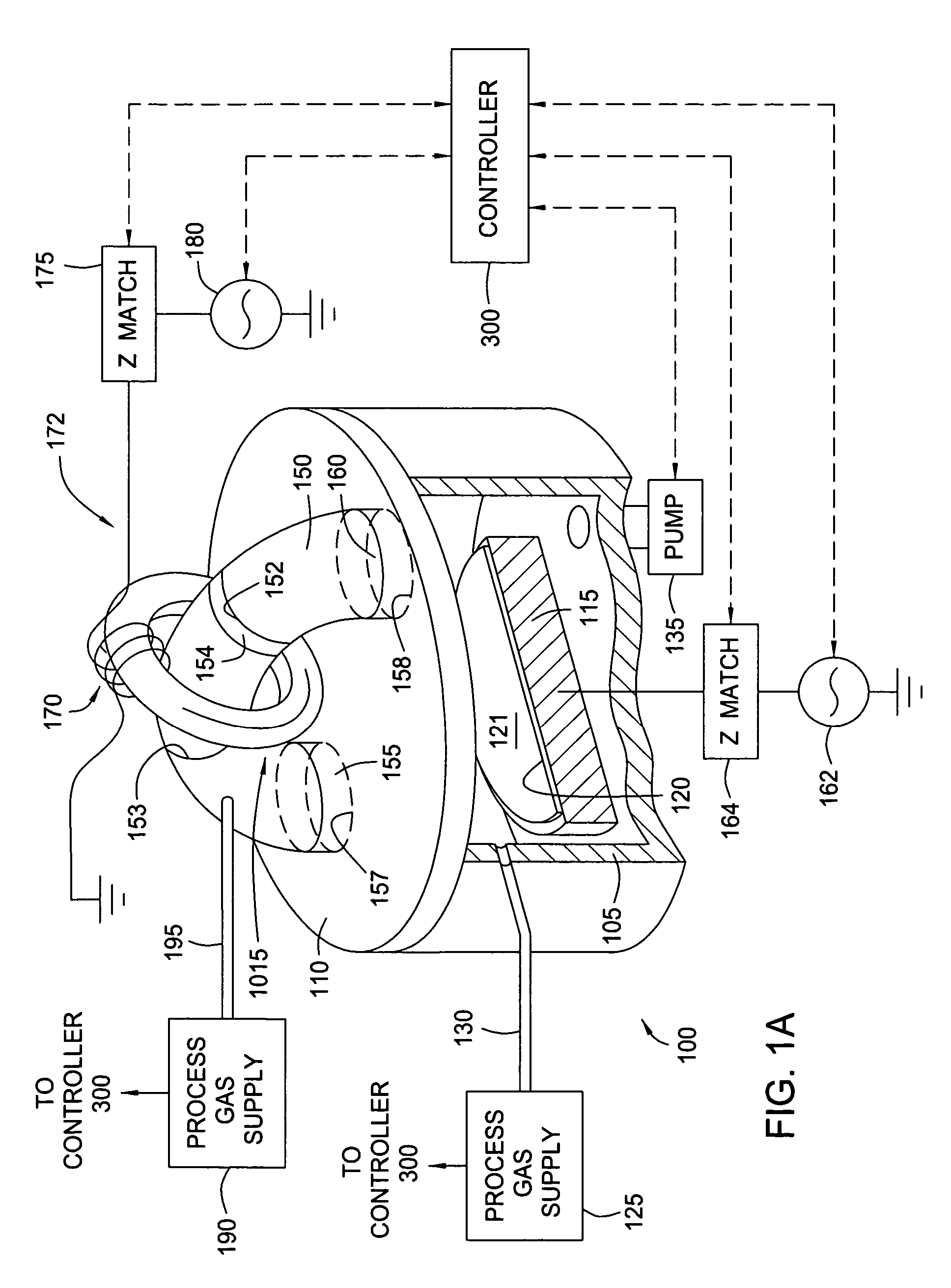

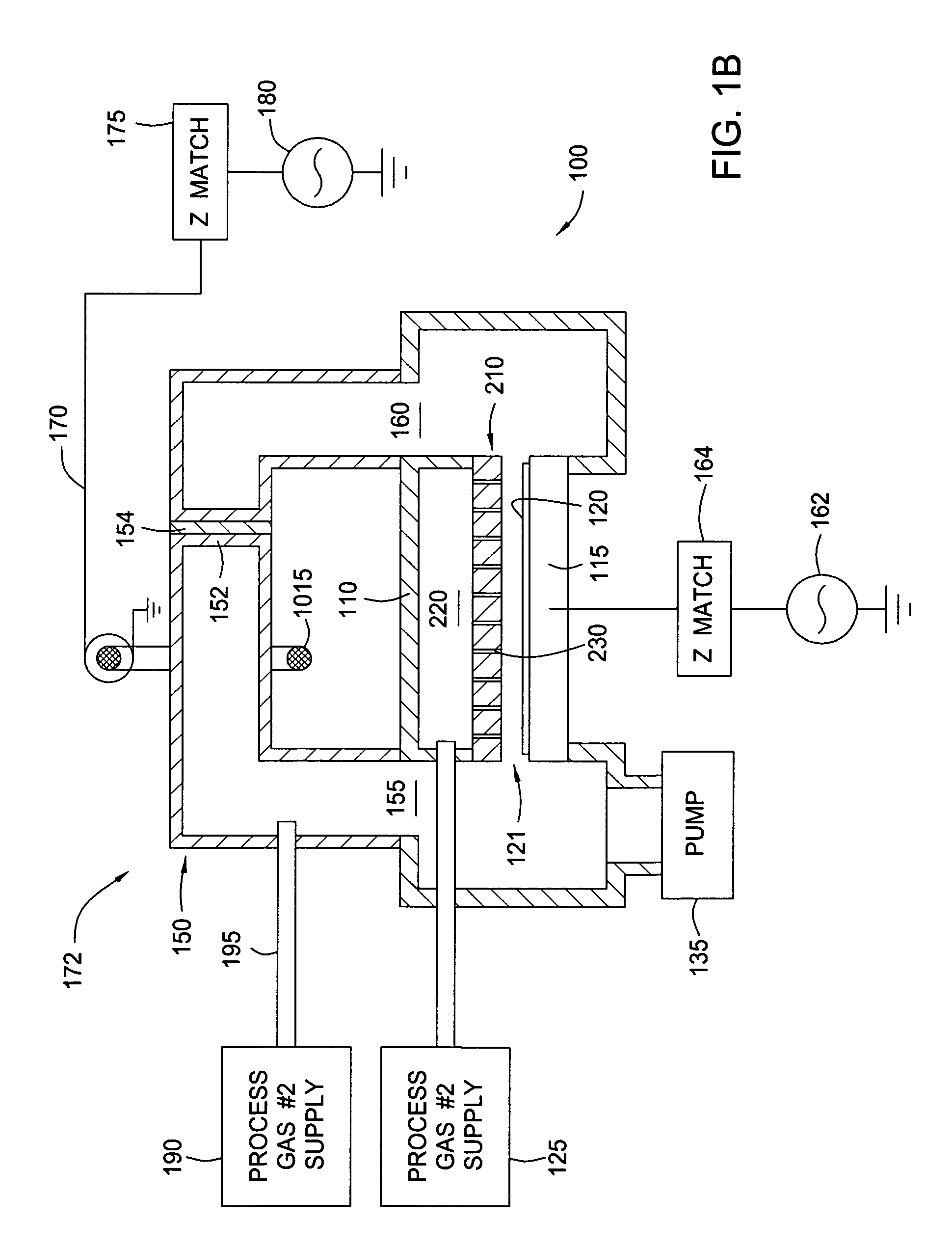

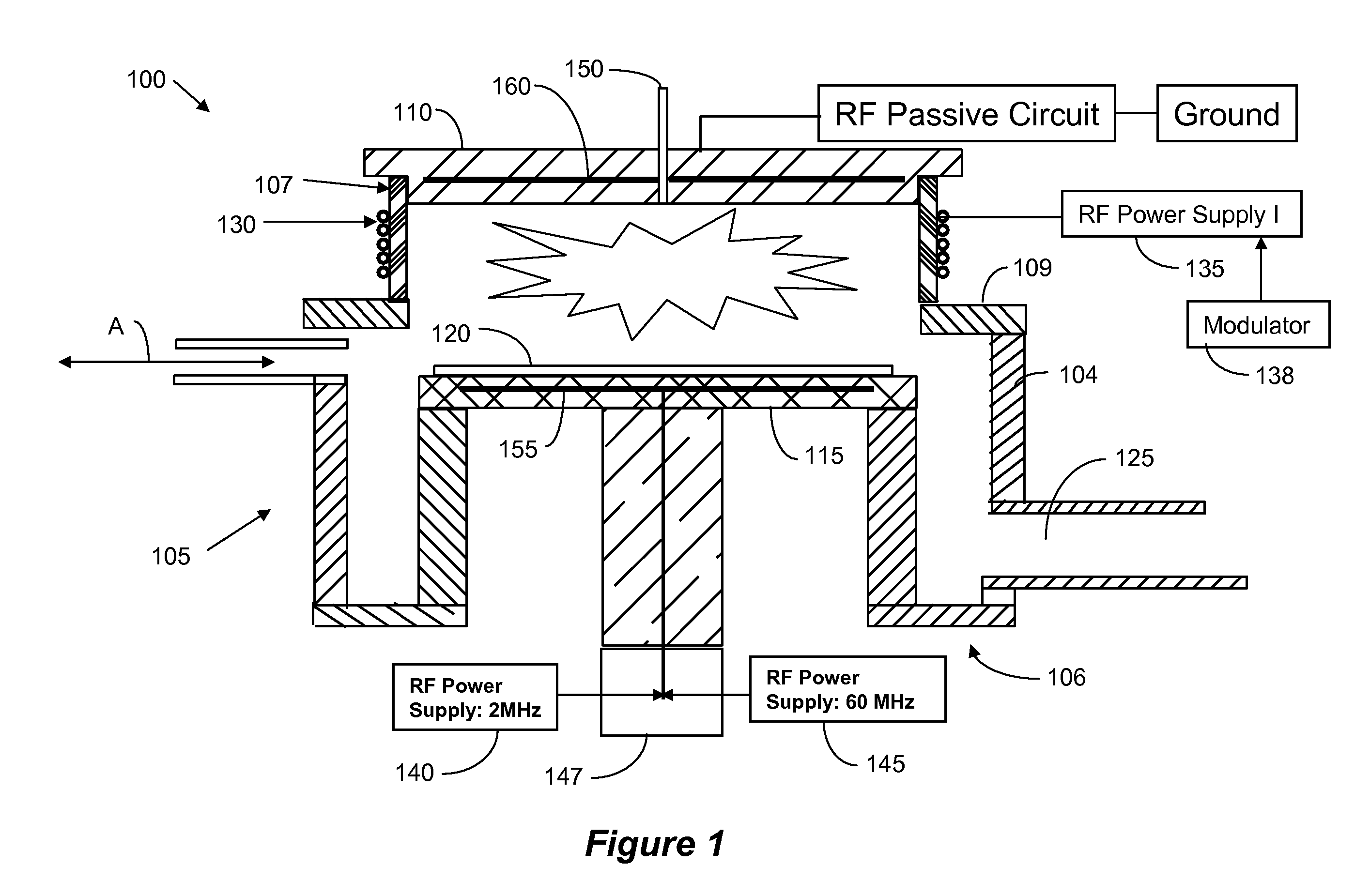

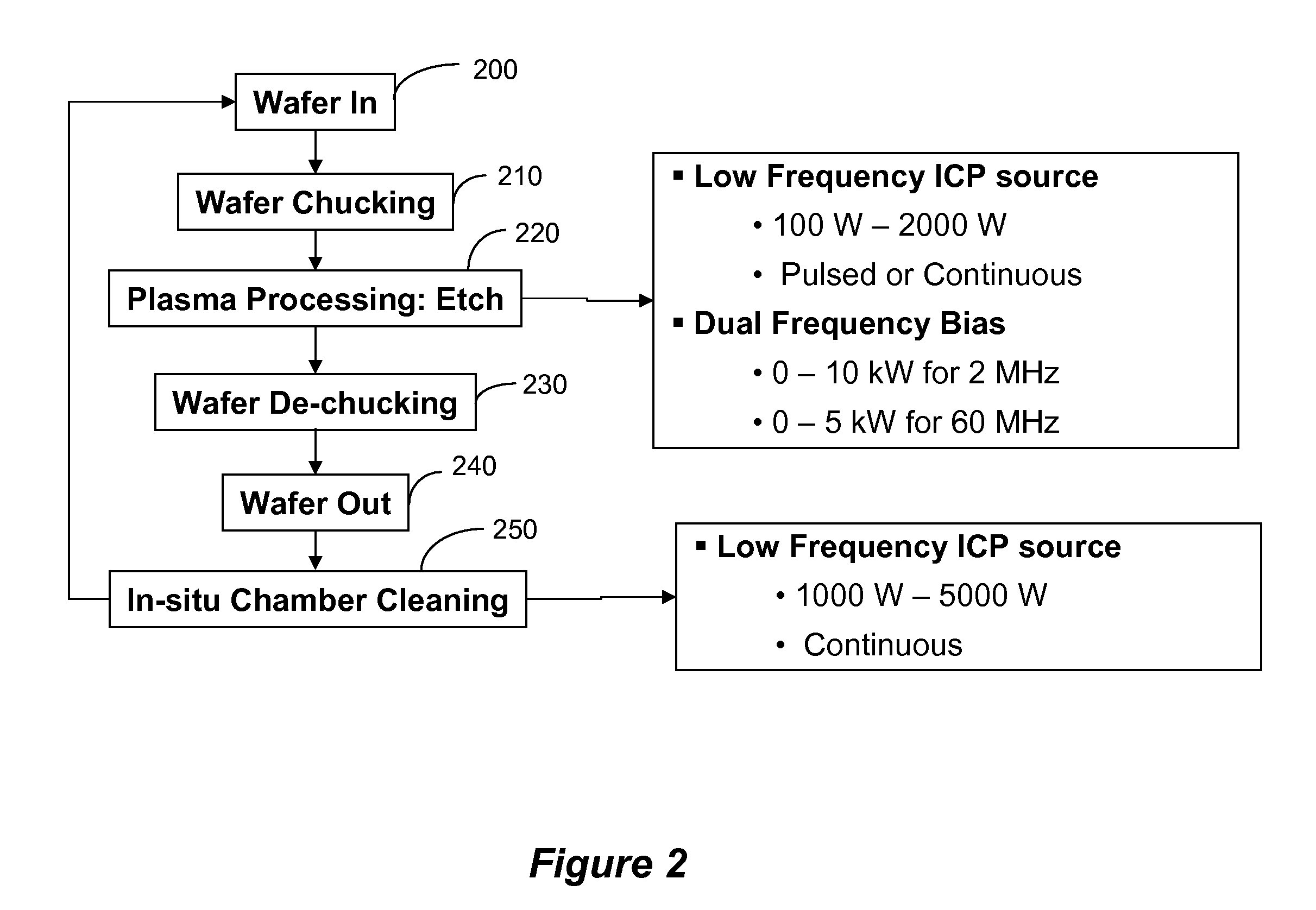

Hybrid etch chamber with decoupled plasma controls

InactiveUS20090004873A1Electric discharge tubesSemiconductor/solid-state device manufacturingDual frequencyCapacitance

A dielectric etch chamber and method for improved control of plasma parameters. The plasma chamber comprises dual-frequency bias source that capacitively couples the RF energy to the plasma, and a single or dual frequency source that inductively couples the RF energy to the plasma. The inductive source may be modulated for improved etch uniformity.

Owner:INTEVAC

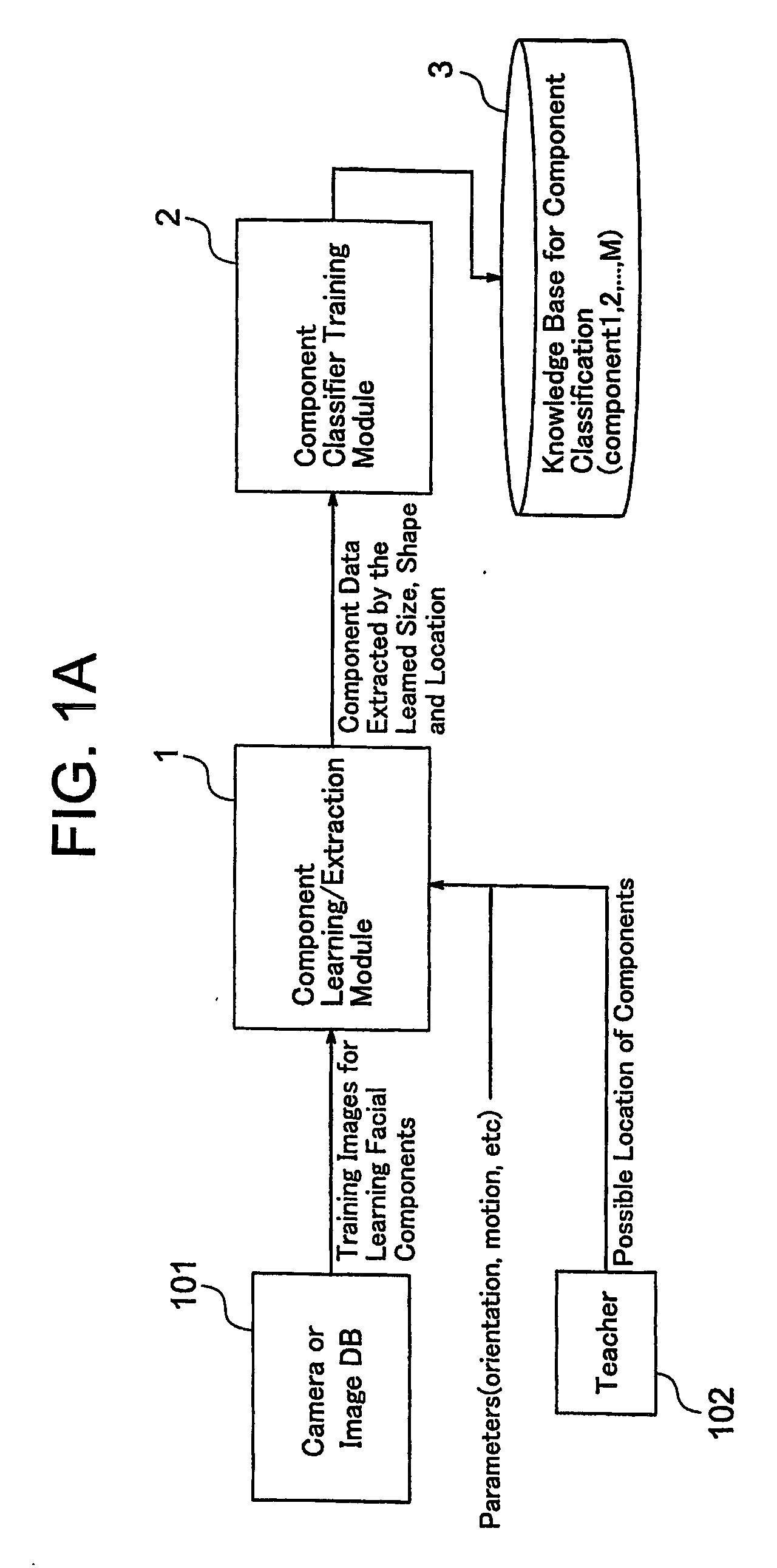

System and method for face recognition

ActiveUS20060280341A1Improve accuracyMinimized volumeCharacter and pattern recognitionEvaporationEngineering

A production device and method which produce a multiple-system film having metal components such as TiAlN greatly different in melting point by a melting-evaporation type ion plating method that provides a high material utilization efficiency and a good film quality. Power needed to evaporate a material (4) is first supplied, and then power gradually increased over the initail power is repeatedly supplied until a needed maximum power is reached. Concurrently, a plasma control is performed for converging plasma (7) onto an initial area needed to evaporate the material, and then a plasma control is performed for continuously and sequentially moving / expanding plasma from the initial plasma area up to a maximum plasma area to thereby gradually melt the non-melted portion of the material.

Owner:HONDA MOTOR CO LTD

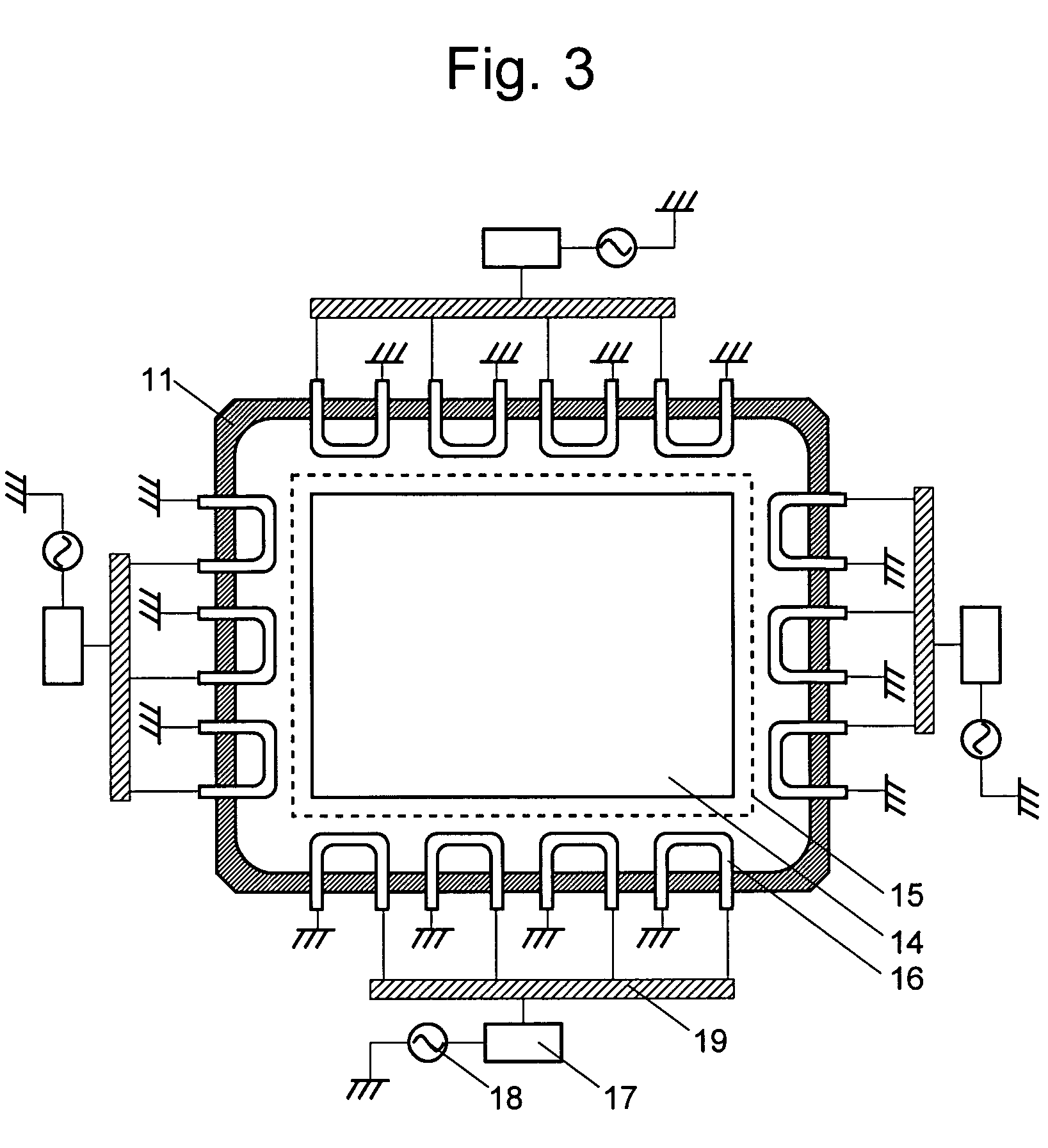

Plasma generation device, plasma control method, and substrate manufacturing method

ActiveUS20060049138A1Reduce loadIncrease plasma densityElectric discharge tubesDecorative surface effectsElectrical conductorHigh density

