Manufacturing method for efficient three-component catalyst coating

A technology of three-way catalyst and production method, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., which can solve the problems of high production cost, unfavorable optimization treatment, and catalyst coating slurry production process Complicated issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

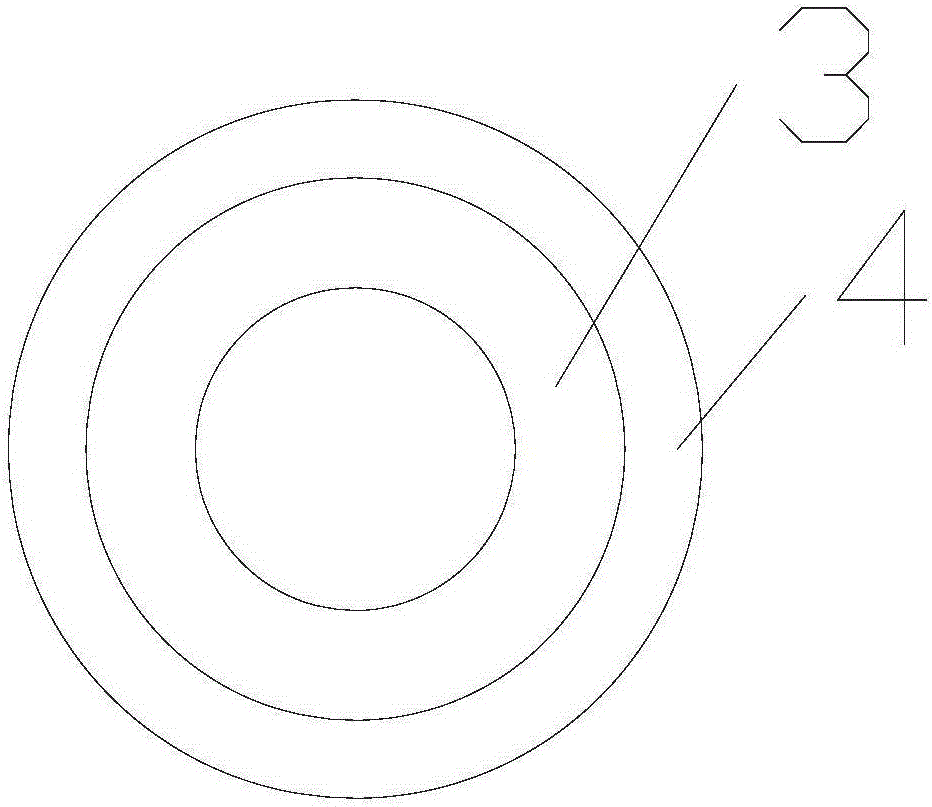

[0043] Apply the catalyst carrier made by the three-stage, two-layer, two-baking coating scheme described in the second coating scheme of the present invention, cylindrical, with a pore density of 600cpsi (number of holes per square inch), a diameter of 105.7mm, and a length of 130.0mm. Volume is 1.14 liters.

