Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Improve high temperature aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature wear-resisting ceramic composite fiber brake block

InactiveCN103122959AInhibition of devitrification changesImprove adhesionOther chemical processesFriction liningCeramic compositeBarium titanate

The invention relates to a high-temperature wear-resisting ceramic composite fiber brake block which is manufactured by processing framework materials and auxiliary materials through material mixing, mould pressing, hot press molding and solidification procedures, wherein the framework materials comprise bismaleimide modified phenolic resin, short aramid fiber, high-purity ceramic fiber, potassium titanate fiber, mineral fiber, barium titanate and nickel; the auxiliary materials comprise molybdenum sulfide and / or tin sulfide, graphite and / or coke, acrylonitrile-butadiene rubber, mica, zinc oxide, stearic acid, barium sulfate and 4010-type antiager. The high-temperature wear-resisting ceramic composite fiber brake block solves the problems existing in the prior brake blocks, can well avoid high-speed decay and high-temperature decay, has the advantages of being good in staibility and long in service life, and is a high-temperature wear-resisting ceramic composite fiber brake block which is low in noise, high in intensity and low in pollution.

Owner:山东金山汽配有限公司

High-temperature-resistant ultraviolet-resistant epoxy resin prepolymer and preparation method thereof

InactiveCN105384914AImprove high temperature aging resistanceImproves UV resistancePolyolAntioxidant

The present invention discloses a high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer comprising the following components: 20-50wt% of epoxy resin, 40-60wt% of an anhydride curing agent, 1-15wt% of a polyol, 0.1-2wt% of a coupling agent and 0.1wt%-5wt% of an antioxidant; a preparation method of the high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer is as follows: after the epoxy resin and the antioxidant are evenly mixed, the anhydride curing agent and the coupling agent are added, when the reaction system is cooled to 40 DEG C-80 DEG C, the polyol is added for ring opening reaction with anhydride to obtain a carboxylic compound, and the carboxyl compound is reacted with the epoxy resin to obtain the epoxy resin prepolymer. Advantages of the high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer are that: the high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer has excellent high-temperature aging resistance and ultraviolet resistance, and the preparation method is simple, raw materials are easily available, the process is controllable, industrial production is easy, and the high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer can be widely used in electronic device packaging materials, coatings and adhesives and other field.

Owner:WUXI CHUANGDA ELECTRONICS

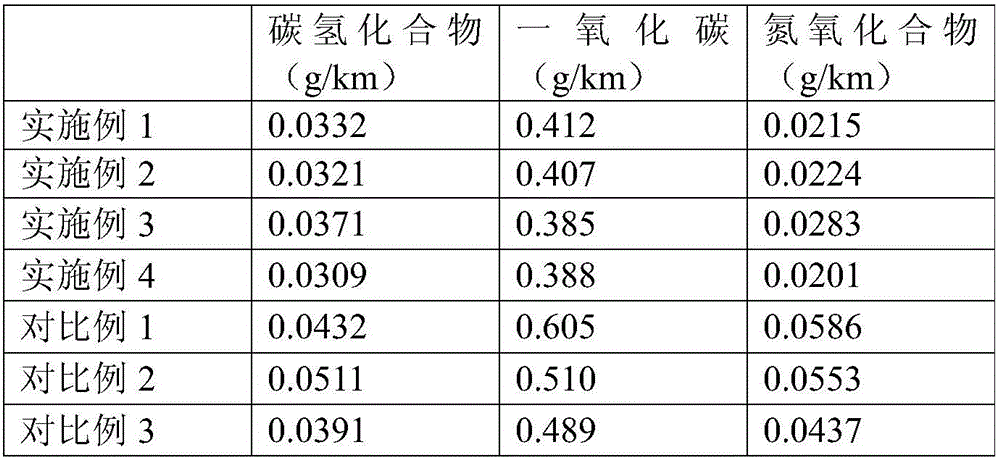

Automobile ternary catalytic converter

InactiveCN107790124AImprove high temperature aging resistanceReduce failure rateMolecular sieve catalystsInternal combustion piston enginesMolecular sieveComposite oxide

The invention discloses an automobile ternary catalytic converter. The automobile ternary catalytic converter comprises a honeycomb ceramic carrier, and a catalyst used for coating the honeycomb ceramic carrier. The automobile ternary catalytic converter is of a double-layer structure; the internal layer is a Pd layer catalyst converter, the external layer is a Rh catalytic layer used for coatingthe Pd layer catalyst converter; the Pd layer catalyst converter is composed of the honeycomb ceramic carrier and a Pd catalyst layer used for coating the honeycomb ceramic carrier; the Pd catalyst layer is prepared via mixing of a ceria-zirconia composite oxide, modified Al2O3, a molecular sieve, and precious metal Pd; the Rh catalyst layer is prepared via mixing of the ceria-zirconia composite oxide, modified Al2O3, a molecular sieve, and precious metal Rh. The double-layer structure is adopted by the automobile ternary catalysis converter, so that the high temperature and aging resistance of the automobile ternary catalysis converter are improved, the probability of activator failure caused by alloy formed among metal is reduced, the Rh layer on the external surface is beneficial for preferential adsorption conversion of NOx, increasing of NOx conversion efficiency, and reducing NOx discharge.

Owner:CHONGQING BRILLIANT TIGER CATALYTIC

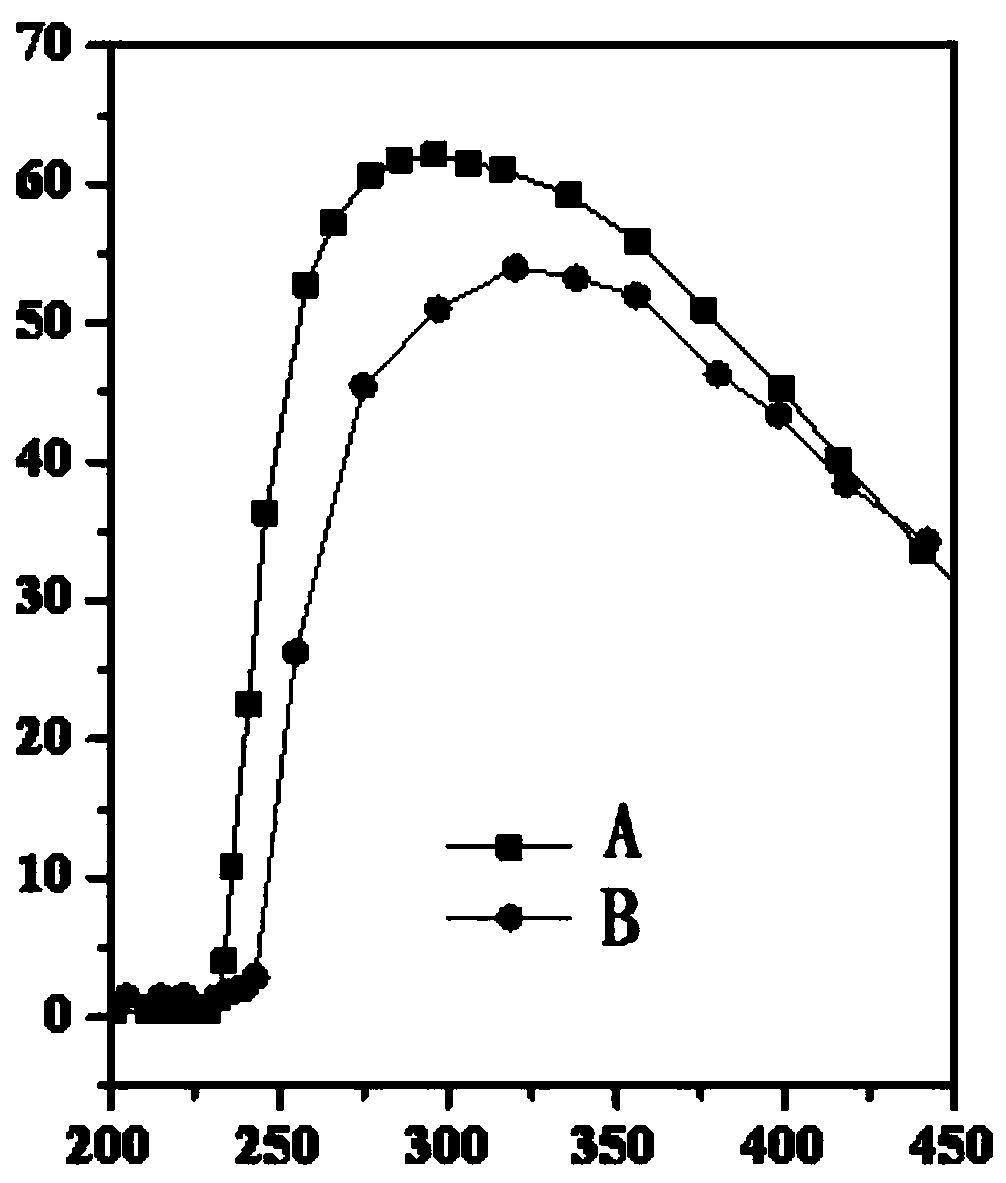

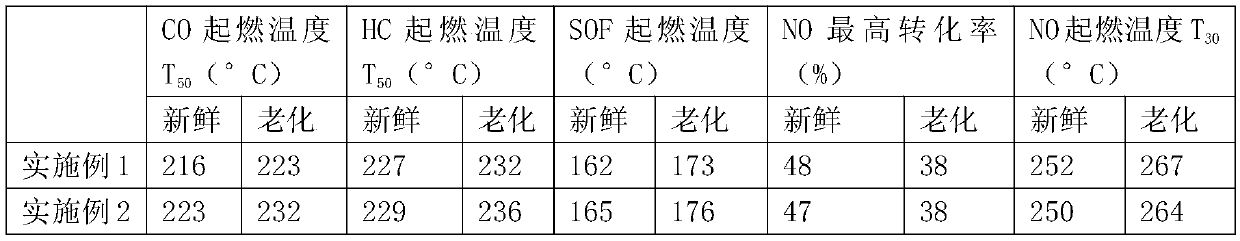

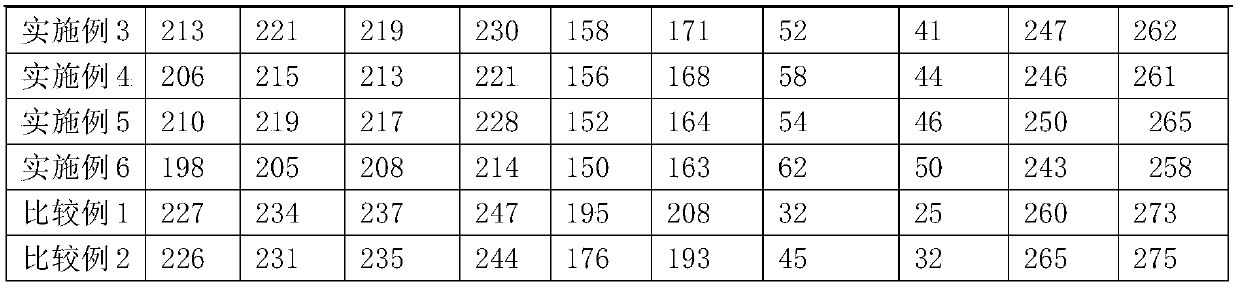

Integral diesel vehicle tail gas oxidization catalyst and preparation method thereof

ActiveCN109590014AGood activity and stabilityImprove thermal stabilityGas treatmentMolecular sieve catalystsAlkaline earth metalRare earth

The invention discloses an integral diesel vehicle tail gas oxidization catalyst and a preparation method thereof. The preparation method comprises the following steps: loading noble metal on a SiO2-Al2O3 carrier modified by an auxiliary agent to obtain a catalyst powder material; and coating a cordierite matrix with the catalyst powder material to prepare the integral diesel vehicle tail gas oxidization catalyst, wherein the mass percent content of SiO2 in the carrier is 10 to 30 weight percent, noble metal is Pt and / or Pd and the total loading amount is 1 to 3 weight percent. The SiO2-Al2O3carrier is prepared by modifying through auxiliary agents including rare earth metal, alkaline earth metal and the like; and a DOC (Diesel Oxidation Catalyst) prepared from the carrier can be used forimproving the activity of CO, HC, SOF and NO and high-temperature ageing resisting performance, especially the NO oxidation activity.

