Staggered wafer surface wet cleaning system and method

A wet cleaning, staggered technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as inability to clean nano-wafers, increase the effective spray radius, improve spray Range, use of flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

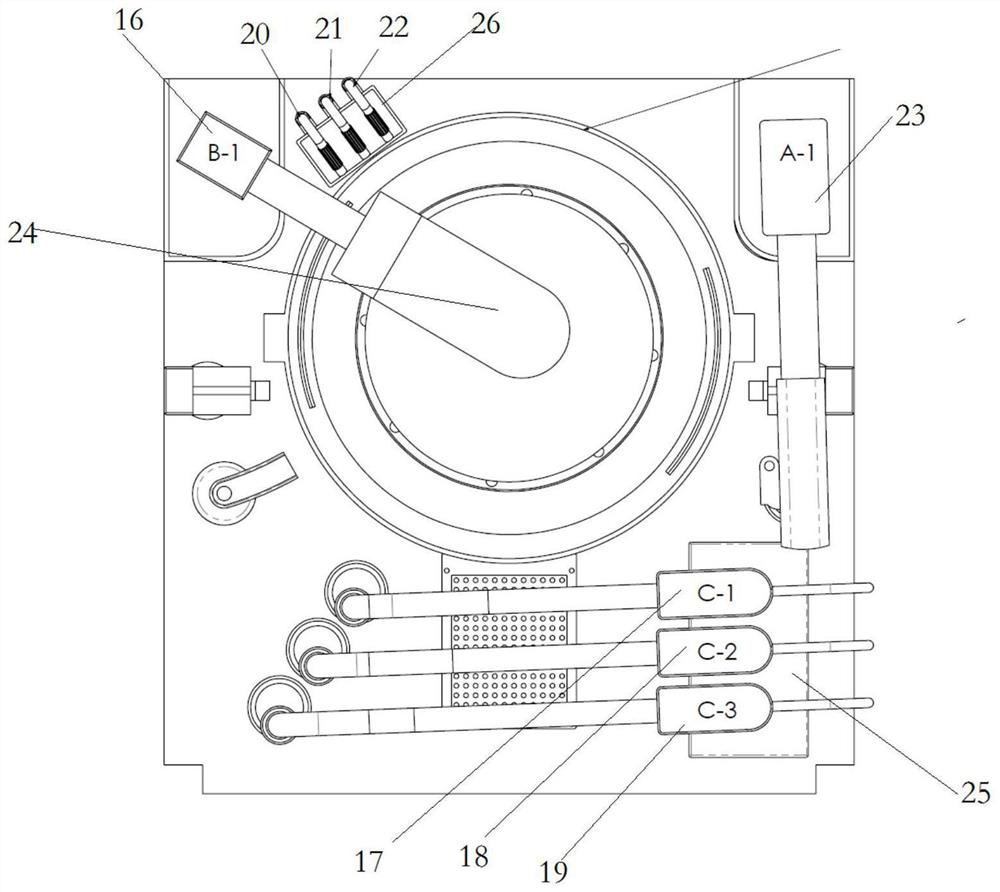

[0051] This embodiment provides a staggered wafer surface wet cleaning system, which is characterized in that it includes a wafer carrying mechanism and a wafer cleaning mechanism, the wafer carrying mechanism is used to place wafers, and the wafers are fixed Rotate on the surface of the wafer carrying mechanism and driven by the wafer carrying mechanism; the wafer cleaning mechanism includes a first cleaning mechanism 23, a second cleaning mechanism 24, a third cleaning mechanism 25 and a fourth cleaning mechanism 26, so The first cleaning mechanism 23 , the second cleaning mechanism 24 , the third cleaning mechanism 25 , and the fourth cleaning mechanism 26 are all arranged outside the wafer carrying mechanism for cleaning the surface of the wafer.

