Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Improve mechanical properties at room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

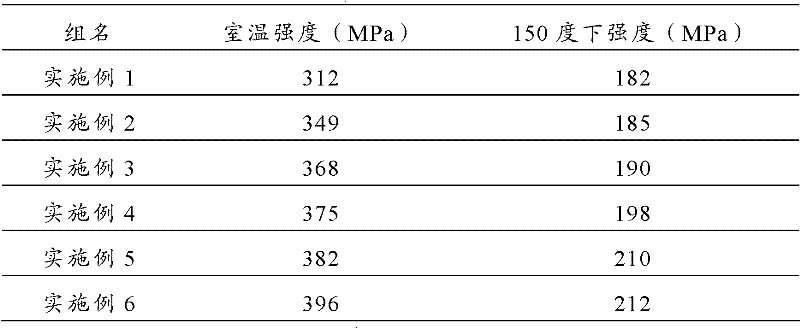

High-strength and heat-resistant magnesium alloy containing two rare earths and preparation method thereof

ActiveCN103820689AImprove mechanical properties at room temperatureStable high temperature mechanical propertiesRare-earth elementSmelting process

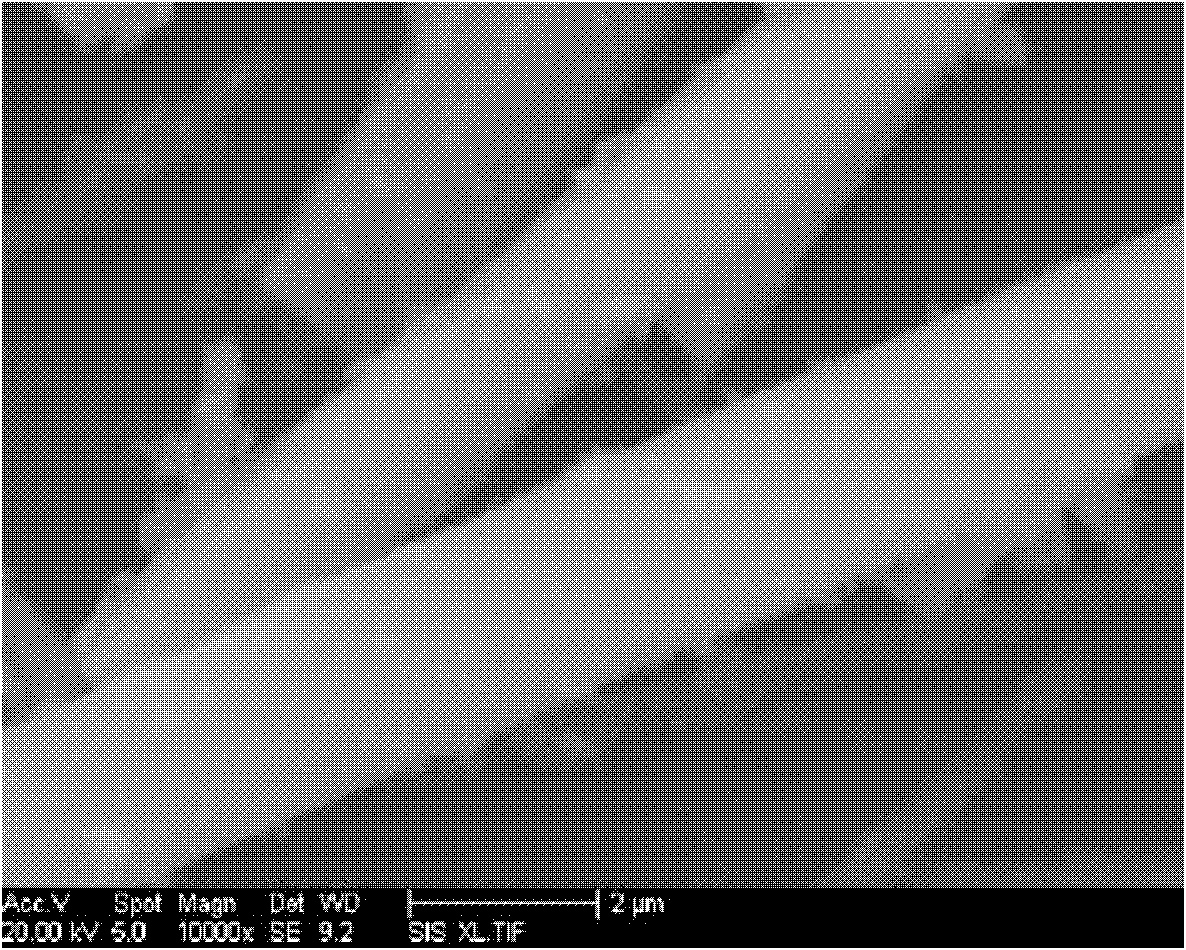

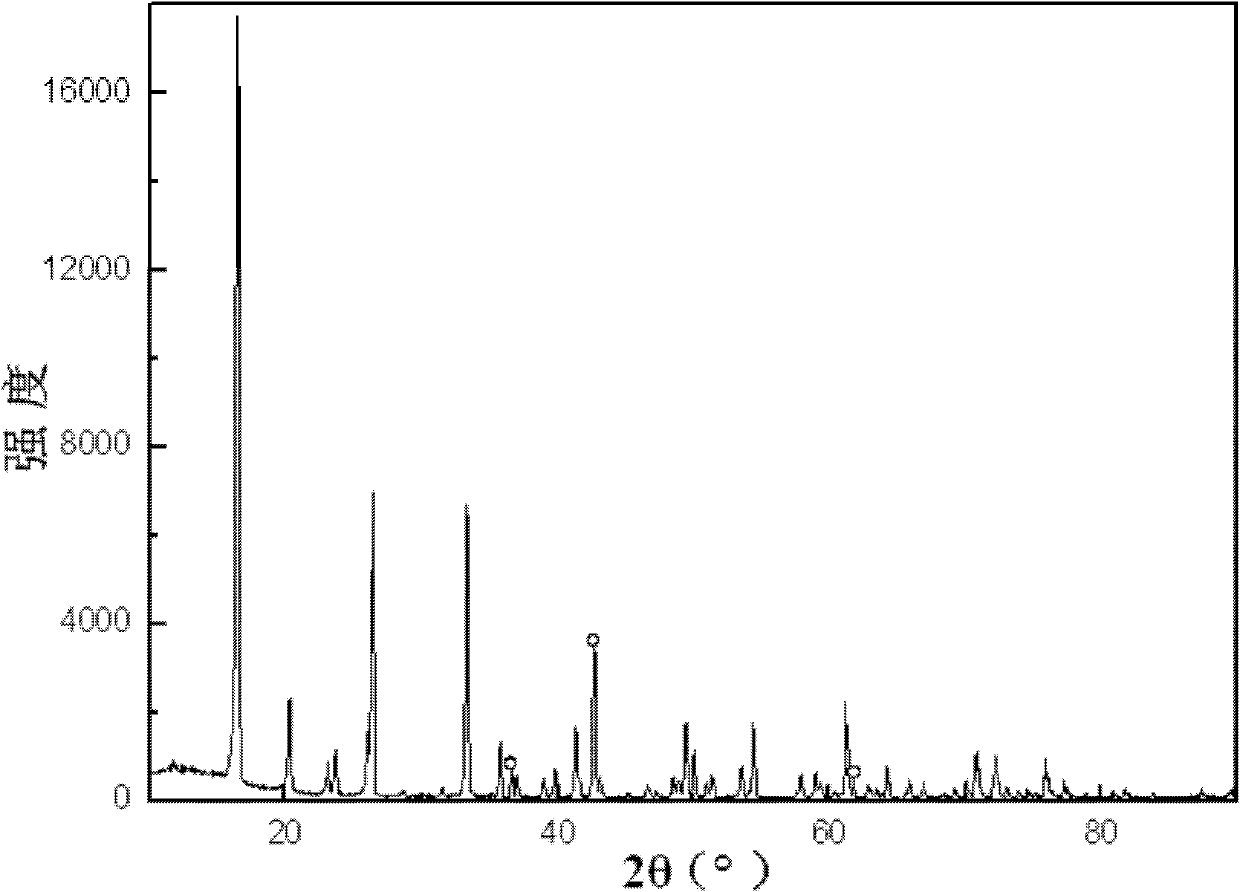

The invention discloses a high-strength and heat-resistant magnesium alloy containing two rare earths. The high-strength and heat-resistant magnesium alloy containing the two rare earths comprises the components as follows: 14.0-17.0wt% of Y rare earth, namely Gd, Y and Er, 0.5-2.5wt% of Ce rare earth, namely one or several of La, Ce, Pr, Nd and Sm, 0.3-1.0wt% of Zr, impurities and the balance of Mg, wherein Gd is 11.0-15.0wt%, Y is 0.5-4.0wt% and Er is 0.5-2.0wt%; the content of Nd and Sm elements is 0.2wt% or less of the total amount of the magnesium alloy, or 0; the impurities including Fe, Si, Mn and a small amount of chloride; Fe is less than or equal to 0.002wt %, Si is less than or equal to 0.04wt%, Mn is less than or equal to 0.02wt%, and chloride is less than or equal to 0.002wt%; the impurity content is more than 0; Er in the Y rare earth can be replaced by one or several of Tb, Dy, Ho, Yb and Tm. The magnesium alloy has relatively high mechanical properties at room temperature and relatively stable high temperature creep resistance, and has relatively high yield rate of rare earth elements in the smelting process.