The present invention aims to provide a plasma generator capable of creating a spatially uniform distribution of high-density plasma. This object is achieved by the following construction. Multiple antennas 16 are located on the sidewall of a vacuum chamber 11, and a RF power source is connected to three or four antennas 16 in parallel via a plate-shaped conductor 19. The length of the conductor of each antenna 16 is shorter than the quarter wavelength of the induction electromagnetic wave generated within the vacuum chamber. Setting the length of the conductor of the antenna in such a manner prevents the occurrence of a standing wave and thereby maintains the uniformity of the plasma within the vacuum chamber. In addition, the plate-shaped conductor 19 improves the heat-releasing efficiency, which also contributes to the suppression of the impedance.

Owner:JAPAN SCI & TECH CORP +3

Alternating asymmetrical plasma generation in a process chamber

InactiveUS20080023443A1Improve uniformityElectric discharge tubesDecorative surface effectsCapacitanceNon symmetric

Embodiments of the invention generally provide etch or CVD plasma processing methods and apparatus used to generate a uniform plasma across the surface of a substrate by modulation pulsing the power delivered to a plurality of plasma controlling devices found in a plasma processing chamber. The plasma generated and / or sustained in the plasma processing chamber is created by the one or more plasma controlling devices that are used to control, generate, enhance, and / or shape the plasma during the plasma processing steps by use of energy delivered from a RF power source. Plasma controlling devices may include, for example, one or more coils (inductively coupled plasma), one or more electrodes (capacitively coupled plasma), and / or any other energy inputting device such as a microwave source.

