Epoxy resin ab glue for high temperature environment and method for making and using the same

A technology of epoxy resin and high-temperature environment, which is applied in the direction of epoxy resin glue, adhesive, polymer adhesive additive, etc., can solve the problems of epoxy resin AB glue strength decline, easy aging, and brittleness, etc., to achieve adhesion Improvement of junction performance, improvement of thermal stability and aging resistance, and improvement of high temperature aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

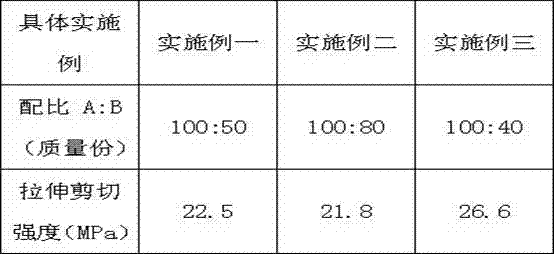

Embodiment 1

[0055] An epoxy resin AB glue for high-temperature environment conditions, including AB two components, the AB two components are proportioned according to the following components and parts by weight:

[0056] 1) Group A is divided into:

[0057] E44 epoxy resin 60 parts

[0058] F51 epoxy resin 25 parts

[0059] MHR-070 hydantoin epoxy resin 10 parts

[0060] JEW-0113 aliphatic epoxy resin 10 parts

[0061] 10 parts of polyurethane modified epoxy resin

[0062] 25 parts of silica powder;

[0063] 2) Group B is divided into:

[0064] 50 parts of 650 low molecular weight polyamide

[0065] 4,4'-Diaminodiphenylsulfone 2 parts

[0066] 5 parts of 2-ethyl 4-methylimidazole

[0067] 20 parts m-phenylenediamine

[0068] Silica powder 20 parts

[0069] 3 parts of fumed white carbon black.

[0070] During preparation, the two components of A and B are prepared separately and packaged independently, wherein:

[0071] 1) The preparation of component A is as follows:

[007...

Embodiment 2

[0083] An epoxy resin AB glue for high-temperature environment conditions, including AB two components, the AB two components are proportioned according to the following components and parts by weight:

[0084] 1) Group A is divided into:

[0085] E44 epoxy resin 80 parts

[0086] F51 epoxy resin 55 parts

[0087] MHR-070 Haiying epoxy resin 20 parts

[0088] JEW-0113 aliphatic epoxy resin 20 parts

[0089] 10 parts of liquid carboxylated nitrile rubber

[0090] 25 parts of calcium carbonate;

[0091] 2) Group B is divided into:

[0092] 50 parts of 650 low molecular weight polyamide

[0093] 2 parts of 4-4 diaminodiphenylmethyl sulfone

[0094] 5 parts of 2-ethyl 4-methylimidazole

[0095] 20 parts m-phenylenediamine

[0096] 23 parts of calcium carbonate.

[0097] The method of preparation and use of the second embodiment is the same as that of the first embodiment.

Embodiment 3

[0099] An epoxy resin AB glue for high-temperature environment conditions, including AB two components, the AB two components are proportioned according to the following components and parts by weight:

[0100] 1) Group A is divided into:

[0101] E51 epoxy resin 50 parts

[0102] F51 epoxy resin 30 parts

[0103] MHR-070 Haiying epoxy resin 15 parts

[0104] JEW-0112 aliphatic epoxy resin 5 parts

[0105] Nitrile 40 rubber 12 parts

[0106] 28 parts of silica powder;

[0107] 2) Group B is divided into:

[0108] 30 parts of 651 low molecular weight polyamide

[0109] 3 parts of 4-4 diaminodiphenyl sulfone

[0110] 5 parts of 2-ethyl 4-methylimidazole

[0111] 25 parts m-phenylenediamine

[0112] Silica powder 20 parts

[0113] 2 parts of fumed white carbon black.

[0114] The preparation and use method of the third embodiment is basically the same as that of the first embodiment, except that the curing method is different. The curing method is: under the contact pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com