High-temperature ageing resisting PA (Polyamide) material and preparation method thereof

A high-temperature-resistant and anti-aging agent technology, which is applied in the field of polymer materials and their processing, can solve problems such as failure to reach, and achieve the effect of facilitating dispersion, realizing long-term high-temperature aging resistance, and improving the effect of high-temperature aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

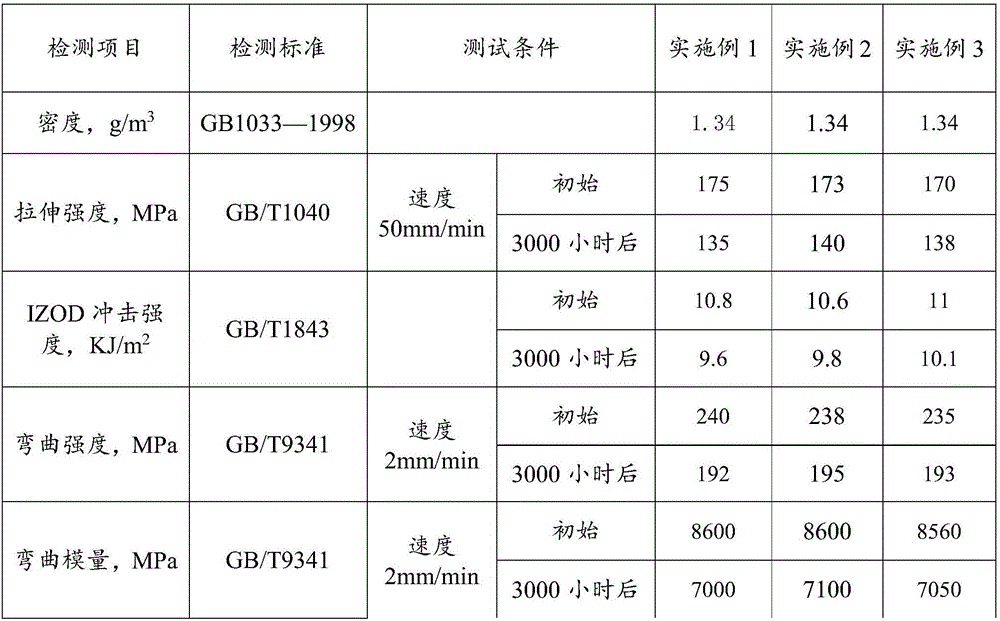

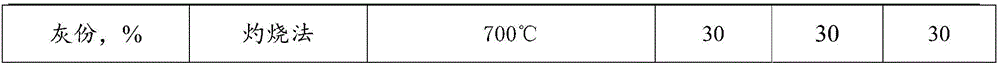

Examples

preparation example Construction

[0056] A preparation method of high temperature aging resistant PA material, the preparation method comprises the following steps:

[0057] 1) First, mix PA66 and PA6 evenly with a high mixer, and remove the moisture on the surface to obtain the mixture polyamide;

[0058] 2) Then premix the anti-aging agent and lubricant first, then add it to the polyamide mixture, and stir evenly to obtain a premix;

[0059] 3) Transfer the above-mentioned premixed material into a twin-screw extruder for melt extrusion and granulation.

[0060] In the preparation method of the high-temperature aging-resistant PA material described in the present invention, as a further scheme, the stirring time of step 1) is 3-8 minutes, and the rotation speed is 1000-1500 r / min.

[0061] In the preparation method of the high-temperature aging-resistant PA material described in the present invention, as a further scheme, the time for step 2) mixing the anti-aging agent and the lubricant is 5-8 minutes.

[...

Embodiment 1

[0065] A high-temperature aging-resistant PA material, which comprises the following components by weight percentage:

[0066] PA66 63.6%

[0067] PA6 5%

[0068] Anti-aging agent 0.8%

[0069] Lubricant 0.6%

[0070] Glass fiber 30%;

[0071] 1) Firstly, PA66 and PA6 were stirred at a speed of 1500r / min for 3 minutes with a high mixer, and the moisture on the surface was removed to obtain the mixture polyamide;

[0072] 2) Then premix the anti-aging agent and lubricant for 5 minutes, then add it to the polyamide mixture, and continue to stir for 10 minutes to obtain a premix;

[0073] 3) Transfer the above-mentioned premixed materials into a twin-screw extruder for melt extrusion and granulation, wherein the extrusion temperature is 230° C., and the rotational speed of the twin-screws is 150 r / min.

Embodiment 2

[0075] A high-temperature aging-resistant PA material, which comprises the following components by weight percentage:

[0076] PA66 63.2%

[0077] PA6 5%

[0078] Anti-aging agent 1%

[0079] Lubricant 0.8%

[0080] Glass fiber 30%;

[0081] The preparation method of the above-mentioned high temperature aging resistant PA material is:

[0082] 1) First, PA66 and PA6 were stirred at a speed of 1200r / min for 5 minutes with a high mixer, and the moisture on the surface was removed to obtain the mixture polyamide;

[0083] 2) Then premix the anti-aging agent and lubricant for 6 minutes, then add it to the polyamide mixture, and continue stirring for 12 minutes to obtain a premix;

[0084] 3) Transfer the above premixed material into a twin-screw extruder for melt extrusion and granulation, wherein the extrusion temperature is 255° C., and the rotational speed of the twin-screw is 120 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com