Owner:SICHUAN UNIV

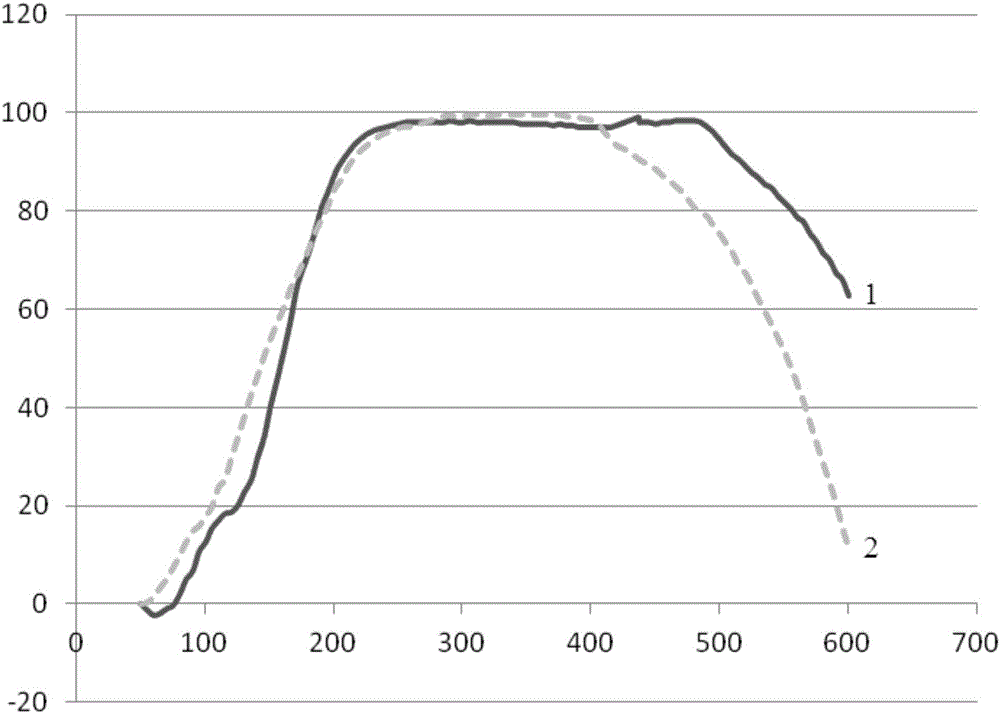

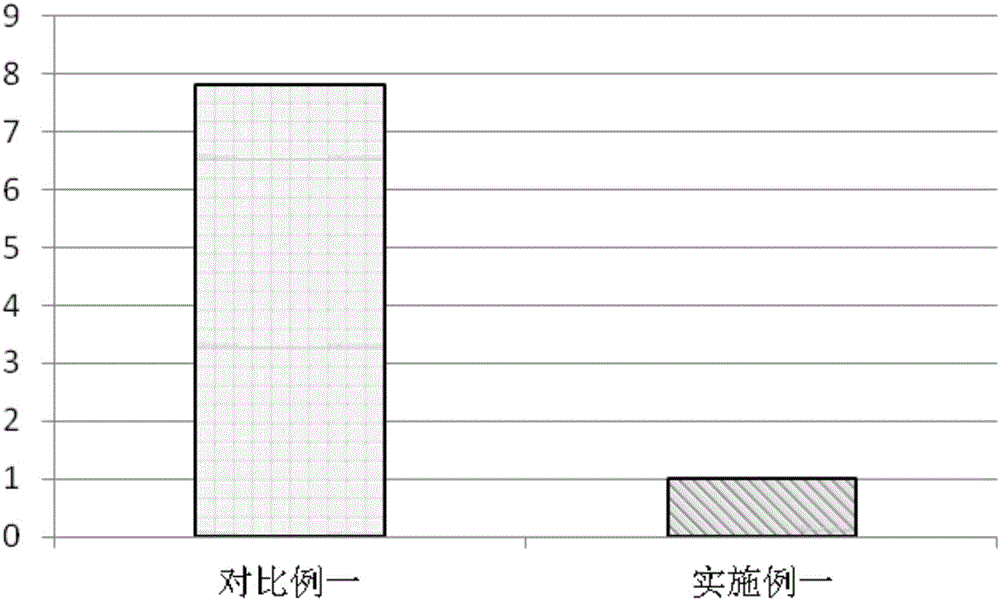

Manufacturing method for efficient three-component catalyst coating

InactiveCN105772023ATo achieve the best effect of controlAvoid Alloying DisadvantagesHeterogenous catalyst chemical elementsDispersed particle separationNitric oxideChemistry

The invention discloses a manufacturing method for an efficient three-component catalyst coating. The manufacturing method comprises the following steps: combining coating materials which are formed from a catalysis element, auxiliaries and various coating oxides and have different functions according to CO, HC and NOx oxidation and reduction control mechanism; segmenting a same carrier (at segmenting ratio of 1:2, 1:1 or 2:1), layering (at weight duty ratio of inner layer and surface layer of 2:1 or 1:1) and coating, wherein totally different tail gas control characteristics along axial direction of the carrier (airflow direction) is obtained according to an inner and outer two-layer secondary roasting forming compounding technique, so that the reduction process of nitric oxide (NOx) and the oxidation process for removing hydrocarbon compound (HC) and carbon monoxide (CO) happen in a certain sequence as required. The catalyst activity is effectively utilized, and meanwhile, the high-temperature ageing resisting property is promoted, the defects of alloying of different precious metals and alloying of precious metal and coating metallic oxide material are avoided, the design flexibility of the catalyst is enhanced and the optimal effect of the automobile exhaust control is achieved.