Owner:PATERSON ALEXANDER +6

Capacitively coupled plasma reactor with magnetic plasma control

InactiveUS20060157201A1Improve uniformityElectric discharge tubesDecorative surface effectsCapacitanceAxis of symmetry

A plasma reactor includes a vacuum enclosure including a side wall and a ceiling defining a vacuum chamber, and a workpiece support within the chamber and facing the ceiling for supporting a planar workpiece, the workpiece support and the ceiling together defining a processing region between the workpiece support and the ceiling. Process gas inlets furnish a process gas into the chamber. A plasma source power electrode is connected to an RF power generator for capacitively coupling plasma source power into the chamber for maintaining a plasma within the chamber. The reactor further includes at least a first overhead solenoidal electromagnet adjacent the ceiling, the overhead solenoidal electromagnet, the ceiling, the side wall and the workpiece support being located along a common axis of symmetry. A current source is connected to the first solenoidal electromagnet and furnishes a first electric current in the first solenoidal electromagnet whereby to generate within the chamber a magnetic field which is a function of the first electric current, the first electric current having a value such that the magnetic field increases uniformity of plasma ion density radial distribution about the axis of symmetry near a surface of the workpiece support.

Owner:APPLIED MATERIALS INC

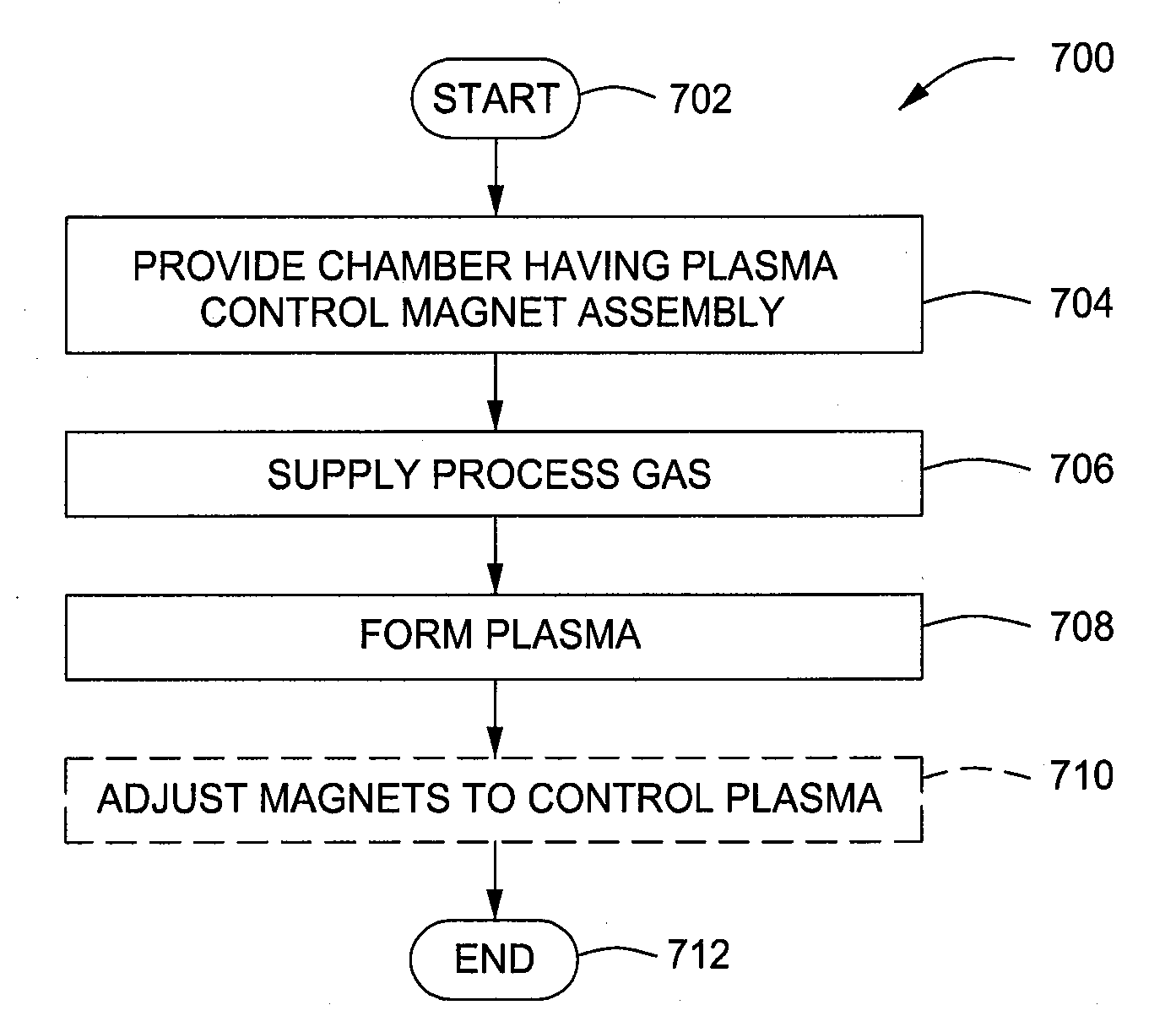

Plasma processing method

InactiveUS20080260966A1Negligible strengthElectric discharge tubesPlasma techniqueEngineeringPlasma processing

Embodiments of the present invention relate to plasma processing apparatus and methods of use thereof. In some embodiments, a method of controlling a plasma in a process chamber includes providing a chamber for processing a substrate and having a processing volume defined therein wherein a plasma is to be formed during operation, the chamber further having a plasma control magnet assembly comprising a plurality of magnets that provide a magnetic field having a magnitude is greater than about 10 Gauss in an upper region of the processing volume and less than about 10 Gauss in a lower region of the processing volume proximate a substrate to be processed; supplying a process gas to the chamber; and forming a plasma in the processing volume from the process gas.

Owner:APPLIED MATERIALS INC

Plasma control using dual cathode frequency mixing

InactiveUS20070000611A1Electric discharge tubesSemiconductor/solid-state device manufacturingDual frequencyEngineering

A method and apparatus for controlling characteristics of a plasma in a semiconductor substrate processing chamber using a dual frequency RF source is provided. The method comprises supplying a first RF signal to a first electrode disposed in a processing chamber, and supplying a second RF signal to the first electrode, wherein an interaction between the first and second RF signals is used to control at least one characteristic of a plasma formed in the processing chamber.

Owner:APPLIED MATERIALS INC

Process for in-situ formation of TiC/metal composite cladding layer controlled by plasma

The invention discloses a TiC / metal composite fusing coating producing method for original position controlled by plasma, which comprises the following steps: allocating precoating material; allocating graphite and titanium powder with ferric base or nickel base or cobalt base powder according to the chemical metering rate of TiC as precoating paint; blending organic adhesive evenly through two-step method or synchronous powder sending method; coating composite material on the metal surface; scanning the metal surface continuously of precoating composite paint through plasma; fusing to obtain continuous or single-way fusing layer on the metal surface.