Owner:GRIMAT ENG INST CO LTD

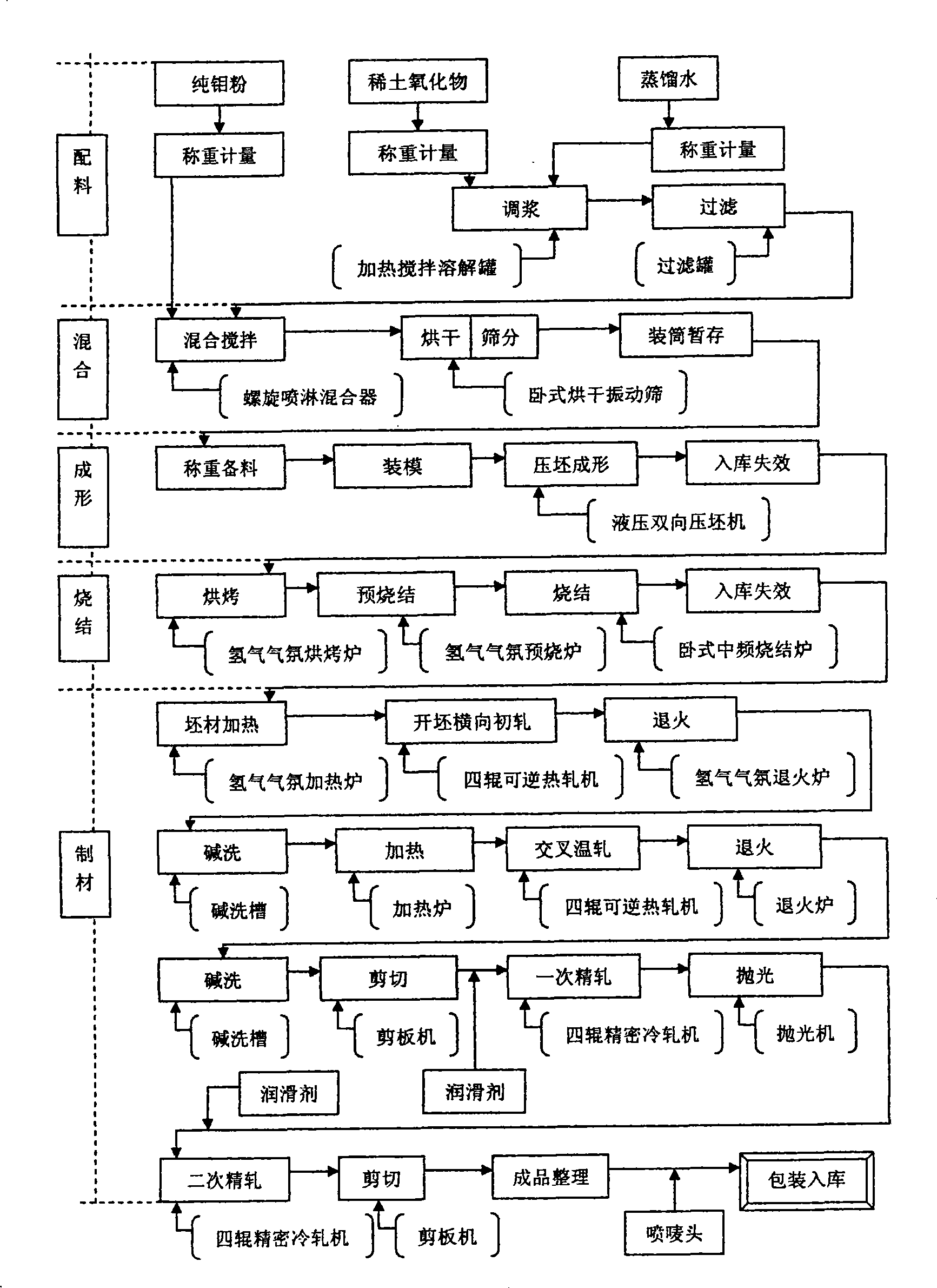

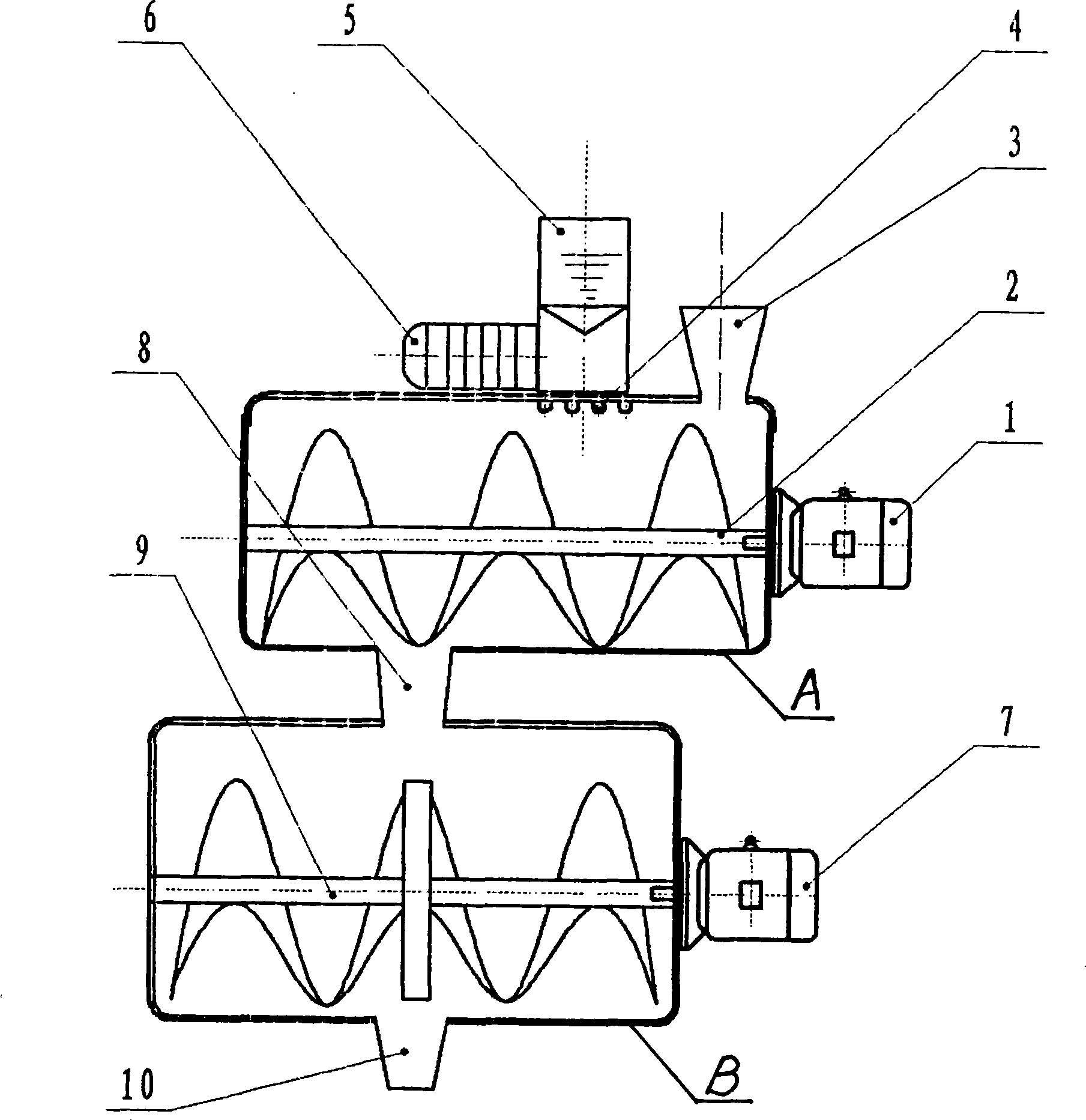

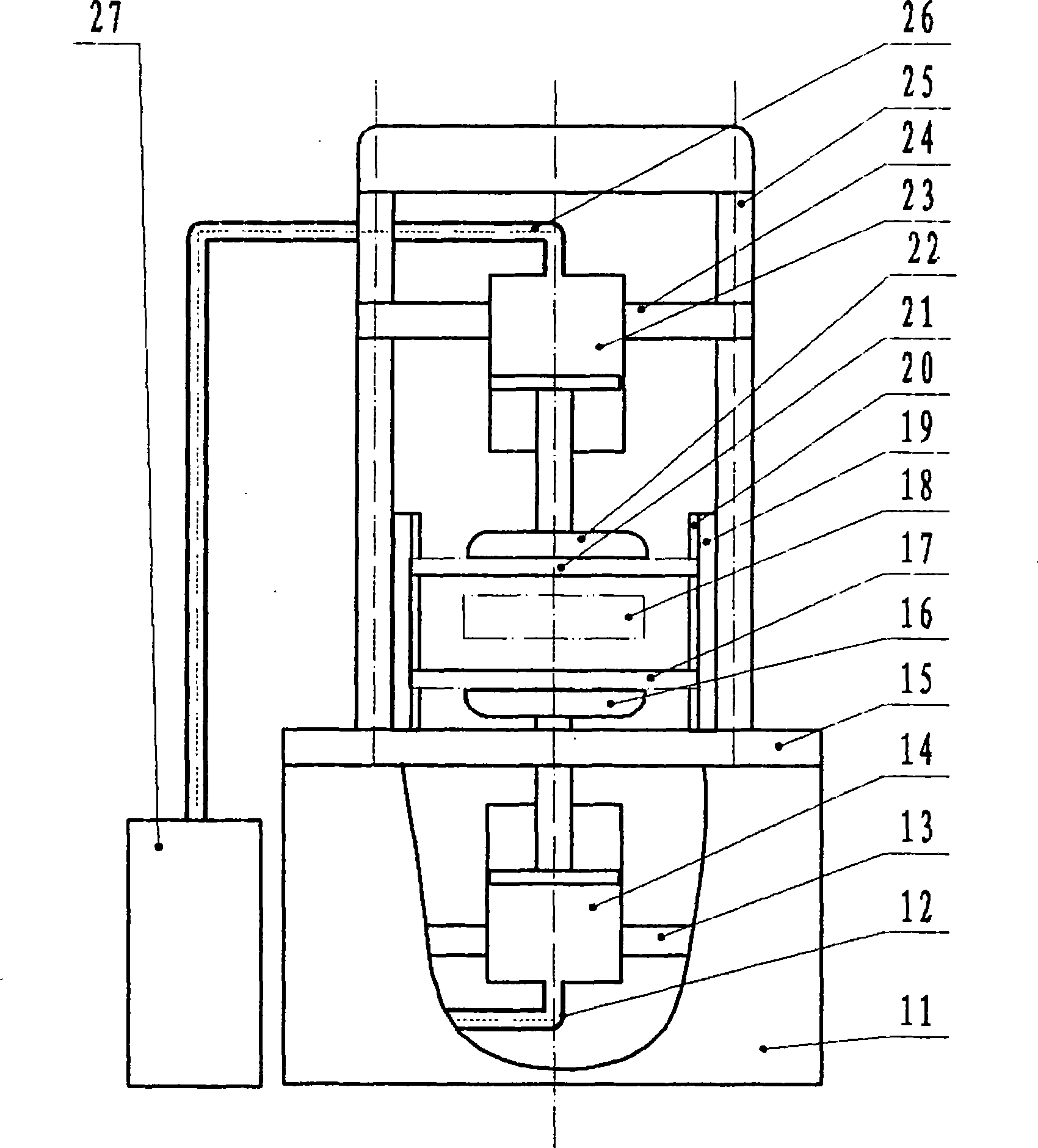

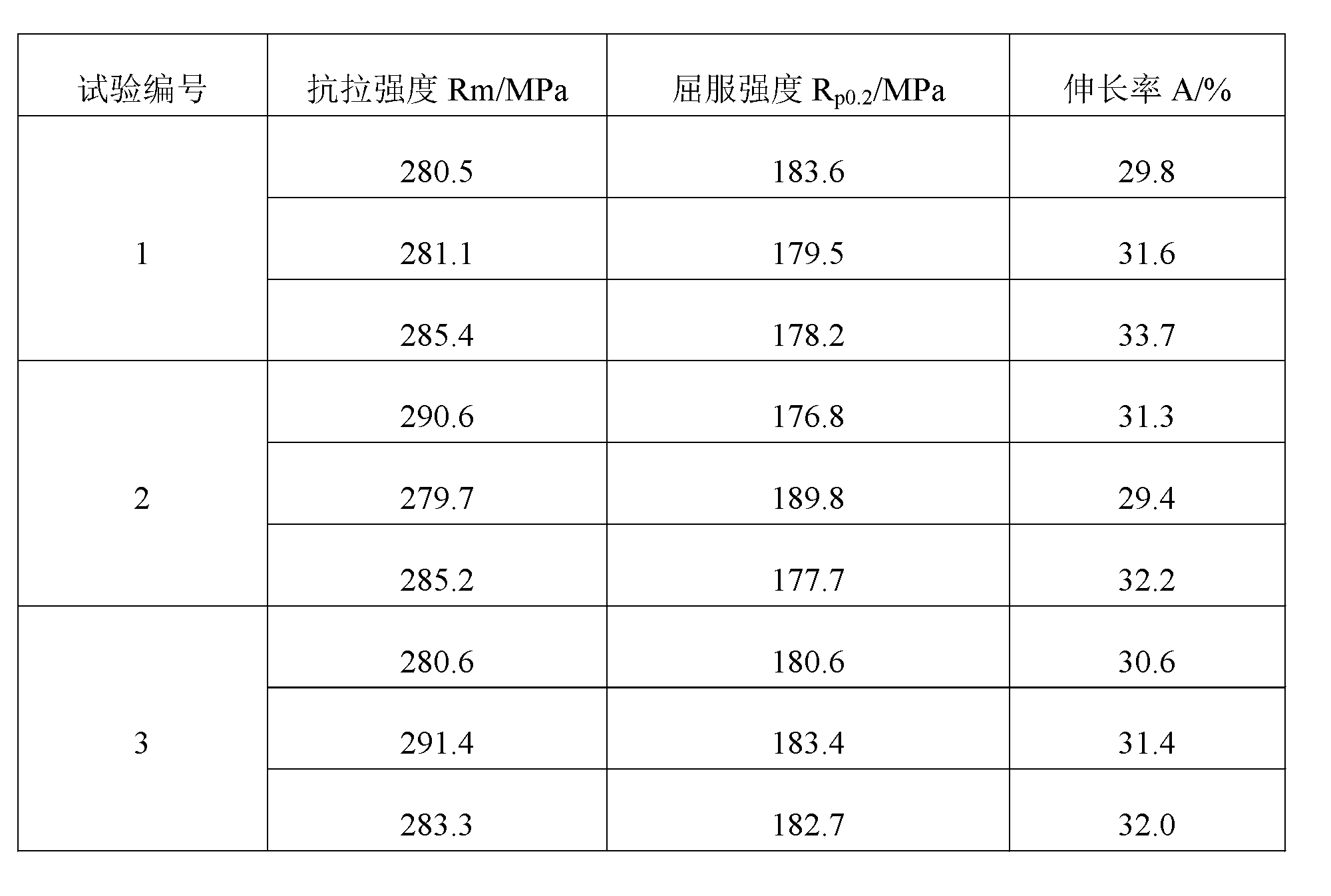

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

Rare earth magnesium-lithium alloy sheet and preparation method thereof

The invention discloses a rare earth magnesium-lithium alloy sheet and a preparation method thereof, belonging to the field of metal processing. The rare earth magnesium-lithium alloy sheet is characterized by comprising the following components in percentage by weight: 11-15% of Li, 0.5-2% of Y, 0.5-2% of Gd, 0.1-1% of Sc, 7-9% of Al and the balance of magnesium. The preparation method comprises the following steps of: melting magnesium and intermediate alloy by using an industrial medium-frequency or line-frequency induction melting furnace, adjusting the furnace temperature for heat preservation treatment, sampling from the furnace and carrying out rapid on-the-spot sample analysis after the heat preservation time is reached, and detecting whether the components are qualified; and hot rolling and cold rolling a pouring and rolling sheet, carrying out T6 treatment, then, making a mechanical sample, and measuring the mechanical property. By using the rare earth magnesium-lithium alloy sheet and the preparation method thereof, the strength of magnesium-lithium alloy is ensured, the plastic deformation capability of the magnesium-lithium alloy is also greatly enhanced, the production difficulty of the deformed magnesium-lithium alloy sheet is lowered, and the production efficiency is increased. The alloy smelting process is simple, convenient and reliable, convenient to operate and free of special processing process and alloy adding methods. A cast ingot is fine and uniform in tissue, free of meshy and thick sheet-like Mg17Al12 phase and uniform in precipitated phase. The rolling process is simple, convenient, reliable and feasible, and the sheet has favorable comprehensive mechanical property.

Owner:INNER MONGOLIA 52 SPECIAL MATERIAL ENG TECH RES CENT

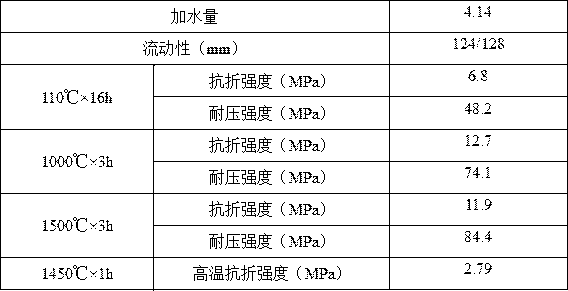

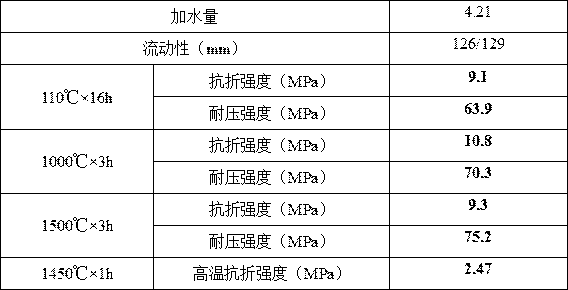

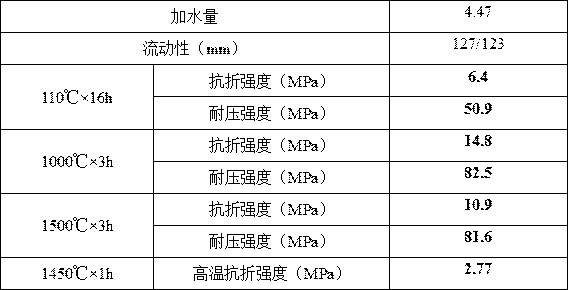

Anti-erosion iron runner castable for large blast furnace

InactiveCN111574206APrevent penetrationLow apparent porosityCeramicwareOxidation resistantCarbon black

The invention relates to an anti-erosion iron runner castable for a large blast furnace. The material comprises, according to weight percentage, 58-64 parts of compact brown fused alumina particles, 2-5 parts of white corundum particles, 16-23 parts of silicon carbide, 5-7 parts of aluminum oxide micro-powder, 2-3 parts of pure calcium aluminate cement, 2-3 parts of silicon dioxide micro-powder, 1.5-2.5 parts of spherical asphalt particles, 0.5-1.2 parts of carbon black powder, 1.5-3.5 parts of metal silicon powder, 0.2-0.6 part of boron carbide, 0.1-0.2 part of metal aluminum powder, 0.15-0.2part of a water reducing agent, 0.6-1 part of an anti-erosion agent and 0.05-0.08 part of explosion-proof fibers. According to the castable, the service life of a primary runner of a main runner is prolonged, and the stability of safe operation of an iron runner is improved. It is verified that the requirements for rapid baking without cracking, erosion resistance, oxidation resistance, slag adhesion resistance and iron flux can be met, the iron flux can reach 180000 tons or above without repairing, and good application prospects are achieved.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

High-strength magnesium alloy tube

InactiveCN101805865AImprove mechanical properties at room temperatureHigh strengthBand shapeRare earth

The invention relates to a high-strength magnesium alloy tube containing the following components in percent by weight: 7.8%-9.2% of aluminum Al, 0.2%-0.8% of zinc Zn and 0.2%-0.5% of manganese Mn. The high-strength magnesium alloy tube is characterized by also containing 0.5%-2.0% of rare earth RE in percent by weight. Because the rare earth RE can react with the aluminum Al to generate an Al-RE compound, the dispersion-strengthening function of the Al-RE compound can improve the strength of alloy and refine crystal particles so that the amount of a Mg17Al12 phase in the alloy is reduced, the original continuous and semi-continuous net-shaped crystal boundary structure is gradually changed into an interrupted and dispersion-distribution belt-shaped structure so that the fine crystal strengthening and the crystal boundary strengthening are more obvious, and meanwhile, the rare earth RE has the function of strong solid-dissolving strengthening, and the comprehensive mechanical properties of the alloy at room temperature are improved.

Owner:嘉兴中科亚美合金技术有限责任公司

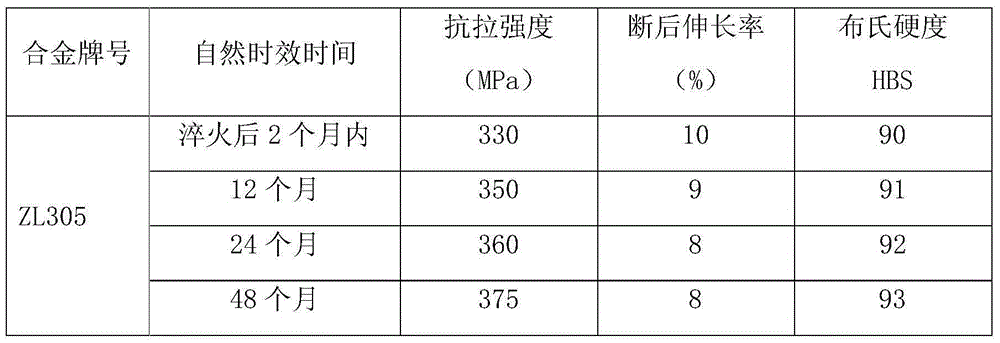

High-strength/toughness and high-stability cast aluminum magnesium alloy material and preparation method thereof

ActiveCN105063440AEnhance solid solution strengtheningImprove mechanical properties at room temperatureMagnesium alloyRoom temperature

The invention provides a high-strength / toughness and high-stability cast aluminum magnesium alloy material. The material comprises the following components in percentage by mass: 9.3-9.8% of Mg, 1.3-1.5% of Zn, 0.2-0.4% of Ca, 0.2-0.4% of Ti, 0.2-0.5% of Ce, 0.1-0.15% of Sr, Fe not more than 0.15%, Ni not more than 0.03%, Cu not more than 0.06%, Si not more than 0.1%, Mn not more than 0.01%, and the balance is Al. The obtained aluminum magnesium alloy material is excellent in room-temperature mechanical property, excellent in natural aging stability and harmless in alloy components.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

High-thermal-conductivity die-casting magnesium alloy and preparation technology thereof

The invention discloses high-thermal-conductivity die-casting magnesium alloy and a preparation technology thereof. Chemical components of the high-thermal-conductivity die-casting magnesium alloy comprise, by mass, 8-13% of Zn, 0.1-1% of Ca, 0-1% of Mn, 0-1% of La, 0-1% of Ce and the balance Mg, wherein the content of Mn, the content of La and the content of Ce are not zero at the same time. The magnesium alloy is suitable for die casting and has excellent mechanical properties and high thermal conductivity, the thermal conductivity of the magnesium alloy at room temperature can reach about two times that of commonly used die-casting AZ91, and the tensile strength of the magnesium alloy is similar to that of AZ91 magnesium alloy.