Owner:HUNAN JIANTE TECH CO LTD

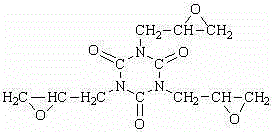

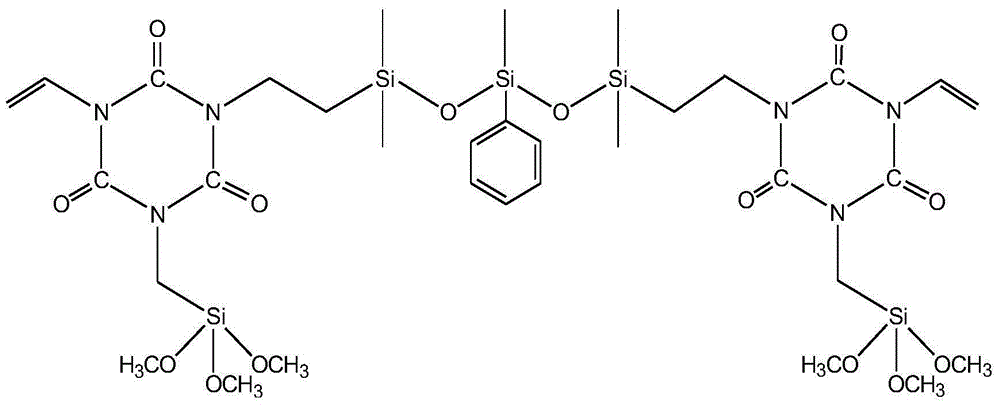

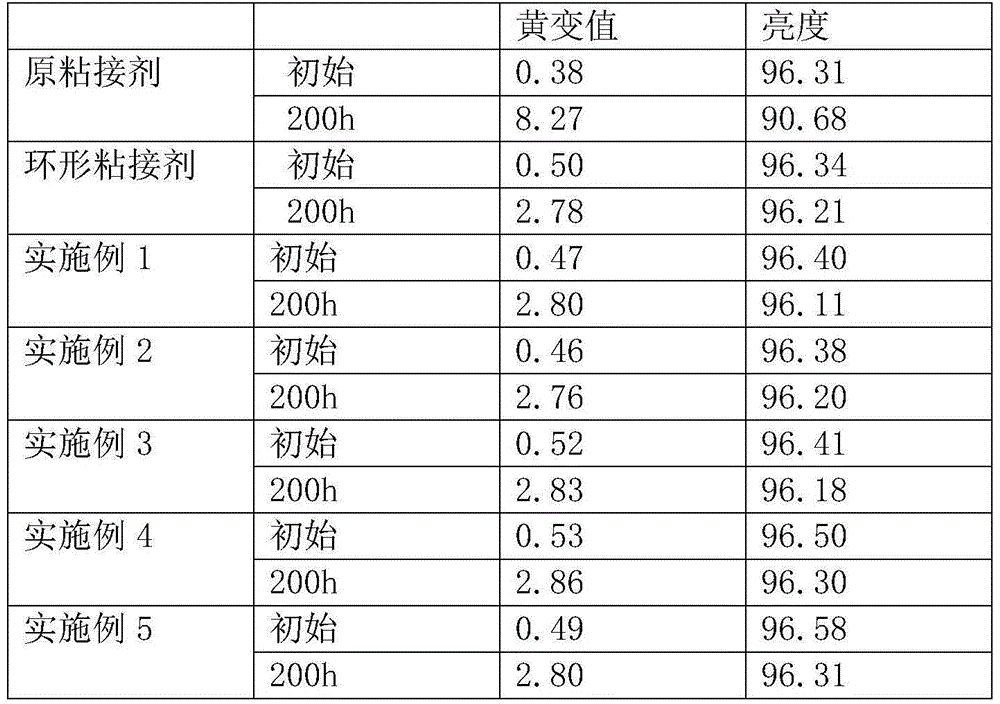

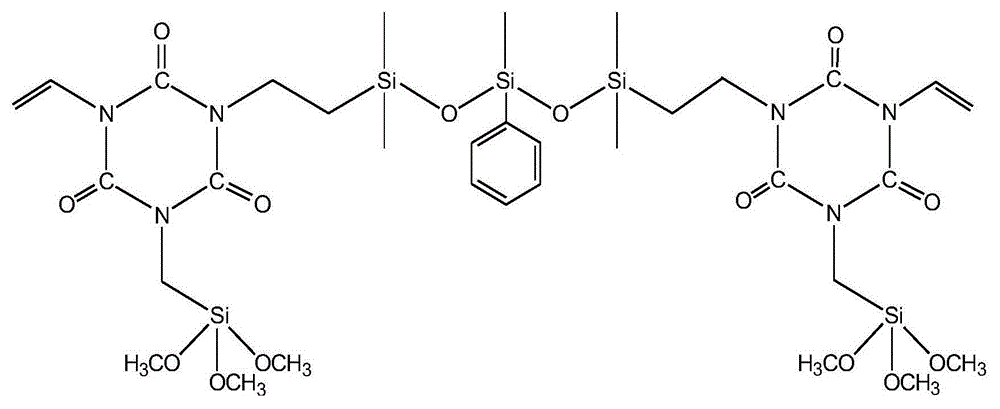

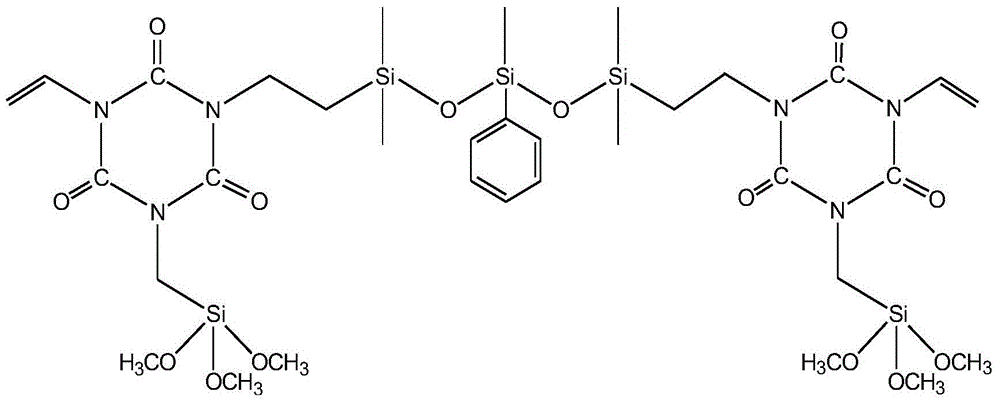

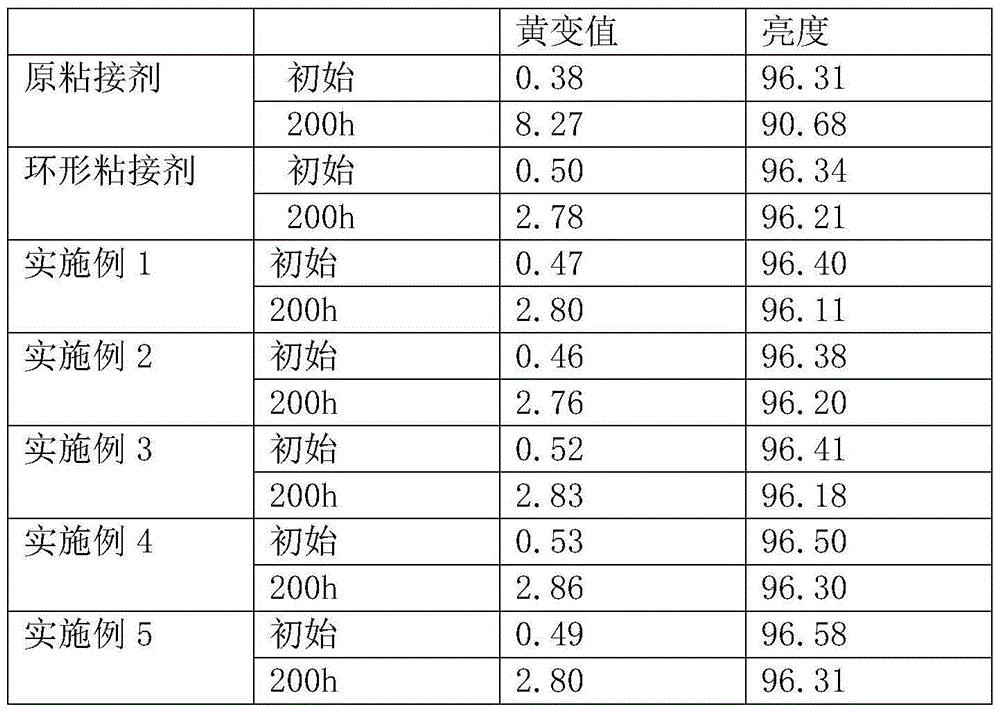

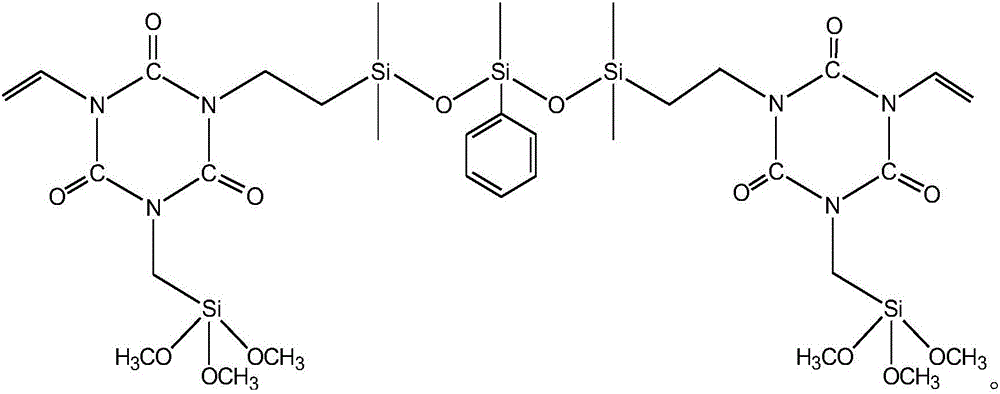

Annular adhesive and synthesizing method thereof

InactiveCN104987853AImprove vulcanization resistanceImprove high temperature aging resistanceAdhesivesActivated carbonAdhesive

Provided is an annular adhesive synthesizing method. The method comprises the steps of: adding 40-60 parts of triallyl isocyanurate and 0.0015-0.0040 parts of platinum catalyst into a three-necked flask; at the 65-80 DEG C reaction temperature, slowly dropping 17-28 parts of 1,1,3,5,5-pentamethyl-3-phenyl trisiloxanes into the three-necked flask,and finishing the dropping within 0.5 hours; and stirring and reacting the mixture for 3-4 hours; adding 21-33 parts of trimethoxysilane into the three-necked flask and finishing the dropping within 0.5 hours; continuing the stirring and reaction for four hours; and then stopping the reaction; and removing low boiling materials by performing distillation at a reduced pressure. 6-9 parts of activated carbon are added into the substance, stirring and adsorbing are performed for 12 hours, and the annular adhesive is obtained after the material is filtered.

Owner:YANTAI DARBOND TECH

Flame-retardant high-temperature-resistance polyamide composition and preparation method thereof

The invention discloses a flame-retardant high-temperature-resistance polyamide composition and a preparation method thereof. The composition is characterized by being prepared from the following components in parts by weight: 40-70 parts of polyamide, 5-15 parts of polyester, 0-10 parts of an impact-resistant modifier, 15-60 parts of a filler, 5-200 parts of a fire retardant and 0.2-1 part of a thermal stabilizing agent. According to the method, polyester and polyamide are mixed and modified, the polyamide carbonizing capability can be improved by means of polyester, the flame retarding performance of polyamide can be improved, the usage amount of flame retardant can be reduced, and further the attenuation of high-temperature aging resistance caused by introducing massive flame retardant can be further reduced; the alloy fluidity is further improved by using polyester, and the mold filling capability in the material injection-molding process can be improved. The flame-retardant high-temperature-resistance polyamide composition is especially applicable to the most advanced fields of precise electronic appliance parts, automobile engine compartment high-temperature high-humidity application environment, aerospace and the like.

Owner:SHANGHAI KINGFA SCI & TECH +2

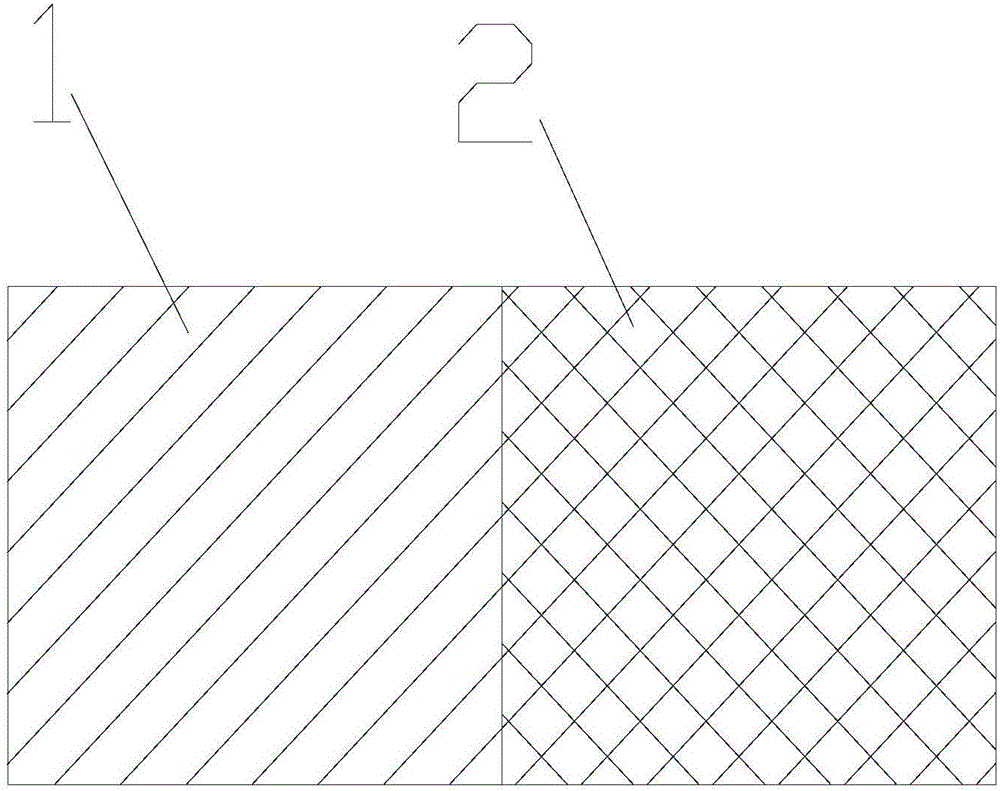

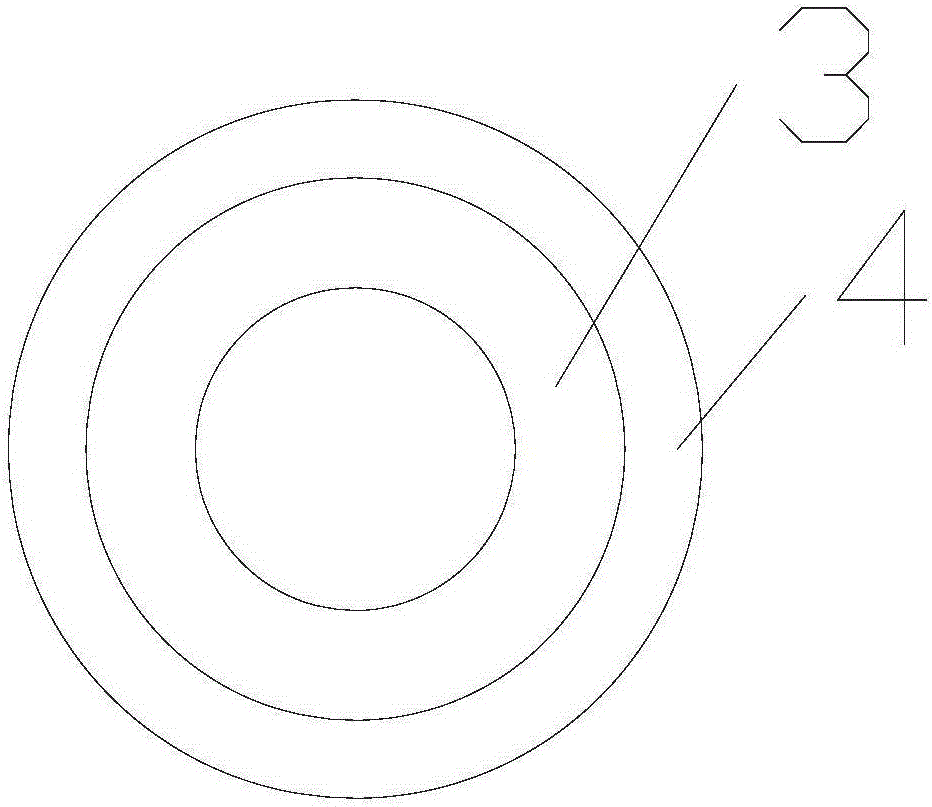

Pavement structure of steel bridge deck and construction method thereof

PendingCN109594471AClear functionalityClear securityBridge structural detailsBridge erection/assemblyEpoxyPolymer modified

The invention provides a pavement structure of a steel bridge deck and a construction method thereof. the pavement structure of the steel bridge deck comprises a first waterproof bonding layer, a modified epoxy asphalt macadam layer, a second waterproof bonding layer and an ultra-high performance structural layer which are sequentially paved on the surface of a steel plate of the steel bridge deck; the ultra-high performance structural layer is a pavement structural layer taking polymer modified asphalt as an adhesive, or comprises a pavement structural layer taking the polymer modified asphalt as the adhesive and a third waterproof bonding layer; the second waterproof bonding layer and the third waterproof bonding layer are the layers formed by at least one material of epoxy emulsified asphalt, polymer modified asphalt and polymer modified emulsified asphalt. The pavvement structure of the steel bridge deck provided by the invention has better resistance and stability.