Owner:HOHAI UNIV

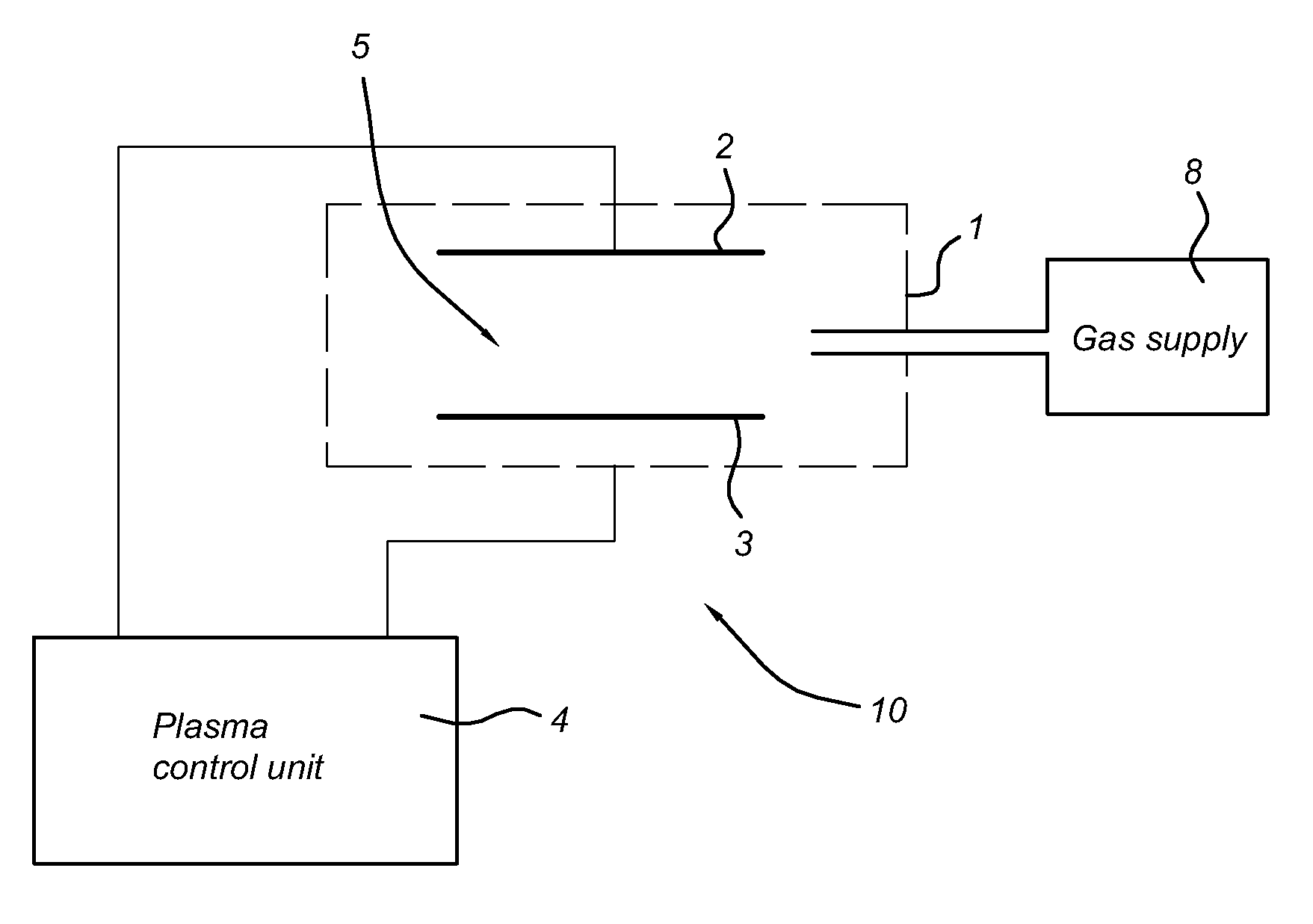

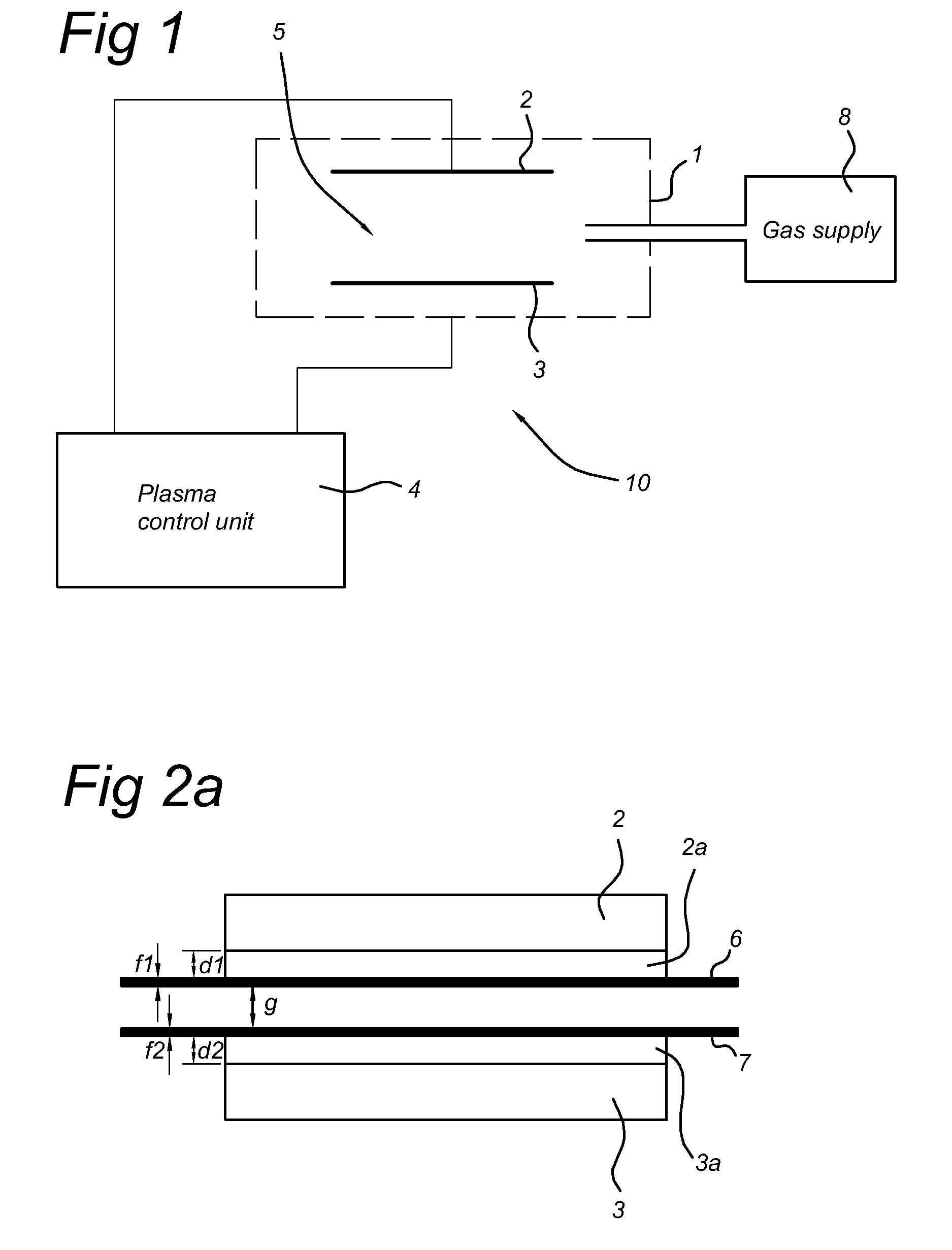

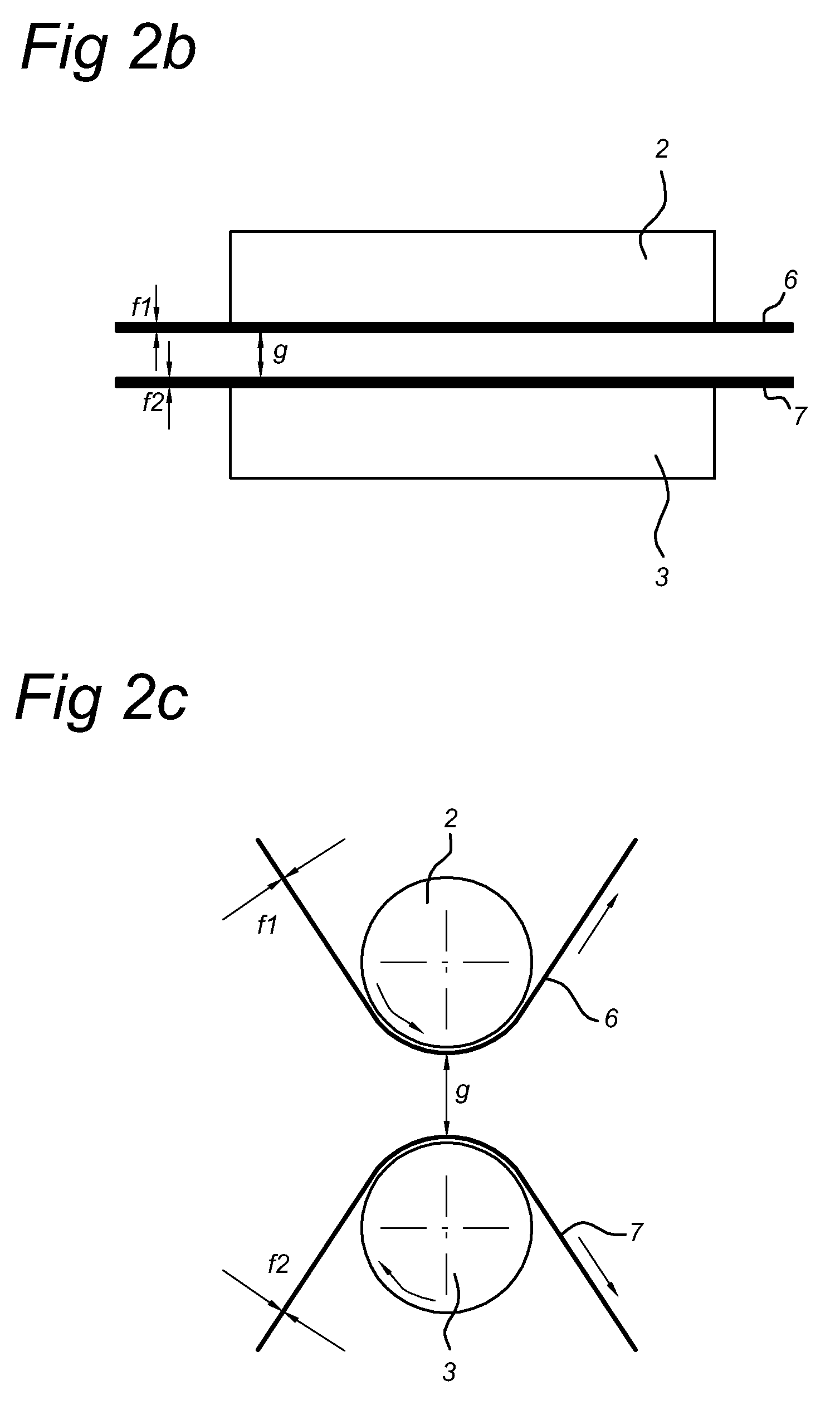

Plasma treatment apparatus and method for treatment of a substrate with atmospheric pressure glow discharge electrode configuration

InactiveUS20110014424A1Increase plasma stabilityImprove stabilityElectric discharge tubesLayered productsFree distanceEngineering

Plasma treatment apparatus and method for treating a substrate (6, 7) e.g. for deposition of a layer on the substrate (6, 7). Two opposing electrodes (2, 3) and a treatment space (5) are provided. A dielectric barrier (6, 7; 2a, 3a), comprising in operation the substrate, is provided in the treatment space (5) between the at least two opposing electrodes (2, 3) which are connected to a plasma control unit (4). A gap distance (g) is the free distance in the treatment space (5) of a gap between the at least two opposing electrodes (2, 3) in operation. A total dielectric distance (d) is the sum of the dielectric thickness of the dielectric layers (2a, 3a) and the substrate (6, 7). The product of gap distance (g) and total dielectric distance (d) is controlled to a value less than or equal to 1.0 mm2.

Owner:FUJIFILM MFG EURO

Tissue Factor Antibodies and Uses Thereof

ActiveUS20090081200A1Immunoglobulins against blood coagulation factorsAnimal cellsBlood plasmaBlood coagulations

The present invention provides antibodies capable of binding to human tissue factor, which do not inhibit tissue factor mediated blood coagulation compared to a normal plasma control. Further described are methods of making and methods of using the antibodies of the invention.

Owner:PURDUE PHARMA LP

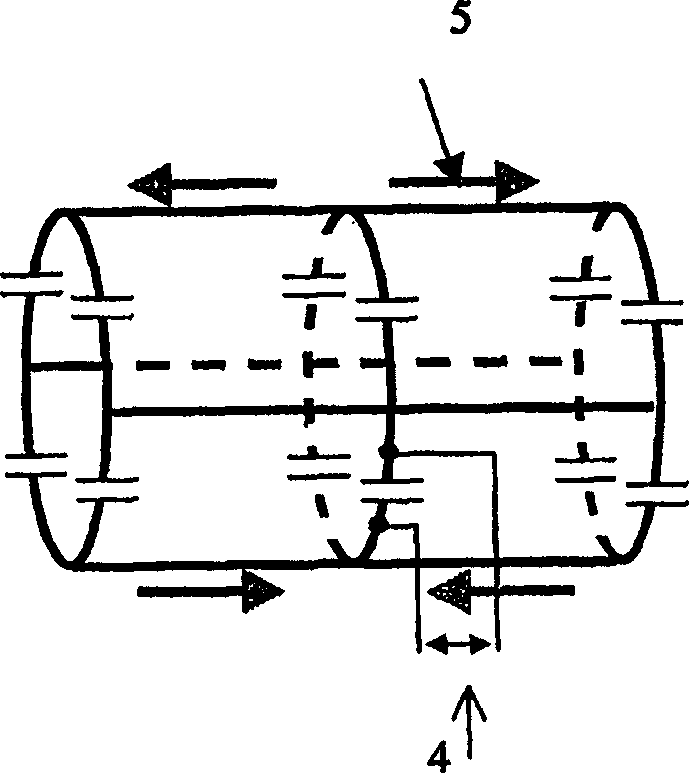

A high density plasma reactor

ActiveCN1809911AElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequency energyNuclear engineering

The high density RF plasma source of this invention uses a special antenna configuration to launch waves at frequency such as 13,56MHz. The tunability of this antenna allows to adapt actively the coupling of the RF energy into an evolutive plasma as found in plasma processings in semiconductor manufacturing. This plasma source can be used for the following applications : plasma etching, deposition, sputtering systems, space propulsion, plasma - based sterilization , plasma abatement systems. In another embodiment, the plasma source is in conjunction with one or several process chambers , which comprise an array of magnets and RF coils too . These elements can be used, on one hand, for plasma confinement or the active plasma control (Plasma rotation ) thanks to feedback control approach , and one the other hand, for in situ NMR Monitoring or analysis such as moisture monitoring inside a process chamber , before or after the plasma process, or for in situ NMR Inspection of wafers or others workpieces.

Owner:HELYSSEN

Capacitively coupled plasma reactor with magnetic plasma control

InactiveUS20080023143A1Improve uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceAxis of symmetry

A plasma reactor includes a vacuum enclosure including a side wall and a ceiling defining a vacuum chamber, and a workpiece support within the chamber and facing the ceiling for supporting a planar workpiece, the workpiece support and the ceiling together defining a processing region between the workpiece support and the ceiling. Process gas inlets furnish a process gas into the chamber. A plasma source power electrode is connected to an RF power generator for capacitively coupling plasma source power into the chamber for maintaining a plasma within the chamber. The reactor further includes at least a first overhead solenoidal electromagnet adjacent the ceiling, the overhead solenoidal electromagnet, the ceiling, the side wall and the workpiece support being located along a common axis of symmetry.

Owner:HOFFMAN DANIEL J +6

Capacitively coupled plasma reactor with magnetic plasma control

InactiveCN1669108AImprove uniformitySemiconductor/solid-state device manufacturingIon beam tubesCapacitanceAxis of symmetry

A plasma reactor includes a vacuum enclosure including a side wall and a ceiling defining a vacuum chamber, and a workpiece support within the chamber and facing the ceiling for supporting a planar workpiece, the workpiece support and the ceiling together defining a processing region between the workpiece support and the ceiling. Process gas inlets furnish a process gas into the chamber. A plasma source power electrode is connected to an RF power generator for capacitively coupling plasma source power into the chamber for maintaining a plasma within the chamber. The reactor further includes at least a first overhead solenoidal electromagnet adjacent the ceiling, the overhead solenoidal electromagnet, the ceiling, the sidewall and the workpiece support being located along a common axis of symmetry. A current source is connected to the first solenoidal electromagnet and furnishes a first electric current in the first solenoidal electromagnet whereby to generate within the chamber a magnetic field which is a function of the first electric current, the first electric current having a value such that the magnetic field increases uniformity of plasma ion density radial distribution about the axis of symmetry near a surface of the workpiece support.

Owner:APPLIED MATERIALS INC

Plasma processing apparatus

InactiveUS20080257261A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma processing

Embodiments of the present invention relate to plasma processing apparatus and methods of use thereof. In some embodiments, a plasma control magnet assembly includes a plurality of magnets arranged in a predetermined pattern that generate a magnetic field having a strength greater than 10 Gauss in a region proximate the assembly and less than 10 Gauss in a region remote from the assembly.