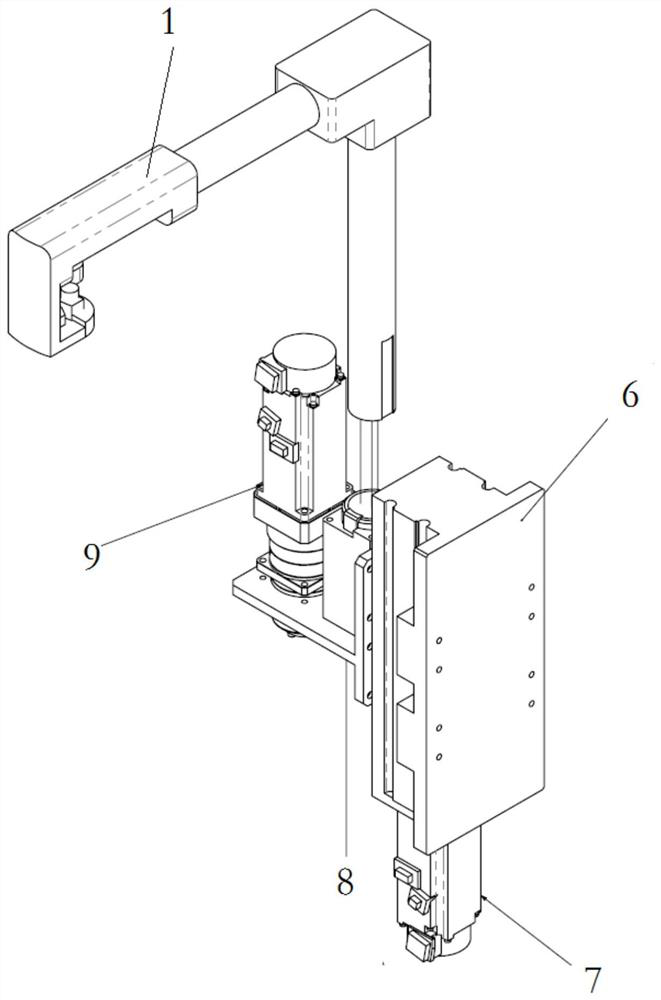

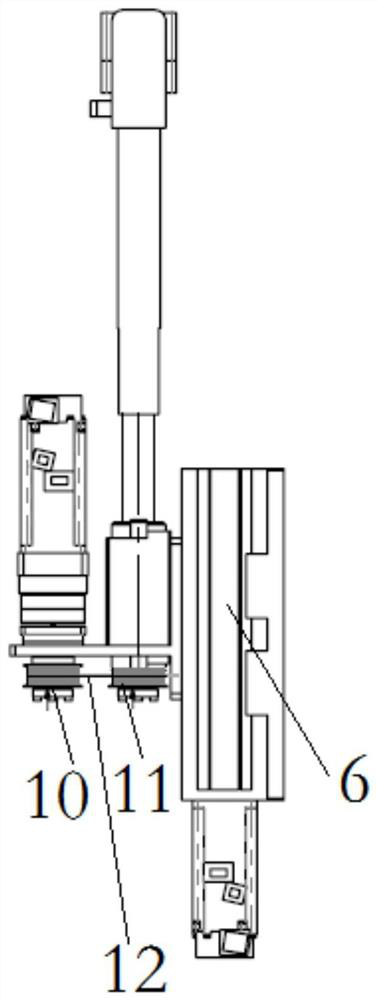

[0052] The first cleaning mechanism 23 includes a driving mechanism, a cleaning housing 1, a liquid cleaning nozzle 3, an atomized cleaning nozzle 2, a nitrogen gas nozzle 4, and an ultrasonic vibrating plate 5. One end of the cl...

Embodiment 2

[0061] This embodiment provides a method for staggered wafer surface wet cleaning, comprising the following steps:

[0062] Step 1, the third cleaning mechanism 25 moves to the top of the wafer, the wafer carrying mechanism drives the wafer to rotate, the third cleaning mechanism 25 sprays hydrofluoric acid solution on the surface of the wafer, after the cleaning is completed, the third The cleaning mechanism 25 drives the third cleaning mechanism 25 away from the wafer;

[0063] Step 2, the fourth cleaning mechanism 26 sprays ultrapure water on the surface of the wafer, and the wafer carrying mechanism stops rotating after the spraying is completed;

[0064] Step 3, the wafer carrying mechanism drives the wafer to rotate at a high speed for 5-10 seconds and then stops to complete the drying of the wafer;

[0065] Step 4, the wafer carrying mechanism drives the wafer to rotate, the fourth cleaning mechanism 26 sprays nitrogen to the surface of the wafer, and the wafer carryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com