Integral diesel vehicle tail gas oxidization catalyst and preparation method thereof

An oxidation catalyst, a technology for diesel vehicles, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of pore structure collapse, catalyst activity decline, catalytic activity reduction and other problems, and achieve good catalytic oxidation activity and The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

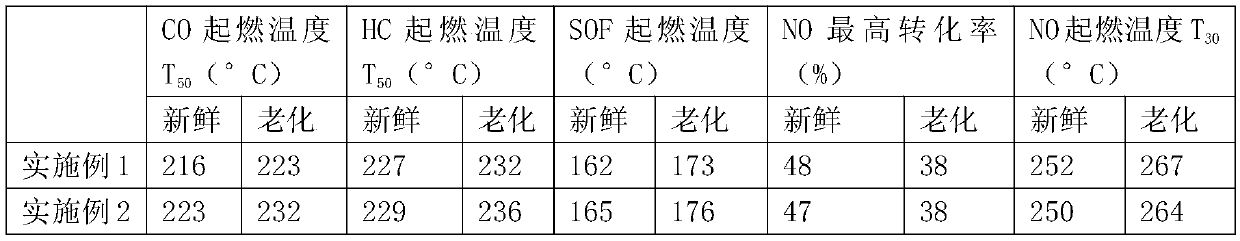

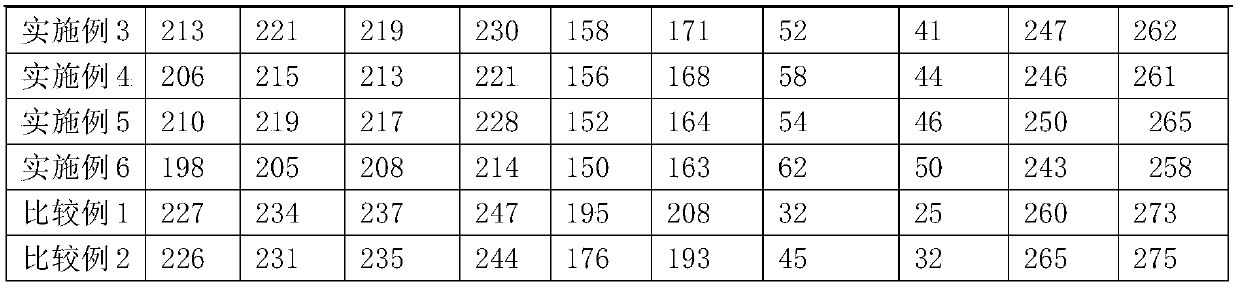

Embodiment 1

[0022] This embodiment provides Pt / Y 2 o 3 / SiO 2 -Al 2 o 3 The preparation method of catalyst comprises the following steps:

[0023] (1) the calculated amount of yttrium nitrate (15wt% Y 2 o 3 ) was dissolved in deionized water and impregnated in SiO by the isoporous volume impregnation method 2 -Al 2 o 3 On the carrier, let stand for 2h;

[0024] (2) Place the sample obtained in (1) in a drying oven to dry at 60°C for 12 hours, and then bake it in a roasting furnace at 550°C for 3 hours to obtain Y 2 o 3 / SiO 2 -Al 2 o 3 Modified carrier powder;

[0025] (3) Properly dilute the platinum nitrate solution (1wt% Pt), and impregnate the Y obtained in (2) by the isoporous volume impregnation method. 2 o 3 / SiO 2 -Al 2 o 3 Powder, dry, roast the same as (2) to get Pt / Y 2 o 3 / SiO 2 -Al 2 o 3 Catalyst powder material;

[0026] (4) Grinding the catalyst powder material obtained in (3) with 2-5wt% aluminum sol and 2-5wt% acetic acid to make a catalyst slurry...

Embodiment 2

[0030] (1) The calculated amount of Ca(NO 3 ) 2 (10wt% CaO) was dissolved in deionized water and impregnated in SiO 2 -Al 2 o 3 On the support, drying, roasting (same as the step (2) of embodiment 1), make CaO / SiO 2 -Al 2 o 3 carrier material;

[0031] (2) According to the same method of embodiment 1 step (3), impregnate the platinum nitrate solution in the CaO / SiO prepared by (1) 2 -Al 2 o 3 On the carrier material, dry and calcined to obtain Pt / CaO / SiO 2 -Al 2 o 3 catalyst powder;

[0032] (3) According to the same method of steps (4) in Example 1, (5) and (6), the monolithic Pt / CaO / SiO is prepared 2 -Al 2 o 3 catalyst.

Embodiment 3

[0034] (1) Mn(NO 3 ) 2 Solution (15wt%MnO 2 ) isoporous volume method impregnated in SiO 2 -Al 2 o 3 On the carrier, drying, roasting and (the same method as step (2) of Example 1), obtain MnO x / SiO 2 -Al 2 o 3 carrier material;

[0035] (2) According to the same method of embodiment 1 step (3), impregnate the platinum nitrate solution in the CaO / SiO prepared by (1) 2 -Al 2 o 3 On the carrier material, dry and calcined to obtain Pt / MnO x / SiO 2 -Al 2 o 3 catalyst powder;

[0036] (3) According to the same method of steps (4) in Example 1, (5) and (6), the monolithic Pt / MnO is prepared x / SiO 2 -Al 2 o 3 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com