Owner:BAOSHAN IRON & STEEL CO LTD

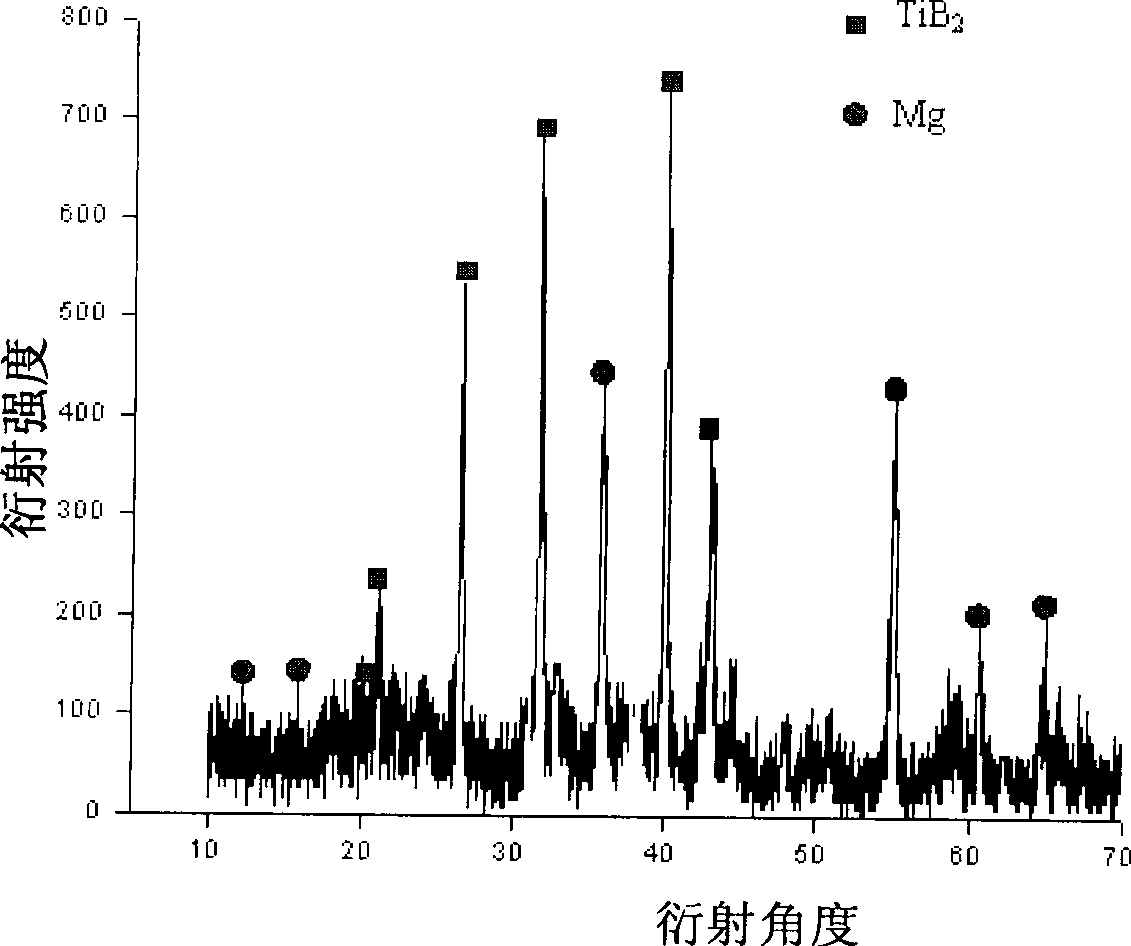

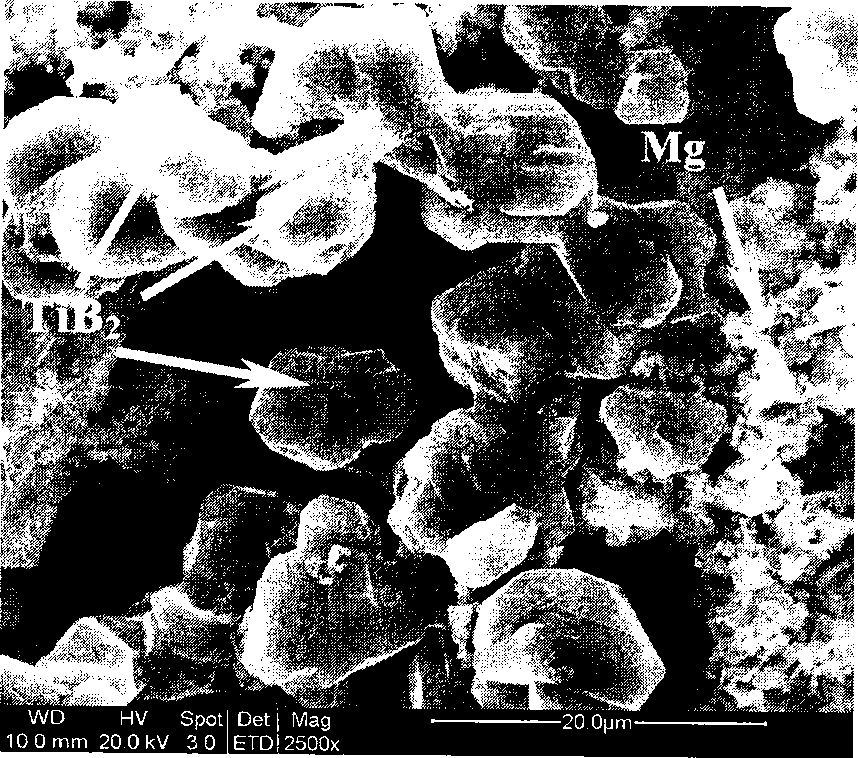

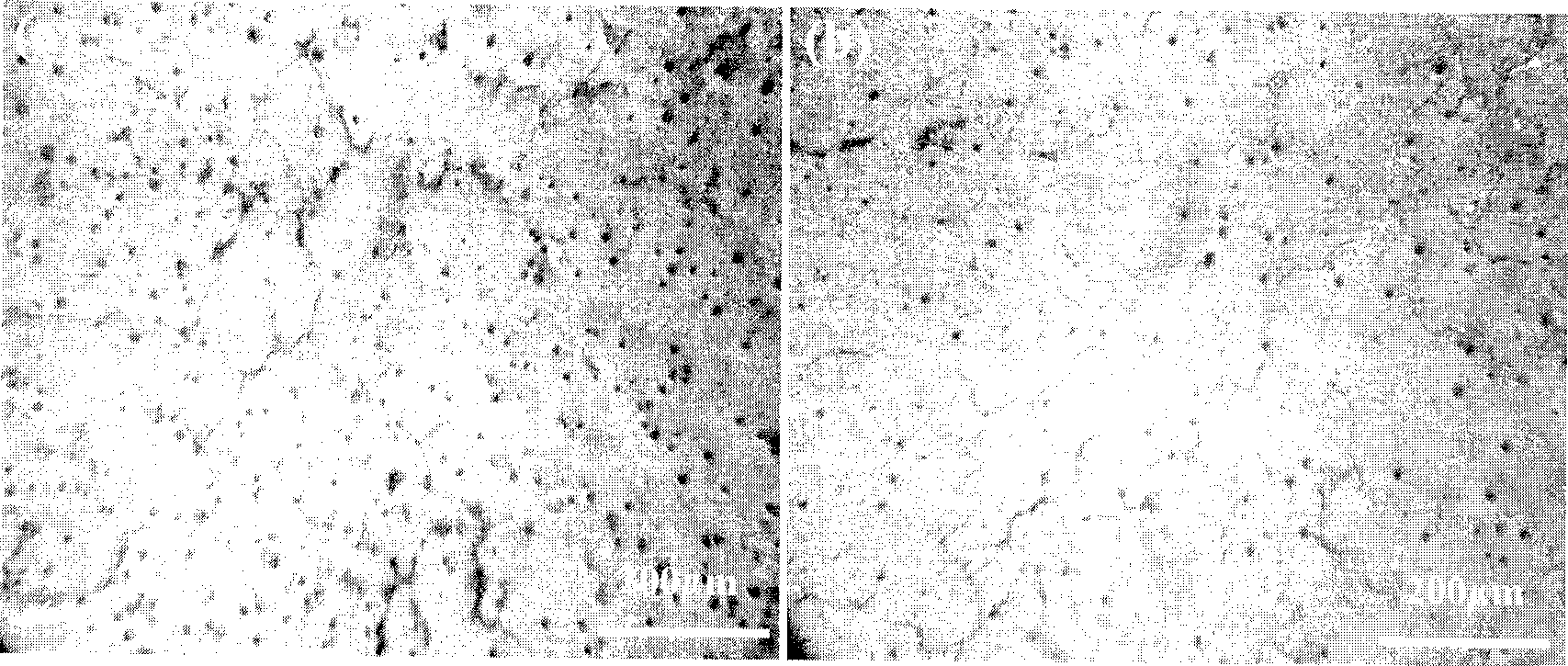

Method for preparing Mg-Ti-B grain refiner for magnesium and magnesium alloy

InactiveCN101457312APrevent oxidative combustionSimple preparation processChemical compositionCrucible

The invention provides a method for preparing a grain refiner for magnesium and magnesium alloy. The chemical compositions of the refiner are as follows (by weight percent): 13.78-55.10% of titanium, 6.22-24.90% of boron and the balance of magnesium. The preparation method comprises the following steps: titanium powder, boron powder and magnesium powders are mixed in a drying status, compacted and dried and then are arranged in a corundum crucible; the crucible is landfilled with fire-resisting powder; an isothermal treatment is carried out at the temperature of 700 to 1000 DEG C in a box-type resistance furnace for 60 to 180 min to prepare the Mg-TiB2 grain refiner. The method is simple in preparation procedure, easy in controlling the content of TiB2 and adding the TiB2, and capable of prominently refining the grain of the magnesium and magnesium alloy.

Owner:WUHAN UNIV OF TECH

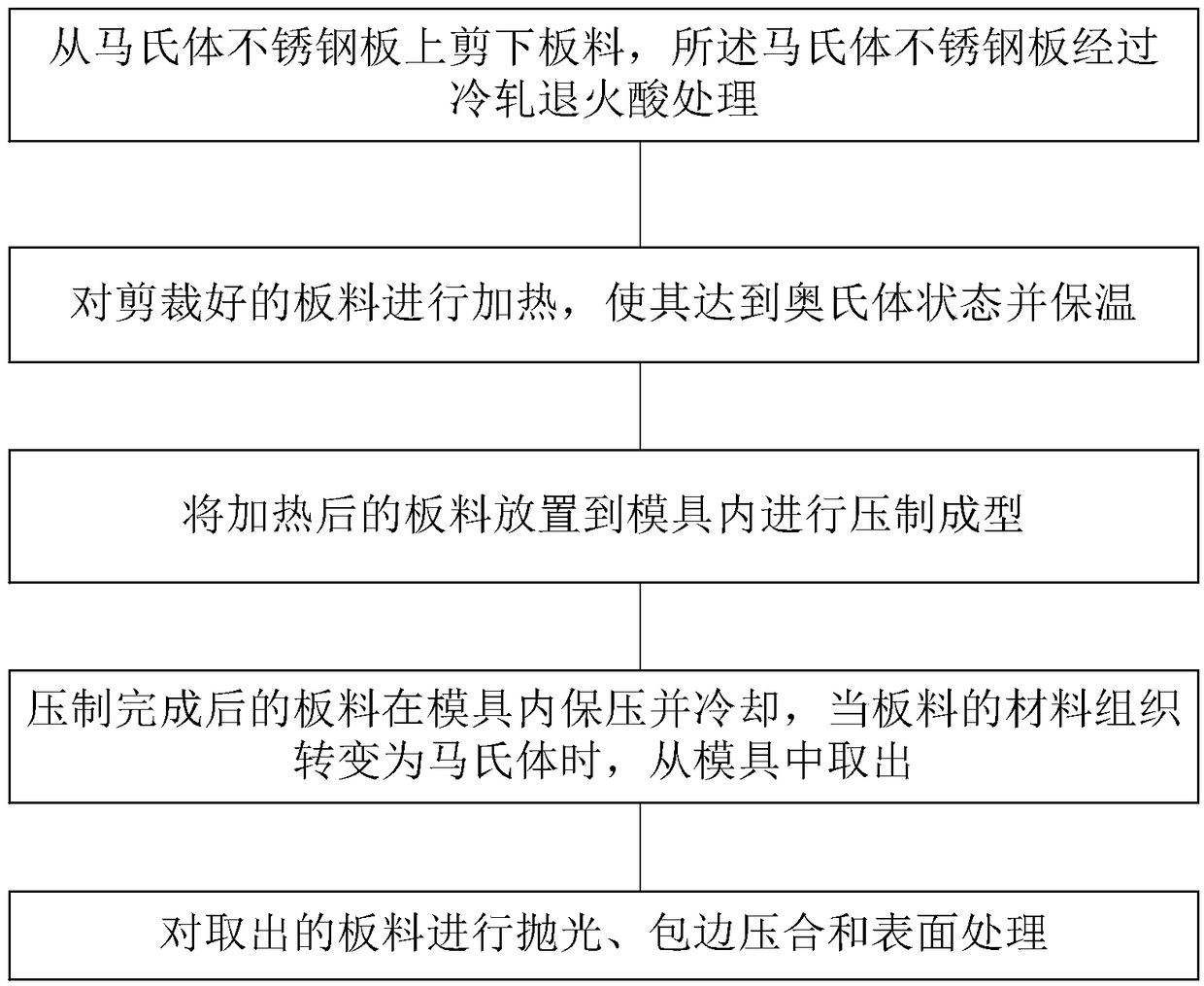

Hot stamping high strength steel automobile body covering part and manufacturing method and system thereof

InactiveCN109433960AImprove mechanical properties at room temperatureLow elongationVehicle componentsHot stampingForeign object

The invention discloses a hot stamping high strength steel automobile body covering part and a manufacturing method and system thereof. The manufacturing method includes the steps that a martensitic stainless steel plate is cut, and the martensitic stainless steel plate is in a cold rolling annealing pickling state; a cut sheet material is put in a heating unit and heated to an austenitic state for heat preservation; the heated sheet material is placed into a mould of a press for compression moulding; and the compressed sheet material is maintained the pressure and cooled in the mould, when the material structure of the sheet material is transformed into martensite, the surface treatment is conducted finally after being removed from the mould. According to the hot stamping high strength steel automobile body covering part and the manufacturing method and system thereof, a martensitic stainless steel material is adopted, the outer covering part of an automobile body is obtained by hot stamping forming, the elasticity is excellent due to the high yield strength, more impact energy of foreign objects can be absorbed, excellent pit resistant performance is achieved, and the thickness of workpieces can further be reduced; and since stainless steel has good corrosion resistance, the surface of the material and the automobile outer covering part are not required to be galvanized.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