Owner:广州珠江黄埔大桥建设有限公司 +2

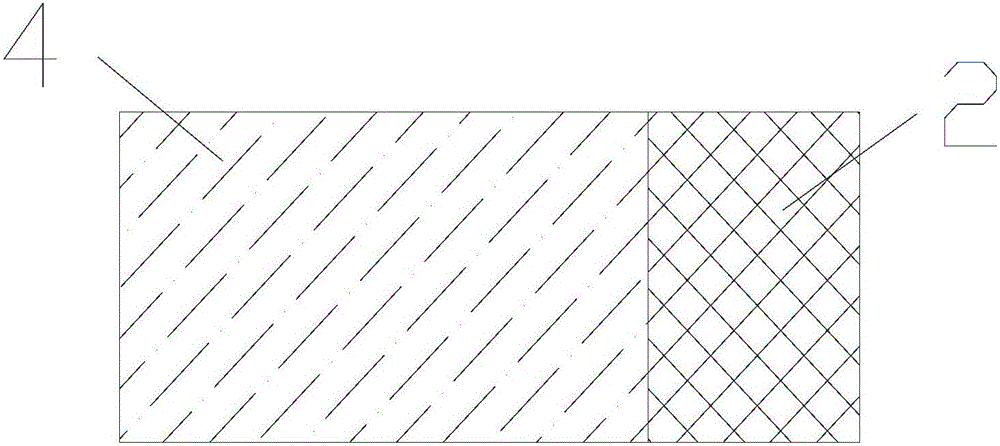

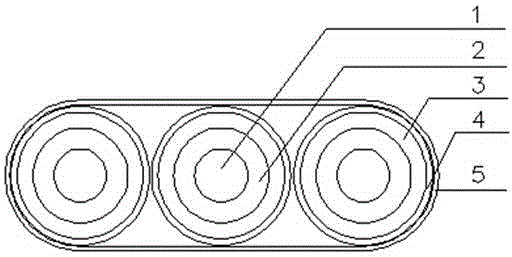

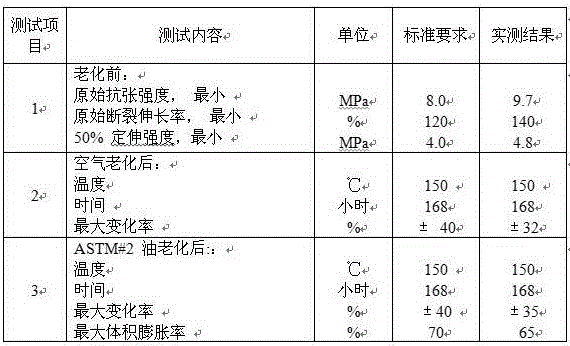

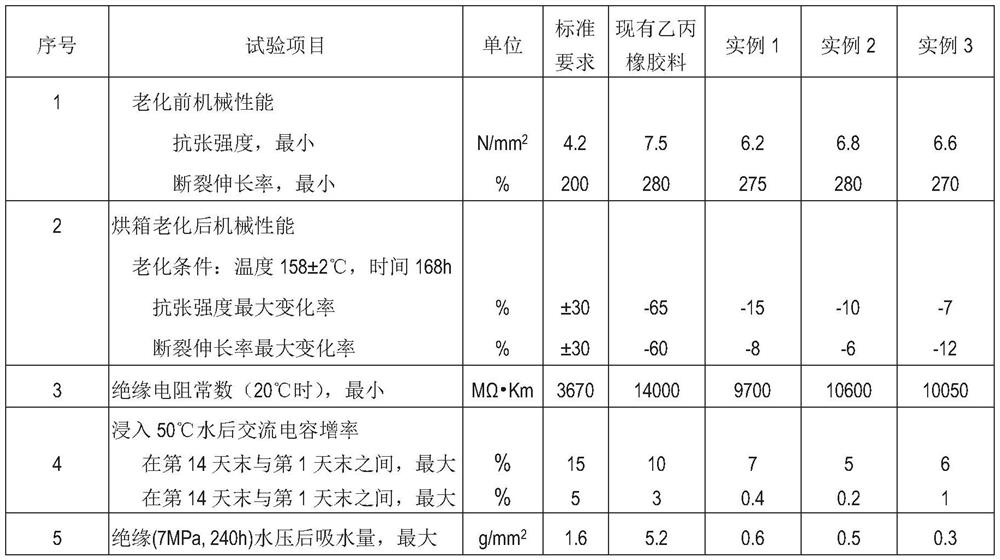

High-temperature submersible oil pump cable and manufacturing process thereof

InactiveCN104485163AImprove high temperature aging resistanceRubber insulatorsClimate change adaptationElectrical conductorEthylene-propylene-diene-monomer

The invention relates to a high-temperature submersible oil pump cable and a manufacturing process thereof, and belongs to the technical field of submersible oil pump cables for an oil field. The technical solution is that the high-temperature submersible oil pump cable comprises a conductor (1), an ethylene propylene insulating layer (2), a lead sheath (3), an isolating layer (4) and a steel-tape armor layer (5), where the ethylene propylene insulating layer which is ethylene propylene diene monomer is extruded outside the conductor; the surface of the conductor is coated with a binder at a temperature-resist grade of 232 DEG C before the ethylene propylene diene monomer is extruded; special ethylene propylene diene monomer is adopted; after the ethylene propylene insulating layer is extruded outside the conductor, highly anti-corrosive alloy lead is extruded outside to serve as the lead sheath; a high-temperature resistant adhesive tape is wound on the surface of the lead sheath to serve as the isolating layer to form a core wire; and three core wires are arranged in line and are coated with a linked steel tape outside which serves as the steel-tape armor layer, thus, the production of the cable is completed. According to the invention, the special ethylene propylene diene monomer is taken as the ethylene propylene insulating layer, so that the high-temperature resistant and anti-aging performance of the cable are improved; the continuous working temperature of the conductor is as high as 232 DEG C; and the ethylene propylene insulating layer is bonded with the conductor into a whole at a high temperature.

Owner:HEBEI HUATONG WIRES & CABLES GRP CO LTD

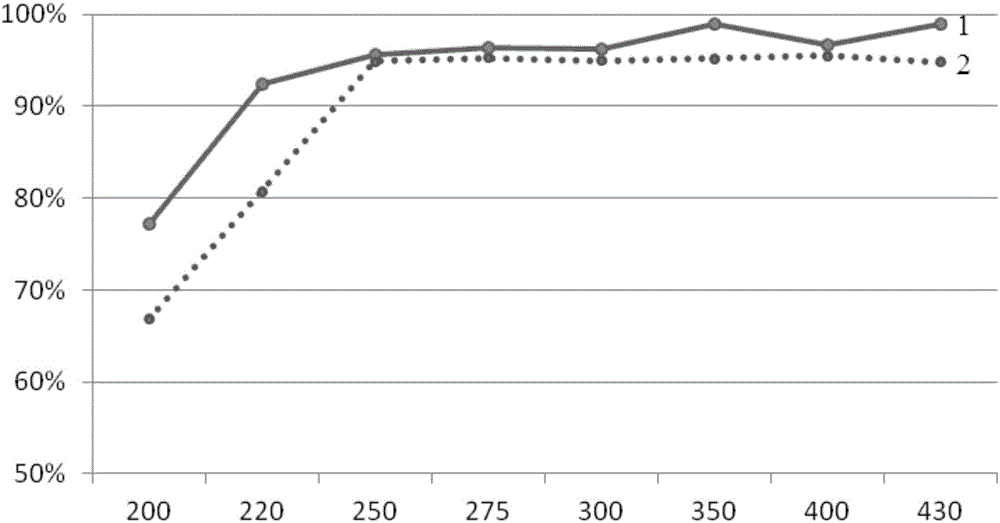

Three-way catalyst

ActiveCN106807370AImprove high temperature aging resistanceAvoid alloyingGas treatmentInternal combustion piston enginesHoneycombAlkaline earth oxides

The invention relates to a three-way catalyst, and belongs to the technical field of catalyst preparation. According to the three-way catalyst, a lower Pd coating is adhered to a honeycomb-shaped carrier; a middle Rh coating is adhered to the lower Pd coating; a solonetz metal oxide coating free of precious metal is adhered to the middle Rh coating; the solonetz metal oxide coating comprises one or more oxides of MgO, BaO, SrO and CaO; the mass ratio of the middle Rh coating to the solonetz metal oxide coating ranges from (10:1) to (30:1). After high-temperature aging, the three-way catalyst provided by the invention has relatively good treatment capability upon carbon monoxide, hydrocarbon and oxynitride.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

Preparation method of CHA molecular sieve SCR monolithic catalyst

InactiveCN106268929ASimple manufacturing processIncreased durabilityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAdhesive

The invention relates to a preparation method of a CHA molecular sieve SCR monolithic catalyst. The preparation method is characterized by comprising the following steps of 1 CHA molecular sieve aqueous solution preparing; 2 adhesive preparing, wherein Al sol and Si Sol are prepared, mixed and stirred to be uniform at uniform velocity, and then the mixture is aged for 1-3 h to obtain an adhesive; 3 viscosity controlling, wherein the CHA molecular sieve aqueous solution and the adhesive are mixed to prepare molecular sieve coating size with the needed solid content, the molecular sieve coating size is stirred for 1-3 h, the viscosity of the molecular sieve coating size is tested and regulated to be 100-1,000 cP by regulating the pH value; 4 carrier coating, wherein after carrier coating is conducted, the surplus molecular sieve coating size is blown out, dried and then calcined for 2-3 h after the temperature is increased to 500 DEG C to 650 DEG C at the temperature increasing speed of 3-5 DEG C / min. According to the preparation method, a preparation technology of the CHA molecular sieve monolithic catalyst is greatly simplified, the size stability is improved, the size viscosity is easily controlled, and therefore the size can adapt to multiple coating processes.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

Photo-catalytic oxidation desulfurization method and catalyst for diesel or gasoline

InactiveCN104357080AImprove high temperature aging resistanceHigh bond energyOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPtru catalystPolystyrene

The invention discloses a photo-catalytic oxidation desulfurization catalyst for diesel or gasoline. The photo-catalytic oxidation desulfurization catalyst is characterized by being prepared by the step that macroporous polystyrene series resin is subjected to fluorine-modification and loaded with phosphotungstic acid. The desulfurization method adopting the catalyst comprises the steps as follows: sulfur-containing diesel or gasoline is taken as the raw material and has a photo-catalytic oxidation desulfurization reaction with existence of an oxidizing agent, the catalyst and an ultraviolet light source, and a material after reaction is separated and then extracted by an extraction agent to obtain product diesel or gasoline. According to the photo-catalytic oxidation desulfurization catalyst for diesel or gasoline, oxygen replaces H2O2 and is used as the oxidizing agent, so that the defects of higher price, poor stability, generation of large quantity of waste water in a desulfurization process and the like of H2O2 are overcome, by means of application of the photocatalytic technology, the reaction condition is mild, the operation cost is low, and environmental friendliness is realized. Fluoride is grafted to the polystyrene resin, and the high temperature aging resistance and photo-catalytic oxidation desulfurization performance of the catalyst are improved by means of the high bond energy of a fluorocarbon bond as well as powerful electronegativity and photoelectricity of fluorine atoms.

