Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve brazing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

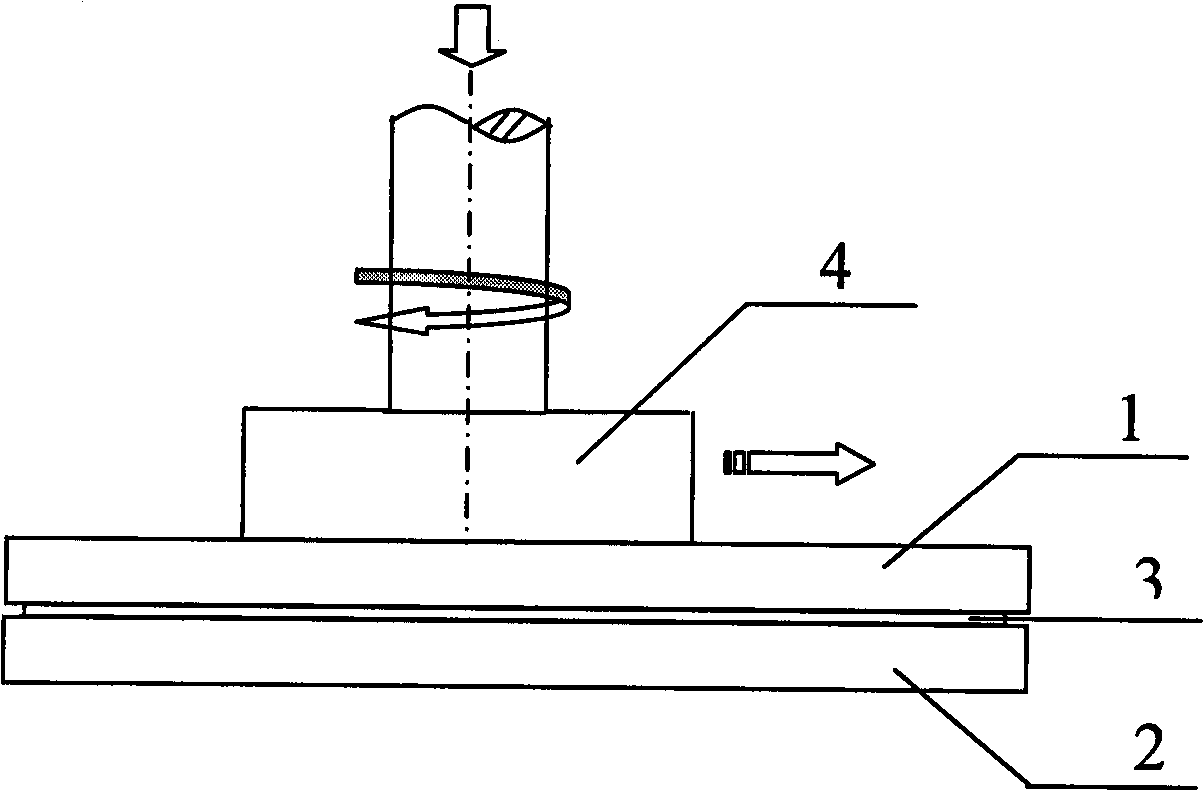

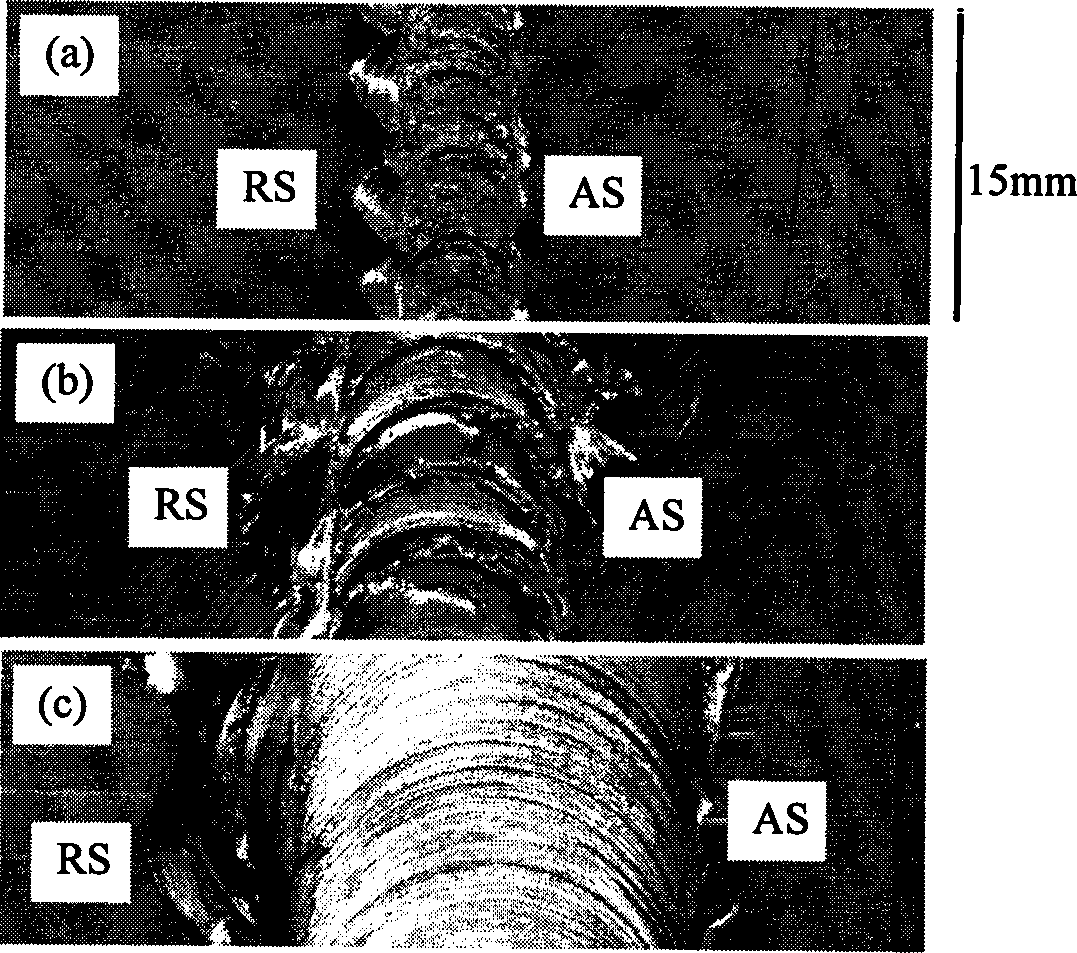

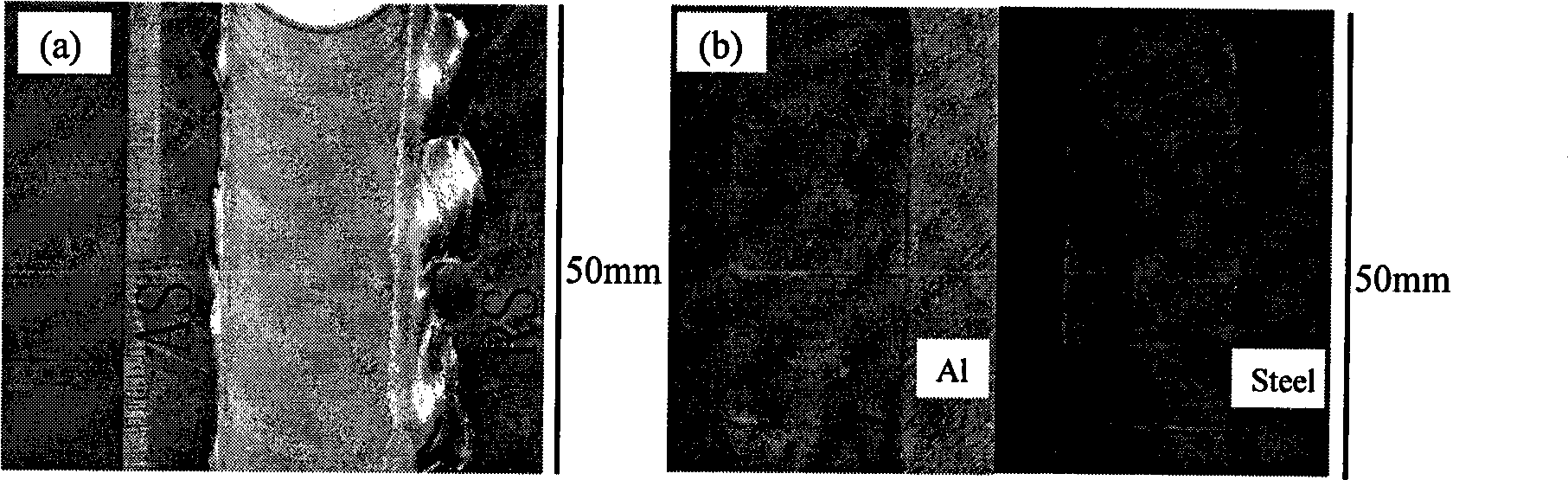

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

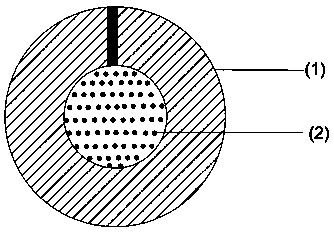

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

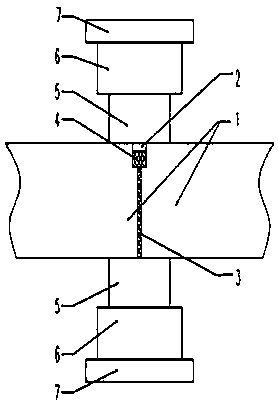

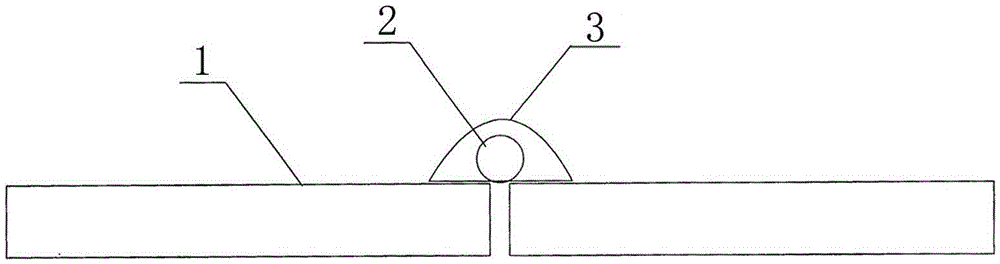

Thick metal plate large-area butt joint braze welding method

ActiveCN104002004AFully filledReduce defectsSoldering apparatusMetal working apparatusButt weldingWeld seam

A thick metal plate large-area butt joint braze welding method is implemented through the following the steps that the connecting portions of a braze welding surface of a metal plate and an upper surface of a metal plate are respectively provided with a rectangular notch through machining, and thus a U-shaped groove is formed when the two metal plates are in butt joint; foil type braze welding flux is arranged between the braze welding surfaces of the two metal plates, the two metal plates and the foil type braze welding flux are tightly combined through a clamp, and the braze welding flux is arranged in the U-shaped groove in advance; the welding seam of the two clamped metal plates is arranged between an upper electrode plate and a lower electrode plate of a resistance welding machine, contact electrodes cover the whole braze welding seam, and the braze welding seam is perpendicular to the contact surface of the contact electrodes; the upper electrode plate and the lower electrode plate of the resistance welding machine are pressurized, the foil type braze welding flux and the braze welding flux arranged in the U-shaped groove in advance are melted through electric heating so as to fill the welding seam, and heating is stopped while pressure is maintained until the welding part is cooled. According to the thick metal plate large-area butt joint braze