Heat-resistant additive for transformer insulating paper, preparation method and application thereof

A technology of heat-resistant additives and insulating paper, which is applied in the direction of paper, papermaking, paper coating, etc., can solve the problems of weak force, easy damage and fracture, etc., and achieve increased bonding strength, good water solubility, and improved high-temperature aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

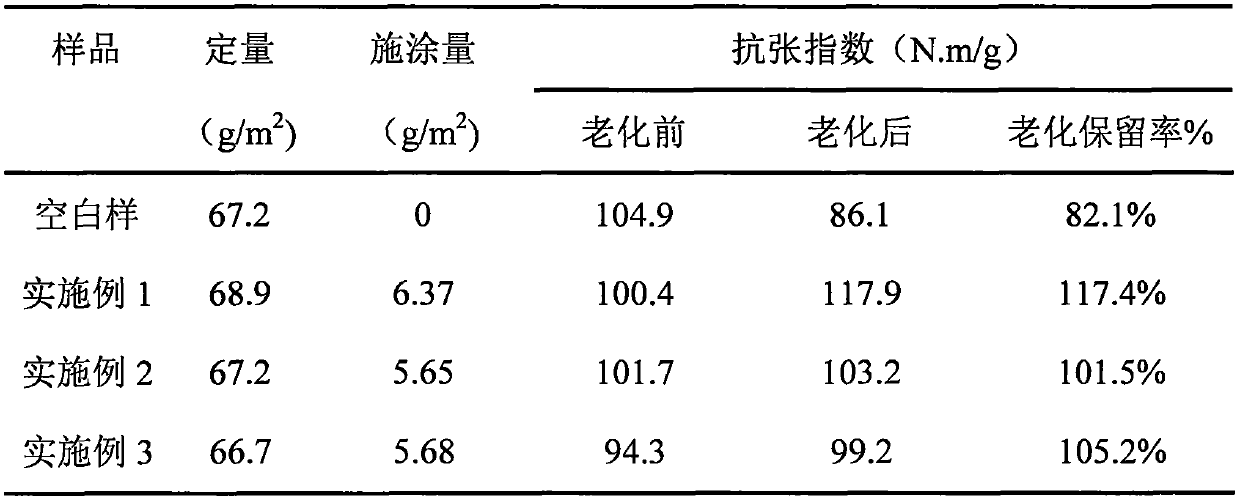

[0013] Example 1: Mix 80g of polyvinylpyrrolidone, 10g of melamine, and 9.5g of dicyandiamide and dissolve in water, heat to 40°C, stir and dissolve, then drop to room temperature and then add 0.5g of ammonium persulfate, stir evenly to form a solid 5% heat-resistant additive. The base paper of insulating paper is pre-dried to 80% moisture, and the dipping method is used to glue the surface with a two-roller glue machine, and the amount of glue dipping is 5-7g / m 2 . The strength index test results of the finished paper after the aging test are shown in Table 1.

Embodiment 2

[0014] Embodiment two: polyvinylpyrrolidone 50g is dissolved in water and stirred at room temperature to dissolve, dicyandiamide 20g and casein 25g are dissolved in ethanol solution (the amount of ethanol is 30% of water) stirred and dissolved at room temperature, and then the two solutions are mixed, After stirring evenly, 5 g of ammonium persulfate was added at room temperature to prepare a heat-resistant additive with a solid content of 8%. Insulation paper base paper is pre-dried to 70% moisture, double-sided coating with a scraper bar, and the total coating amount on both sides is 4-6g / m 2 . The strength index test results of the finished paper after the aging test are shown in Table 1.

Embodiment 3

[0015] Example 3: Add 20 g of polyvinylpyrrolidone, 50 g of dicyandiamide, and 20 g of polyacrylamide into water, stir and dissolve at 90° C., drop to room temperature, add 10 g of potassium persulfate, and stir evenly to prepare a polyvinyl pyrrolidone with a solid content of 20%. Heat-resistant additives. The insulating paper base paper is pre-dried to 80% moisture, and the heat-resistant additive is sprayed on the insulating paper by spraying, and the coating amount is 5-6g / m 2 . The strength index test results of the finished paper after the aging test are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com