Owner:OCEAN UNIV OF CHINA +1

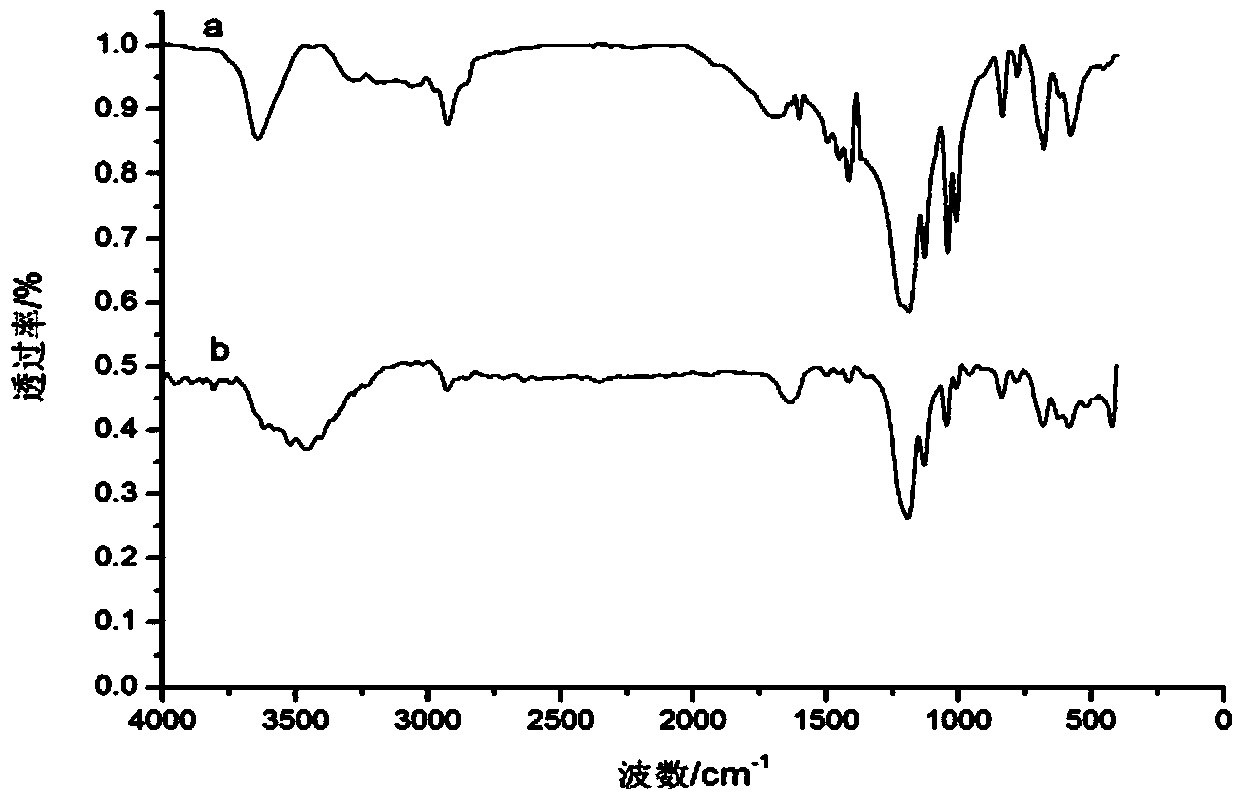

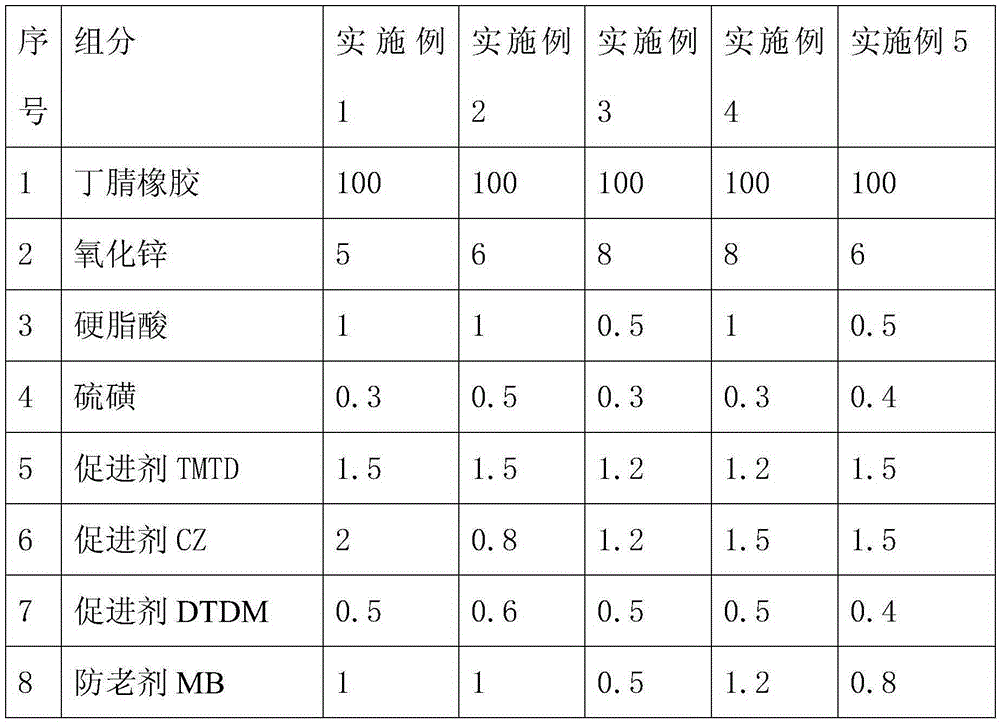

High temperature resistant low voltage variable light-colored acrylonitrile-butadiene rubber formula for skeleton oil seal

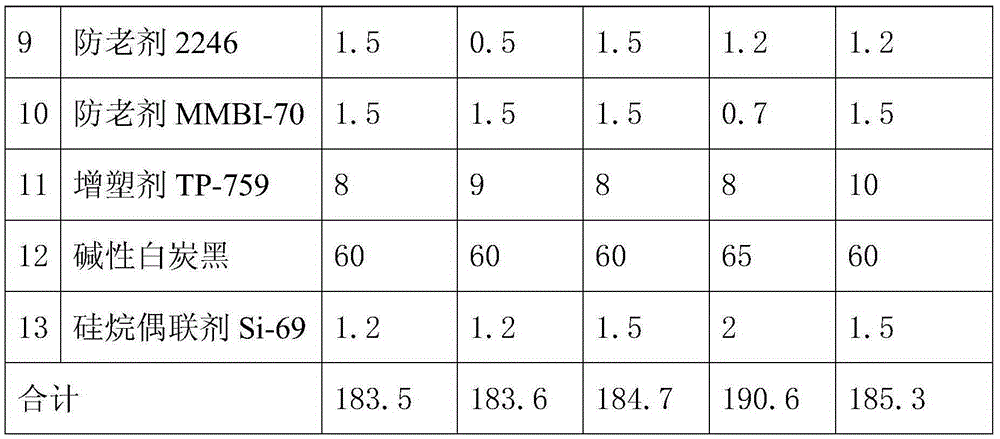

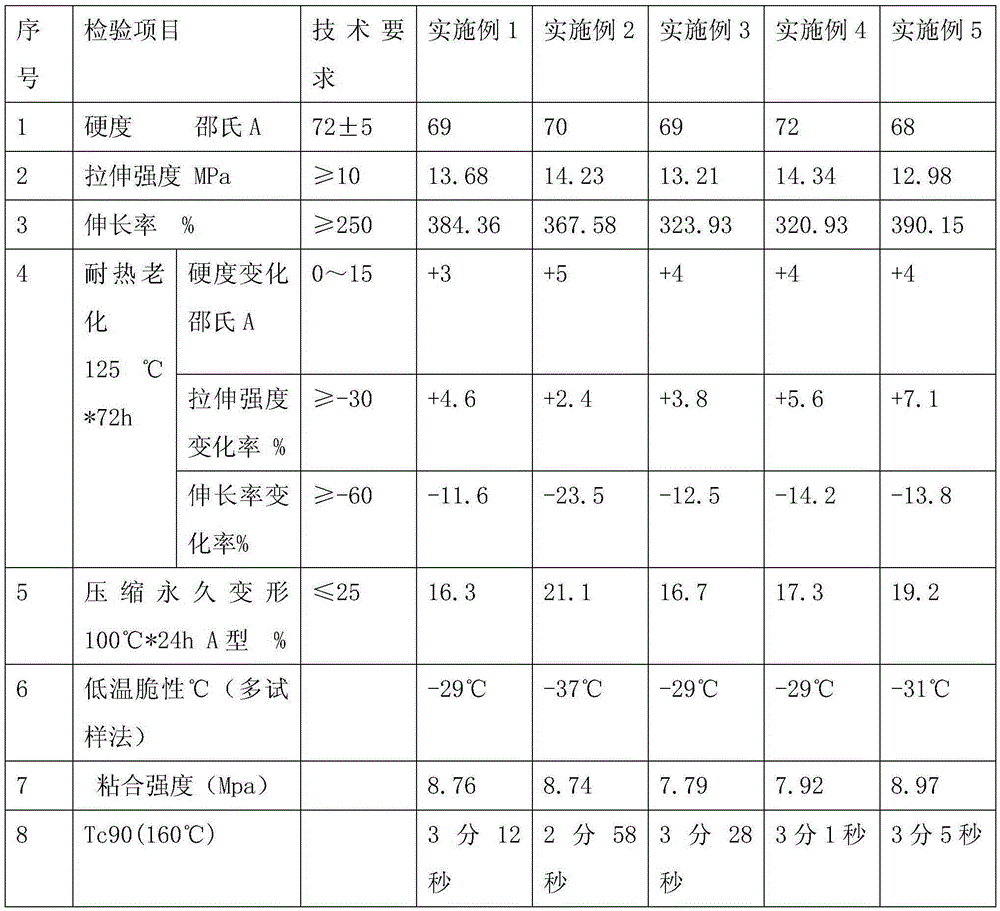

The present invention relates to a high temperature resistant low voltage variable light-colored acrylonitrile-butadiene rubber formula for a skeleton oil seal. The formula comprises the following compounds: acrylonitrile-butadiene rubber, zinc oxide, alkaline white carbon, a silane coupling agent Si-69, stearic acid, sulfur, a promoter TMTD, a promoter CZ, a promoter DTDM, an antioxidant 2246, an antioxidant MB, an antioxidant MMBI-70, and TP-759. According to the rubber provided by the present invention, hardness variation is 3, and a change rate of elongation is -11.6% at 125 DEG C for 72 hours in an experiment. A type voltage variation (25% compression) is 16 at 100 DEG C for 24 hours.

Owner:NANJING ORIENTLEADER TECH CO LTD

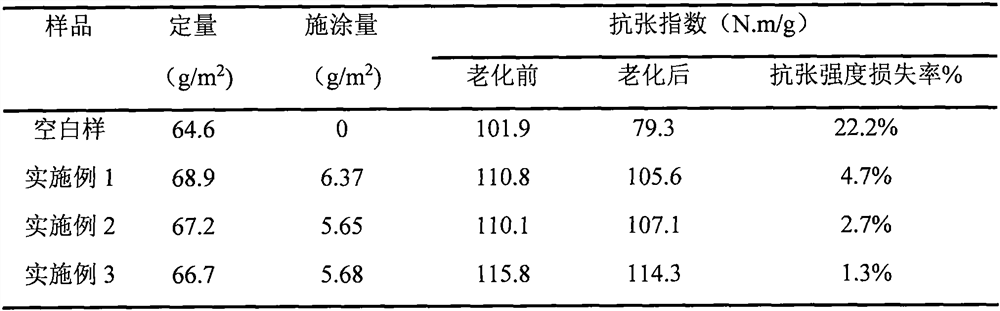

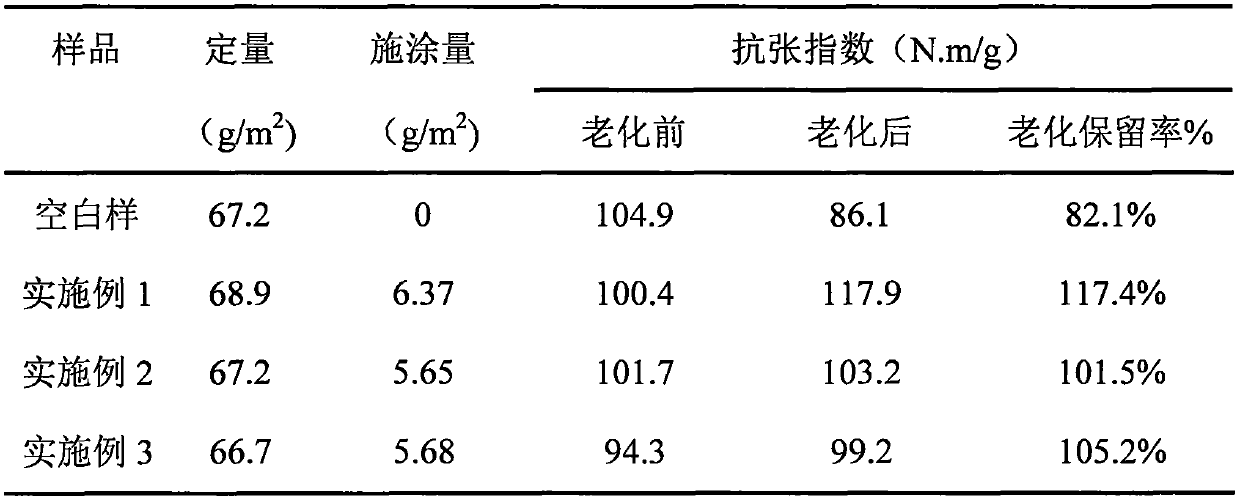

Preparation method of heat-resistant auxiliary agent for temperature-resistant insulating paper

InactiveCN112647347AImprove high temperature resistanceImprove high temperature aging resistanceAgeing prevention agents additionPaper coatingFiberPhysical chemistry

The invention discloses a preparation method of a heat-resistant auxiliary agent for temperature-resistant insulating paper. The method comprises the following steps of: compounding enclosed waterborne polyurethane and a nitrogen-containing compound to prepare a heat-resistant auxiliary agent, and applying the heat-resistant auxiliary agent to the surface of the insulating paper through a coating, spraying or dipping method. According to the invention, a deblocking reaction can be carried out by utilizing a blocking group of blocked waterborne polyurethane, an isocyanate group with strong reaction activity is exposed again, and the isocyanate group and hydroxyl on fibers are subjected to a chemical reaction to form a three-dimensional network structure, so that the bonding points and the bonding strength among the fibers are increased, and the high-temperature aging resistance of the insulating paper is obviously improved. The insulating paper prepared by adding the heat-resistant additive has excellent high-temperature aging resistance, the high-temperature aging resistance is improved by 22-27% under the same condition, and the insulation performance of a transformer system is not influenced.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

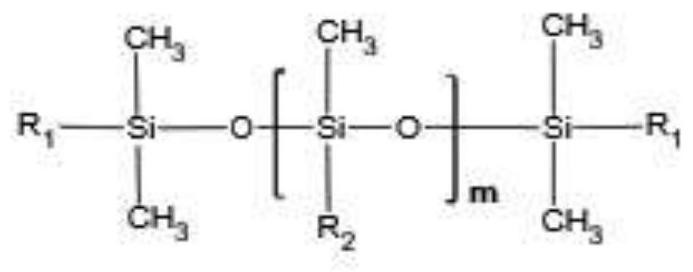

Heat-conducting filler and anti-aging organic silicon heat-conducting gel prepared from heat-conducting filler

PendingCN114015117AReduce agglomerationImprove high temperature aging resistanceHeat-exchange elementsPolymer sciencePtru catalyst

The invention discloses a heat-conducting filler and an anti-aging organic silicon heat-conducting gel prepared from the heat-conducting filler, and belongs to the field of thermal interface materials. The organic silicon heat-conducting gel is prepared from the following components in parts by weight: 100 parts of vinyl-terminated silicone oil, 5-10 parts of hydrogen-containing silicone oil, 1000-1600 parts of heat-conducting filler, 0.02-0.05 parts of inhibitor and 0.1-0.3 parts of catalyst. A silane-modified aluminum oxide and graphene oxide compound heat-conducting filler is prepared, a silane modifier is dissolved in an organic solvent to prepare a modifier solution, and aluminum oxide and graphene oxide can be connected together through silane. The two ends of the silane modifier are hydroxyl groups, the branched chains are methyl and vinyl, a vinyl unit in silane can be crosslinked with hydrogen-containing silicone oil through a hydrosilylation reaction, and the base rubber and the filler form a whole. The compatibility between the heat-conducting filler and the silicone rubber is improved, the hardness climbing at a high temperature is reduced, the heat-conducting property of the heat-conducting gel is remarkably improved, and the problems of limited addition amount, high cost and the like when graphene is independently used are solved.