welding method, the manual flame braze welding mode adopted in the large-area butt joint of the two metal plates is changed, the problems that braze welding flux filling is poor, gas is difficult to discharge, many defects are generated and the brazed rate is low due to the fact that resistance braze welding is adopted in thick metal plate large-area butt joint welding are solved, and a brazed layer is made to have the good brazed rate, good bonding strength and good electrical properties.

Owner:ZHENJIANG SIYANG SPECIAL METAL MATERIAL MFG

Induction brazing method for edge scraper of shielding tunneling machine

ActiveCN105921838AExtended service lifeImprove wear resistanceHeating appliancesSoldering auxillary devicesTemperature differenceShield tunneling

The invention discloses an induction brazing method for an edge scraper of a shielding tunneling machine. An edge scraper body, silver-based brazing filler metal and a hard alloy tool bit which are well assembled are put in the lower end of a profiling coil and are tightly attached to the profiling coil, and then the welding work is completed after preheating, heating welding and post-welding thermal treatment. The adopted profiling coil is a self-made profiling coil. By means of the induction brazing method, the hard alloy at the middle part can be heated, the temperature differences of different positions of the edge scraper are reduced during welding, the same brazing filler metal can be conveniently used for brazing, and the phenomenon that because different types of brazing filler metal are used for brazing, mutual interference is caused is avoided. By means of the induction brazing method, brazing of the hard alloy tool bit and the edge scraper body can be completed at a time; and meanwhile, the weld joint brazed rate is increased, the shear strength is also improved, the service life of the edge scraper of the shield tunneling machine is prolonged, and wear resistance of the edge scraper of the shield tunneling machine is improved.