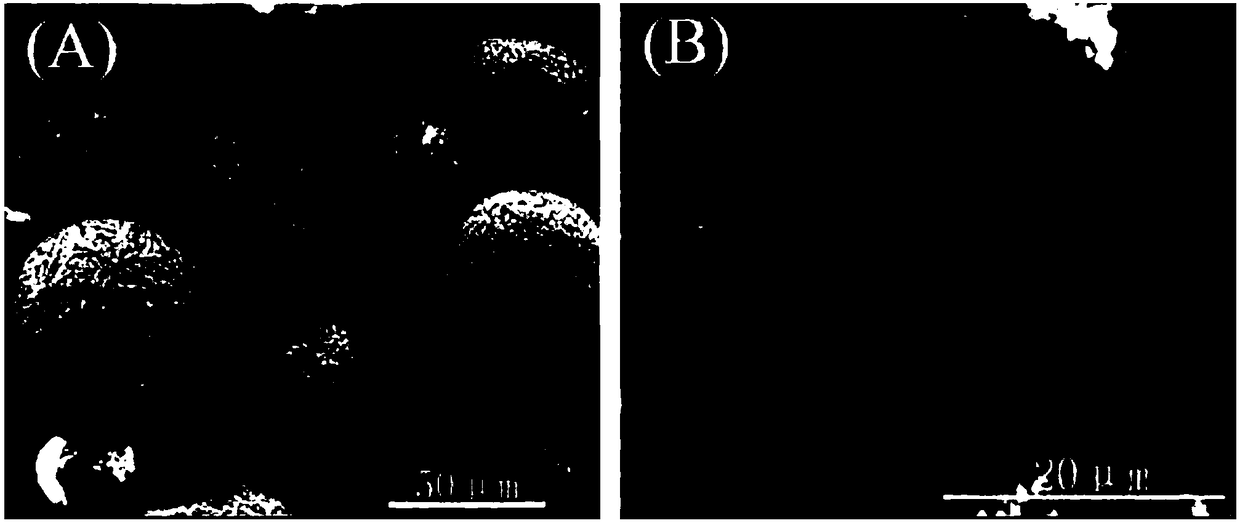

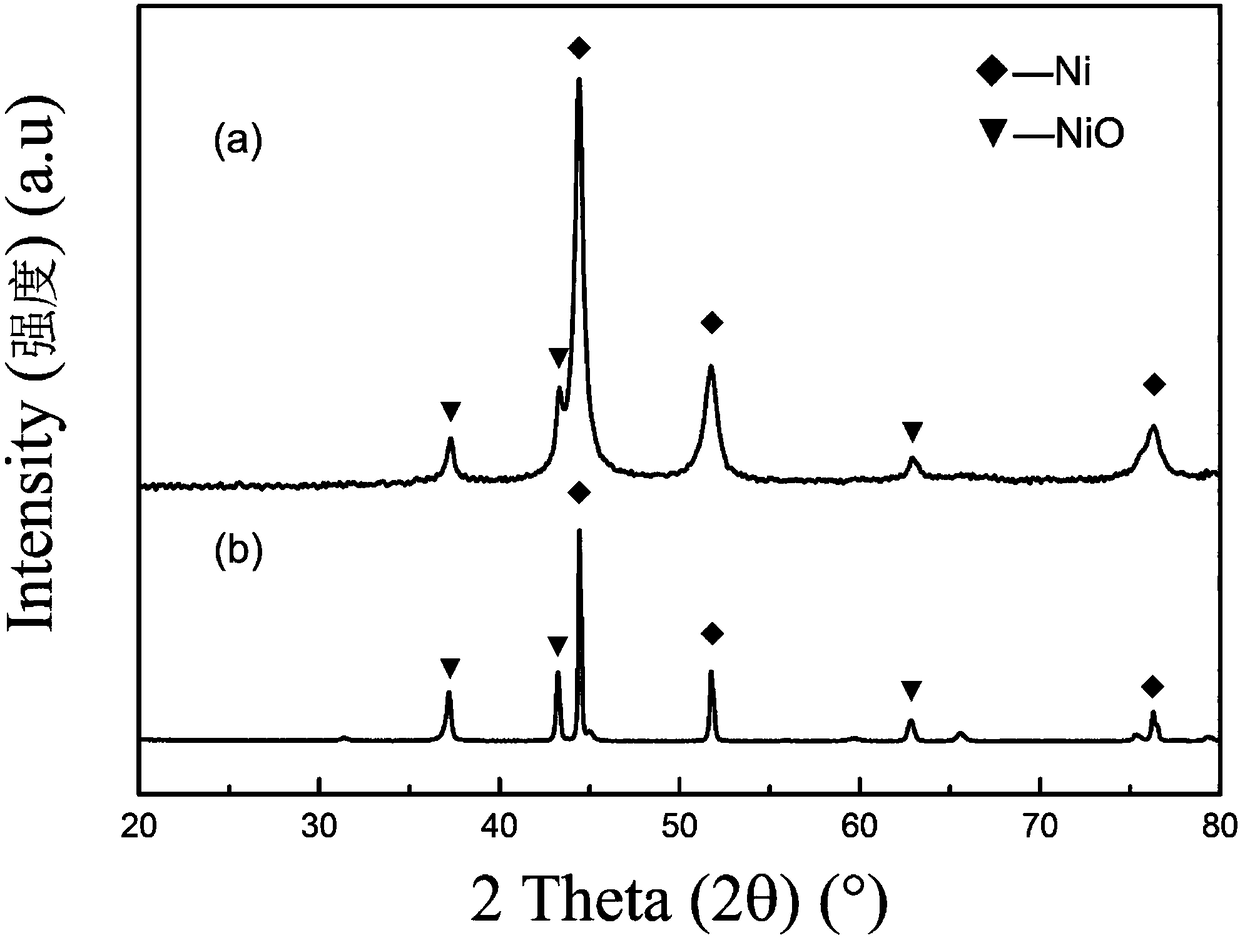

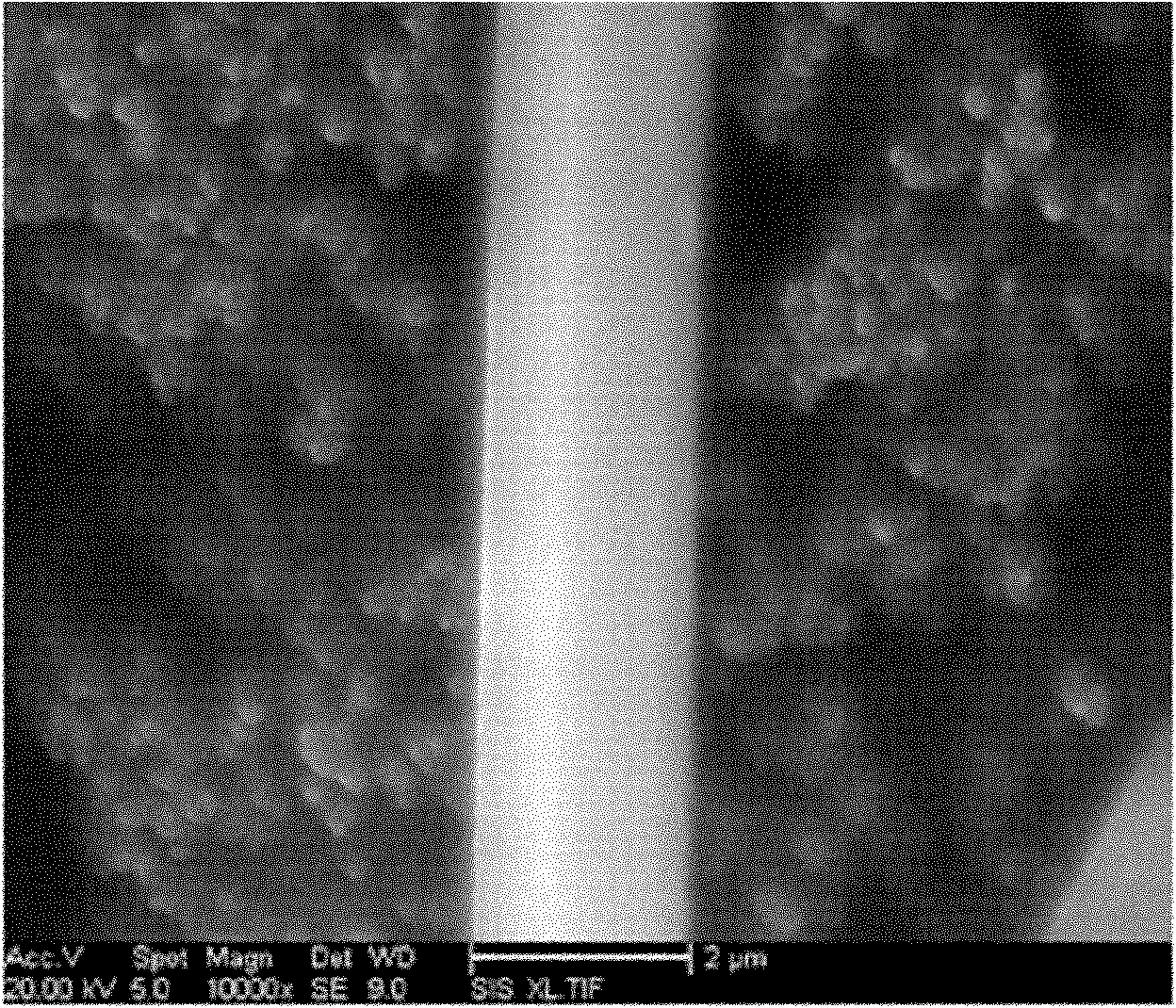

Porous nickel framework material and preparation method thereof

ActiveCN108405848AHigh strengthHigh densityTransportation and packagingMetal-working apparatusPorosityFiltration

The invention discloses a porous nickel framework material and a preparation method thereof. The porous nickel framework material has three-dimensional communication holes, has material density being5.32-9.76g / cm<3>, microhardness being 120-539.8HV, room-temperature compressive strength being 186-930 MPa and porosity being 30-83%. The preparation method comprises the following steps of: A, performing screening, impurity-removal and drying on prepared spherical metal nickel powder, and sealing for storage; and B, adopting a sintering process to sinter and form the spherical metal nickel powerobtained in the step A, thereby obtaining the porous nickel framework block material. The porous nickel framework material is high in strength, is uniform in three-dimensional hole distribution, and is good in compactness; and the preparation method is simple and reliable in process, is free of harmful gas in process, and does not cause environmental pollution. Meanwhile, the front engineering material with advantages in function and structure can be applied to the fields such as industrial wastewater treatment, filtration and separation, automobile tail gas treatment, catalyst carriers, energy storage and chemical engineering.

Owner:SOUTHWEST JIAOTONG UNIV

High-strength heat-resistant magnesium alloy containing Ag and preparation method thereof

ActiveCN108624793AImprove mechanical properties at room temperatureHigh tensile strengthRare-earth elementHeat resistance

The invention provides high-strength heat-resistant magnesium alloy containing Ag. The high-strength heat-resistant magnesium alloy comprises the following components in percentage by weight: 4.5-6.5percent of Y, 1.5-4.0 percent of Nd, 1.5-4.0 percent of Gd, 0.1-1.5 percent of Ag, 0.15-1.5 percent of Zr and the balance of Mg, wherein the total amount of the rare earth elements does not exceed 10percent by weight. The high-strength heat-resistant magnesium alloy comprises the following components: Mg-Y-Nd-Gd-Ag-Zr; a precipitate containing a rare earth inter-metallic compound is strengthenedas a main strengthening mechanism; a RE-Ag fine high temperature stable phase and an Mg-RE-Ag eutectic are formed through adding the Ag as a non-rare earth element; the newly-formed phase has the characteristics of fine dispersion and high temperature stability; the heat treatment age hardening effect and the heat resistance of the high-strength heat-resistant magnesium alloy are significantly improved. The invention further provides a preparation method of the high-strength heat-resistant magnesium alloy containing the Ag.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

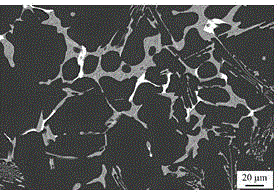

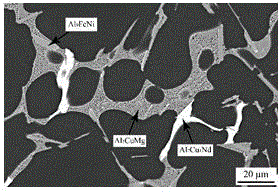

Rare earth alloying Al-Cu-Mg-Fe-Ni high-strength and heat-resistance aluminum alloy

InactiveCN104862563AImprove mechanical properties at room temperatureReduce the mechanical properties at room temperatureHeat resistanceRare earth

The invention discloses a rare earth alloying Al-Cu-Mg-Fe-Ni high-strength and heat-resistance aluminum alloy. The aluminum alloy comprises the following components in percentage by weight: 2.6-3.5% of Cu, 1.3-1.8% of Mg, 0.1-0.8% of Fe, 0.1-0.8% of Ni, 0.05-0.5% of Nd, 0.1-0.25% of Mn, and 0.1-0.25% of Zr. Through mutual matching and combined actions of high Cu, low Fe, Ni and rare earth Nd, the room-temperature mechanical performance and high-temperature heat resistance of the alloy are synchronously improved, and the alloy obtains excellent comprehensive performance.