Owner:世晨材料技术(上海)有限公司

High-temperature-resistant polyvinyl chloride pipe

The invention discloses a high-temperature-resistant polyvinyl chloride pipe, which is prepared from the following raw materials in parts by weight: 40-50 parts of polyvinyl chloride, 15-24 parts of methyl vinyl silicone rubber, 1-2 parts of 1, 3-bis (tert-butyl peroxy isopropyl) benzene, 0.2-0.8 part of N-cyclohexyl-2-benzothiazolesulfenamide, 1-2 parts of zinc oxide, 40-50 parts of a filling reinforcing agent, 1-3 parts of magnesium oxide, 1-2 parts of carboxymethyl cellulose, 1-3 parts of an anti-aging agent, 1-2 parts of poly-metaphosphoric acid and 3-6 parts of a plasticizer. The high-temperature-resistant polyvinyl chloride pipe provided by the invention has high temperature aging resistance, thus being used for a long time at the temperature of 230 DEG C and better maintaining the physical properties at the temperature of 280 DEG C; the high-temperature-resistant polyvinyl chloride pipe has ultra-low compression permanent deformation, thus achieving the effect of effective sealing in a using process.

Owner:ANHUI LANTONG TECH CO LTD

High-temperature-resistant silica gel for high-temperature roller and preparation method thereof

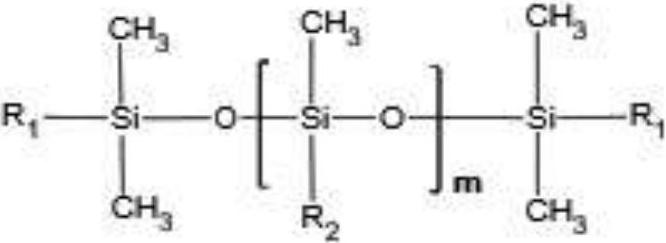

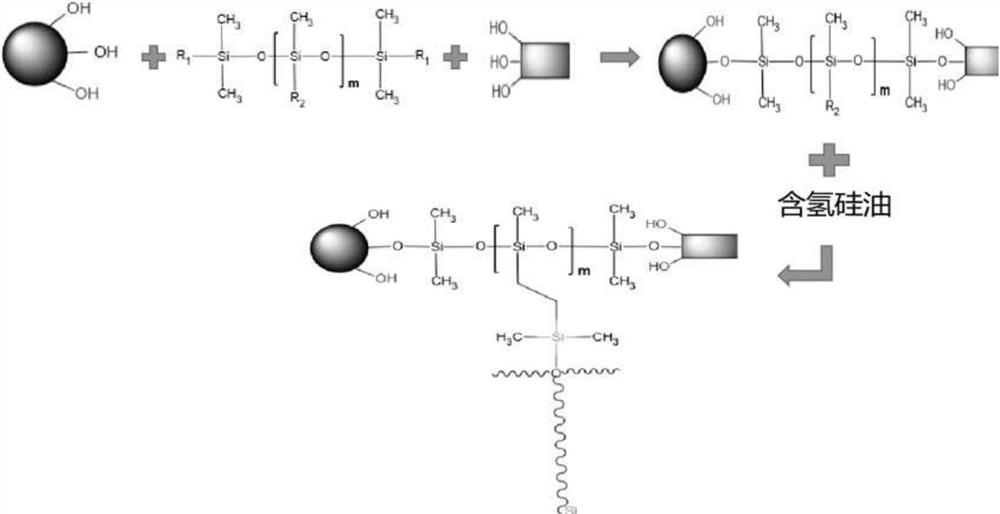

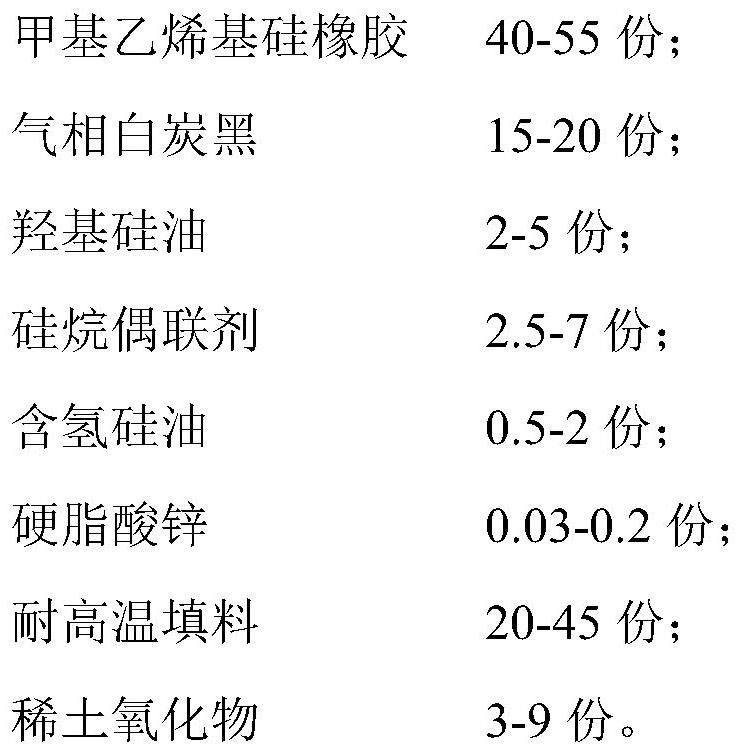

PendingCN113462164AImprove structural strengthImprove high temperature aging resistanceSilane couplingPolymer chemistry

The invention relates to the technical field of silica gel products, and particularly discloses high-temperature-resistant silica gel for a high-temperature roller and a preparation method thereof. The high-temperature-resistant silica gel is prepared from the following raw materials in parts by weight: 40-55 parts of methyl vinyl silicone rubber; 15-20 parts of fumed silica; 2-5 parts of hydroxyl silicone oil; 2.5-7 parts of a silane coupling agent; 0.5-2 parts of hydrogen-containing silicone oil; 0.03-0.2 part of zinc stearate; 20-45 parts of a high-temperature-resistant filler; and 3-9 parts of rare earth oxide. The preparation method comprises the following steps: stirring and kneading the methyl vinyl silicone rubber, the hydroxyl silicone oil, the silane coupling agent and the hydrogen-containing silicone oil for 5-10 minutes to obtain a mixture, mixing the fumed silica, the zinc stearate and the high-temperature-resistant filler, adding the mixture into the mixture in 4-5 times, heating to 180 DEG C after charging, adjusting the vacuum degree to -0.09 to -0.1 MPa, stirring for 2-4 hours, and after stirring and cooling to 40-50 DEG C, adding rare earth oxide, stirring and kneading for 0.5-1 hour, and sub-packaging by using a 200-mesh filter screen. The high-temperature-resistant silica gel can be used in the industries of silica gel rollers and gold stamping wheels, and has the advantages of high temperature aging resistance and high degradation resistance.

Owner:上海珏晟新材料科技有限公司

High-temperature-resistant high-pressure-resistant hose and production process thereof

ActiveCN112693198AImprove toughnessHigh mechanical strengthSynthetic resin layered productsFlexible pipesPolymer sciencePentaerythritol

The invention relates to the technical field of PVC materials, in particular to a high-temperature-resistant high-pressure-resistant hose which sequentially comprises an outer layer, a second winding layer, a middle layer, a first winding layer and an inner layer from outside to inside, and the inner layer is prepared from the following raw materials in parts by weight: PVC, a plasticizer, a polymer of dipentaerythritol and sebacic acid, a high-temperature-resistant stabilizer, tackifying resin and a lubricant. The production process of the high-temperature-resistant high-pressure-resistant hose comprises the following steps of preparation of a first material, preparation of a second material, extrusion molding of an inner layer, preparation of a first winding layer, extrusion molding of a middle layer, preparation of a second winding layer and extrusion molding of an outer layer. By adding the polymer of dipentaerythritol and sebacic acid, the toughness, mechanical strength and high-temperature aging resistance of the inner layer are improved. The pH value is adjusted to be less than 3 so that the toughness of the inner layer is further improved, and the inner layer is convenient to bend. Tthe heat resistance of the inner layer is improved by adding the heptadecenoic acid triglyceride.

Owner:浙江新洁新材料科技有限公司

A kind of annular adhesive and its synthesis method

InactiveCN104987853BImprove vulcanization resistanceImprove high temperature aging resistanceAdhesivesActivated carbonAdhesive

Provided is an annular adhesive synthesizing method. The method comprises the steps of: adding 40-60 parts of triallyl isocyanurate and 0.0015-0.0040 parts of platinum catalyst into a three-necked flask; at the 65-80 DEG C reaction temperature, slowly dropping 17-28 parts of 1,1,3,5,5-pentamethyl-3-phenyl trisiloxanes into the three-necked flask,and finishing the dropping within 0.5 hours; and stirring and reacting the mixture for 3-4 hours; adding 21-33 parts of trimethoxysilane into the three-necked flask and finishing the dropping within 0.5 hours; continuing the stirring and reaction for four hours; and then stopping the reaction; and removing low boiling materials by performing distillation at a reduced pressure. 6-9 parts of activated carbon are added into the substance, stirring and adsorbing are performed for 12 hours, and the annular adhesive is obtained after the material is filtered.

