Hard coating film with high dyne value

A technology of hardened film and hardened layer, which is applied in the direction of coating, pretreatment surface, and device for coating liquid on the surface, etc. It can solve the problems of poor printing and coating effects, difficult to use requirements of downstream customers, and easy peeling off of coatings, etc. , to achieve good printing performance, high hardness, and improve the effect of surface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

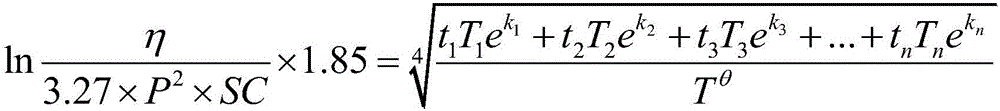

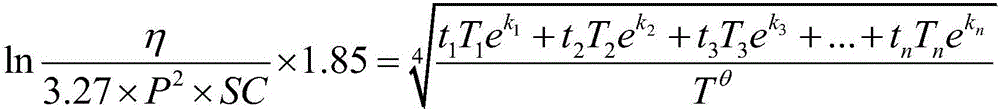

Method used

Image

Examples

Embodiment 1

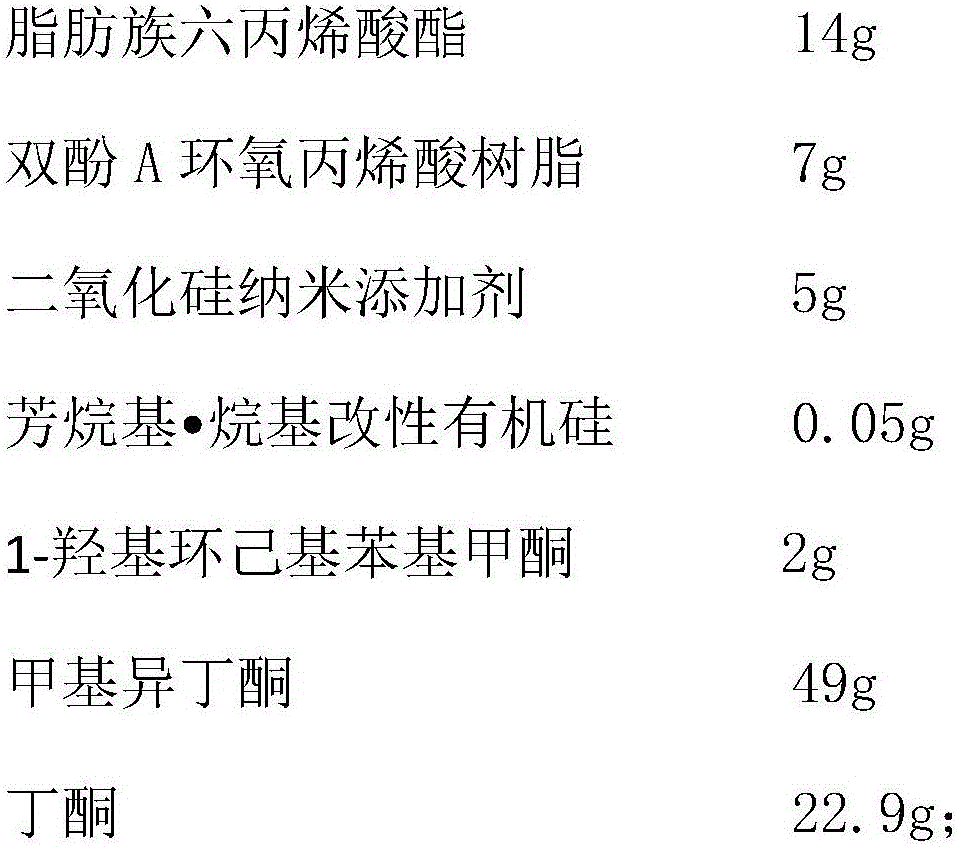

[0031] The components and parts by weight of the cured film coating solution are:

[0032]

[0033] Add 7 g of bisphenol A epoxy acrylic resin [manufactured by Taiwan Double Bond Chemical Co., Ltd., trade name: 127-TP20] in 14 g of aliphatic hexaacrylate resin [manufactured by Taiwan Double Bond Chemical Co., Ltd., trade name: 571] , after stirring evenly, add 5g of silica nano-additive [manufactured by BYK, trade name: NANOBYK-3651], stir again and add 0.05g of surface additive aralkyl·alkyl modified silicone [manufactured by BYK , trade name: BYK-322], 2g photoinitiator 1-hydroxycyclohexyl phenyl ketone [manufacture of Taiwan Double Bond Chemical Co., Ltd., trade name: Doublecure 184], after stirring, add 49g methyl isobutyl ketone and Diluted with 22.9 g of methyl ethyl ketone, stirred thoroughly and left to stand for 1-2 hours to obtain the hardened layer coating solution.

[0034] The coating solution for the hardening layer was coated on both sides of a PET support, ...

Embodiment 2

[0040] The components and parts by weight of the cured film coating solution are:

[0041]

[0042]Add 3g of epoxy acrylate [manufactured by Sartomer Asia Co., Ltd., trade name: CN104NS] in 12g of solvent-modified urethane acrylate resin [manufactured by Taiwan Changxing Chemical Industry Co., Ltd., trade name: DR-U092], and stir evenly Then add 2g of silicon dioxide nano-additive [manufactured by BYK, trade name: NANOBYK-3651], stir again and add 3g of surface additive polyether modified silicone [manufactured by BYK, trade name: BYK-325] , 7.0g photoinitiator 1-hydroxycyclohexyl phenyl ketone [manufacture of Taiwan Double Bond Chemical Co., Ltd., trade name: Doublecure 184], add 48.5g methyl isobutyl ketone and 31.5g propylene glycol monomethyl ether after stirring After diluting and fully stirring, let it stand for 1-2 hours to obtain the hardened layer coating solution.

[0043] The coating solution for the hardening layer was coated on both sides of a PET support body...

Embodiment 3

[0049] The components and parts by weight of the cured film coating solution are:

[0050]

[0051] Add 9 g of zinc oxide nano-additives [manufactured by BYK Chemicals, trade name: NANOBYK-3860] to 30 g of polyurethane acrylate resin [manufactured by Sartomer Asia Co., Ltd., trade name: CN750], stir evenly and add 1.5 g of surface additives [Hemings Specialty Chemical Co., trade name: Adherant ADK], 7g photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-propanone [manufactured by Taiwan Double Bond Chemical Co., Ltd., trade name: Doublecure 1173], after stirring evenly, add 52.5g of isopropanol for dilution, fully stir and then let it stand for 1-2h to obtain the hardened layer coating solution.

[0052] The coating solution for the hardening layer was coated on both sides of a PET support, the thickness of the PET support was 125 microns, and the control coating thickness was 3.5 microns. After testing, the viscosity of the above-mentioned coating liquid is 3.4mPa.s, the solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com