Owner:SHANDONG NANSHAN ALUMINUM

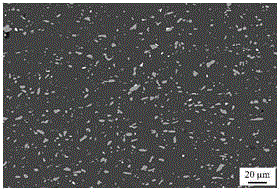

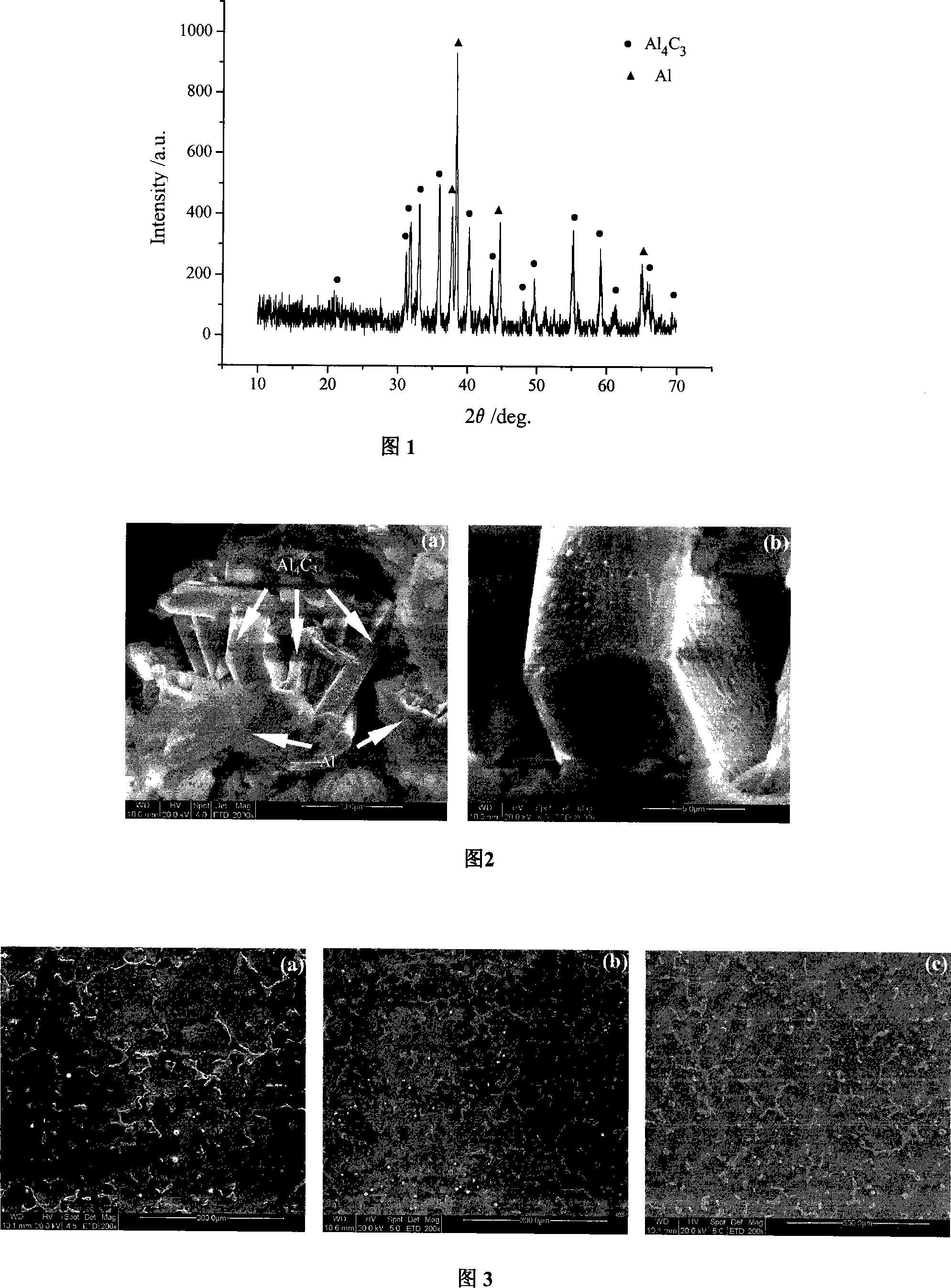

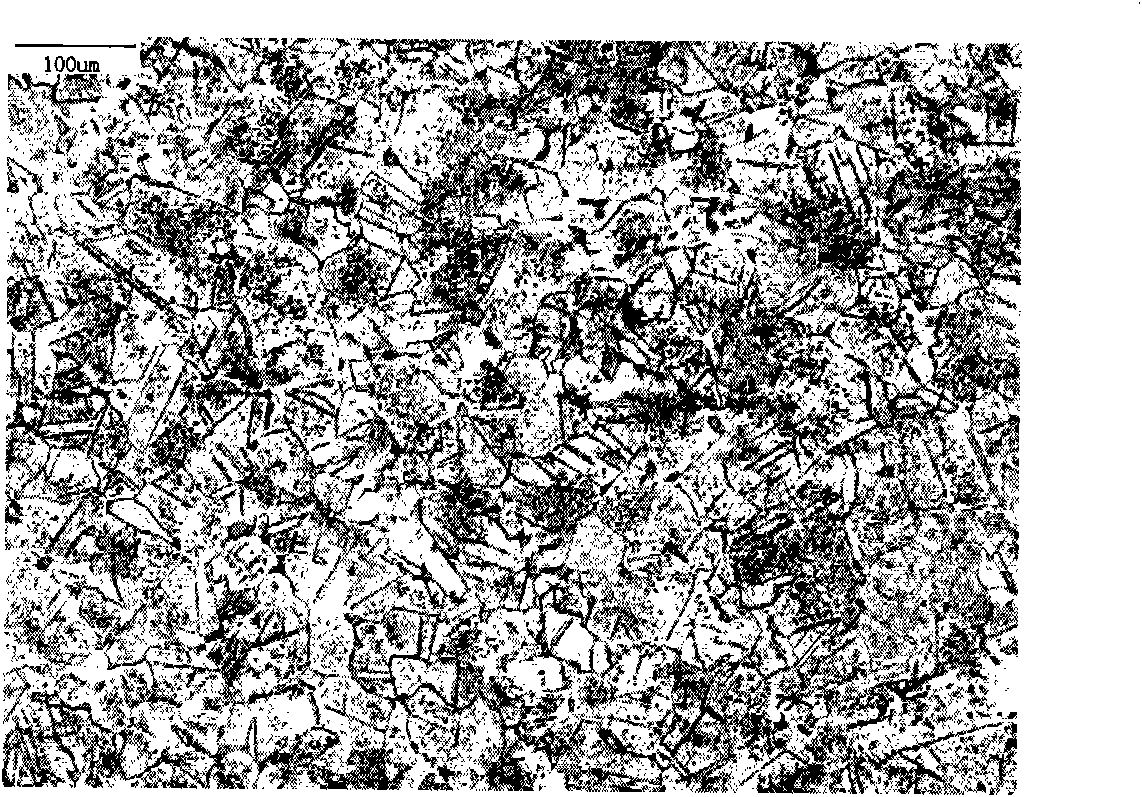

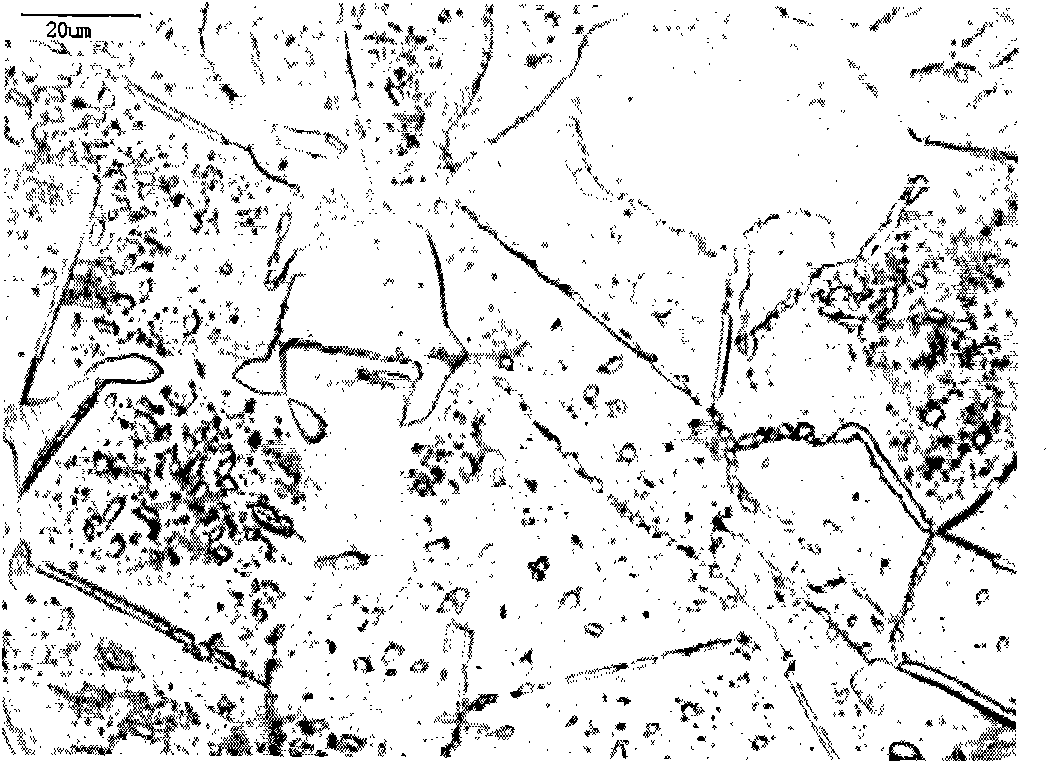

Mg-Al series alloy composite grain refiner and method for making same

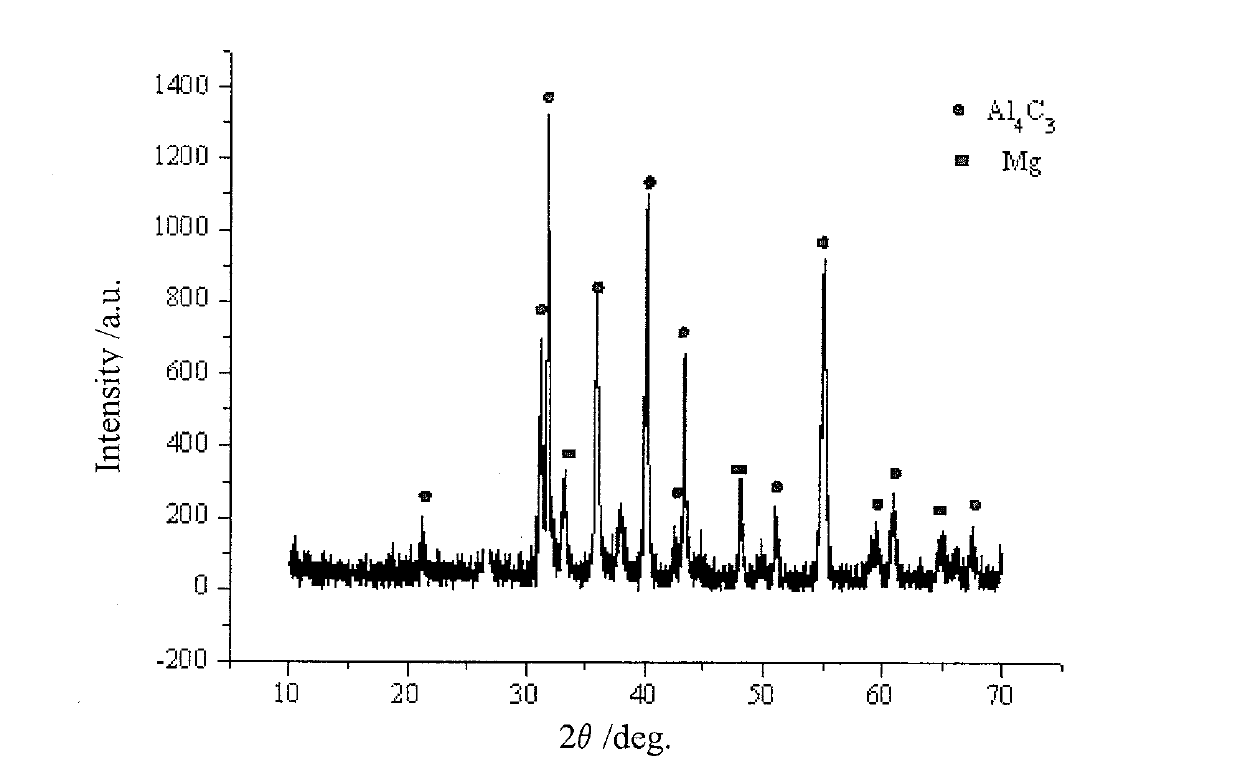

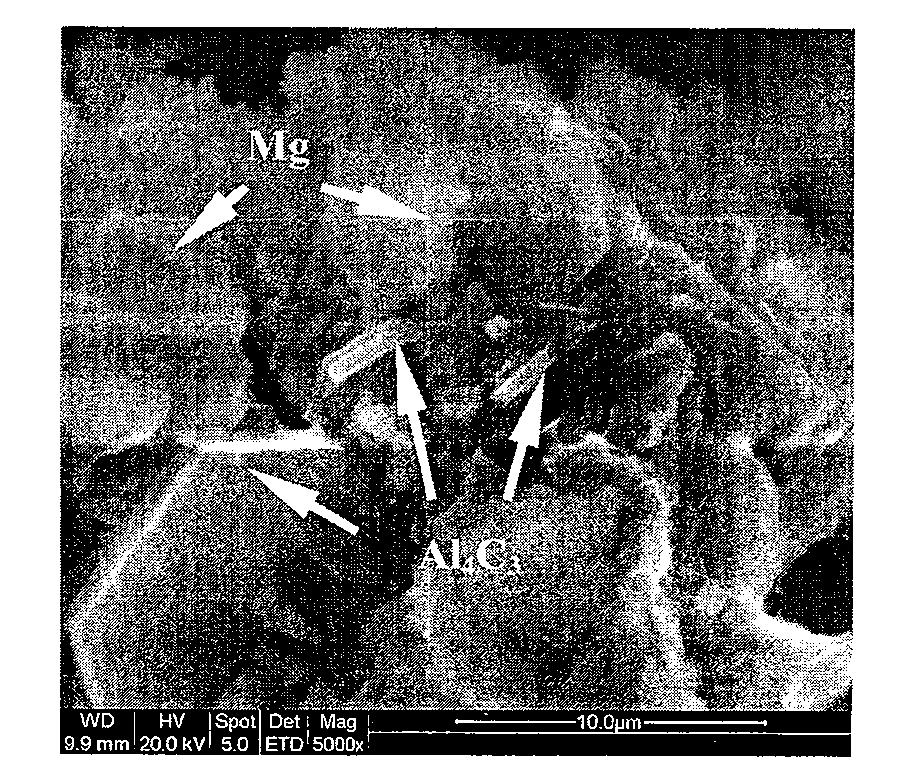

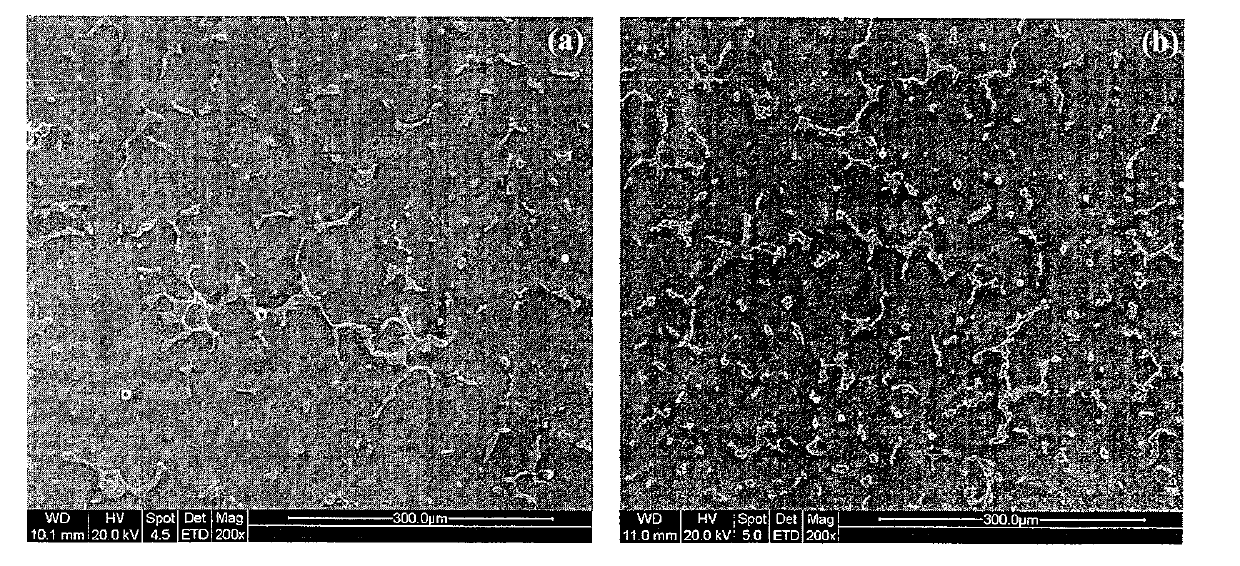

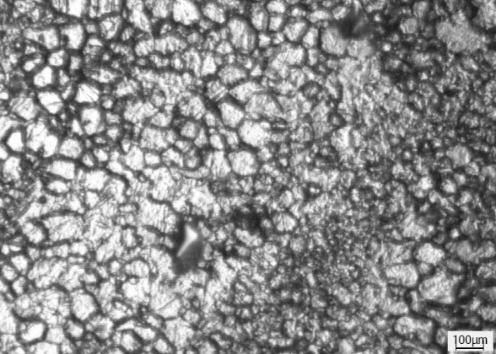

The present invention provides one kind of composite grain refiner for Mg-Al alloy and its preparation process. The composite grain refiner has the chemical composition including C 5-15 wt%, calcium 2.8-28 wt% or Ce 3-6 wt%, and Al for the rest. Its preparation process includes the following steps: mixing aluminum powder and carbon powder; pressing into block and stoving, setting inside corundum crucible and covering with refractory powder, isothermal treatment inside a box-type resistance furnace at 1000-1200 deg.c for 30-120 min to prepare intermediate Al-Al4C3 alloy, and remelting together with aluminum ingot and intermediate Al-70 %Ca or Al-10 %Sr alloy to prepare Al-Al4C3-Ca / Sr as composite grain refiner finally. The composite grain refiner can fine grains of Mg-Al alloy obviously.

Owner:WUHAN UNIV OF TECH

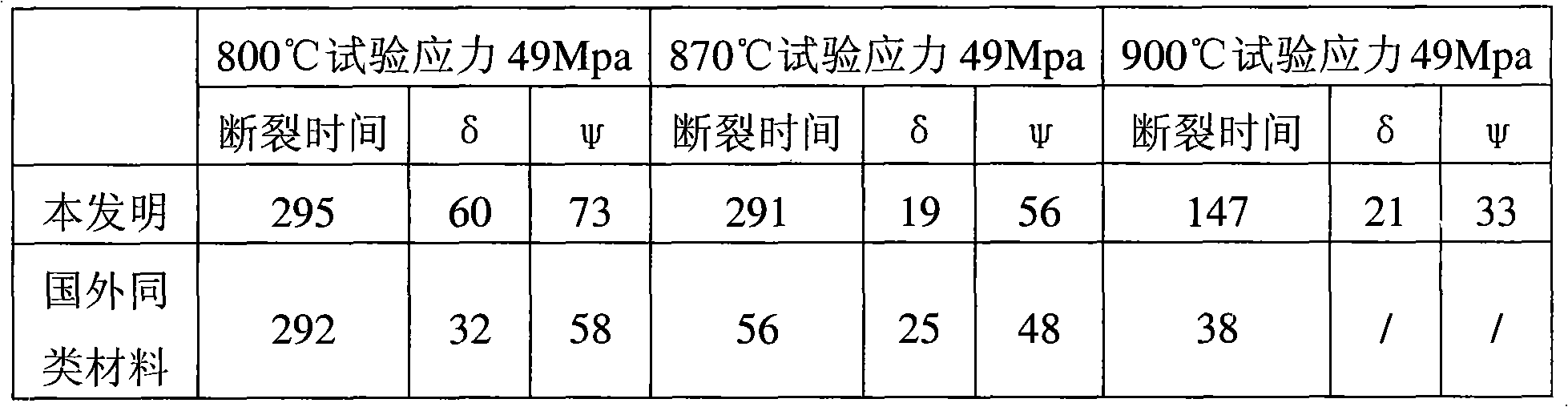

Stainless steel with capabilities of high temperature resistance and anti-corrosion, manufacturing method and application thereof

The present invention provides a stainless steel with capabilities of high temperature resistance and anti-corrosion, which comprises components by weight percentage as follows: 0.1%<=C<=0.2%, 0.5%<=Si<=1.0%, 1.0%<=Mn<=2.0%, P<=0.009%, S<=0.004%, Al<=0.03%, 0.02%<=Nb<=0.04%, 0.02%<=Ti<=0.03%, 0.015%<=V<=0.060%, 0.0015%<=B<=0.0020%, the residual is Fe and other unavoidable impurity. A manufacturingmethod includes: vacuum smelting + electroslag remelting steel-making technology, forging technology and solid-smelting treatment technology. Compared with the same kind of material in foreign, the stainless steel provided by the invention has obviously increased room-temperature mechanical property, lasting test and creep deformation test result, which is specially suitable for manufacturing a furnace shaft with capability of high temperature resistant.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing magnesium alloy

The invention provides a method for preparing a magnesium alloy. The method comprises the following steps of: a) performing high-energy ball milling on magnesium silicide nano powder, zinc powder, aluminum powder and magnesium powder for 1 to 2 hours to obtain mixed powder, wherein the mixed powder comprises 2.2 to 3.6 weight percent of magnesium silicide, 0.5 to 1.5 weight percent of zinc, 4.5 to 5.5 weight percent of aluminum and 90.5 to 91.9 percent of magnesium; b) pressing the mixed powder to form a blank; and c) heating the blank under the protection of inert gas at the temperature of between 420 and 450 DEG C, preserving the heat for 30 to 50 minutes, extruding after heating, performing water cooking on the extruded blank, and thus obtaining the magnesium alloy. The magnesium alloyprepared by directly adding the magnesium silicide nano powder into the raw materials and adopting the method of combining high-energy ball milling for preparing the powder and hot extruding has fineand uniform microstructure, reinforcing phase particles are uniformly distributed in the matrix structure, and the room temperature mechanical property of the magnesium alloy is improved.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

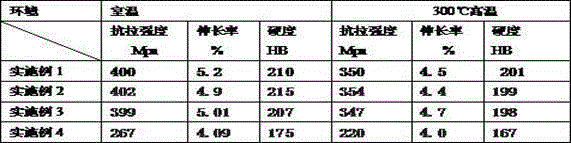

Heatproof magnesium alloy material with high strength and preparation method thereof