Owner:SICHUAN GUANGZHENG TECH

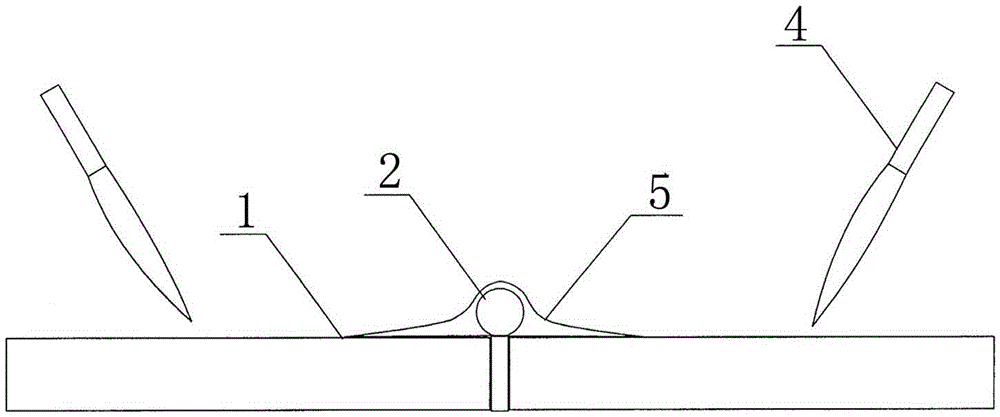

Flame preheating tungsten electrode argon arc brazing method

ActiveCN105397222AAvoid severe thermal deformationAvoid the problem of easy cracking of the interfaceArc welding apparatusHeating appliancesButt jointThermal deformation

The invention relates to a flame preheating tungsten electrode argon arc brazing method used for austenitic stainless steel brazing and connection. The method includes the following steps that multiple pieces of stainless steel parent metal are in butt joint, the brazing seam gap width ranges from 0.05 mm to 0.5 mm, brazing filler metal is prearranged above brazing seams, gaps can be filled with the brazing filler metal, and the gaps of the brazing seams and brazing filler metal welding wires are covered with brazing flux; the surfaces of the pieces of parent metal far away from the brazing seams are preheated through flame guns, and the brazing flux is melted through heat transfer; and after the brazing flux is completely melted, argon tungsten-arc welding guns are used for conducting arc discharge to heat the brazing filler metal wires quickly, gaps of the parent metal are filled with the melted brazing filler metal, and the parent metal is baked through flames in the cooling process to prevent the parent metal from being cooled too quickly or cooled at uneven temperatures. The flame preheating tungsten electrode argon arc brazing method has the beneficial effects that the problems that thermal stress and thermal deformation are serious and interfaces are prone to cracking when austenitic stainless steel is directly brazed in an argon arc manner are solved, and brazing joints high in density, high in brazed rate and small in deformation can be obtained.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

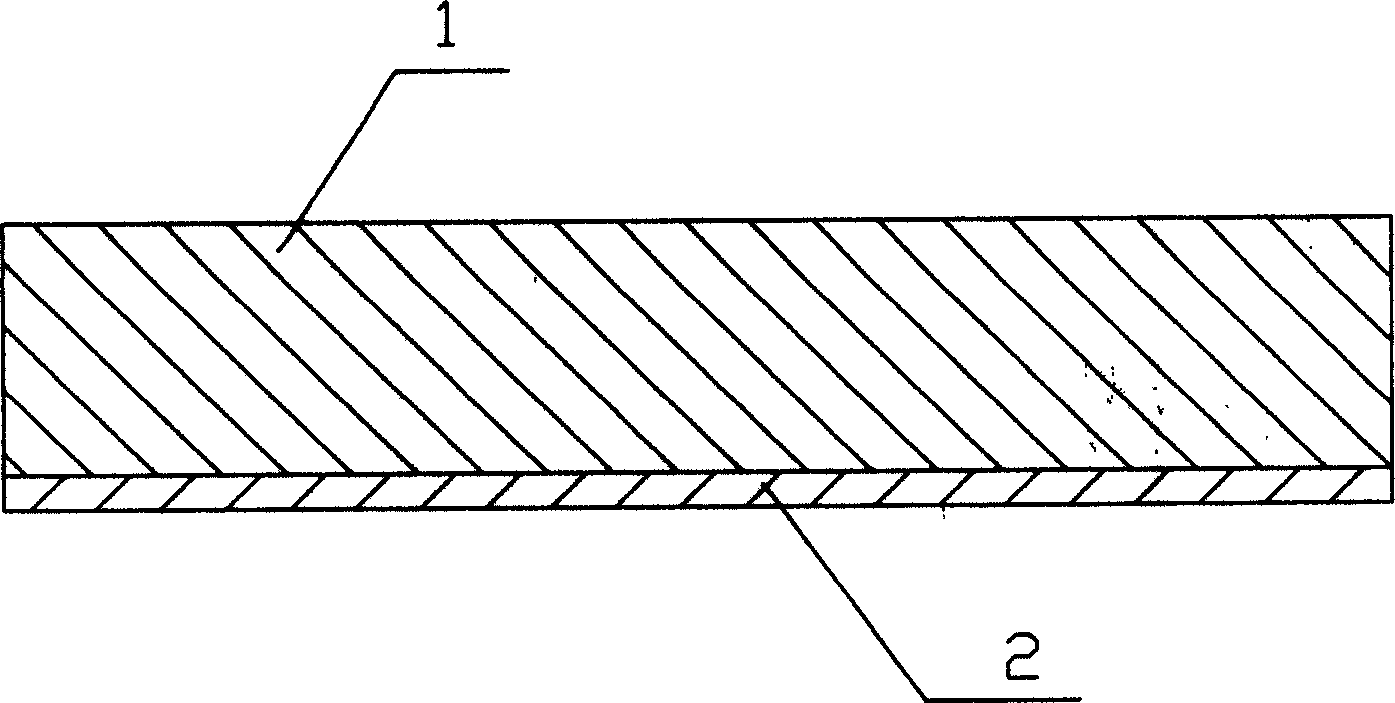

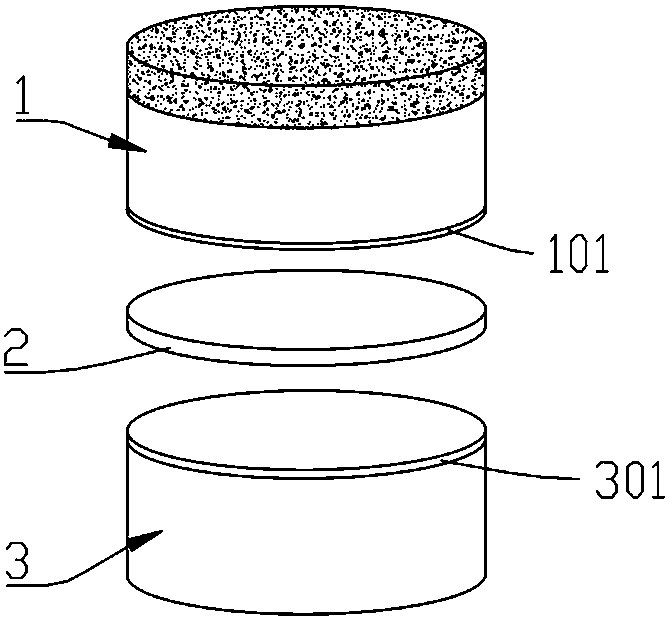

Copper-based non-silver electric contacts with brazing filler metal coating and production thereof

The invention includes following steps:The copper base non-silver contact material is taken as main material on which a layer of solder is coated; the thickness of the solder is 0.01-0.50; the solder with soldering flux is preplaced on the copper base non-silver contact, through bonding process, metal press work or heater work the solder is uniformly coated on the copper base non-silver contact.