Owner:APPLIED MATERIALS INC

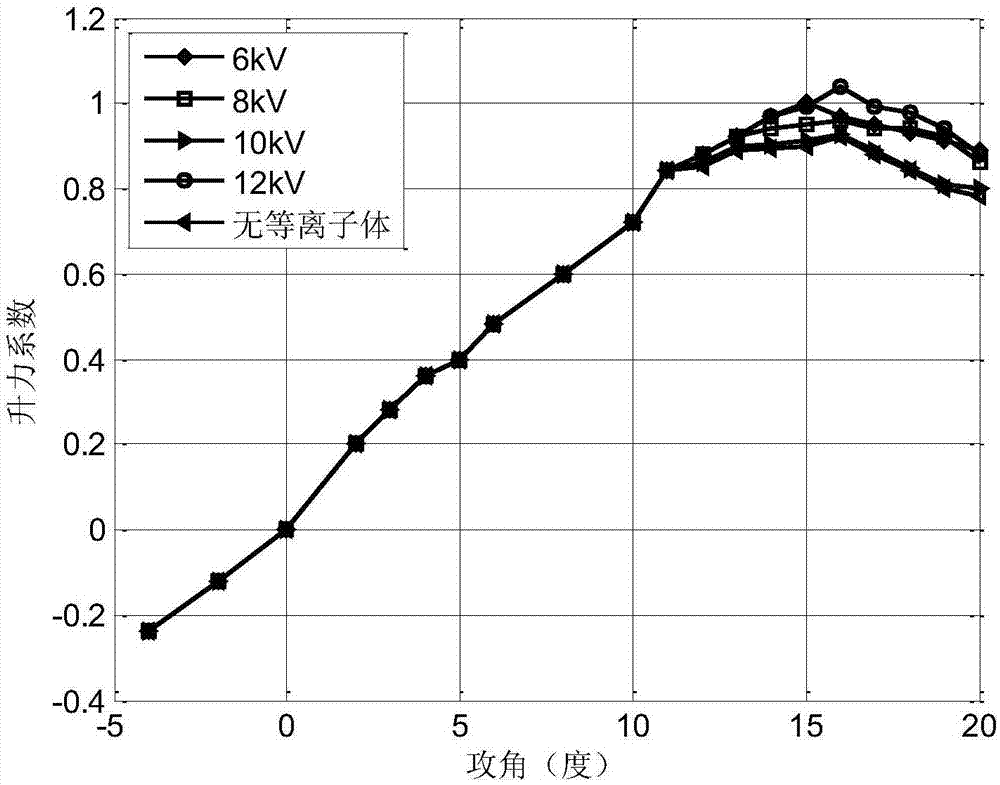

Plasma-based aircraft aerodynamic characteristic analysis method

ActiveCN107238481ADoes not increase stealthReduce weightAerodynamic testingAnalysis methodDrag coefficient

The invention relates to a plasma-based aircraft aerodynamic characteristic analysis method. According to the method, the lift coefficient is improved and the drag coefficient is reduced based on the dielectric barrier discharge (DBD) plasma control technology. The lift-drag ratio of an aircraft is improved and the aerodynamic characteristic performance of the aircraft is improved. Furthermore, in the dielectric barrier discharge (DBD) plasma condition, the aerodynamic characteristics of the surface of the aircraft can be analyzed and obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Tissue factor antibodies and uses thereof

ActiveUS7425328B2Immunoglobulins against blood coagulation factorsAntibody ingredientsFactor iiBlood plasma

The present invention provides antibodies capable of binding to human tissue factor, which do not inhibit tissue factor mediated blood coagulation compared to a normal plasma control. Further described are methods of making and methods of using the antibodies of the invention.