Owner:YANTAI DARBOND TECH

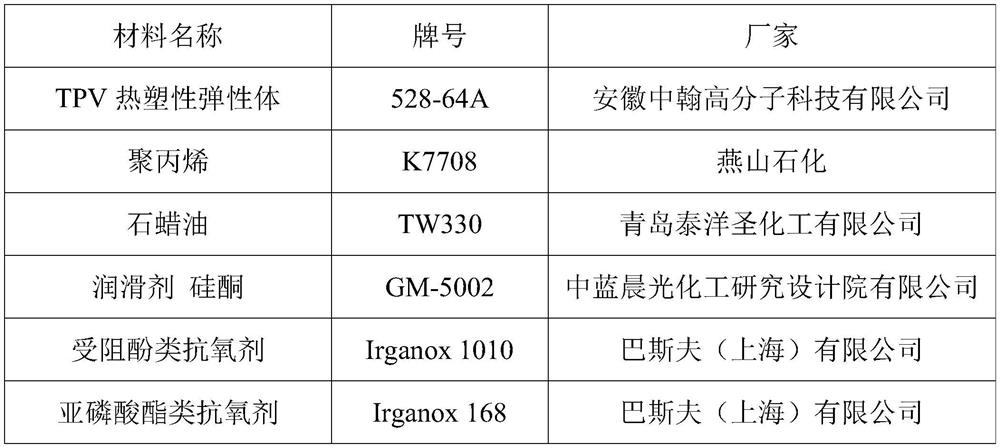

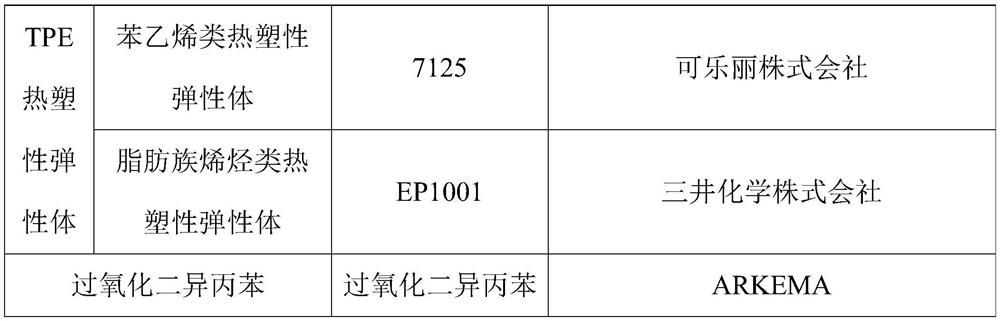

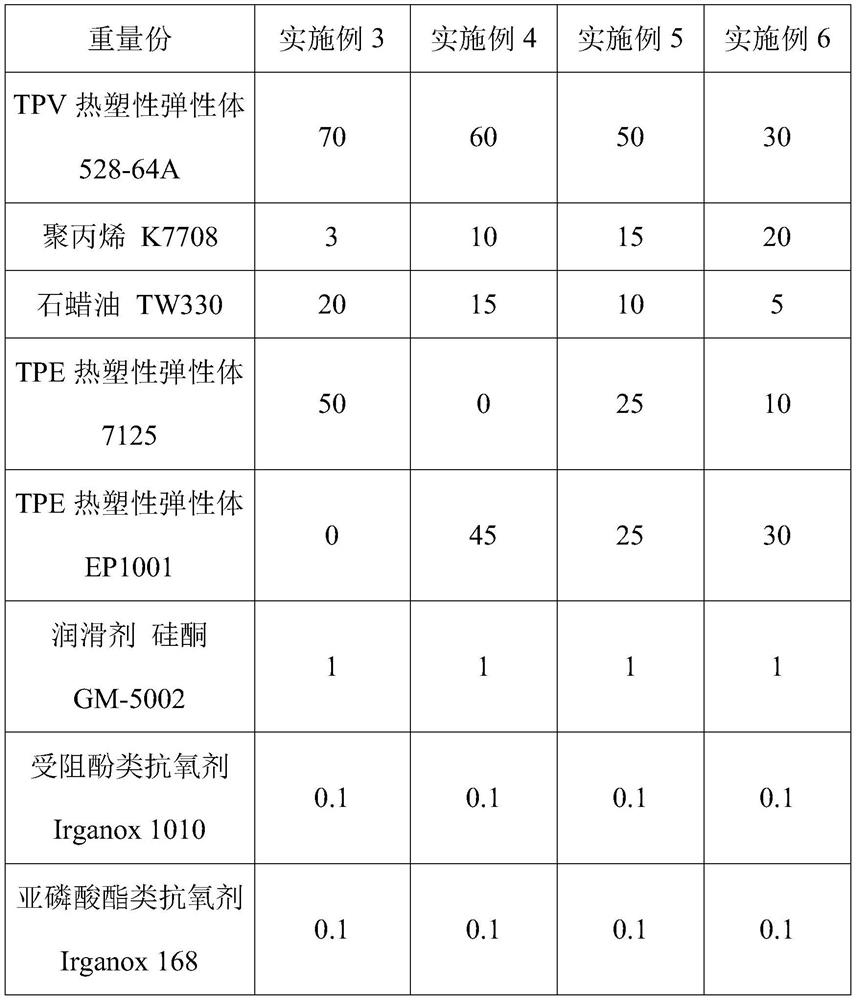

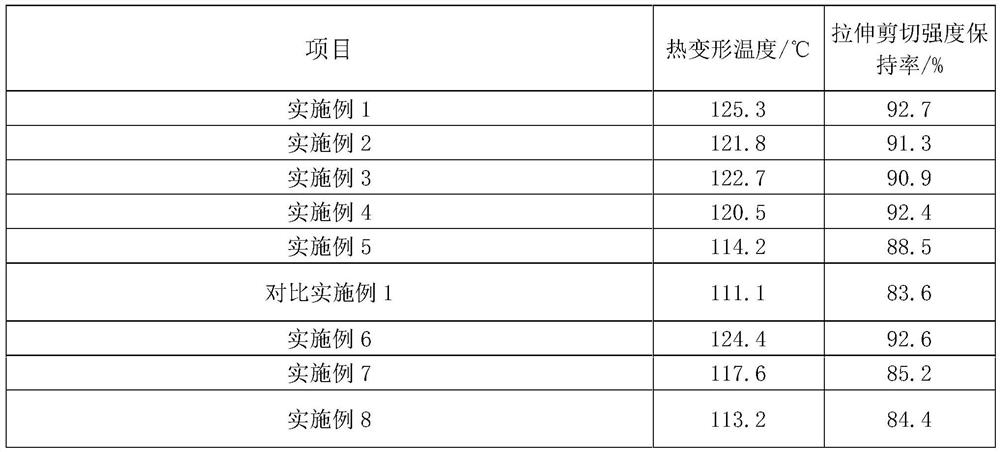

A kind of damping and shock-absorbing thermoplastic elastomer material and preparation method thereof

ActiveCN110628106BImprove high temperature resistanceImprove mechanical propertiesThermoplasticElastomer

The invention discloses a damping and shock-absorbing thermoplastic elastomer material. The raw materials include: 20-80 parts of TPV thermoplastic elastomer, 10-80 parts of TPE thermoplastic elastomer, 2-30 parts of polyolefin resin, and 2 parts of processing oil. -20 parts, 0.1-5 parts of processing aids, 0.1-1 parts of anti-aging agent, 0.6-0.8 parts of dicumyl peroxide, wherein, TPE thermoplastic elastomers are aliphatic olefin thermoplastic elastomers, styrene thermoplastic elastomers at least one of the body. The invention also proposes a preparation method of the above-mentioned damping and shock-absorbing thermoplastic elastomer material. The invention has good hand feeling, good mechanical performance, excellent damping and shock absorption performance, and good high-temperature pressure change performance.

Owner:安徽中翰高分子科技有限公司

A kind of intelligent slow-bonding prestressed steel strand and preparation method thereof

ActiveCN112280511BImprove heat resistanceImprove high temperature resistanceNon-macromolecular adhesive additivesForce measurement by measuring optical property variationPolymer scienceAdhesive

The invention provides an intelligent slow-bonding prestressed steel strand and a preparation method thereof. The intelligent slow-bonding prestressed steel strand comprises: a fiber-reinforced composite smart bar of an optical fiber sensor, an edge wire, and a slow-bonding type bond agent and sheath, the edge wire is kinked on the outer circumference of the smart bar to form an intelligent prestressed steel strand, and the slow-bonding adhesive is coated on the outer circumference of the intelligent prestressed steel strand, so that the intelligent prestressed steel strand is formed. The stranded wire is bonded to the sheath; the raw materials for preparing the slow-bonding adhesive include: epoxy resin, curing agent, diluent and filler. The slow-bonding adhesive adopts the compound of fluorine-containing polyamide, low-molecular-weight polyamide and carboxyl-functional silicone as a curing agent to cure the main resin, and utilizes the curing reaction of carboxyl and epoxy groups. Organosilicon is introduced into the slow-adhesion adhesive to obtain the slow-adhesion adhesive with good heat resistance and high temperature aging resistance.

Owner:BEIJING ACAD OF BUILDING ENG +1

High-temperature fire-resistant watertight insulating rubber for cable applied to safe return of ship to port, and manufacturing method of high-temperature fire-resistant watertight insulating rubber

The invention belongs to the technical field of cables, and discloses a high-temperature fire-resistant watertight insulating rubber for a cable applied to safe return of a ship to a port, and a manufacturing method of the high-temperature fire-resistant watertight insulating rubber. The rubber comprises the following raw material components in parts by weight: 20 parts of methyl vinyl silicone rubber 110-3-B, 20 parts of EPDM (ethylene propylene diene monomer) Mitsui EPT 4045M, 0.6 to 1 part of bis(tert-butylperoxyisopropyl)benzene (BIPB), 0.2 to 0.3 part of trimethylolpropane trimethacrylate (LS-3-80); 0.4 to 0.6 part of an amine aldehyde compound anti-aging agent XH-3, 0.2 to 0.4 part of 2-mercapto benzimidazole (MBI), 5 to 9 parts of white carbon black having undergone gas-phase-method surface treatment, 4 to 8 parts of low-temperature low-melting-point glass powder with a softening temperature of 400-700 DEG C, 4 to 8 parts of high-temperature low-melting-point glass powder with a softening temperature of 600-1100 DEG C, 0.5 to 1.5 parts of iron sesquioxide, 0.4 to 1 part of diphenylsilanediol and and 0.1 to 0.2 part of SI69-50. The manufacturing method comprises the following steps: firstly, carrying out two-side mixing operation in an open mill, then adding the methyl vinyl silicone rubber 110-3-B and the raw rubber of EPDM Mitsui EPT 4045M, conducting mixing for 2-3 minutes, then sequentially adding other components, carrying out mixing for 7-8 minutes, performing discharging, conducting extruding and granulating on a double-screw granulator, and preforming cooling for separate use.

Owner:NANJING QUANXIN CABLE TECH

Heat-resistant additive for transformer insulating paper, preparation method and application thereof

ActiveCN106812020BExcellent high temperature aging resistanceImprove high temperature aging resistanceCoatings with pigmentsPaper/cardboardChemical LinkageFiber

The invention discloses a preparation and application method of an assistant for improving high-temperature aging resistance of transformer insulating paper and belongs to the field of the transformer insulating paper. The method comprises the steps of compounding a polyvinyl pyrrolidone macromolecular compound with a high-temperature self-crosslinking property, an initiator and a nitrogen containing compound so as to prepare the heat-resistant assistant, and applying the heat-resistant assistant to the surface of the insulating paper by a coating, spray-coating or dipping method. Polyvinyl pyrrolidone is subjected to a self-crosslinking reaction in the presence of the initiator at a high temperature so as to form a three-dimensional network structure, and fibers of the paper are interwoven in a chemical bond forming manner, so that the bonding action among the fibers is enhanced, and the improvement on the aging resistance of the paper is facilitated. According to the insulating paper prepared by adding the heat-resistant assistant disclosed by the invention, the high-temperature aging resistance is excellent and is improved by 15% to 30% under the same conditions, and the insulating performance of a transformer system is not affected.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Modified asphalt waterproof coating material

InactiveCN111440539APhase angle increasesIncreased rutting factorFireproof paintsConjugated diene hydrocarbon coatingsBituminous waterproofingPlasticizer

The invention discloses a modified asphalt waterproof coating material, which is prepared from the following raw materials in parts by weight: 100-120 parts of modified asphalt emulsion, 25-30 parts of butadiene styrene rubber, 10-13 parts of desulfurization powder, 20-25 parts of a softener, 10-15 parts of a tackifier, 5-8 parts of a plasticizer, 25-30 parts of a thickener and 3-5 parts of a defoamer. In a waterproof coating material preparation process, the modified asphalt emulsion is prepared, wherein through montmorillonite and carbon nanotubes, the phase angle of asphalt is increased, the complex modulus is increased, the rutting factor is increased, and the high-temperature rutting resistance of the asphalt is improved, so that the high-temperature rutting resistance of the asphaltis further improved, the thermal aging resistance of the waterproof coating material is improved, and the aging resistance of the waterproof coating material is improved due to the fact that the montmorillonite and the carbon nanotubes have good aging resistance,.

Owner:樊雪梅

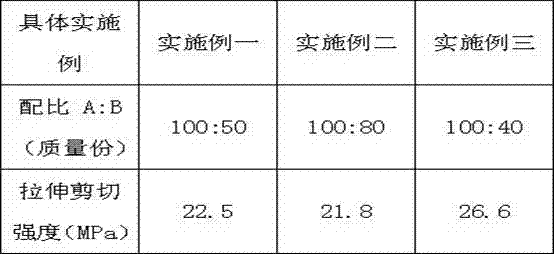

Epoxy resin ab glue for high temperature environment and method for making and using the same

ActiveCN104987849BImprove thermal stabilityImprove aging resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePolyamide

An epoxy resin AB glue for high temperature environment and its production and use method, including AB two components, A component is based on bisphenol epoxy resin, and hydantoin epoxy is added to the component Resin; component B is based on low-molecular-weight polyamide, and 4,4'-diaminodiphenylsulfone is added to the component; when using, the two components of AB are mixed and cured, through hydantoin epoxy resin and The combined effect of 4,4'-diaminodiphenyl sulfone improves the thermal stability and aging resistance of epoxy resin AB glue.

Owner:ZHUZHOU SHILIN POLYMER

High-temperature wear-resisting ceramic composite fiber brake block

InactiveCN103122959BInhibition of devitrification changesImprove adhesionOther chemical processesFriction liningCeramic compositeBarium titanate

The invention relates to a high-temperature wear-resisting ceramic composite fiber brake block which is manufactured by processing framework materials and auxiliary materials through material mixing, mould pressing, hot press molding and solidification procedures, wherein the framework materials comprise bismaleimide modified phenolic resin, short aramid fiber, high-purity ceramic fiber, potassium titanate fiber, mineral fiber, barium titanate and nickel; the auxiliary materials comprise molybdenum sulfide and / or tin sulfide, graphite and / or coke, acrylonitrile-butadiene rubber, mica, zinc oxide, stearic acid, barium sulfate and 4010-type antiager. The high-temperature wear-resisting ceramic composite fiber brake block solves the problems existing in the prior brake blocks, can well avoid high-speed decay and high-temperature decay, has the advantages of being good in staibility and long in service life, and is a high-temperature wear-resisting ceramic composite fiber brake block which is low in noise, high in intensity and low in pollution.

