Working structure of eight-planet brush

A brush and planet technology, applied in the field of eight-planet brush working structure, can solve the problems of long cleaning time, low cleaning efficiency, general cleaning quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

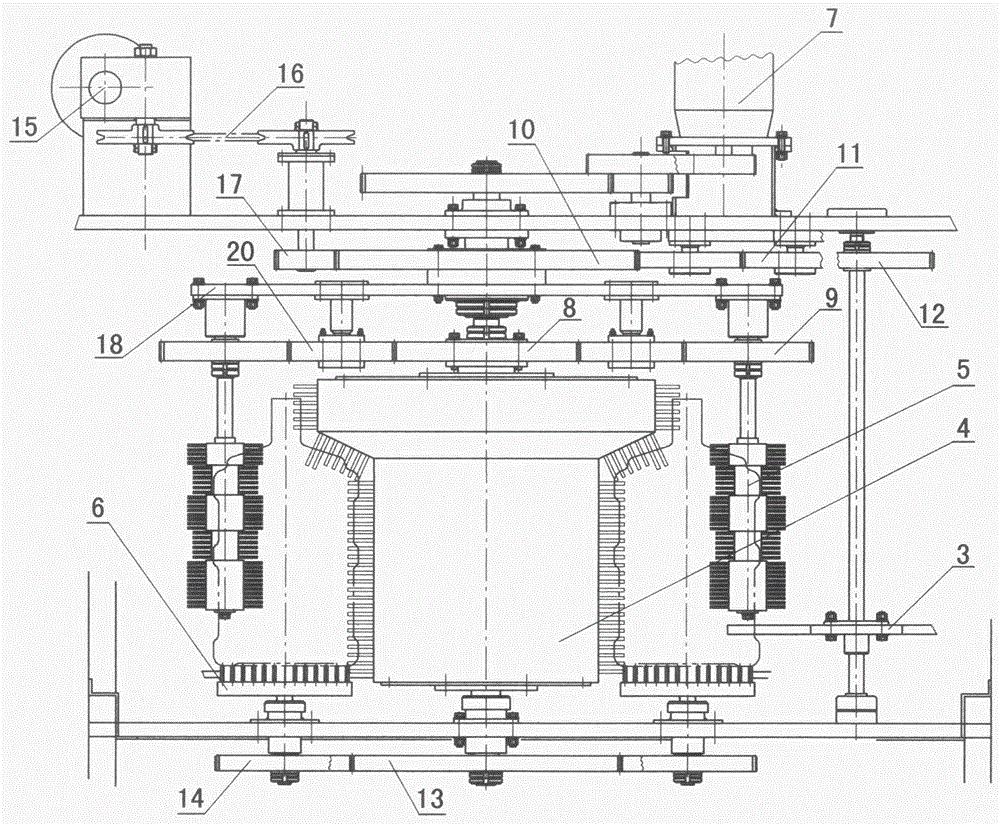

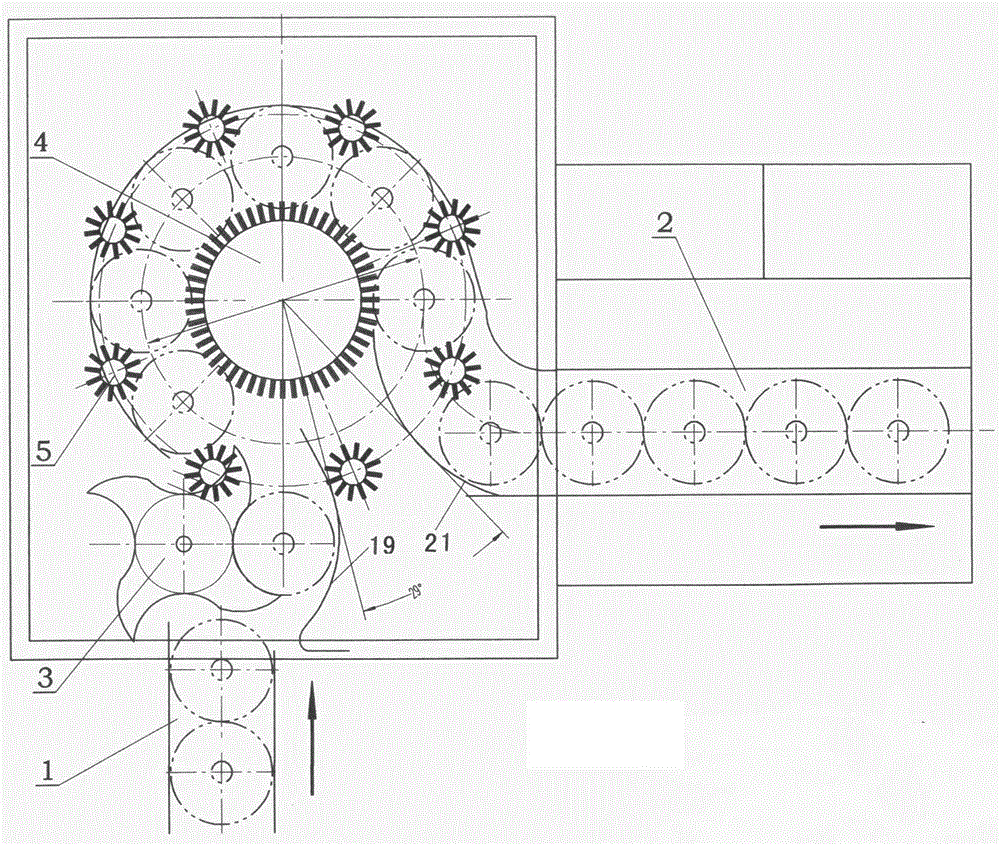

[0012] The eight-planet hairbrush working structure described in embodiment 1 of the present invention, as figure 1 , figure 2 As shown, it is connected between the bottle-in conveyor belt 1 and the bottle-out conveyor belt 2. The working structure of the eight-planetary brush includes: a bottle dial arranged at the end of the bottle-in conveyor belt 1 to dial the bottle to be washed into the cleaning process of the outer wall of the bottle The feeding wheel 3 and the bottle feeding guide plate 19, the bottle dialing wheel 3 rotates clockwise at the first rotation; the travel trajectory of the bottle in the bottle outer wall cleaning line is a circle, and the actual travel of the bottle from entering the trajectory to exiting the trajectory occupies the 360 degrees 331 degrees in a circular trajectory. Bottle walks out this locus place and is provided with the bottle-out guide plate 21 that guides bottle to go out of circular locus. The central hairbrush 4 that rotates in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com