Owner:PURDUE PHARMA LP

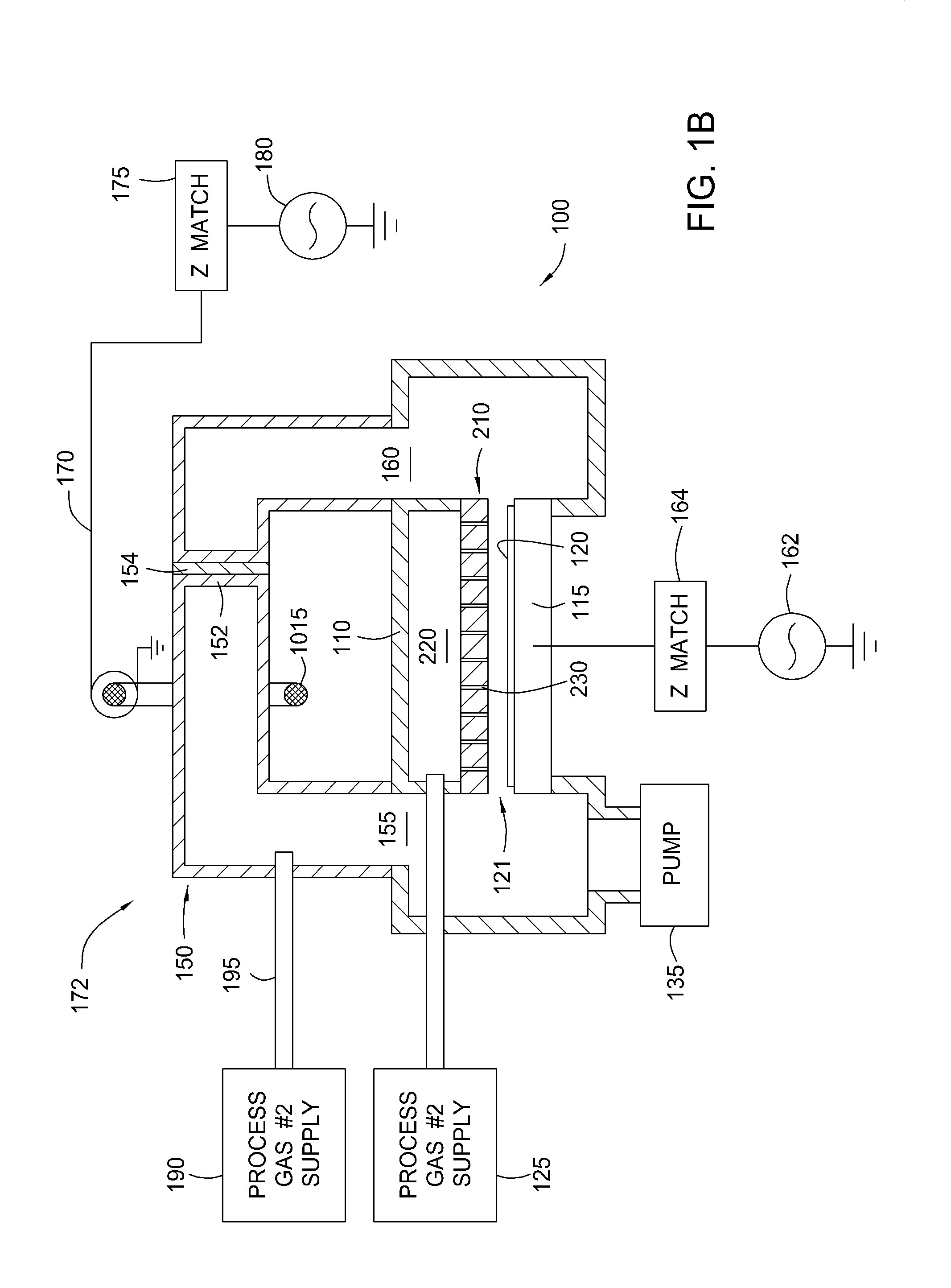

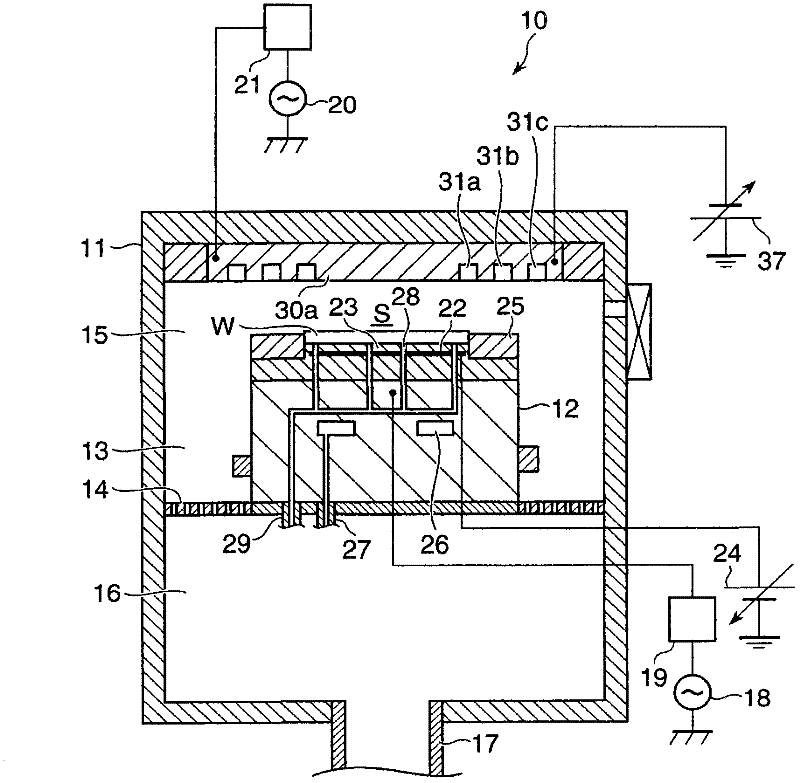

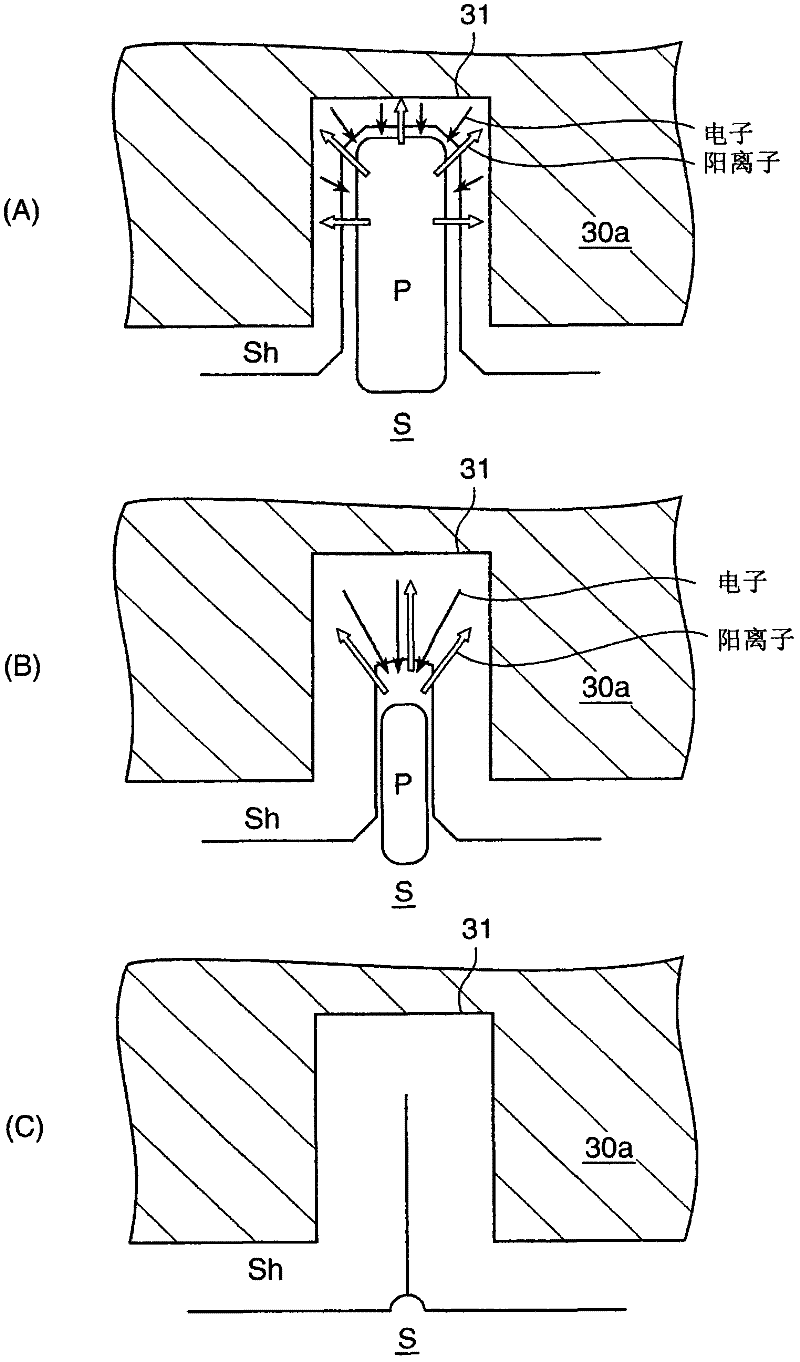

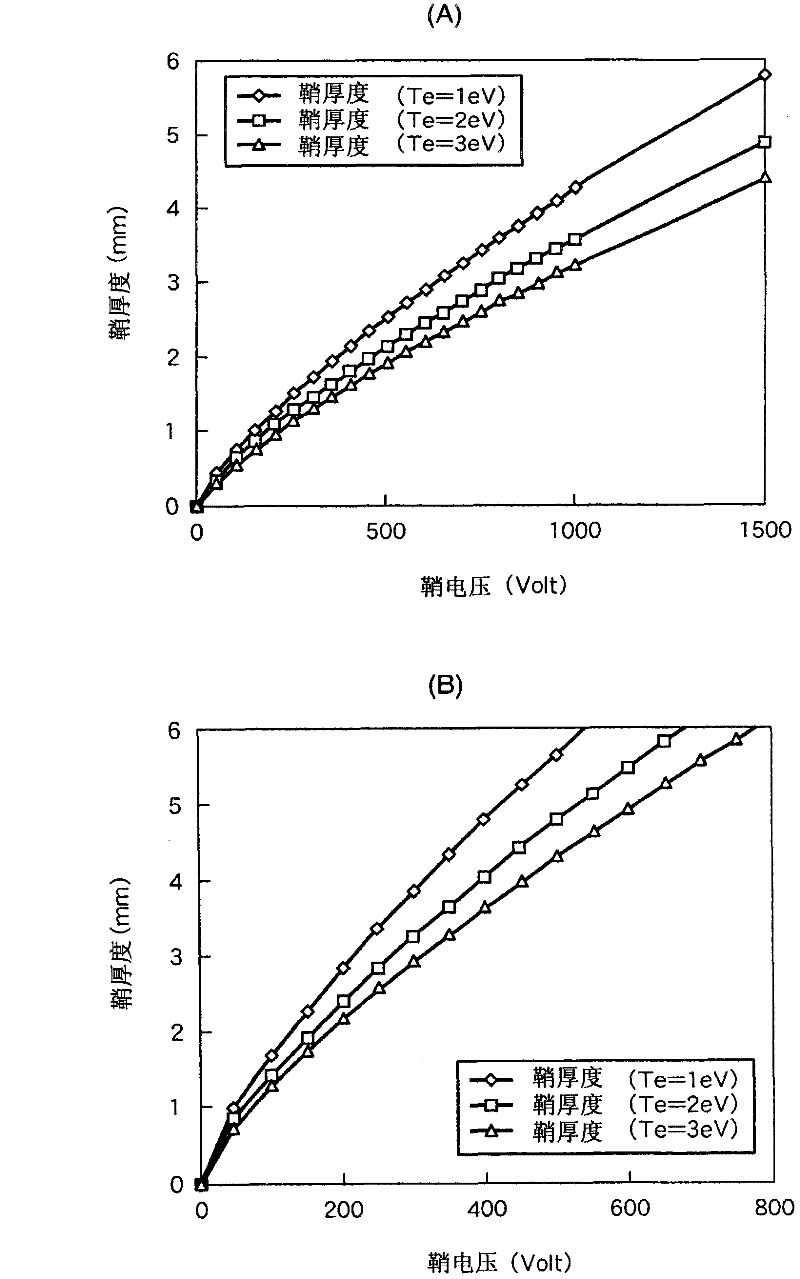

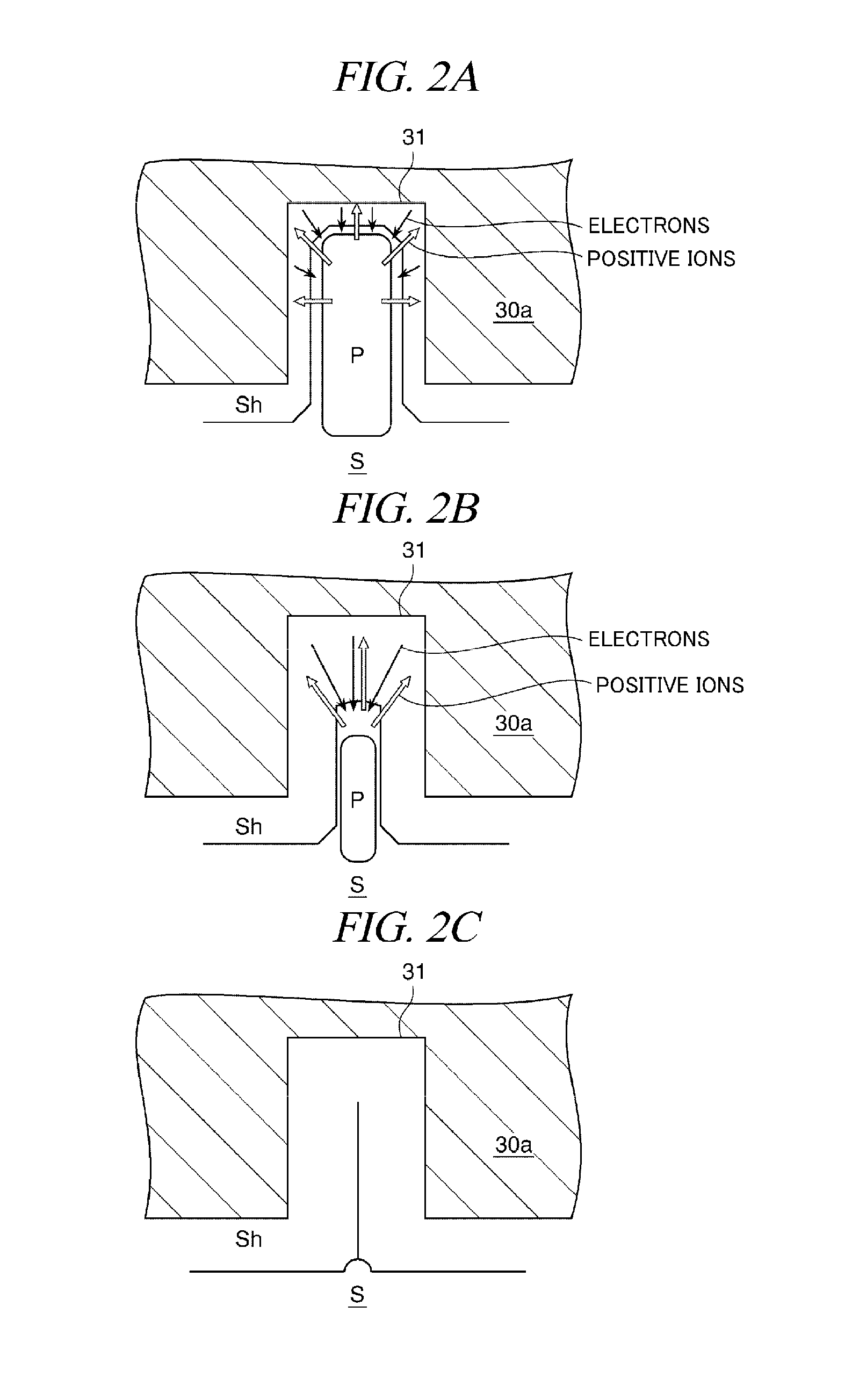

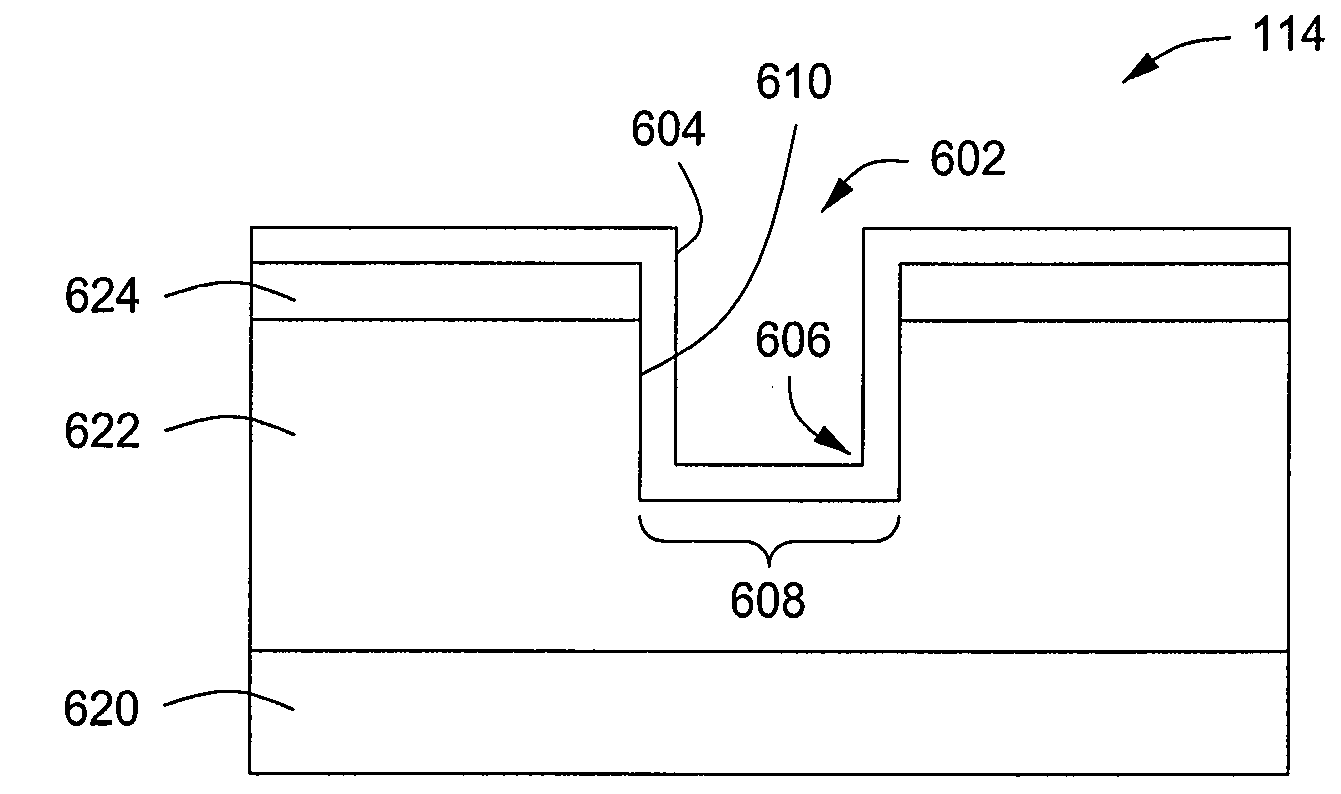

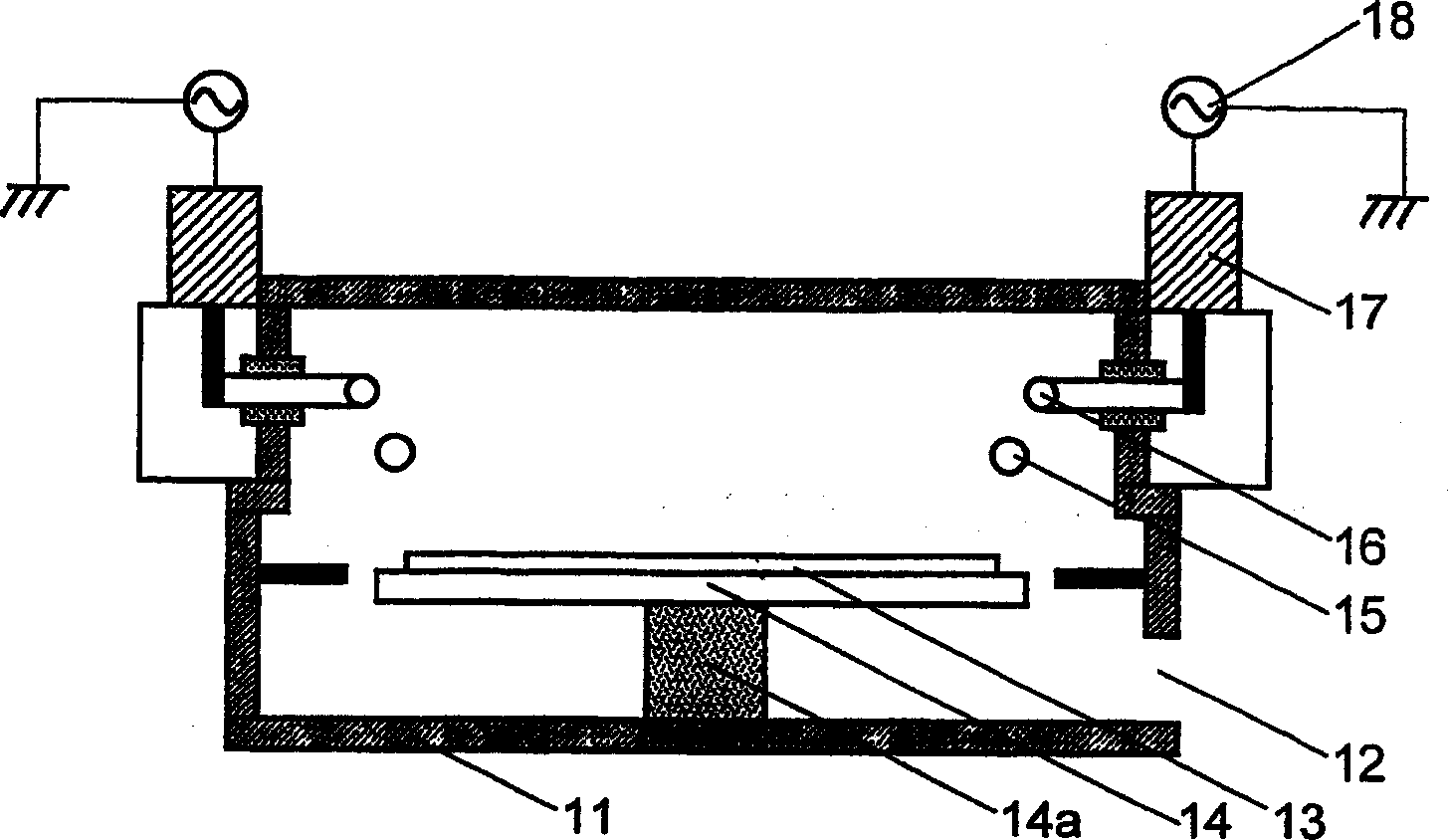

Plasma processing apparatus and plasma control method

ActiveCN102376521AControl distributionUniform densityElectric discharge tubesPlasma techniqueSusceptorPlasma density

