Polypropylene cable material with excellent high temperature ageing resistant performance

Aging performance, polypropylene technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of high temperature aging resistance, low tensile strength, affecting the service life of cables, etc., and achieve excellent high temperature aging resistance performance, improved safety, and the effect of meeting market needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

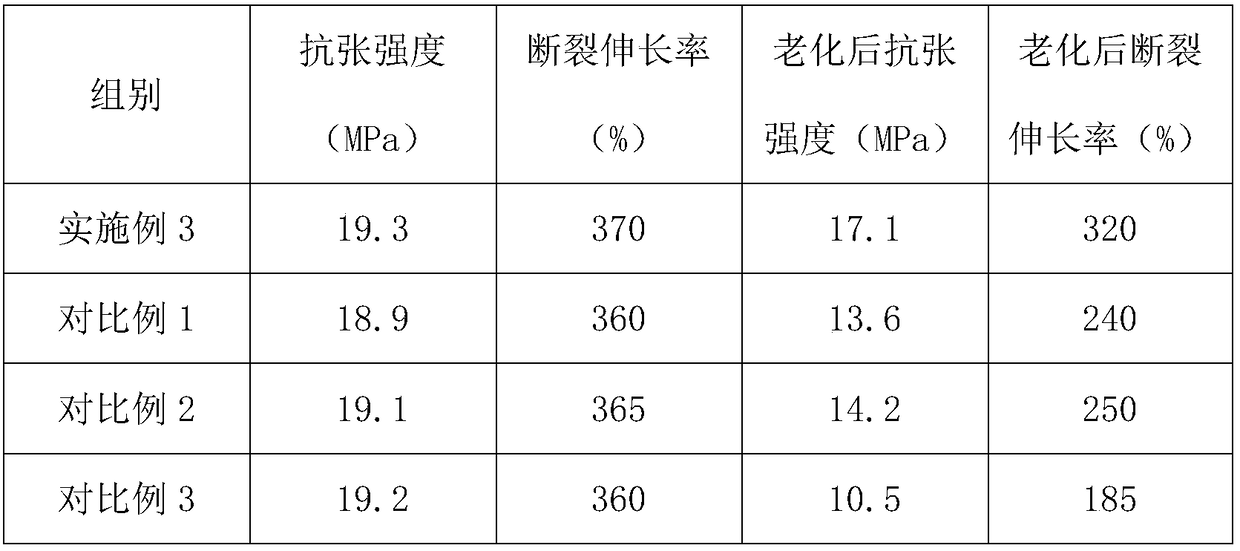

Examples

Embodiment 1

[0023] A polypropylene cable material with excellent high-temperature aging resistance, made of the following materials in parts by weight: 120 parts of polypropylene, 30 parts of styrene-isoprene-styrene block copolymer, grafted maleic anhydride 10 parts of polypropylene, 1 part of antioxidant, 13 parts of magnesium hydroxide, 2 parts of polyethylene wax, 1 part of calcium stearate, 4 parts of talcum powder, 8 parts of calcined clay, 4 parts of calcium zinc stabilizer, 3 parts of shellac 2 parts, rosin acid.

[0024] Wherein, the antioxidant is the antioxidant DNP.

[0025] The preparation method of the polypropylene cable material with excellent high temperature aging resistance, the steps are as follows:

[0026] 1) Weighing abietic acid, pulverizing it, sending it into a ball mill, using ethanol aqueous solution as a ball milling liquid, ball milling for 2 hours, and discharging to obtain an abietic acid dispersion;

[0027] 2) Weigh shellac, pulverize it, and send it in...

Embodiment 2

[0035] A polypropylene cable material with excellent high temperature aging resistance, made of the following materials in parts by weight: 123 parts of polypropylene, 31 parts of styrene-isoprene-styrene block copolymer, maleic anhydride grafted 12 parts of polypropylene, 1.2 parts of antioxidant, 14 parts of magnesium hydroxide, 3 parts of polyethylene wax, 1.3 parts of calcium stearate, 5 parts of talcum powder, 9 parts of calcined clay, 5 parts of calcium zinc stabilizer, 4 parts of shellac part, 2.4 parts of abietic acid.

[0036] Wherein, the antioxidant is the antioxidant DNP.

[0037] The preparation method of the polypropylene cable material with excellent high temperature aging resistance, the steps are as follows:

[0038] 1) Weighing abietic acid, pulverizing it, sending it into a ball mill, using ethanol aqueous solution as a ball milling liquid, ball milling for 2.2 hours, and discharging to obtain an abietic acid dispersion;

[0039] 2) Weighing the shellac, p...

Embodiment 3

[0047] A polypropylene cable material with excellent high temperature aging resistance, made of the following materials in parts by weight: 125 parts of polypropylene, 32 parts of styrene-isoprene-styrene block copolymer, grafted maleic anhydride 12.5 parts of polypropylene, 1.5 parts of antioxidant, 15 parts of magnesium hydroxide, 3.5 parts of polyethylene wax, 1.5 parts of calcium stearate, 6 parts of talc, 10 parts of calcined clay, 6 parts of calcium zinc stabilizer, 4.5 parts of shellac 2.5 parts, rosin acid.

[0048] Wherein, the antioxidant is the antioxidant DNP.

[0049] The preparation method of the polypropylene cable material with excellent high temperature aging resistance, the steps are as follows:

[0050] 1) Weighing abietic acid, pulverizing it, sending it into a ball mill, using ethanol aqueous solution as a ball milling liquid, ball milling for 2.5 hours, and discharging to obtain an abietic acid dispersion;

[0051] 2) Weighing the shellac, pulverizing it,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com