Owner:山东金山汽配有限公司

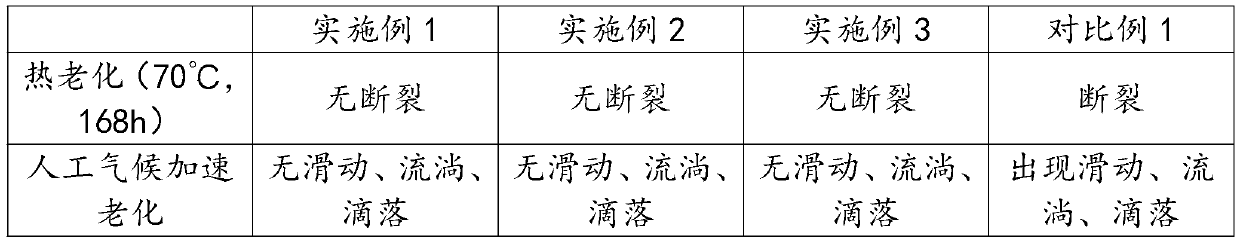

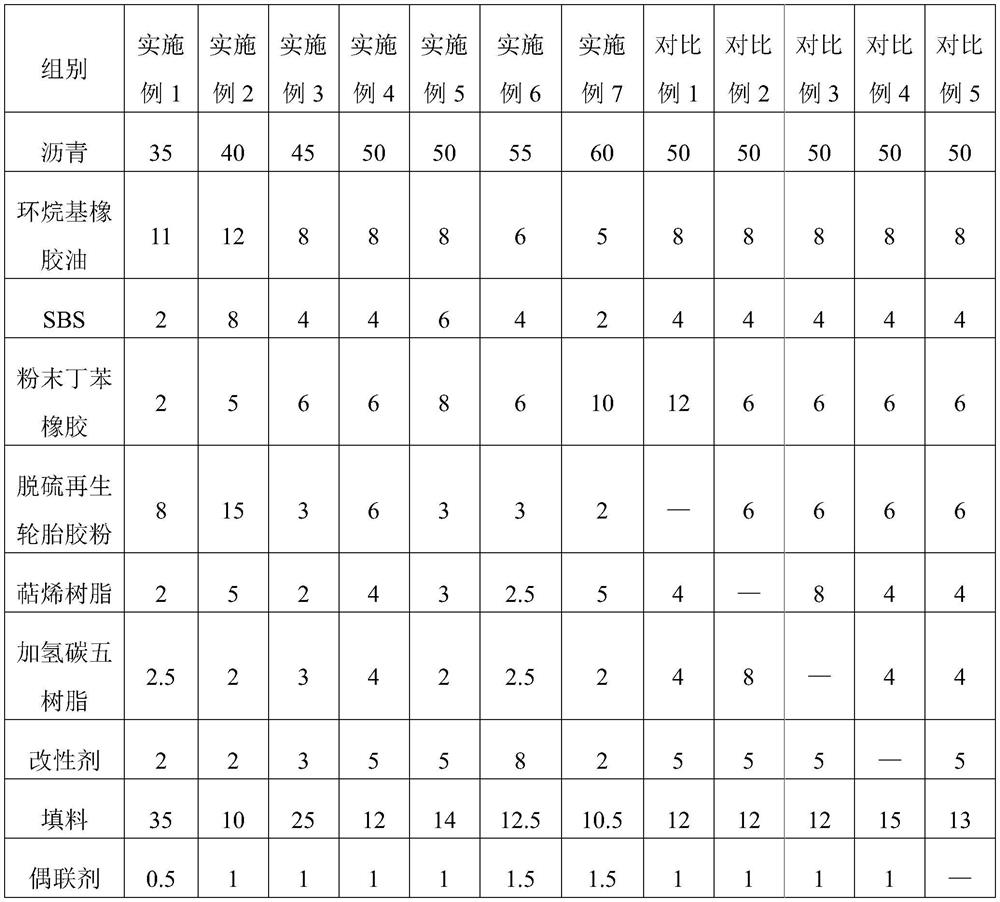

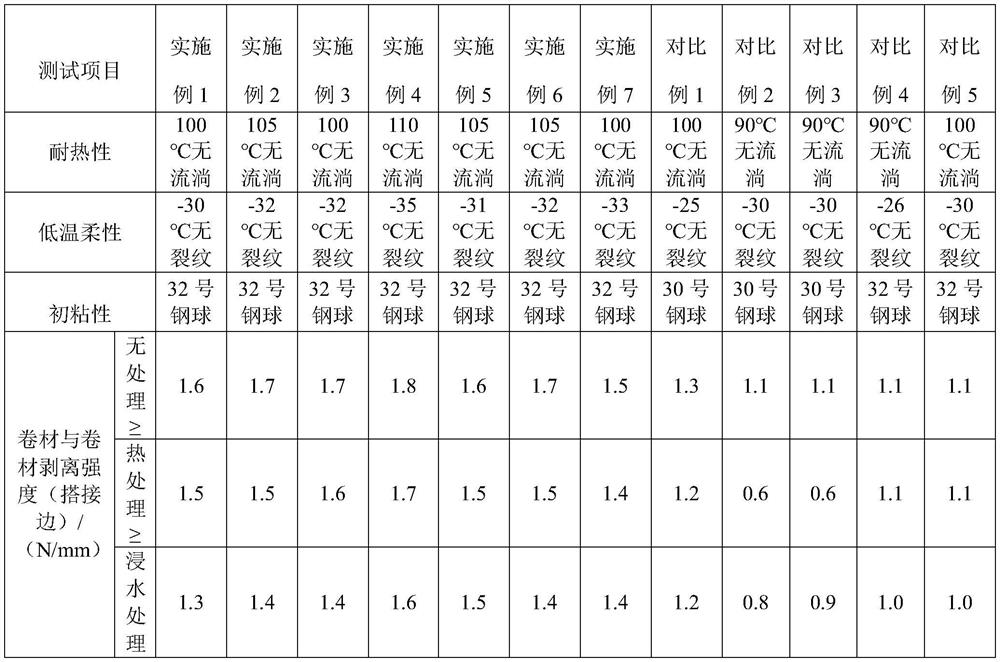

A kind of self-adhesive waterproof glue applied on metal roof and preparation method thereof

ActiveCN109971419BGood high and low temperature resistanceImprove constructabilityNon-macromolecular adhesive additivesBituminous material adhesivesAdhesive glueButadiene-styrene rubber

The invention belongs to the technical field of construction materials, and provides a self-adhesive waterproof glue applied to a metal roof. The self-adhesive waterproof glue is composed of followingcomponents in percentage by weight: 35 to 60% of asphalt, 5 to 12% of naphthenic base rubber oil, 2 to 8% of SBS, 3 to 10% of powdery butadiene styrene rubber, 2 to 15% of desulfurized regenerated tire rubber powder, 2 to 5% of terpene resin, 2 to 5% of hydrogenated C5 resin, 2 to 8% of a modifier, 10 to 35% of a filling material, and 0.5 to 1.5% of a coupling agent. The preparation method comprises following steps: adding asphalt and naphthenic base rubber oil, stirring, raising the temperature to 140 DEG C, carrying out dehydration for 0.5 hour, adding desulfurized regenerated tire rubber powder and powdery butadiene styrene rubber, raising the temperature to 180 DEG C, stirring for 1 hour, adding SBS, stirring for 1 hour at a temperature of 180 DEG C, maintaining the temperature of 180DEG C, adding the modifier, stirring for 1 hour; then adding terpene resin and hydrogenated C5 resin, stirring for 15 to 20 minutes at a temperature of 176 DEG C, grinding, dispersing for 40 to 50 minutes, adding the filling material and the coupling agent, raising the temperature to 160-170 DEG C, and stirring for 40 to 60 minutes. The problems that in the prior art, the high temperature resistant performance of a conventional self-adhesive glue is bad, and the self-adhesive glue is difficult to peel off after aging or water soaking are solved.

Owner:河南驼峰防水科技有限公司

Ternary catalyst

ActiveCN103143351BOptimize and improve catalytic activityEliminate fluctuations in air-fuel ratioDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumSolid solution

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

A high temperature and high pressure resistant hose and its production process

ActiveCN112693198BImprove toughnessHigh mechanical strengthSynthetic resin layered productsFlexible pipesPolymer sciencePentaerythritol

The application relates to the technical field of PVC materials, a high-temperature and high-pressure resistant hose, which sequentially includes an outer layer, a second winding layer, an intermediate layer, a first winding layer, and an inner layer from the outside to the inside, and the inner layer consists of the following parts by weight: Made of raw materials: PVC, plasticizer, polymer of dipentaerythritol and sebacic acid, high temperature stabilizer, tackifying resin, lubricant. A production process for a high temperature and high pressure hose, comprising the following steps: preparation of the first material, preparation of the second material, extrusion molding of the inner layer, preparation of the first winding layer, extrusion molding of the middle layer, and second winding Layer preparation, extrusion of the outer layer. By adding a polymer of dipentaerythritol and sebacic acid, the toughness, mechanical strength, and high temperature aging resistance of the inner layer are improved. The pH value is adjusted to be less than 3 to further improve the toughness of the inner layer and make the inner layer easy to bend. The heat resistance of the inner layer is improved by adding heptadecenyl triglyceride.

Owner:浙江新洁新材料科技有限公司

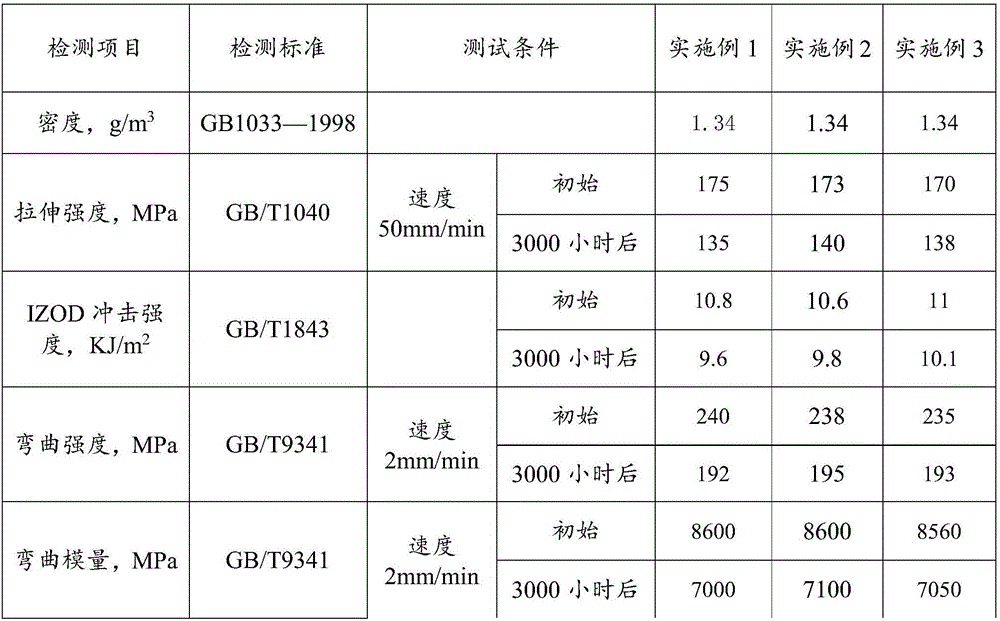

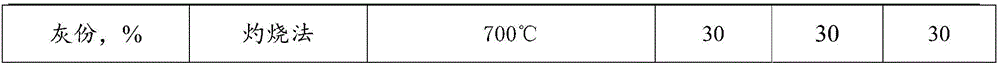

High-temperature ageing resisting PA (Polyamide) material and preparation method thereof

The invention discloses a high-temperature ageing resisting PA (Polyamide) material and a preparation method thereof. The high-temperature ageing resisting PA material is prepared from the following components in percentage by weight: 60 percent to 70 percent of PA66, 5 percent to 10 percent of PA6, 0.5 percent to 1 percent of an anti-ageing agent, 0.4 percent to 1 percent of a lubricant and 20 percent to 30 percent of glass fiber. The high-temperature ageing resisting PA material is compounded with the multi-element anti-ageing agent, so as to realize a long-period high-temperature ageing resisting effect, so that a product can be used for a long period at 160 DEG C, and the high-temperature ageing resisting time reaches 3000 hours.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com