There is provided a plasma processing apparatus capable of performing a uniform plasma process on a substrate by controlling a plasma distribution within a chamber to a desired state and uniformizing a plasma density within the chamber. The plasma processing apparatus includes an evacuable chamber (11) for performing a plasma process on a wafer (W); a susceptor (12) for mounting the wafer (W) within the chamber (11); an upper electrode plate (30a) facing the susceptor (12) with a processing space (S); a high frequency power supply (20) for applying a high frequency power to one of the susceptor (12) and the upper electrode plate (30a) to generate plasma within the processing space (S); and an inner wall member facing the processing space (S). Hollow cathodes (31a to 31c) are formed at the upper electrode plate (30a) connected with a DC power supply (37) for adjusting a sheath voltage.

Owner:TOKYO ELECTRON LTD

Plasma processing apparatus and plasma control method

ActiveUS20120037597A1Uniform plasma treatmentElectric discharge tubesDecorative surface effectsPlasma densityHigh frequency power

There is provided a plasma processing apparatus capable of performing a uniform plasma process on a substrate by controlling a plasma distribution within a chamber to a desired state and uniformizing a plasma density within the chamber. The plasma processing apparatus includes an evacuable chamber 11 for performing a plasma process on a wafer W; a susceptor 12 for mounting the wafer W within the chamber 11; an upper electrode plate 30a facing the susceptor 12 with a processing space S; a high frequency power supply 20 for applying a high frequency power to one of the susceptor 12 and the upper electrode plate 30a to generate plasma within the processing space S; and an inner wall member facing the processing space S. Hollow cathodes 31a to 31c are formed at the upper electrode plate 30a connected with a DC power supply 37 for adjusting a sheath voltage.

Owner:TOKYO ELECTRON LTD

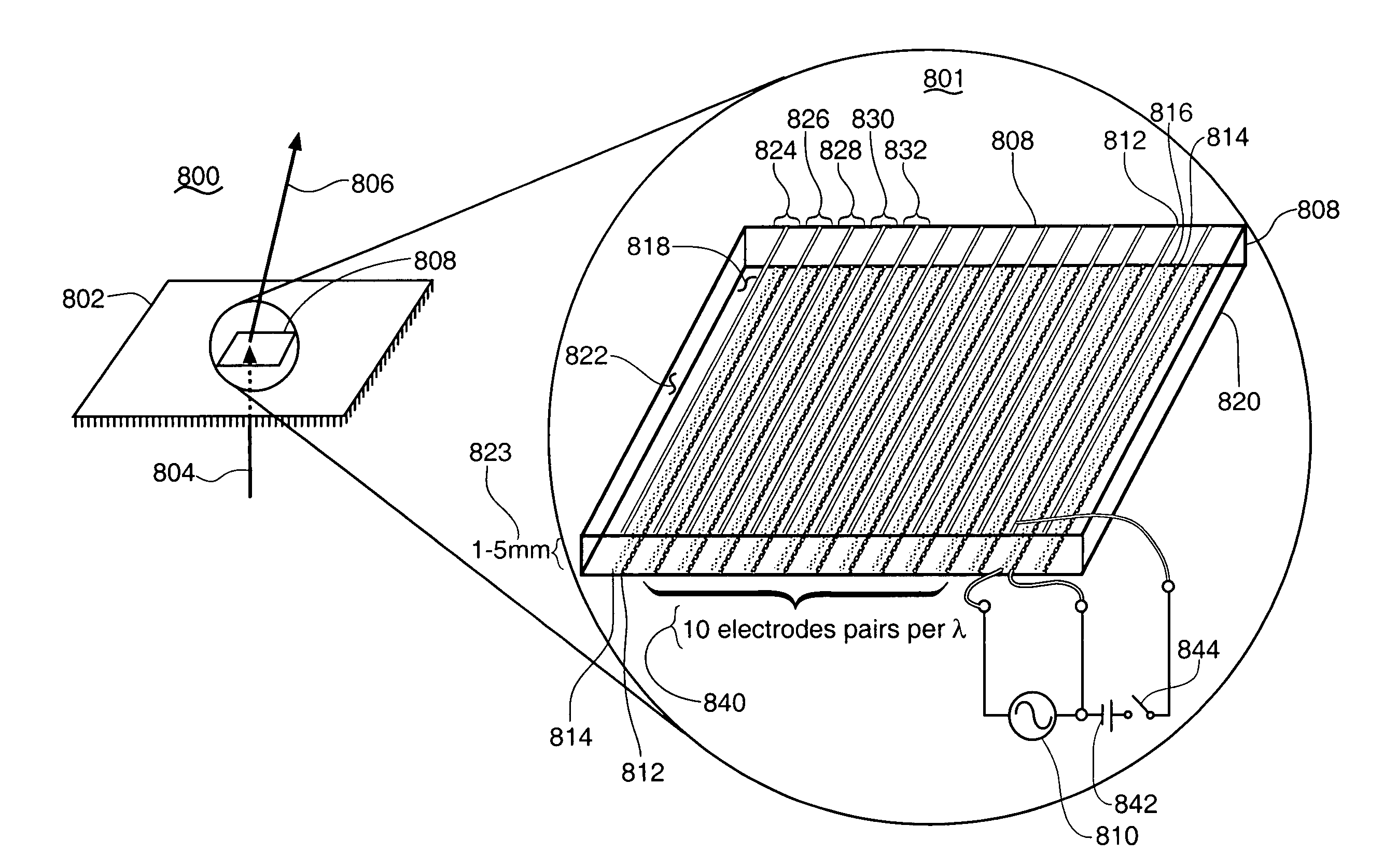

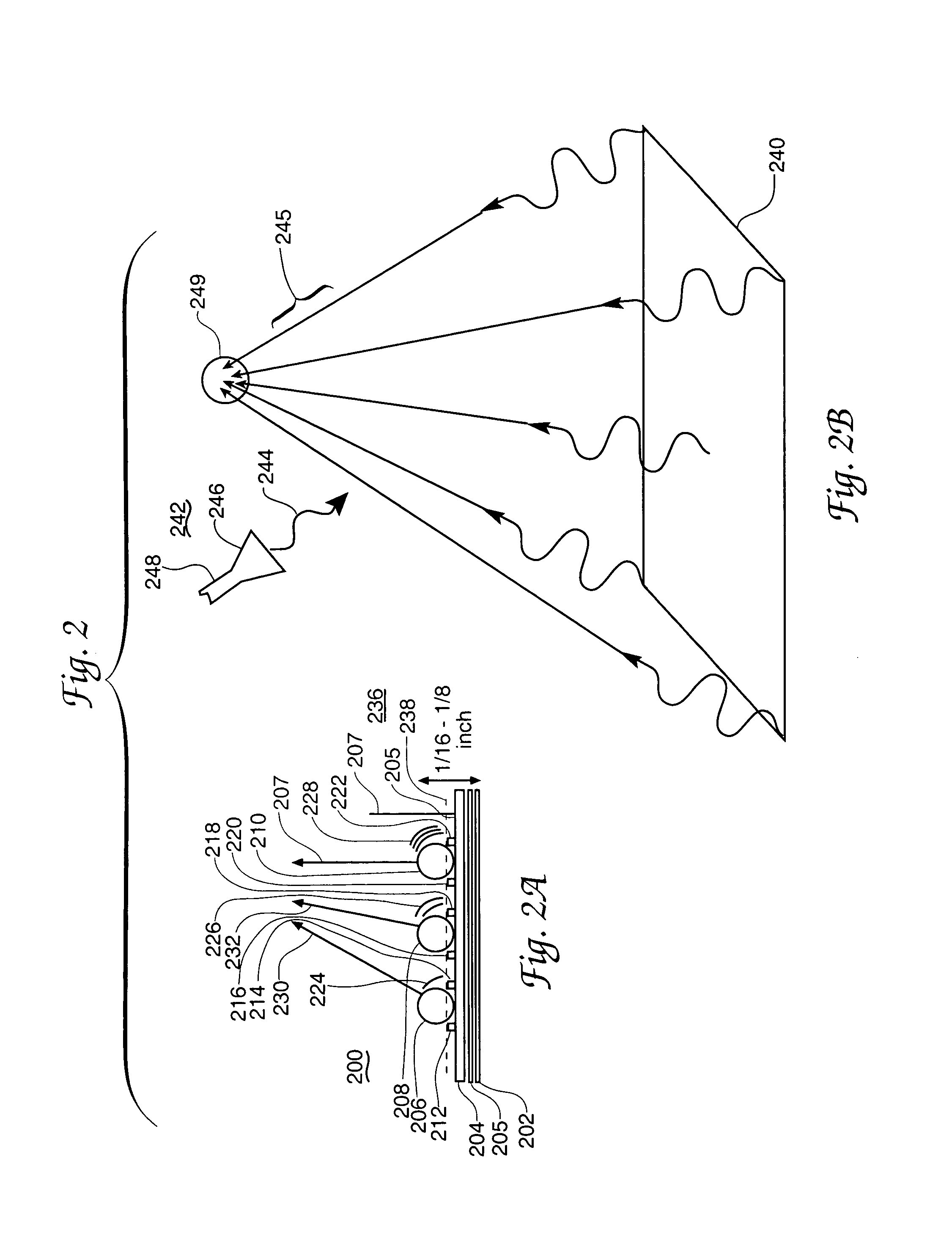

Transmissive dynamic plasma steering apparatus for radiant electromagnetic energy

An ionized plasma based radiant electromagnetic energy steering or diverting apparatus wherein controlled differences in plasma density and resulting plasma electron density achieve phase shift, reflection or refraction of the controlled radiant electromagnetic energy. Plasma density determination through use of selected plasma control electrode electrical potentials and hence by the waveforms applied to plasma-adjacent electrodes is employed. Plasma controlled radiant electromagnetic energy is thereby usable for inertia free steering of a radar beam or for other applications of radiant electromagnetic energy. Radiant electromagnetic energy control by way of pass-through refraction of the energy and reflection of the energy directly from the plasma and also by reflection involving a reflector element are included. Radio frequency and optical electromagnetic energy wavelengths for the radiant electromagnetic energy are included.