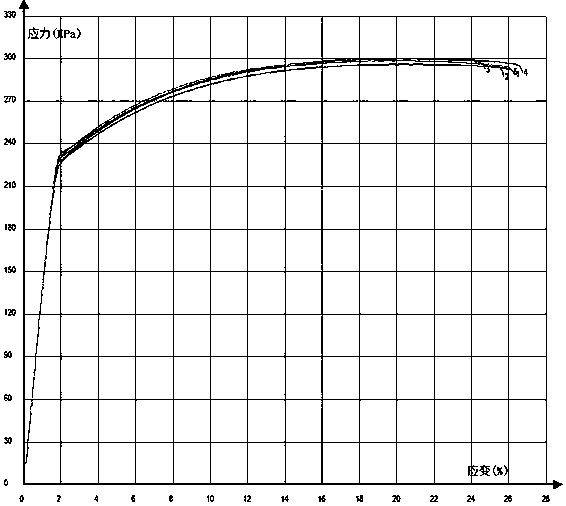

InactiveCN101603139AImprove mechanical properties at room temperatureImprove high temperature elongationRoom temperatureHigh intensity

The invention discloses a heatproof magnesium alloy material with high strength, which is characterized in that the heatproof magnesium alloy material with high strength is prepared by 2.5-3.5wt% of Nd, 1.0-2.0wt% of Gd, 0.05-0.1wt% of Zn, 0.4-0.6wt% of Zr, at most 0.25wt% of impurity (wherein, Cu is at most 0.1%, and Ni is at most 0.01%) and the balance of Mg. The invention also discloses a preparation method of the heatproof magnesium alloy material with high strength. By controlling time and temperature for adding Zn, Mg-Gd preliminary alloy and Mg-Zr preliminary alloy, the room temperature tensile strength alpha b of the prepared heatproof magnesium alloy material with high strength is improved to 270MPa from 230MPa of the prior art, yield strength alpha is improved to 205MPa from 135MPa of the prior art, and elongation rate delta is improved to 3.5% from 3% of the prior art. Meanwhile, the 300 DEG C high-temperature instant tensile strength alpha b is improved to 141MPa from 109MPa of the prior art, and the 300 DEG C high-temperature instant tensile strength alpha is improved to 123MPa from 79MPa of the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Tantalic oxide modified molybdenum disilicide based material and preparation method thereof

The invention relates to a tantalum pentoxide modified molybdenum disilicide-based composite material and a corresponding preparation method, wherein, the preparation method comprises following steps: equably mixing tantalum pentoxide and molybdenum disilicide according to a weight proportion that the tantalum pentoxide is 1% to 7% and molybdenum disilicide is 93% to 99%; dispersing by ultrasonic wave and ball milling and mixing to obtain a dry powder, sintering the dry powder in a vacuum heat pressing sintering furnace at a temperature of 1400 DEG C to obtain the antalum pentoxide modified molybdenum disilicide-based composite material. The invention has the advantages that: the Ta2O5 doped MoSi2 composite material has high specific strength, high temperature resistant performance and corrosion resistance performance, strong anti-high temperature oxidation performance and anti-heat shock ability, and good conductivity for electricity and heat.

Owner:HARBIN ENG UNIV

Aluminum and molybdenum high-temperature-resistant nodular cast iron containing chromium and copper elements and preparation method thereof

The invention discloses an aluminum and molybdenum high-temperature-resistant nodular cast iron containing chromium and copper elements. According to the technical scheme, the aluminum and molybdenumhigh-temperature-resistant nodular cast iron containing the chromium and copper elements is characterized in that the cast iron comprises, by weight, 1.4-3.6% of C, 1.5-5.2% of Si, 2.0-9.0% of Al, 0.3-3.0% of Mo, 0.5-2.5% of Cr, 0.3-1.5% of Cu, no more than 0.06% of impurity element Mg, no more than 0.06% of impurity element S, no more than 0.15% of impurity element P, no more than 0.7% of impurity element Mn, and the balance Fe. The aluminum and molybdenum high-temperature-resistant nodular cast iron containing the chromium and copper elements can resist the working temperature of 900 DEG C,has good heat shock performance, good high-temperature oxidation resistance performance and good formability, and is low in cost.

Owner:纳似韦科技(苏州)有限公司

High-wear-resistance high-thermal-conductivity zinc alloy containing strontium and sodium and machining process thereof

The invention discloses a high-wear-resistance high-thermal-conductivity zinc alloy containing strontium and sodium. The alloy comprises, by weight, 0.8-1.2wt% of Na, 0.2-0.3wt% of Sr, 4. 5-6.3wt% ofIn, 0.8-1.2wt% of Zr, 0.4-0. 8wt% of Si, 2.4-3.6wt% of Sn, 0.2-0.5wt% of Yb, 0.1-0.2wt% of Nd, 0.8-1.0wt% of S and the balance of zinc. Compared with a traditional zinc alloy, the high-wear-resistancehigh-thermal-conductivity zinc alloy containing strontium and sodium has excellent mechanical property and heat conduction performance.

Owner:GUANGZHOU YUZHI TECH CO LTD

Platinum alloy containing Sc for highly-conductive highly-thermal-conductive electric contact material

InactiveCN107653392AReduce the amount of alloying elements usedGood electrical conductivity and mechanical propertiesMetal/alloy conductorsThermal conductivityChemical composition

The invention discloses a platinum alloy containing Sc and used as a high-conductivity and high-heat-conduction electrical contact material. In terms of weight percentage, the chemical composition of the alloy is: Sc:1.5‑2.0wt.%, Y:1.5‑2.0wt.%, Mo:0.8‑1.2wt.%, Sn:0.2‑0.6wt.%, Si:1.2‑ 2.6wt.%, Pd: 0.5‑1.0wt.%, Ho: 0.2‑0.6wt.%, Pr: 0.2‑0.5wt.%, B: 0.2‑0.5wt.%, and the balance is platinum. Compared with traditional electrical contact platinum alloys, this material has excellent mechanical properties, thermal conductivity and electrical conductivity.

Owner:GUANGZHOU YUZHI TECH CO LTD

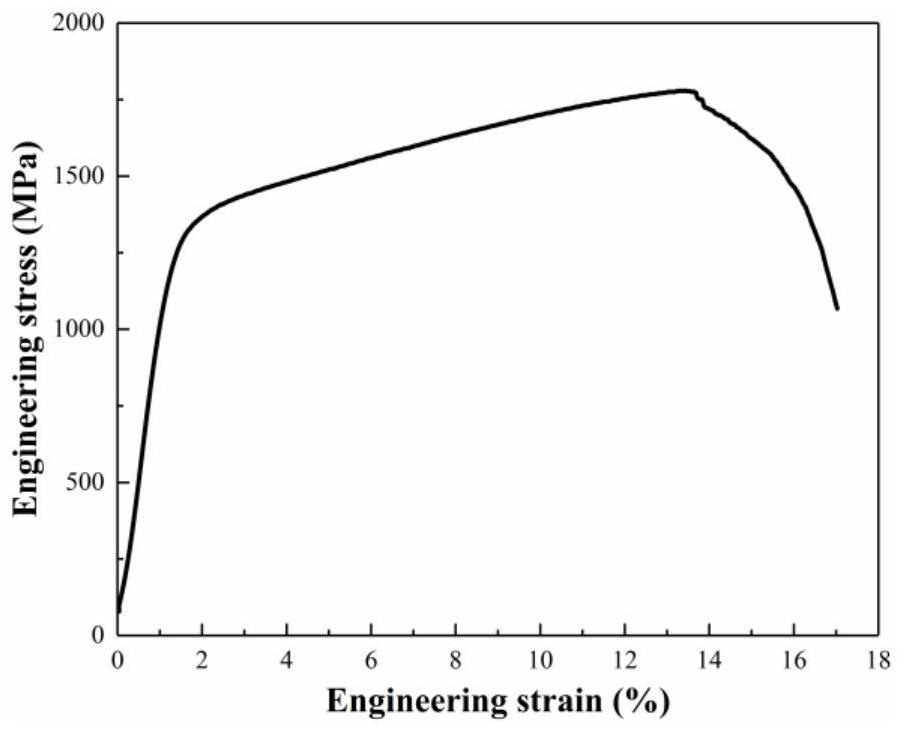

Refractory medium-entropy alloy and preparation method thereof

ActiveCN114134385AImprove mechanical properties at room temperatureImprove structural stabilityElectric arcMechanical properties of carbon nanotubes

The invention discloses a refractory medium-entropy alloy and a preparation method thereof, the refractory medium-entropy alloy is composed of three metal elements, the chemical formula is recorded as AaBbCc, and the atomic percentage content of the elements satisfies the following conditions: 15% < = a < = 70%, 15% < = b < = 70%, 15% < = c < = 70%, and a + b + c = 100. The preparation method comprises the following steps: weighing metal raw materials of each element, and carrying out electric arc melting in a non-self-consumption vacuum environment; and cooling to room temperature and taking out. Through an alloy design strategy of reducing components, the effect of stabilizing a crystal structure of'mixed enthalpy 'in a high-temperature environment can be fully played, room-temperature strengthening and toughening of the alloy can be further promoted by utilizing'mixed enthalpy', and on the premise of ensuring that the alloy has good high-temperature tissue structure stability and excellent high-temperature strength, the alloy has excellent mechanical properties and mechanical properties. And the room-temperature mechanical property of the alloy is greatly improved. A series of refractory medium-entropy alloys are prepared by using a non-consumable vacuum arc melting furnace, and the alloying degree is lower.

Owner:SOUTHEAST UNIV +1

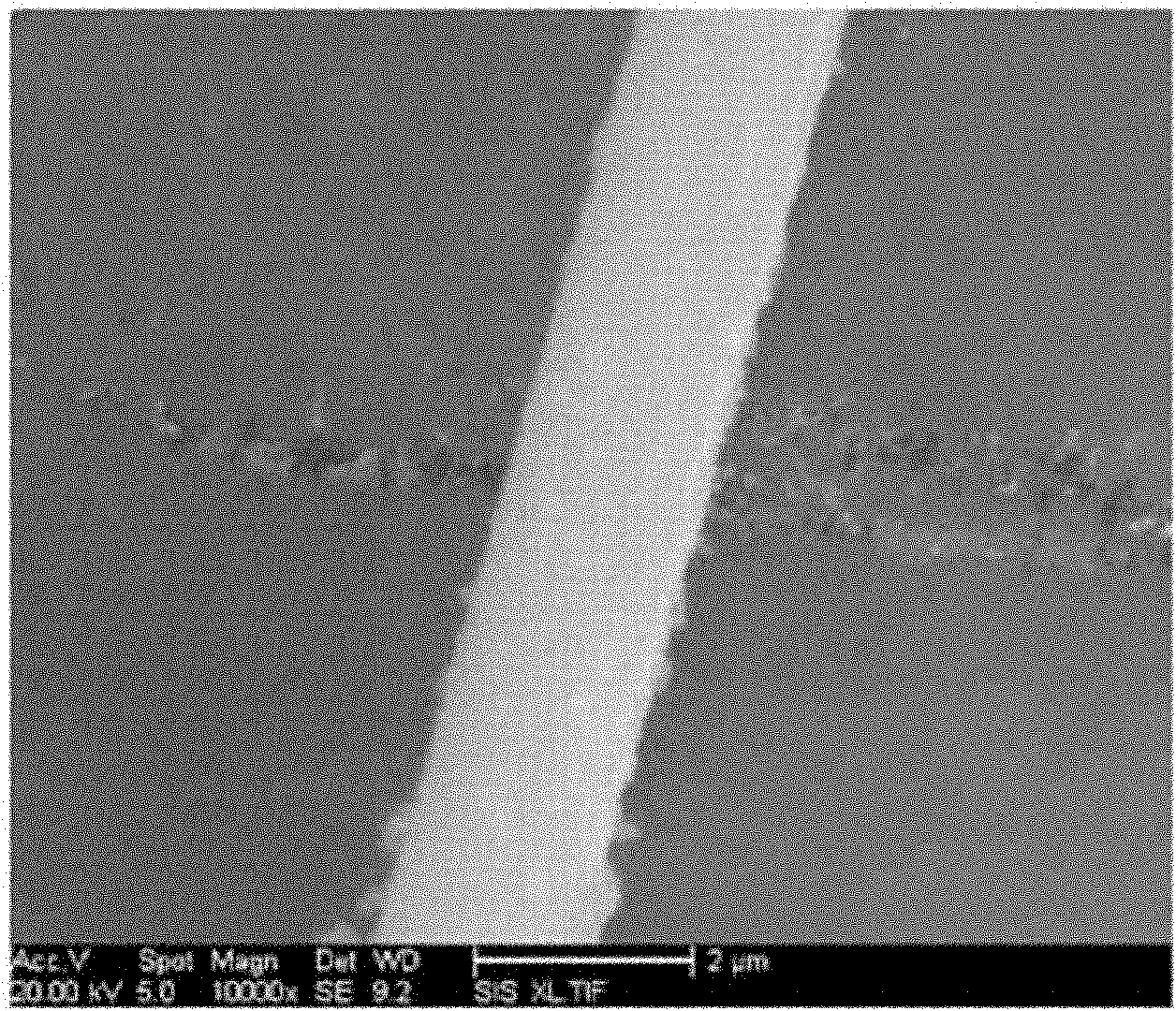

Method for preparing Cr2O3 coated aluminum borate whisker reinforced aluminum matrix composites

InactiveCN102071373AImprove interfacial wettabilityImprove mechanical properties at room temperatureAluminum matrix compositesSqueeze casting

The invention discloses a method for preparing Cr2O3 coated aluminum borate whisker reinforced aluminum matrix composites, which relates to a method for preparing whisker reinforced aluminum matrix composites. The method overcomes the defects of poor mechanical properties and failure of use in high-temperature environment existing in the prior aluminum borate whisker reinforced aluminum matrix composites. The method comprises the steps of: 1, preparation of Cr2O3 sol; 2, preparation of Cr2O3 gel coated aluminum borate whiskers; 3, preparation of Cr2O3 coated aluminum borate whisker performed unit; and 4, preparation of the Cr2O3 coated aluminum borate whisker reinforced aluminum matrix composites by adopting a squeeze casting process. The method can be used for the whisker reinforced aluminum matrix composites.