Owner:哈尔滨东大高新材料股份有限公司

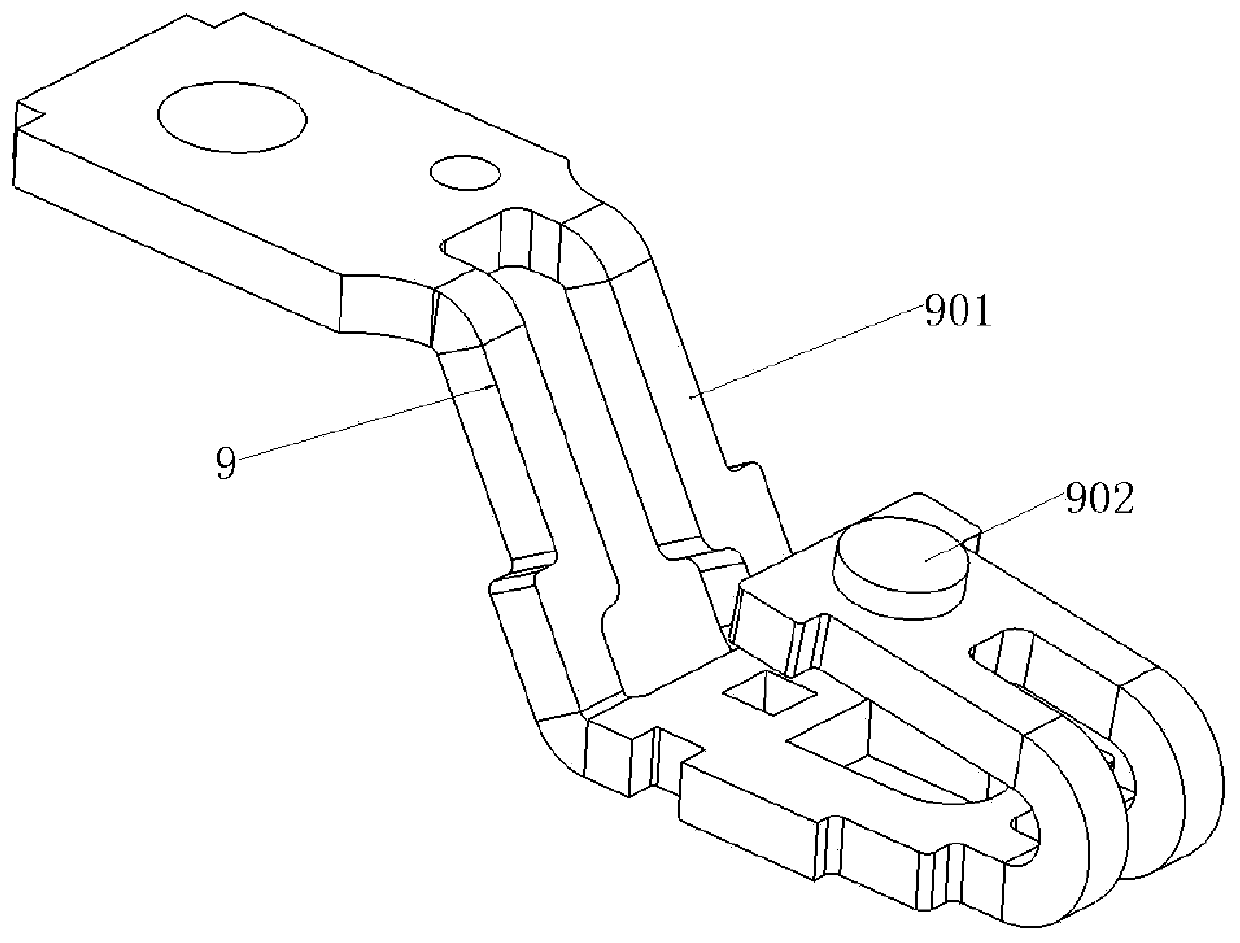

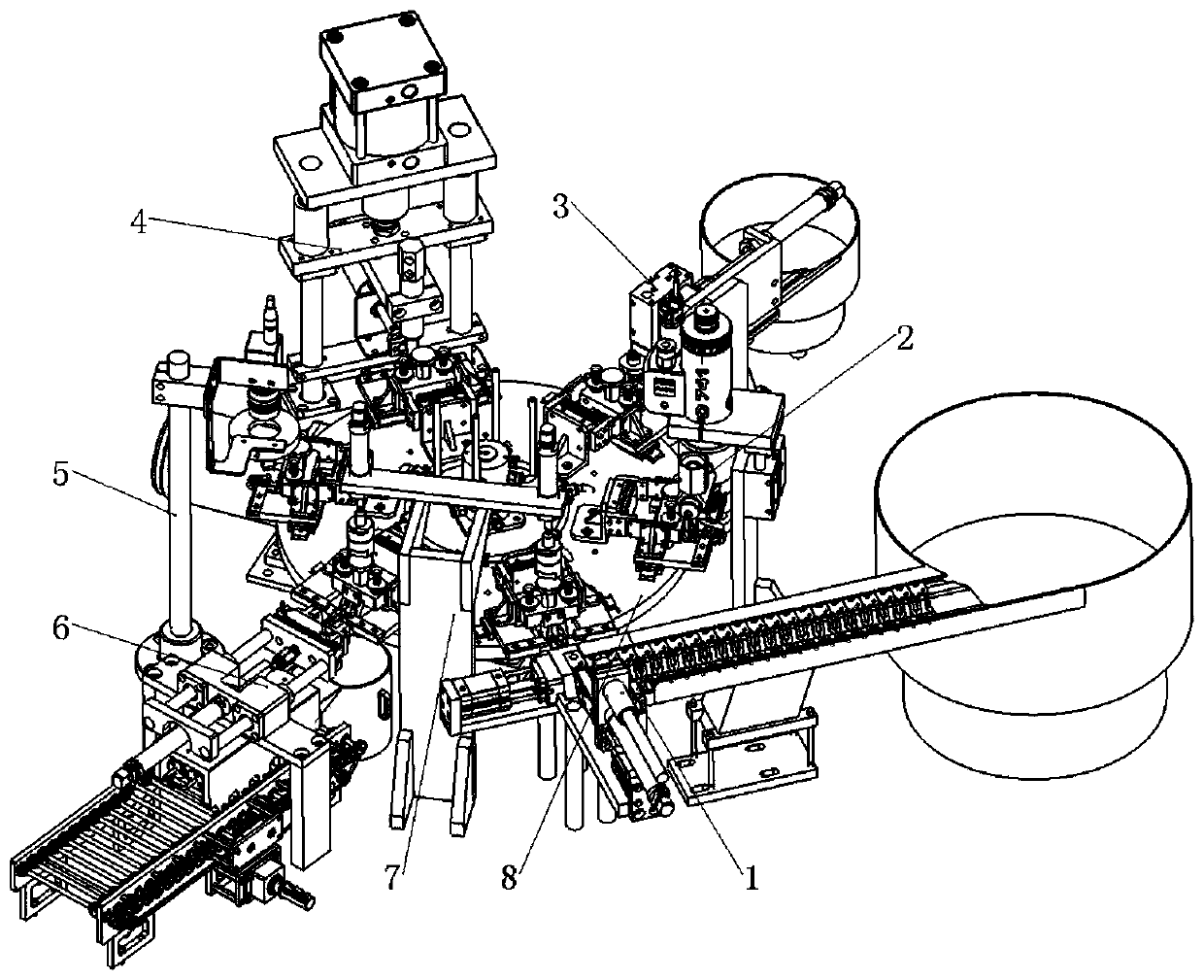

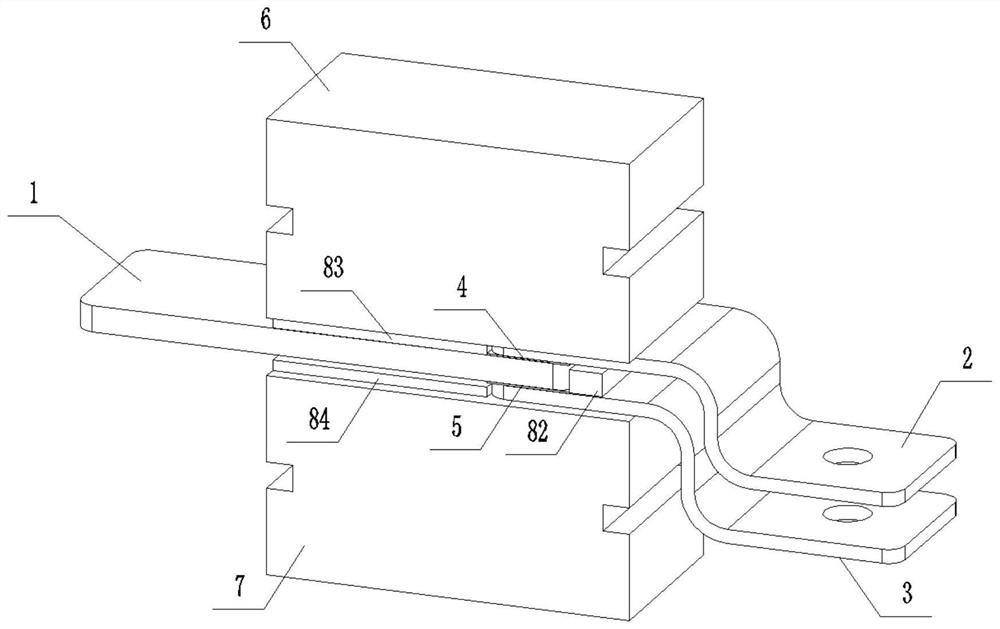