Owner:AIR FORCE THE US SEC THE

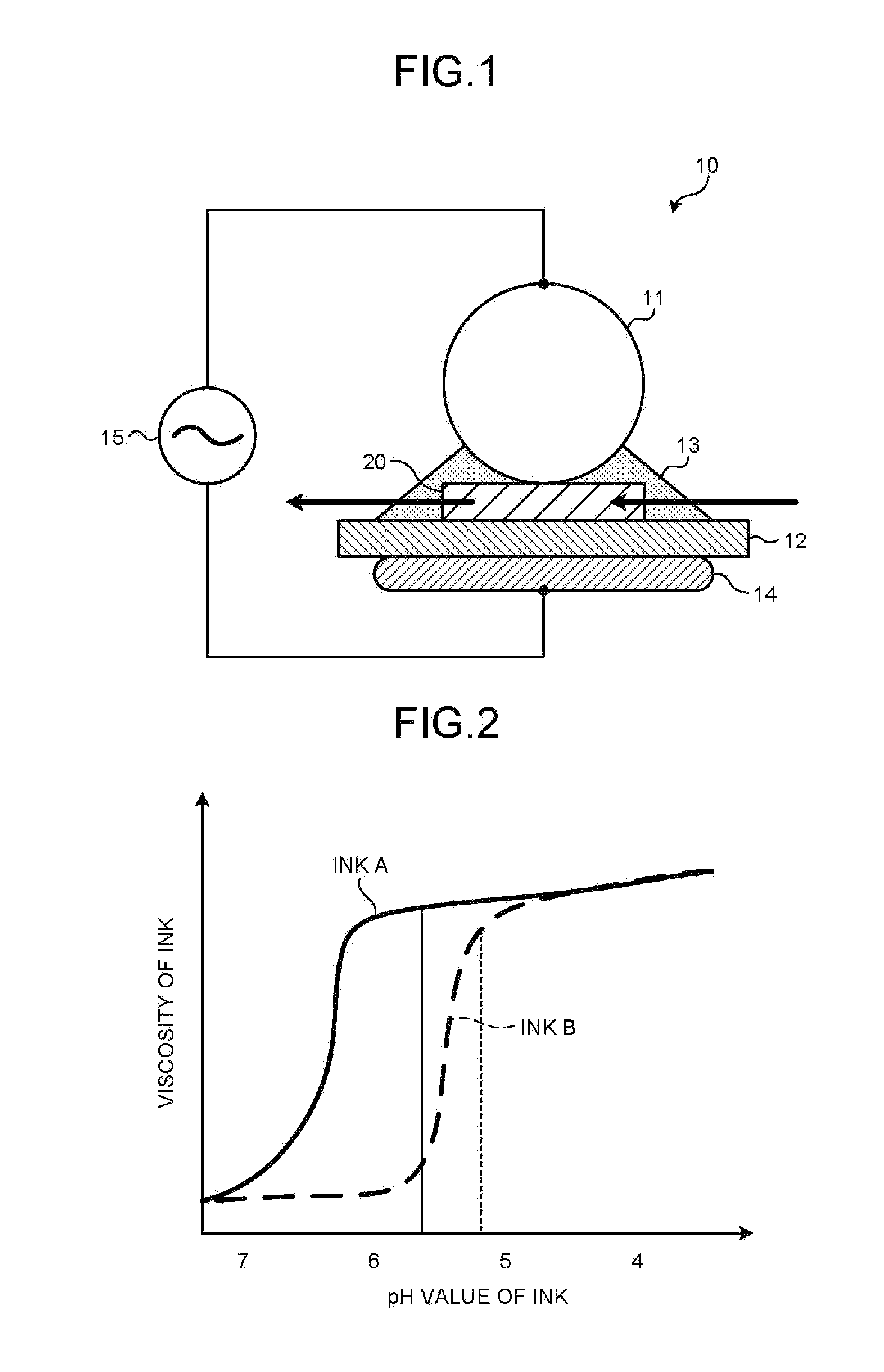

Printing apparatus, printing system, and printed material manufacturing method

ActiveUS20160009107A1Solve problemsDuplicating/marking methodsOther printing apparatusTarget surfaceSurface roughness

A printing apparatus includes: a plasma processing unit that performs plasma processing on a processing target surface side of a processing object; a recording unit that ejects ink on the processing target surface side of the processing object; an acquiring unit that acquires setting information, in which an adjustment target area for adjusting surface roughness and surface roughness of the adjustment target area on a surface of an ink layer formed with the ink are set; and a plasma control unit that controls the plasma processing unit to perform plasma processing on a processing area corresponding to the adjustment target area, on the processing target surface side of the processing object, with an amount of plasma energy for obtaining the set surface roughness on the surface of the ink layer formed on the processing area.

Owner:RICOH KK

Plasma control using dual cathode frequency mixing

InactiveUS20090142859A1Semiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringPolymer

Methods for processing a substrate in a processing chamber using dual RF frequencies are provided herein. In some embodiments, a method of processing a substrate includes forming a plasma of a polymer forming chemistry to etch a feature into a substrate disposed on a substrate support in a process chamber while depositing a polymer on at least portions of the feature being etched. A low frequency and a high frequency RF signal are applied to an electrode disposed in the substrate support. The method further includes controlling the level of polymer formation on the substrate, wherein controlling the level of polymer formation comprises adjusting a power ratio of the high frequency to the low frequency RF signal.

Owner:APPLIED MATERIALS INC

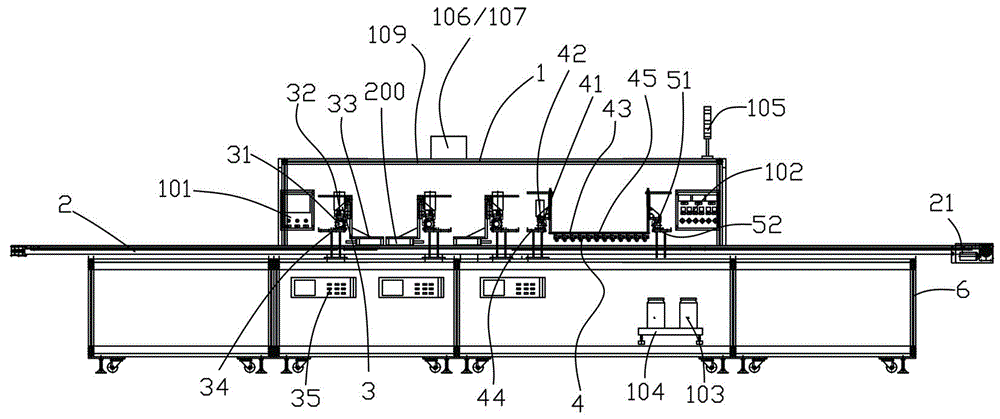

Anti-fingerprint spray coating method and equipment

The invention relates to an anti-fingerprint spray coating method and equipment. The equipment comprises a case, a plasma cleaning linear module and a spray gun linear module, wherein the case is arranged on a material conveying mechanism, the case is provided with a feed inlet and a discharge outlet, and the plasma cleaning linear module and the spray gun linear module are arranged in the case; the plasma cleaning linear module comprises a first guide rail arranged above the conveying trajectory of the material conveying mechanism, a first sliding block, a first motor and a plasma cleaning head connected with a plasma controller, wherein the plasma cleaning head is connected with the first sliding block; the spray gun linear module comprises a second guide rail arranged above the conveying trajectory, a second sliding block, a second motor and a coating feed device connected with a spray coating liquid storage device through a connecting pipe, wherein the coating feed device is provided with a spray gun head and the is connected with the second sliding block. The anti-fingerprint spray coating method and equipment have the advantages that the structure is simple, the production cost is low, the production efficiency is high, the cleaning is thorough, the quality of the produced product is high, the spray coating is uniform, the method and equipment can be widely popularized and the like.

Owner:SHENZHEN SHUNANHENG TECH DEV

Plasma generator, plasma control method, and method of producing substrate

ActiveUS7785441B2Intensively supply energyHigh densityElectric discharge tubesVacuum evaporation coatingHigh densityElectrical conductor

Owner:JAPAN SCI & TECH CORP +3

Plasma generation device, plasma control method, and substrate manufacturing method

ActiveCN1726745APressurized chemical processVacuum evaporation coatingHigh densityElectrical conductor

There is provided a plasma generation device capable of generating spatially uniform and high-density plasma This is achieved as follows. A plurality of antennas (16) are provided on the side wall of a vacuum vessel (11) and one high-frequency power source is connected for three to four antennas (16) in parallel via a plate-shaped conductor (19). The conductor of each antenna (16) has a length smaller than 1 / 4 of the wavelength of the induction electromagnetic wave generated in the vacuum vessel. By defining the length of the antenna conductor in this way, it is possible to prevent generation of a standing wave and prevent deterioration of uniformity of plasma in the vacuum vessel. Moreover, by using the plate-shaped conductor (19), it is possible to effectively release heat, thereby suppressing increase of the impedance.

Owner:JAPAN SCI & TECH CORP +2

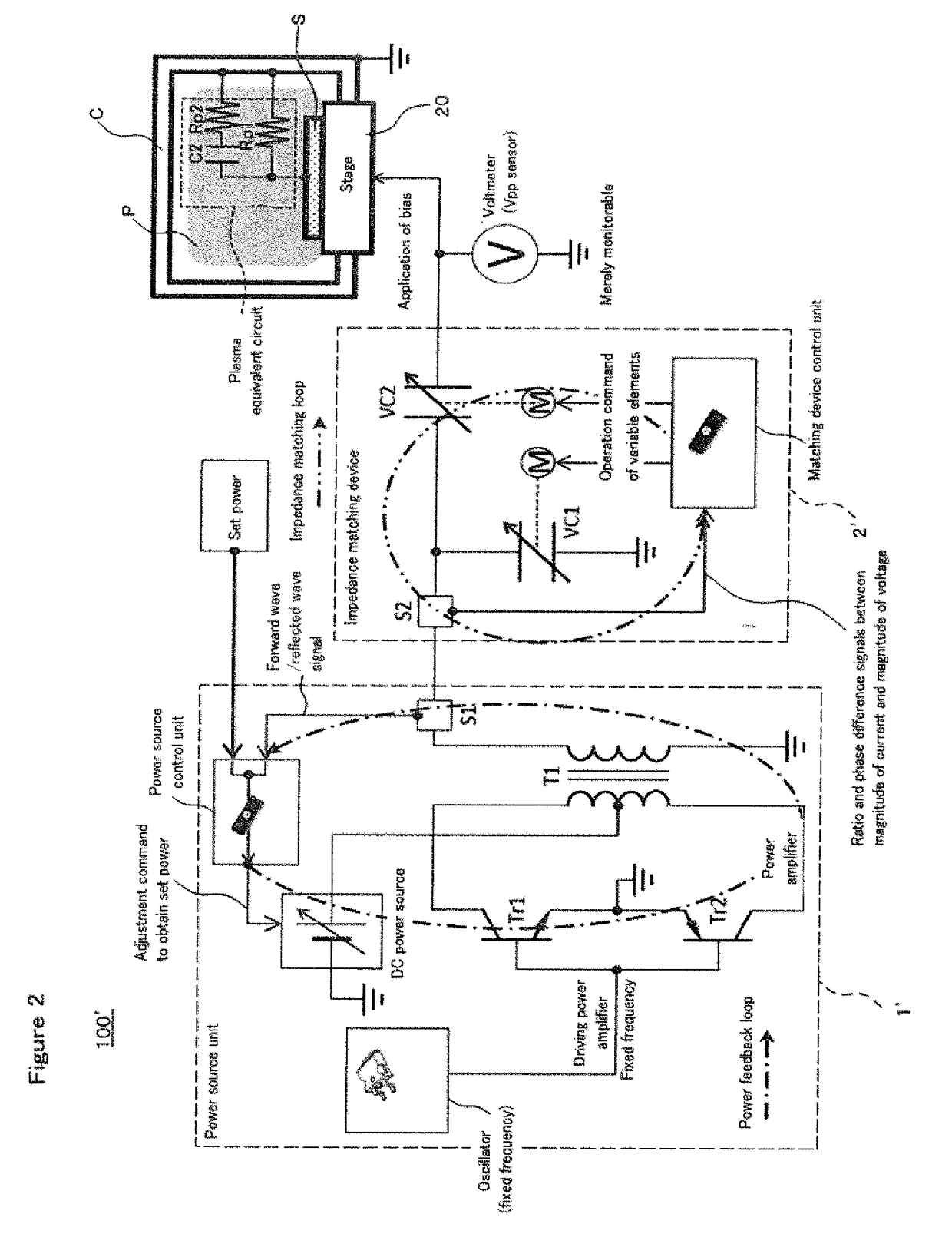

Plasma control apparatus

ActiveUS20180315581A1High-speed impedance matchingImprove accuracyMultiple-port networksElectric discharge tubesCapacitanceResonance

A plasma control apparatus includes a power source unit, a resonance producing unit, and a voltmeter. The resonance producing unit includes an LC circuit formed by a coil L1 and a capacitor C1 connected to each other, and a sensor S2 configured to detect a phase difference between current flowing in and voltage applied to the LC circuit, and the capacitor C1 of the LC circuit has a capacitance larger than an expected capacitance of the plasma P. The power source unit 1 configured to control the magnitude of radio-frequency power to be supplied in such a manner as to bring the voltage measured with the voltmeter 5 close to a set voltage as a target, and controls the frequency of the radio-frequency power to be supplied in such a manner as to minimize the phase difference detected with the sensor S2.

Owner:SUMITOMO PRECISION PROD CO LTD

Plasma processing apparatus

InactiveUS7972469B2Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringUltimate tensile strength

Embodiments of the present invention relate to plasma processing apparatus and methods of use thereof. In some embodiments, a plasma control magnet assembly includes a plurality of magnets arranged in a predetermined pattern that generate a magnetic field having a strength greater than 10 Gauss in a region proximate the assembly and less than 10 Gauss in a region remote from the assembly.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com