Owner:HARBIN UNIV OF SCI & TECH

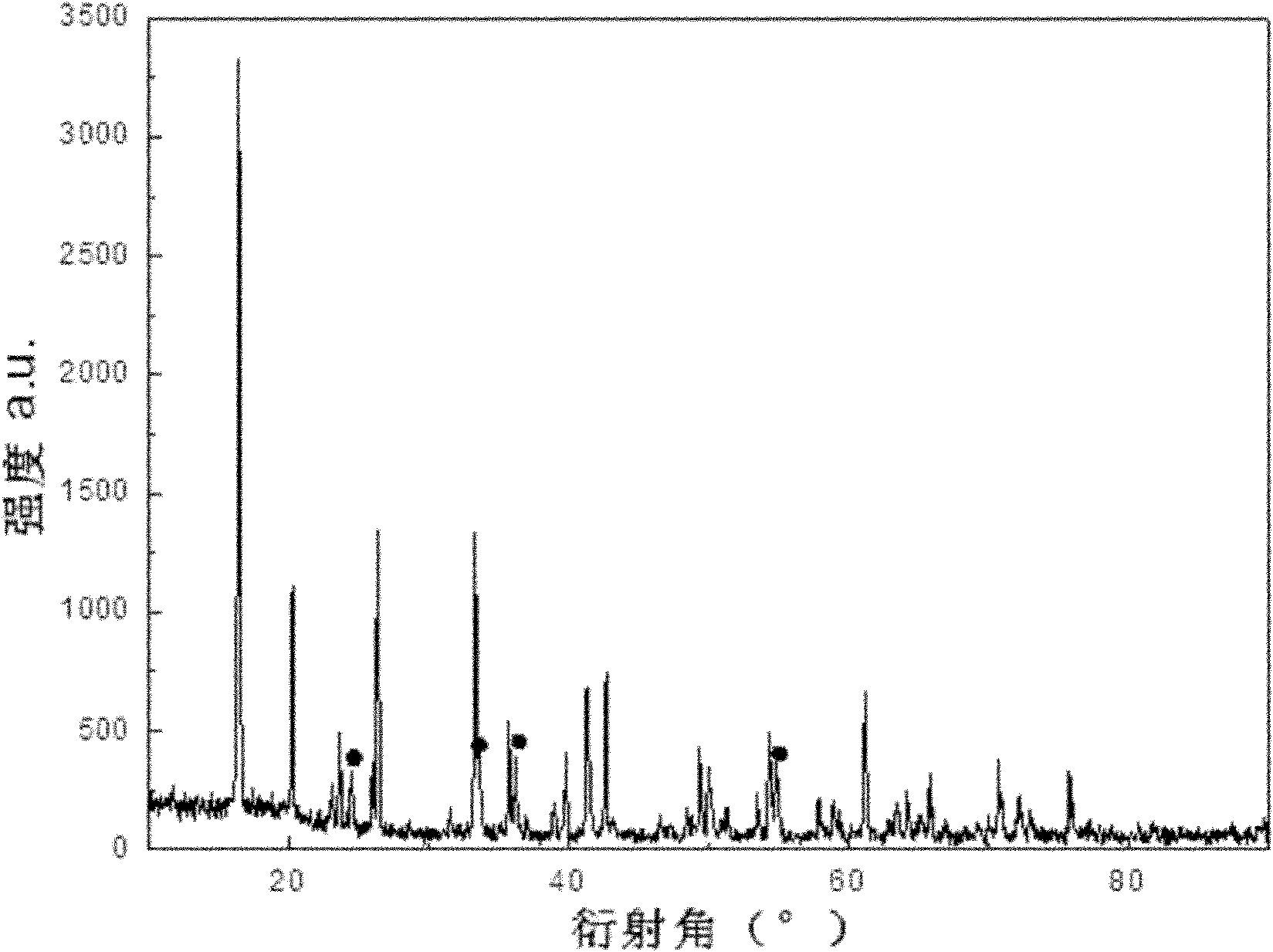

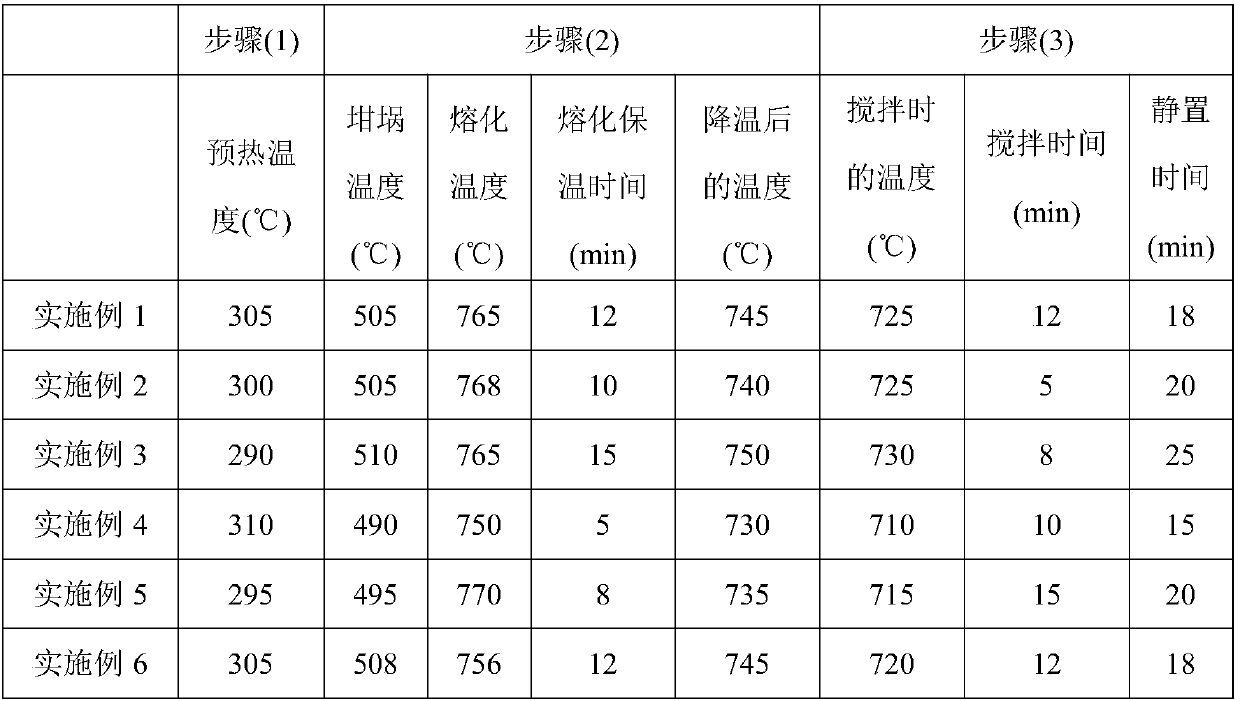

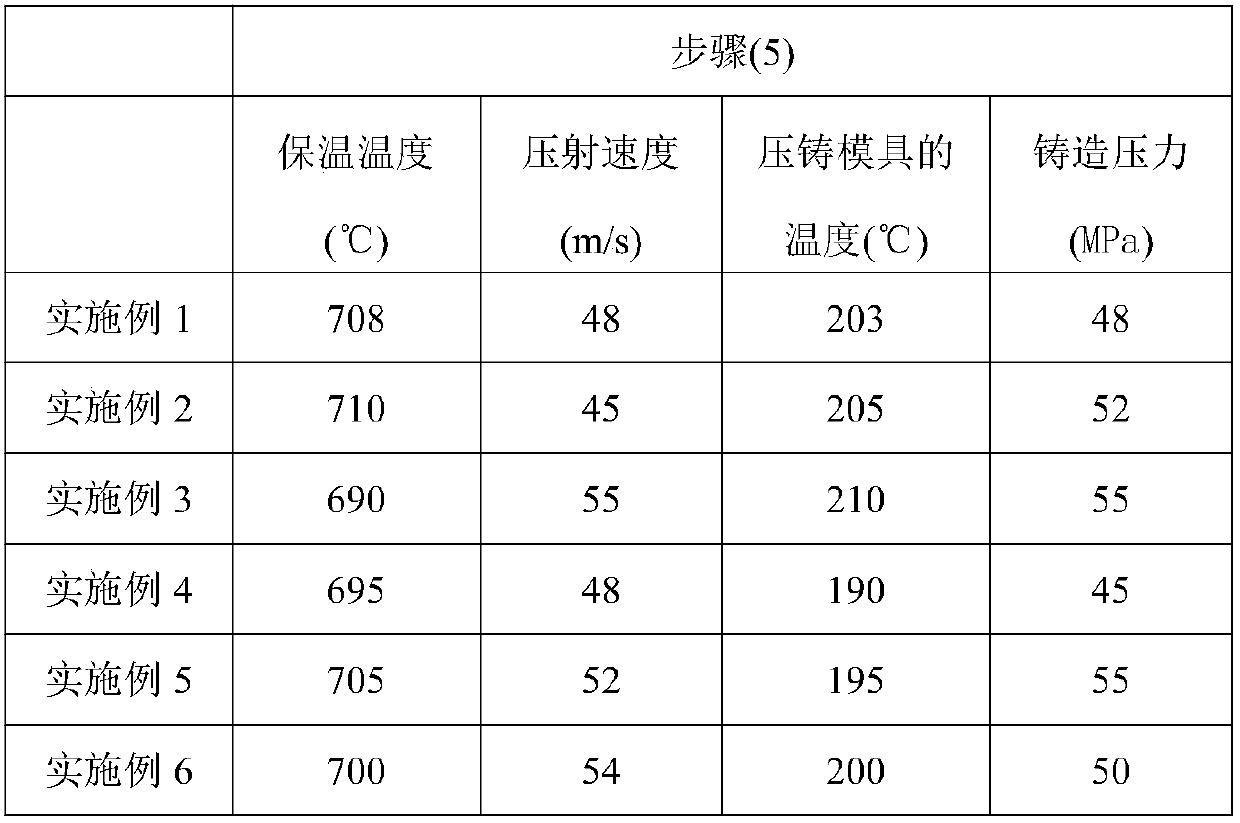

High-thermal-conductivity die-casting magnesium alloy and manufacturing method thereof

The invention discloses a high-thermal-conductivity die-casting magnesium alloy. The alloy comprises the following chemical elements of, by mass, 5-7 wt% of Al, 5-8 wt% of La, 0.3-1 wt% of Sr, 0.2-0.5wt% of Mn, and the balance Mg and other inevitable impurities. The invention further discloses a manufacturing method of the high-thermal-conductivity die-casting magnesium alloy. The manufacturing method comprises the following steps that (1) a crucible is put in a heating furnace to be preheated, and then a release agent is sprayed on the inner wall of the crucible; (2) a pure magnesium ingot isput into the crucible, mixed gas of SF6 and CO2 is introduced into the crucible, heating is conducted to enable the pure magnesium ingot to be completely molten, and heat preservation is conducted for a period of time, then cooling is conducted to 740 DEG C + / -10 DEG C, and pure Al, an Mg-La intermediate alloy, an Mg-Sr intermediate alloy and an Mg-Mn intermediate alloy are added; (3) after complete melting is conducted, cooling is conducted to 720 + / -10 DEG C, stirring is conducted to remove slag, and standing is conducted; (4) the crucible is cooled, and a magnesium alloy ingot is taken out; and (5) the magnesium alloy ingot is molten in a smelting furnace of a die-casting machine and is subjected to heat preservation, and then the molten magnesium alloy is injected into a die-casting die to obtain the high-thermal-conductivity die-casting magnesium alloy.

Owner:CHINA BAOWU STEEL GRP CORP LTD +1

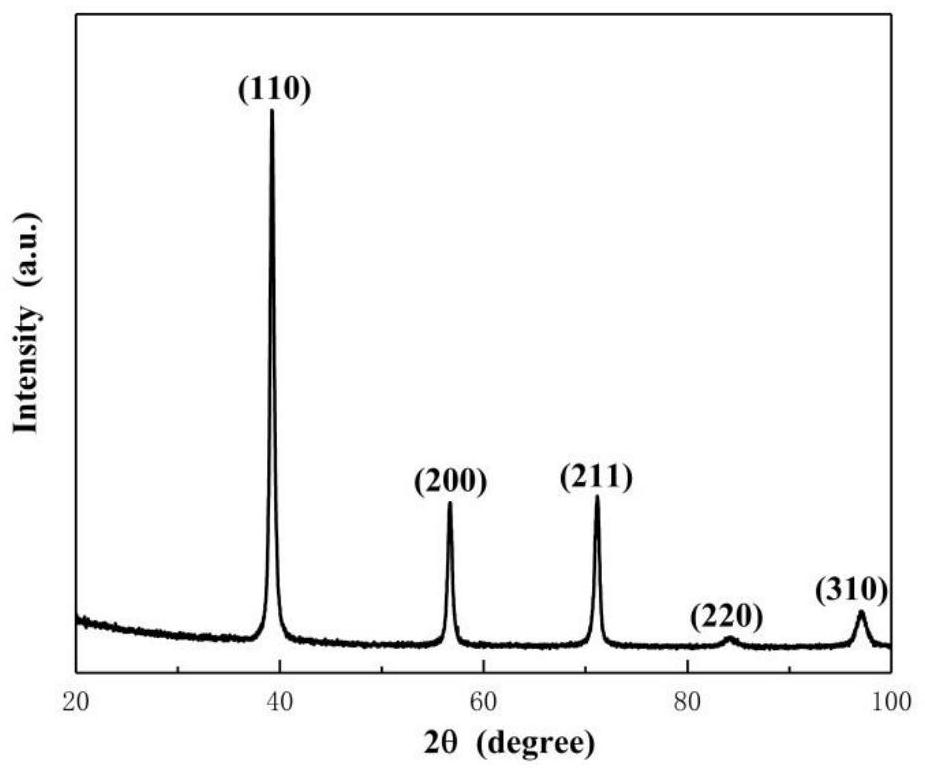

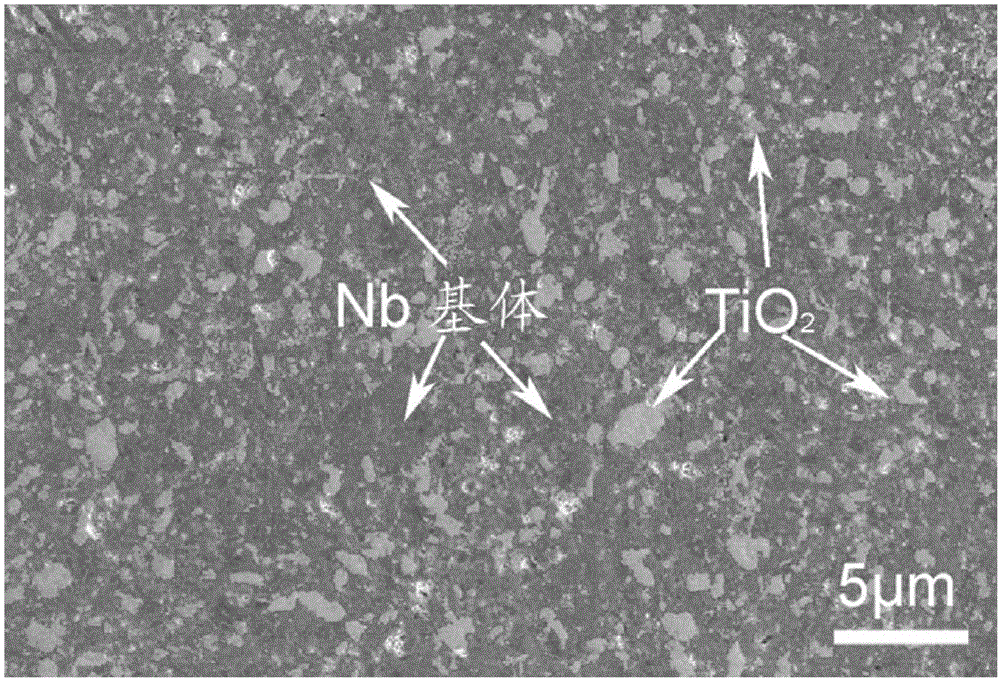

Nb-Hf-Zr-TiO2 alloy bar and preparation method thereof

ActiveCN106119651AImprove room temperature plasticityImprove high temperature mechanical propertiesHot isostatic pressingBall mill

The invention provides a Nb-Hf-Zr-TiO2 alloy bar which is prepared from the following raw materials in percentage by mass: 2-8% of Hf, 3-7% of Zr, 4-10% of TiO2 and the balance of Nb. The invention further provides a preparation method of such alloy bar. The preparation method comprises the following steps: 1, putting Nb, Hf, Zr and TiO2 into a ball mill, and uniformly mixing the raw materials by ball milling under the protection of an argon atmosphere, so as to obtain mixed powder; 2, carrying out compression molding to obtain a blank; 3, putting the blank into a shell, vacuumizing, and then enclosing the shell; 4, carrying out hot isostatic pressing to obtain a Nb-Hf-Zr-TiO2 alloy sintered body; and 5, carrying out hot extrusion to obtain the Nb-Hf-Zr-TiO2 alloy bar. The Nb-Hf-Zr-TiO2 alloy bar provided by the invention is good in room-temperature plasticity and tensile strength, is excellent in fatigue strength and high-temperature strength, and can be applied to an engine component of an aircraft turbine engine.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