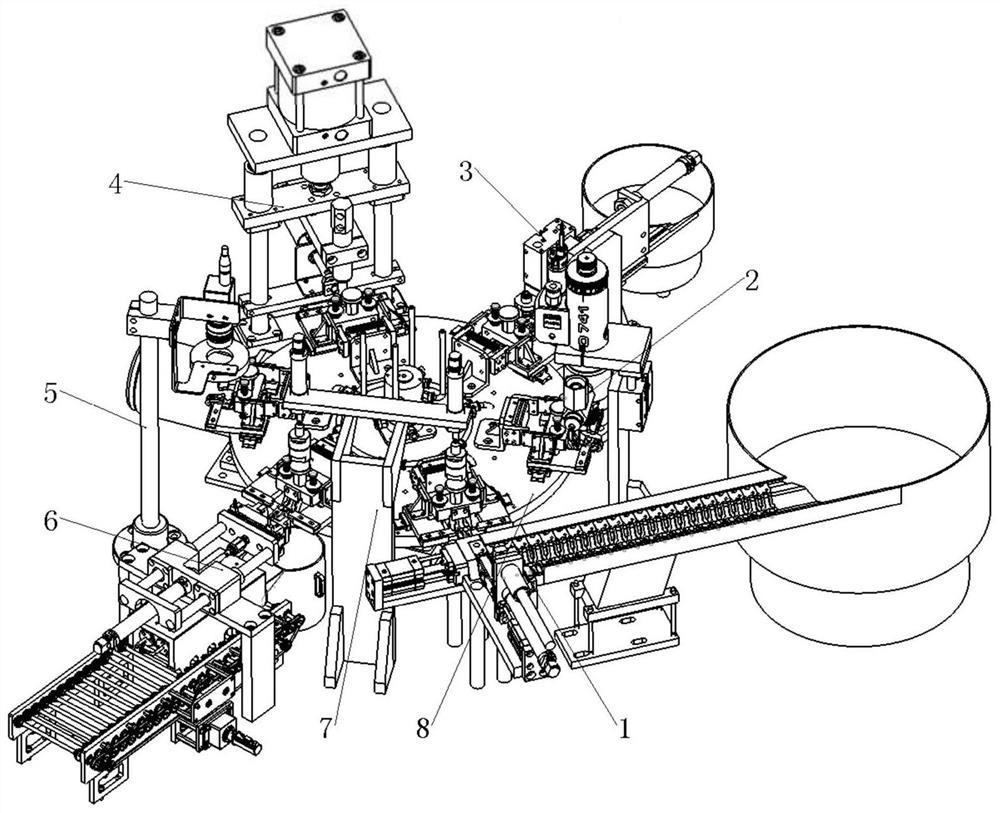

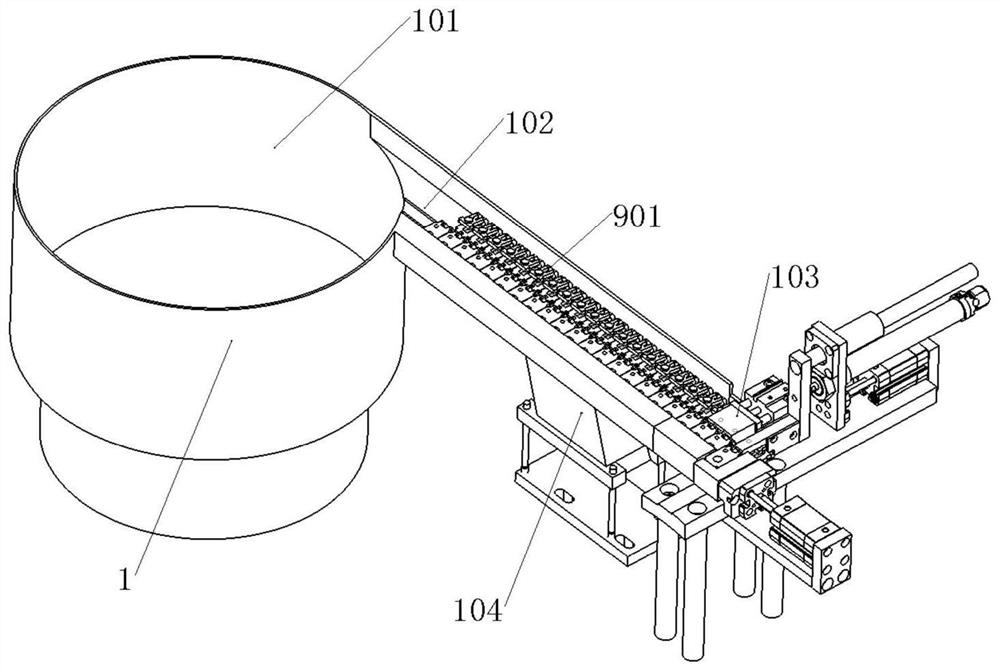

Electrical contact system ultrasonic-assisted high-frequency induction brazing device

