Lithium battery packaging film and preparation method thereof

A lithium battery and packaging film technology, which is applied in the field of lithium battery packaging film and its preparation, can solve the problems of increasing plasma cleaning stations, increasing plasma cleaning processes, and affecting production line efficiency, so as to avoid plasma cleaning stations and save Plasma cleaning process, the effect of improving production line efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

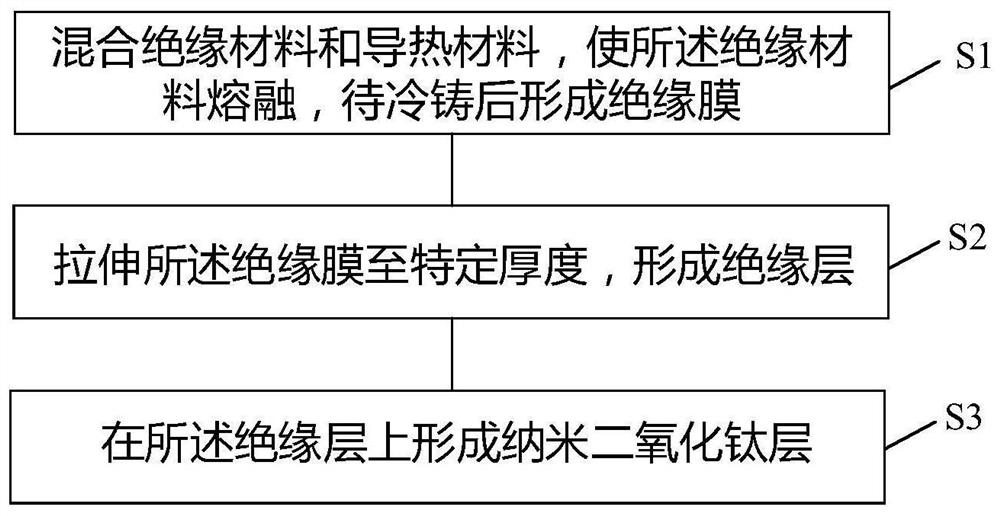

Method used

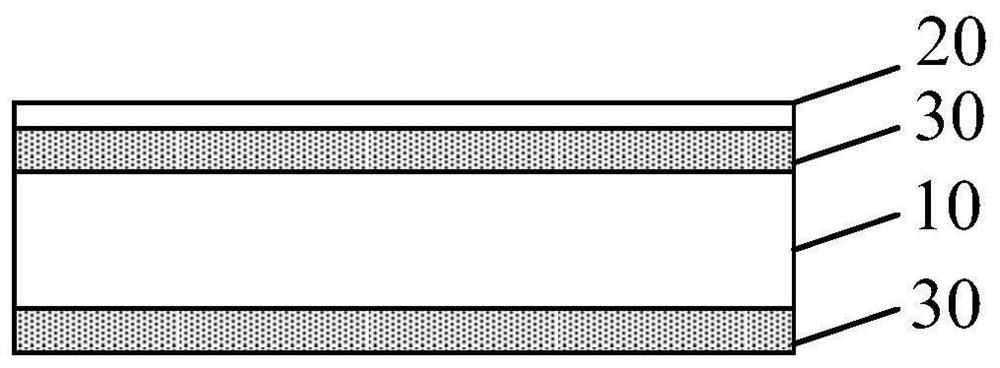

Image

Examples

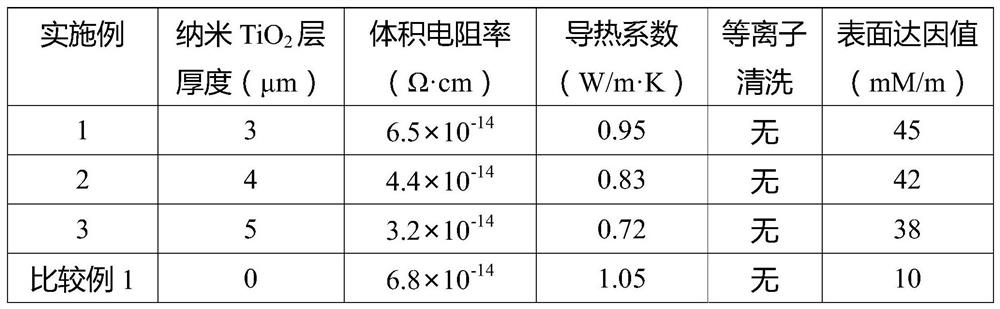

Embodiment 1

[0054] Step S1: Add the dried PET chip or PET base material (95% by mass fraction) and boron nitride particles (5% by mass fraction) into a high-speed mixer, and mix at high speed for 10 minutes. After premixing, mix the mixed materials again After drying in a blast drying oven for 2 hours, the above mixture is fed to a twin-screw high-speed disperser, and the heating temperature of each zone of the twin-screw is controlled between 200°C and 280°C, and gradually dispersed evenly through the twin-screw high-shear, and then transferred to the casting machine. Quantitative extrusion of the mold, cooling cast film after quantitative casting, to obtain PET film.

[0055] Step S2: After preheating the PET film (Tg<preheating temperature<Tm, 210°C~240°C), perform synchronous or asynchronous stretching in the MD (machine direction) and TD (perpendicular to the machine direction) directions to obtain a thickness of 100 μm PET insulation layer.

[0056] Step S3: heat-setting and coolin...

Embodiment 2

[0059] Different from Example 1, the thickness of the nano titanium dioxide layer in Example 2 is 4 μm.

Embodiment 3

[0061] Different from Example 1, the thickness of the nano titanium dioxide layer in Example 3 is 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com