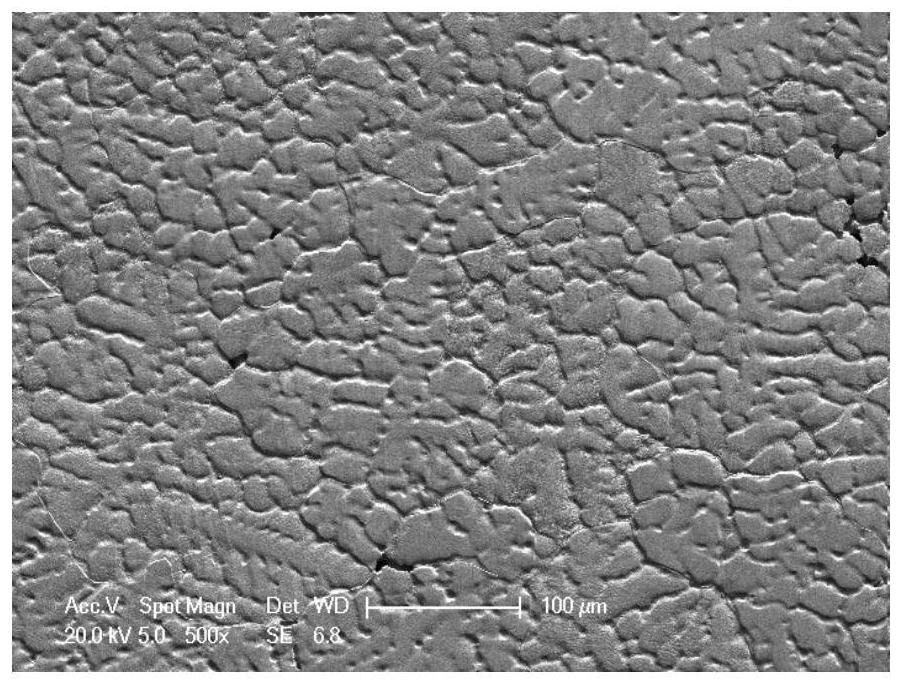

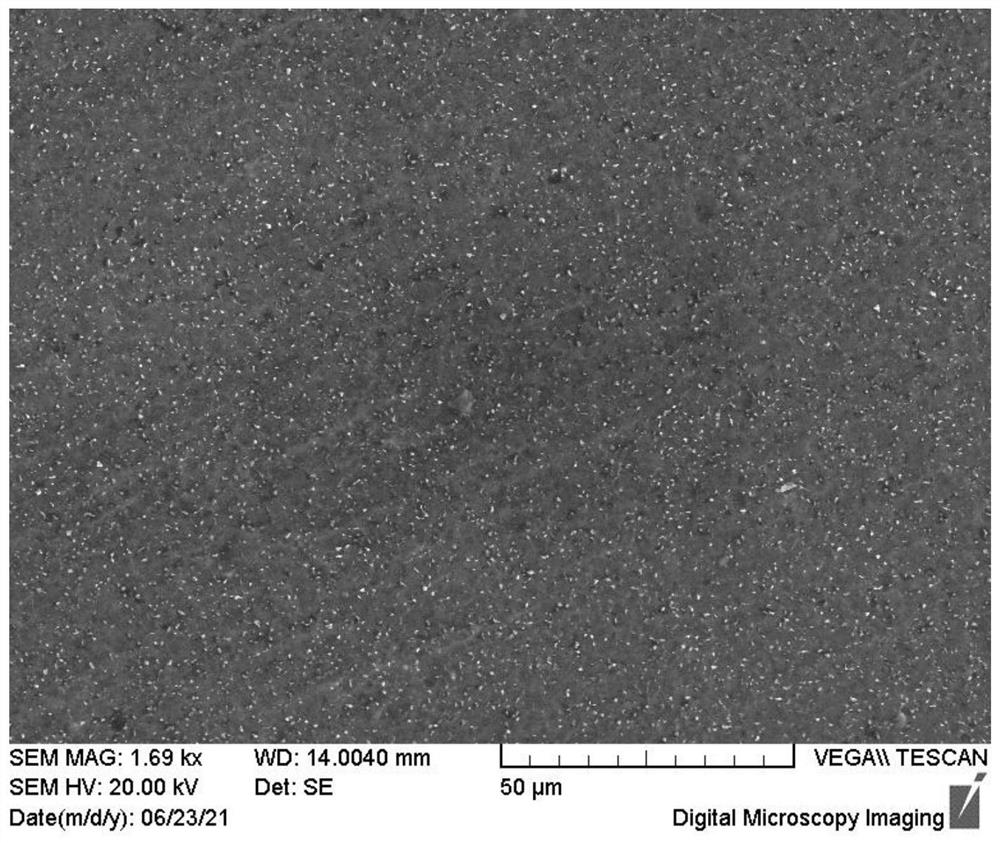

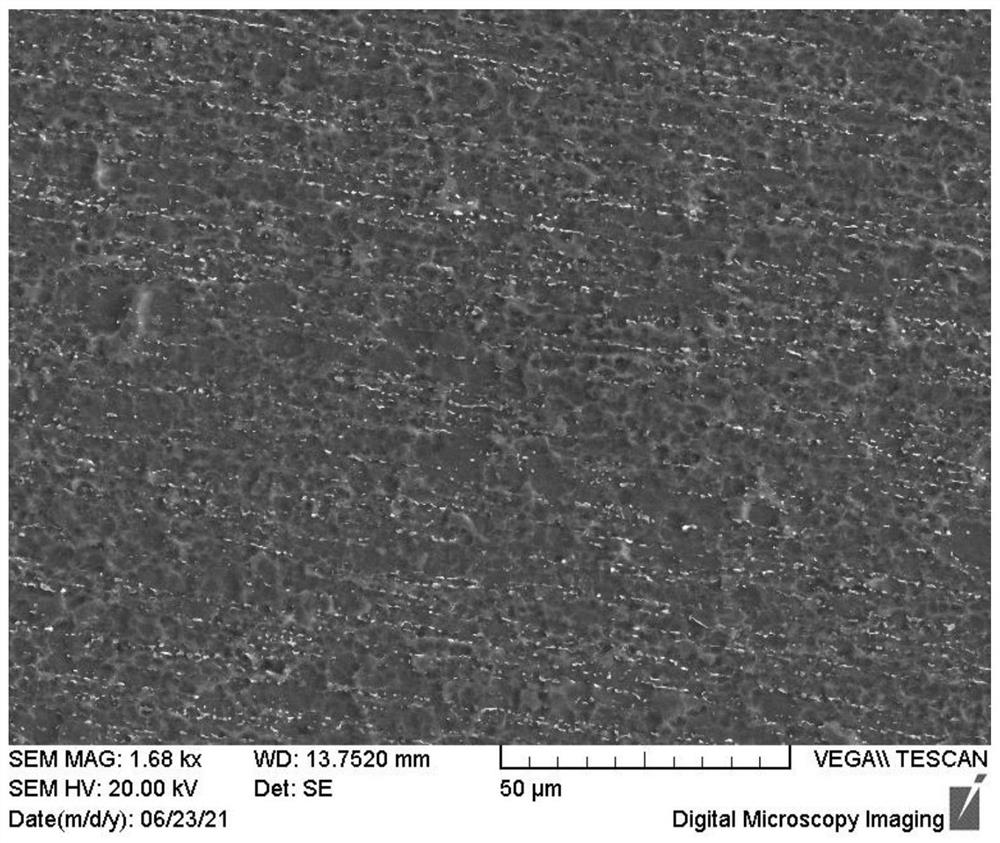

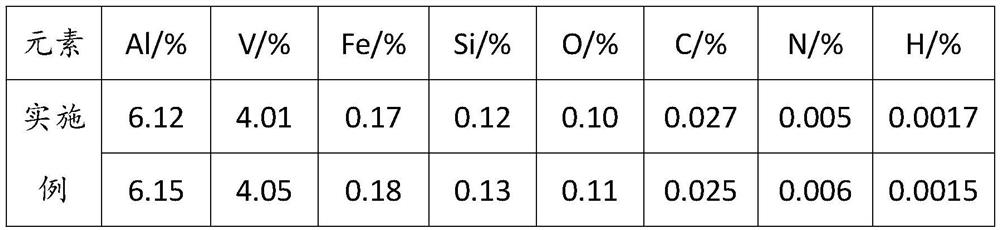

TC4ELI titanium alloy for ultrasonic scalpel and production method of titanium alloy bar

PendingCN113528893AImprove mechanical properties at room temperatureImprove mechanical propertiesTitaniumHot working

The invention belongs to the technical field of medical titanium alloy bars, and provides a TC4ELI titanium alloy for an ultrasonic scalpel and a production method of the titanium alloy bar. The TC4ELI titanium alloy specifically comprises the following material chemical components: 5.5-6.5% of Al, 3.5-4.5% of V, 0.15-0.25% of Fe, 0.1-0.5% of Si, 0.08-0.13% of O, 0-0.05% of C, 0-0.03% of N, 0-0.005% of H, and the balance of Ti and inevitable impurity elements in titanium sponge. The raw materials are subjected to three times of vacuum consumable smelting, so that the components are uniform and consistent without internal defects. The blank is subjected to a series of later hot working and heat treatment, and the performance meets the performance requirement of the ultrasonic scalpel. According to the method, the steps of composition, hot working and heat treatment are controlled step by step, the titanium alloy bar with the best matching strength, plasticity, toughness and fatigue performance is prepared, the ultra-high cycle fatigue of the ultrasonic scalpel is improved, the service life is prolonged, the scalpel breaking phenomenon in the operation process is avoided, and the method has wide application prospects.

Owner:西安圣泰金属材料有限公司

Method for preparing magnesium and magnesium alloy composite grain refiner

The invention provides a magnesium and magnesium alloy composite grain refiner and a preparation method thereof. The chemical composition of the refiner is (percentage by weight): 15-37.5% aluminum, 5-12.5% carbon, 5-20% cerium, and the balance is magnesium. The preparation method of the refiner is as follows: dry-mix aluminum powder, carbon powder and magnesium powder, briquette and dry them, place them in a corundum crucible and fill them with refractory powder, and heat them in a box-type resistance furnace at 700-900°C Mg-Al4C3 is obtained by isothermal treatment for 30-120 minutes, and then remelted with magnesium ingot and Mg-25%Ce master alloy to finally prepare Mg-Al4C3-Ce composite grain refiner. The method is easy to operate and easy to industrialized production, and the prepared compound refiner is easy to control the content and easy to add, and can obviously refine the crystal grains of magnesium and magnesium alloys.

Owner:WUHAN UNIV OF TECH

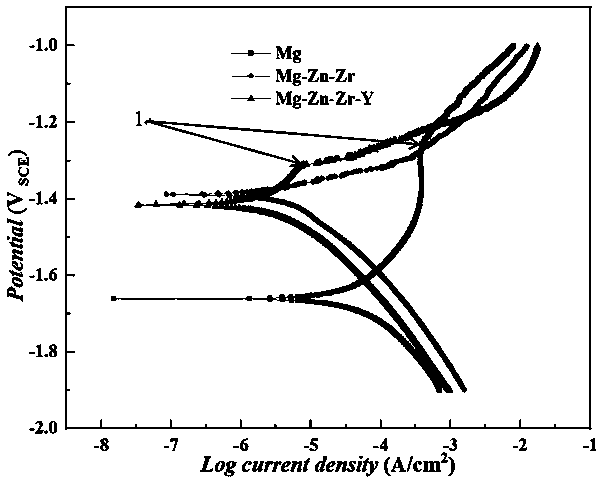

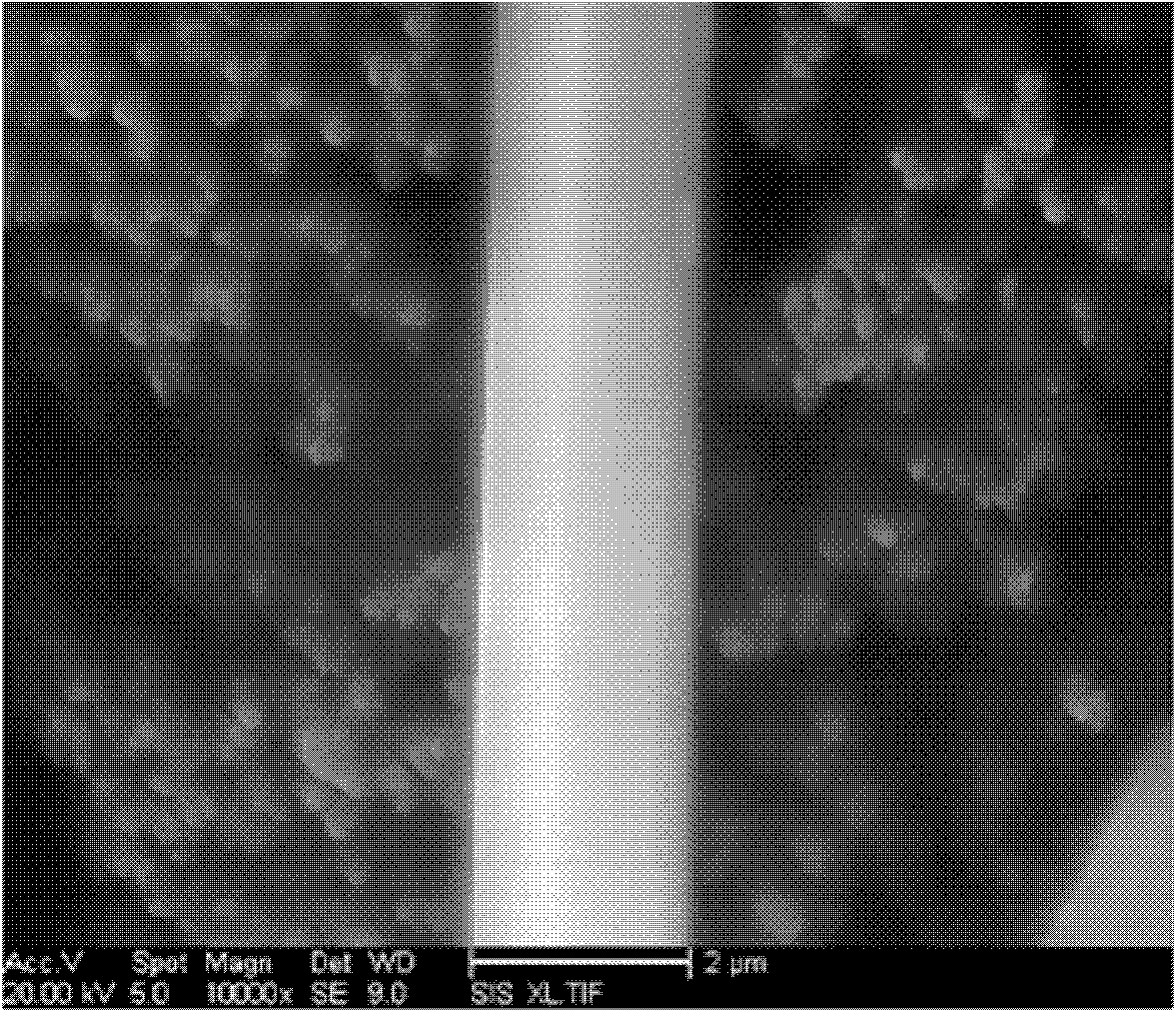

Degradable biomedical forging-state magnesium alloy and preparation method thereof

ActiveCN110144505AExtensive sources of raw materialsRaw material source is easy to getRepair materialImplant material

The invention provides a degradable biomedical forging-state magnesium alloy, and belongs to the field of degradable biomedical materials. The degradable biomedical forging-state magnesium alloy is prepared from the components in percentage by mass: 3.3 to 9 percent of Zn, 0.1 to 0.6 percent of Zr, 0.75 to 2 percent of Y, and the balance Mg, wherein the mass ratio of Zn / Y is larger than 4.38 and smaller than 6. The magnesium alloy not only has a favorable magnesium alloy and good corrosion resistance, but also has favorable biocompatibility, is suitable to be used as bone repair materials suchas a porous magnesium alloy material, a plastic surgery department material, an oral cavity oral cavity implant material and a bone lamella nail, and is particularly suitable to be used as a cardiovascular stent material and a bone repair material.

Owner:NANYANG NORMAL UNIV

Engine cylinder cover

The invention relates to an engine assembly, in particular to an engine cylinder cover. The engine cylinder cover solves the preparation problem of a high-performance large engine cylinder cover. The engine cylinder cover is prepared from cast alloy comprising, by percentage content, 3.7-3.8% of carbon (C), 2.3-2.4% of silicon (Si), 0.5-0.55% of manganese (Mn), 1-3% of copper (Cu), 1-2% of stannum (Sn), 0.03-0.15% of cerium (Ce), 0.04-0.30% of yttrium (Y), 0.01-0.03% of erbium (Er), 0.15-0.25% of titanium (Ti), 0.25-0.50% of stibium (Sb), 0.15-0.25% of bismuth (Bi) and 0.12-0.20% of niobium (Nb). The dissolving rate of austenite is increased due to various rare earth elements in cast iron, so that ferrite nucleation is hindered, and the rare earth elements are strong pearlite promotion elements. The shape of graphite in the cast iron can be changed, the casting technology is improved, and normal-temperature mechanical performance and high-temperature mechanical performance of the cast iron are greatly improved.

Owner:宁静

Preparation method of aluminum based composite material reinforced by aluminium borate whisker coated with CuO

The invention discloses a preparation method of an aluminum based composite material reinforced by aluminium borate whisker coated with CuO, relating to a preparation method of an aluminum based composite material reinforced by the aluminium borate whisker and overcoming the defects that the existing aluminum based composite material reinforced by the aluminium borate whisker is poor in mechanical property and incapable of being used in high-temperature environment. The preparation method includes the steps of firstly preparing CuO sol, secondly preparing the aluminium borate whisker coated with the CuO sol, thirdly preparing an aluminium borate whisker prefabticated member coated with the CuO sol, and fourthly preparing the aluminum based composite material reinforced by the aluminium borate whisker coated with CuO. The preparation method can be used for the aluminum based composite material reinforced by whisker.

Owner:HARBIN UNIV OF SCI & TECH

High-aluminum high-temperature-resistant nodular cast iron containing Mo and Cr elements as well as preparation method of high-aluminum high-temperature-resistant nodular cast iron

ActiveCN107723582AFragmentation is weakImprove high temperature performanceProcess efficiency improvementMechanical propertyOperating temperature

The invention discloses high-aluminum high-temperature-resistant nodular cast iron containing Mo and Cr elements. According to the technical scheme, the nodular cast iron is characterized by comprising the components including, by weight, 1.0%-3.0% of C, 0.15%-3.0% of Si, 19.5%-26.0% of Al, 0.3%-3.0% of Mo, 0.5%-2.5% of Cr, 0.3%-1.5% of Cu, not more than 0.06% of an impurity element Mg, not more than 0.06% of an impurity element S, not more than 0.15% of an impurity element P, not more than 0.7% of an impurity element Mn, and the balance Fe. The nodular cast iron provided by the invention canresist the operating temperature of 950 DEG C, has the good thermal shock property, the good high-temperature oxidation resistance property, the good comprehensive mechanical property, and the good casting formation property, and is relatively low in cost.

Owner:纳似韦科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com