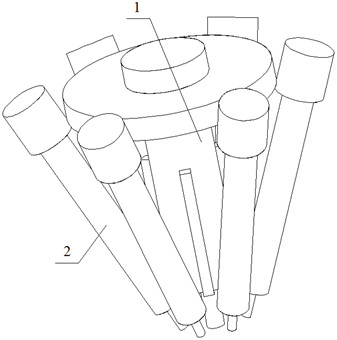

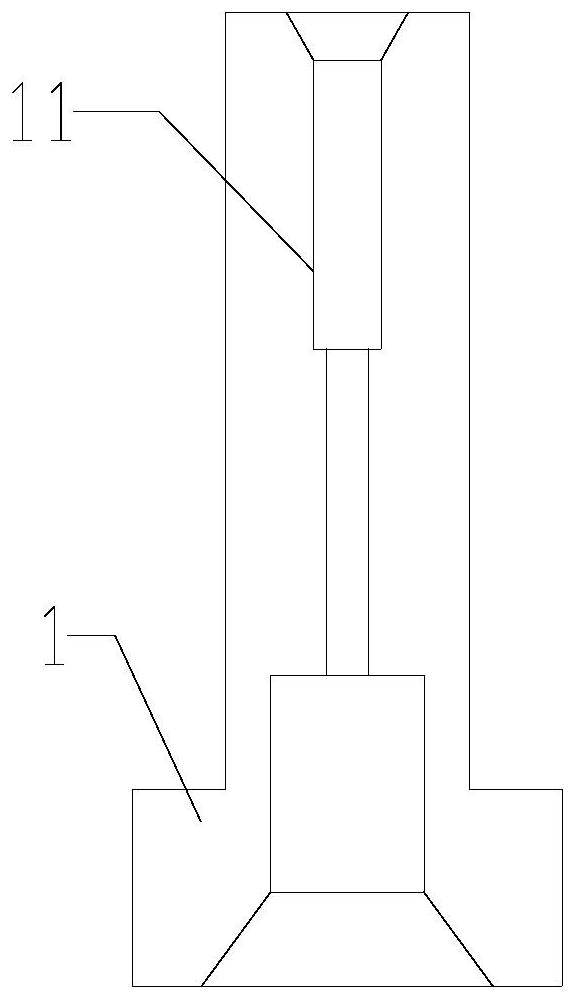

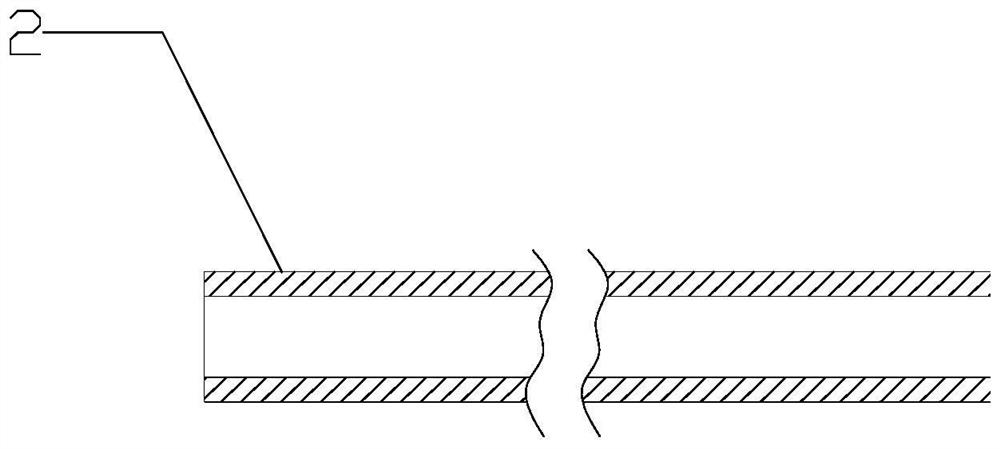

ActiveCN110355437AImprove brazing rateImprove welding strengthMetal working apparatusSoldering auxillary devicesElectricityUltrasonic assisted

The invention provides an electrical contact system ultrasonic-assisted high-frequency induction brazing device. A body of the device adopts a six-index cam divider for driving, six assembling and machining stations are arranged on the periphery of a cam divider workbench in sequence, and a same positioning mould is arranged on each assembling and machining station. The electrical contact system ultrasonic-assisted high-frequency induction brazing device specifically comprises a contact bridge feeding assembly, a soldering paste dripping assembly, a contact feeding assembly, a high-frequency induction brazing assembly, a CCD industrial camera assembly, a discharging assembly, an electric chuck assembly 7 and a cam divider assembly. According to the device, through ingenious and reasonablestructural design, a high-frequency induction heat source and ultrasonic vibration double compound energy field is integrated in a compact space; through process procedure design, the welding positions are optimized before, during and after welding correspondingly; and the automation degree is high, and both the machining efficiency and the brazing quality are taken into consideration.

