Low-climbing high-dyne-value polyurethane protective film and preparation method thereof

A technology of polyurethane and protective film, which is applied in the direction of polyurea/polyurethane adhesive, film/sheet release liner, film/sheet adhesive, etc. It can solve problems that have not yet been seen, and achieve good surface tension, Oxidation and scratch prevention, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

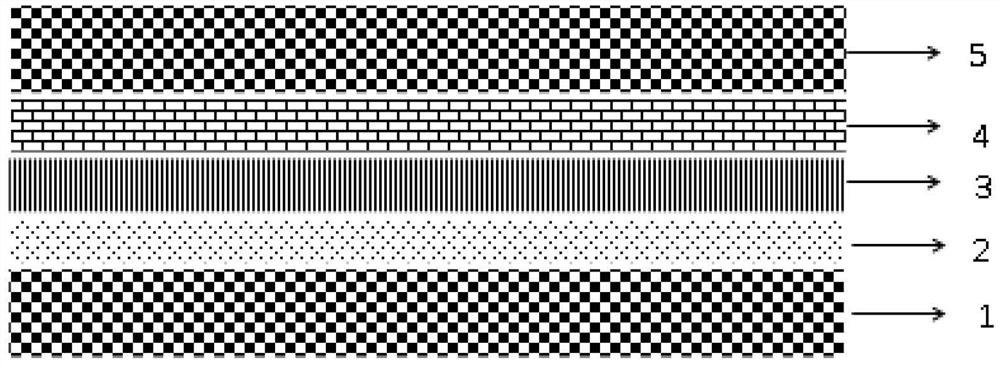

[0048] Embodiment 1: see accompanying drawing.

[0049] A method for preparing a low-climb high factor polyurethane protective film, the steps are:

[0050] a. Prepare polyurethane adhesive (or polyurethane adhesive resin composition):

[0051] At room temperature, put 50 parts by mass of polyurethane prepolymer, 5 parts by mass of isocyanate curing agent [methyl diisocyanate (TDI for short)], 3 parts by mass of heat-resistant hardener (Shanghai Nagase Trading Co., Ltd. Lion King) whose brand name is CROSSLINKING AGENT N temperature-resistant hardener), 1 mass part of retarder (BPU retarder of Nanjing Box New Material Co., Ltd.), 70 mass parts of organic solvent (ethyl acetate), mix well (form System uniform solution), that is, the polyurethane adhesive is prepared; the viscosity of the polyurethane adhesive is (25°C) 230cps;

[0052] b. Preparation of low-climb high-value polyurethane protective film:

[0053] Take the PET film, coat (or call it coating) a layer of primer ...

Embodiment 2

[0057] Embodiment 2: see accompanying drawing.

[0058] A method for preparing a low-climb high factor polyurethane protective film, the steps are:

[0059] a. Prepare polyurethane adhesive (or polyurethane adhesive resin composition):

[0060] At room temperature, put 55 parts by mass of polyurethane prepolymer, 7 parts by mass of isocyanate curing agent [isophorone diisocyanate (IPDI for short)], 2 parts by mass of heat-resistant hardener (Shanghai Nagase Trading Co., Ltd. ( That is, the temperature-resistant hardener whose brand name is CROSSLINKING AGENT N), 1 part by mass retarder (BT-180 retarder from Nanjing Box New Material Co., Ltd.), 80 parts by mass organic solvent (ethyl acetate), Mix evenly (to form a uniform solution of the system), and the polyurethane adhesive is obtained; the viscosity of the obtained polyurethane adhesive is (25°C) 245cps;

[0061] b. Preparation of low-climb high-value polyurethane protective film:

[0062] Take a PET film, apply a layer ...

Embodiment 3

[0066] Embodiment 3: see accompanying drawing.

[0067] A method for preparing a low-climb high factor polyurethane protective film, the steps are:

[0068] a. Prepare polyurethane adhesive (or polyurethane adhesive resin composition):

[0069]At room temperature, put 70 parts by mass of polyurethane prepolymer, 8 parts by mass of isocyanate curing agent [diphenylmethane diisocyanate (MDI for short)], 6 parts by mass of heat-resistant hardener (Zhongshan Heli Chemical Co., Ltd. 3053 temperature-resistant hardener), 3 parts by mass of retarder (Zhengzhou Yuhe Chemical Products Co., Ltd. or Shanghai Yuanji Chemical Co., Ltd. acetylacetone), 80 parts by mass of organic solvent (ethyl acetate), mix well (formation system uniform solution), that is, the polyurethane adhesive is prepared; the viscosity of the polyurethane adhesive is (25°C) 391cps;

[0070] b. Preparation of low-climb high-value polyurethane protective film:

[0071] Take a PET film, apply a layer of primer solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com