Preparation method of heat-resistant auxiliary agent for temperature-resistant insulating paper

A technology of heat-resistant additives and insulating paper, which is applied in the direction of anti-aging paper additives, papermaking, paper coatings, etc., can solve the problems affecting the use of heat-resistant insulating paper and poor folding resistance, and achieve high-temperature aging resistance. Good high temperature performance and excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

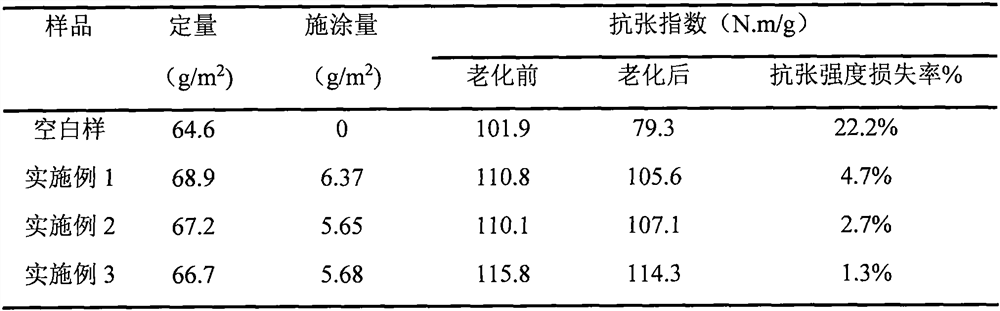

[0011] Example 1: Mix 80 g of water-based polyurethane with methyl ethyl ketone oxime as a sealing agent and 20 g of melamine, add it into water, heat to 30° C., stir and dissolve, and prepare a heat-resistant additive with a solid content of 5%. The insulating paper base paper is pre-dried to 80% moisture, and the dipping method is used to glue the surface with a two-roller glue machine, and the amount of glue dipping is 2-3g / m 2 . The strength index test results of the finished paper after the aging test are shown in Table 1.

Embodiment 2

[0012] Example 2: Mix 50 g of water-based polyurethane with phenol as a sealing agent, 40 g of dicyandiamide, and 10 g of melamine, add to water, stir and dissolve at room temperature, and prepare a heat-resistant additive with a solid content of 10%. Insulation paper base paper is pre-dried to 80% moisture, and coated on one side with a doctor bar, with a total coating weight of 5-6g / m 2 . The strength index test results of the finished paper after the aging test are shown in Table 1.

Embodiment 3

[0013] Example 3: Mix 20 g of water-based polyurethane with caprolactam as a sealing agent, 50 g of dicyandiamide, and 30 g of polyacrylamide, add it to water, stir and dissolve it at 90°C, and stir evenly to form a heat-resistant auxiliary with a solid content of 20%. agent. The insulating paper base paper is pre-dried to 80% moisture, and the heat-resistant additive is sprayed on the insulating paper by spraying, and the coating amount is 9-10g / m 2 . The strength index test results of the finished paper after the aging test are shown in Table 1.

[0014] The insulating paper base paper of Examples 1-3 of the present invention uses 100% unbleached kraft softwood pulp, and the beating degree is about 48°SR. The blank sample compared with Examples 1-3 is the insulating paper base paper without heat-resistant auxiliary agent applied.

[0015] Insulating paper high temperature aging test method: put the insulating paper in a vacuum tube inserted with copper wire, add 25# trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com