Owner:山东承坤信息科技有限公司

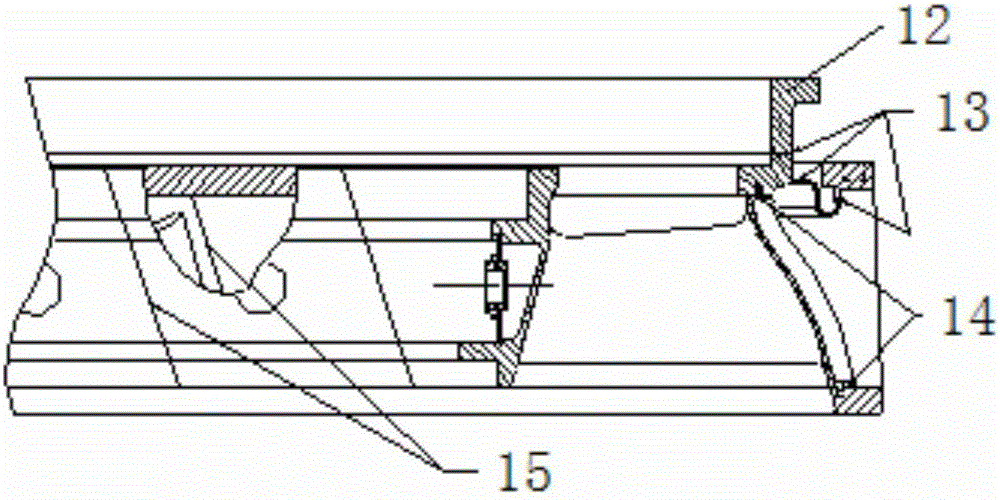

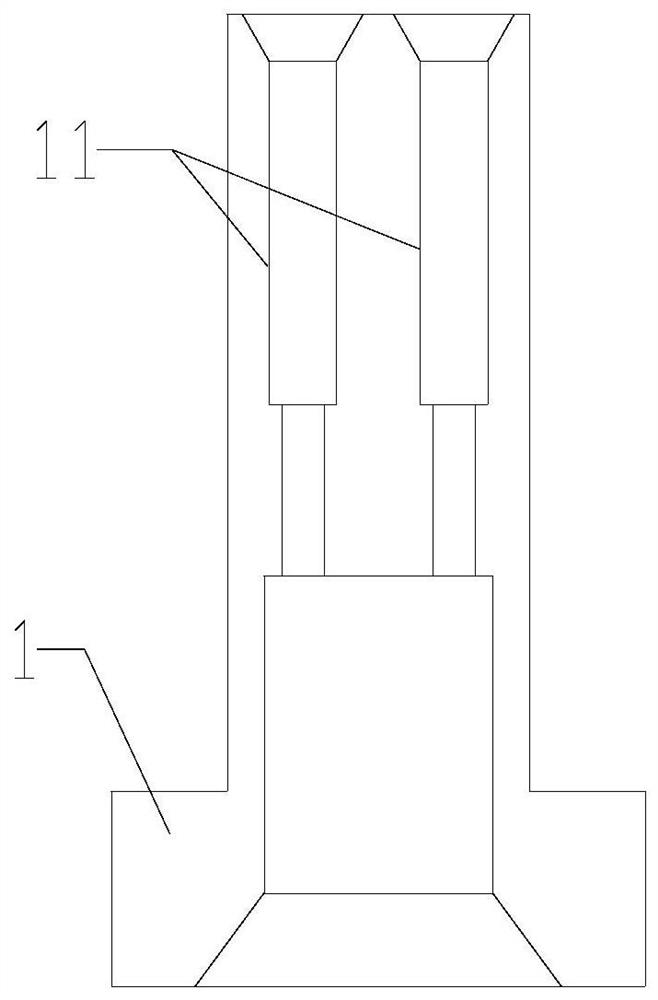

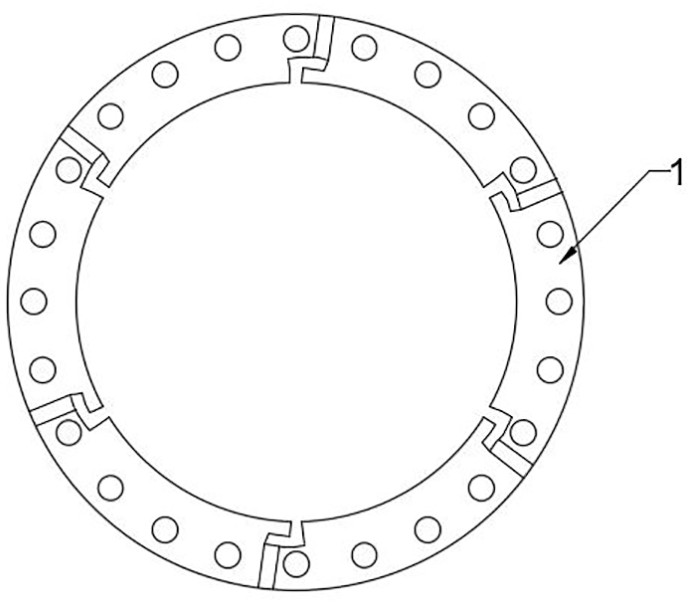

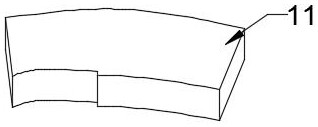

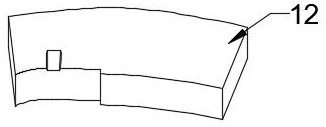

Processing method of integral guide apparatus

The invention relates to a processing method of integral guide apparatus. The processing method comprises the following steps: processing preparation: a front mounting edge, blades and a rear mounting edge are preassembled, and the blades are numbered in sequence; electron beam welding; assembly and fixing: a brazing material is prearranged; vacuum brazing: the surface, making contact with components, of each clamp for component welding is brushed with a welding stop flux; then the components are placed on a clamp base plate with the rear mounting edge facing downwards, and an interval between the bottom surface of the inner edge plate of each blade and the clamp base plate is not larger than 0.10 mm; two ring clamps with spigots are arranged on inner rings and outer rings of the components respectively, the clamped and fixed components are placed into a vacuum furnace together with the clamps for brazing, and stress-relief heat treatment of bellows components is performed simultaneously; combined machining. The processing method thoroughly solves the problem that part of brazing joints on the inner edge plates of the blades crack during processing of the integral guide apparatus, the component machining stress is small, and the dimensions are precise; the manufacture cost is reduced, and the processing efficiency is increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