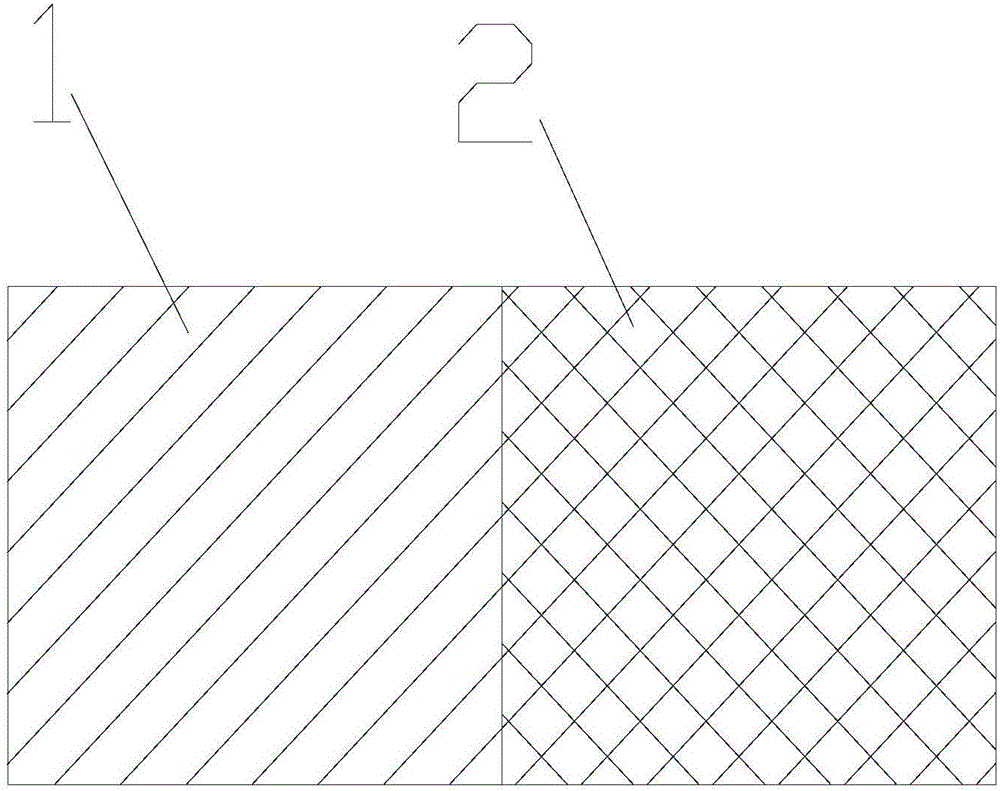

[0044] (Such as Figure 2B One of the second coating schemes shown) The first layer of one-stage (upstream half-stage) catalyst coating material, for the formulation of hydrocarbon (HC) emission control under engine cold start conditions, with a load of 2.26g / L The precious metal palladium (Pd) is used as the main catalyst element, and the loading amount of the coating material is 130g / L (calculated on the basis of half the volume of the carrier). The catalyst raw materials are alumina (45wt%), cerium-zirconium composite solid solution (18wt% ZrO 2 , 27 wt% CeO 2 ). The rest (La 2 o 3 , Y 2 o 3 , NiO, BaO) and other oxides 10wt%;

[0045] The three-way catalyst...

Embodiment 2

[0049] Apply the invention Figure 2A The catalyst carrier made by the shown three-stage two-layer two-baking coating scheme (one of the second schemes) is cylindrical, with a pore density of 600 cpsi (pores per square inch), a diameter of 93.0 mm, a length of 101.6, and a volume of is 0.69 liters.

[0050] The first layer of one-stage (upstream half-stage) catalyst coating material is formulated for the control of hydrocarbon (HC) emissions under engine cold start conditions, and the precious metal Pd (~1.77g / L) with a high loading is used as the main catalyst element , the total coating material loading is 125g / L. The catalyst raw materials are alumina (46wt%), cerium-zirconium composite solid solution (29wt% ZrO 2 , 15wt% CeO 2 ). The rest (La 2 o 3 、Nd 2 o 3 , PrO, NiO) and other oxides 10wt%;

[0051] The three-way catalyst formula used in the second-stage (downstream half-stage) catalyst coating material of the first layer, the total loading of palladium and rho...

Embodiment 3

[0055] This example is mainly aimed at gasoline engines whose nitrogen oxides are the main control objects in the exhaust components of automobiles. The catalyst carrier made by applying the 4-stage, two-layer, two-baking coating scheme of the present invention is cylindrical, with a pore density of 600 cpsi (pores per square inch), a diameter of 93.0 mm, a length of 101.6, and a volume of 0.69 liters.

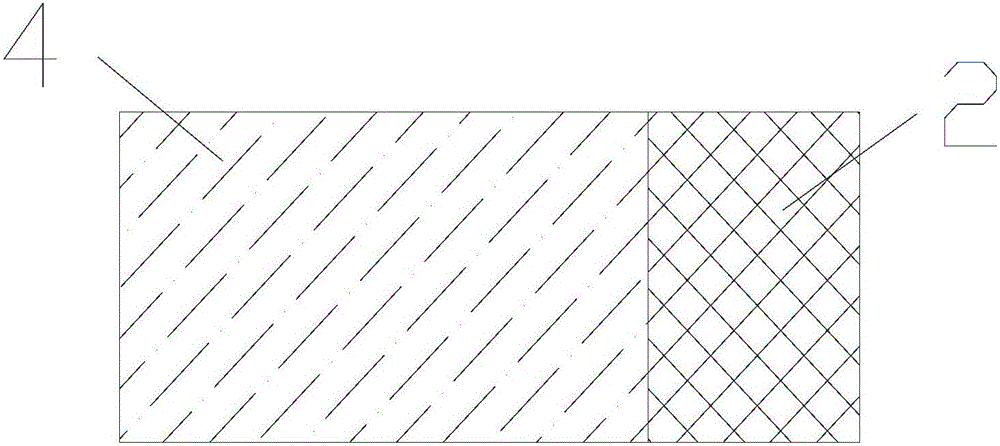

[0056] Such as Figure 3A and 3B As shown, the catalyst coating material of the first stage (upstream half stage) adopts a standard three-way catalyst formula, and the total loading of palladium and rhodium is 0.61g / L (the ratio of palladium and rhodium is 6:1). The coating material load is 125g / L (calculated based on the volume of the carrier in the upstream half section). The catalyst raw materials are alumina (42wt%), cerium-zirconium composite solid solution (18wt% ZrO 2 , 30wt% CeO 2 ). The rest (La 2 o 3 , Yi 2 o 3 , PrO, NiO) and other oxides 10wt%. Higher per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com