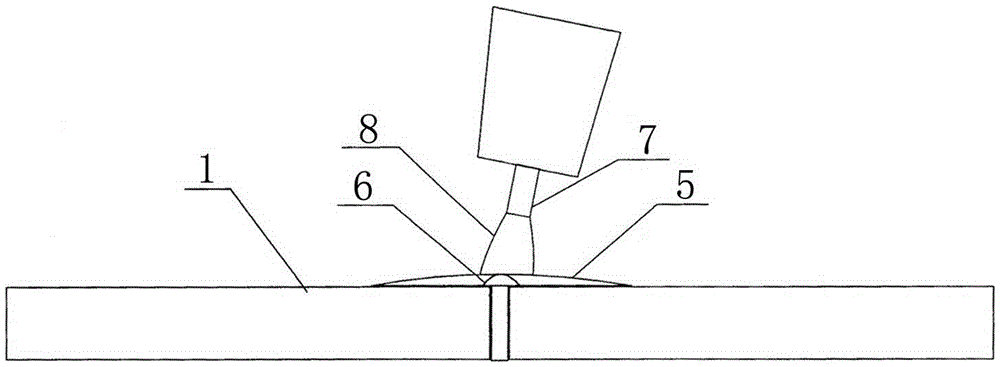

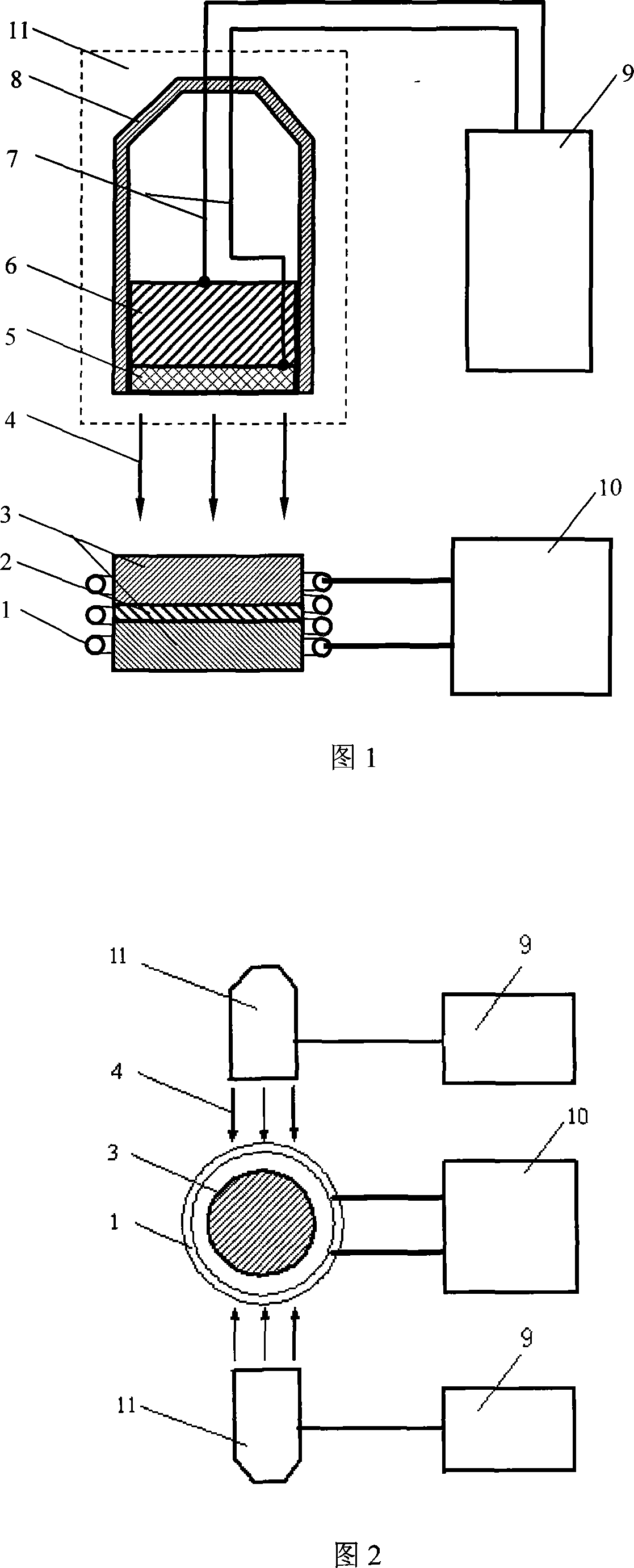

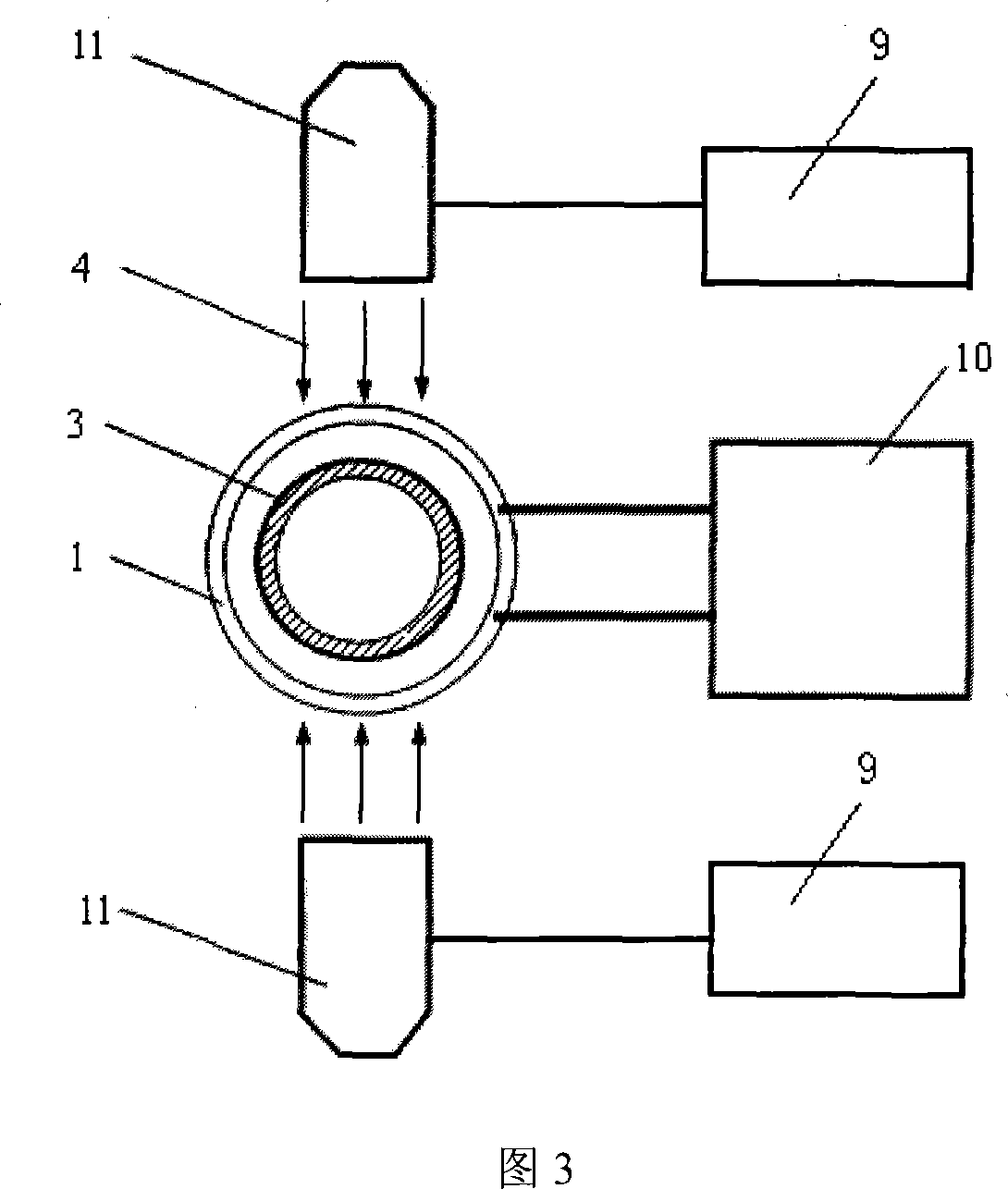

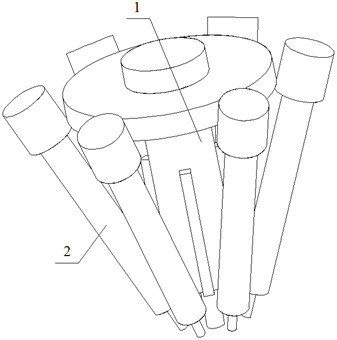

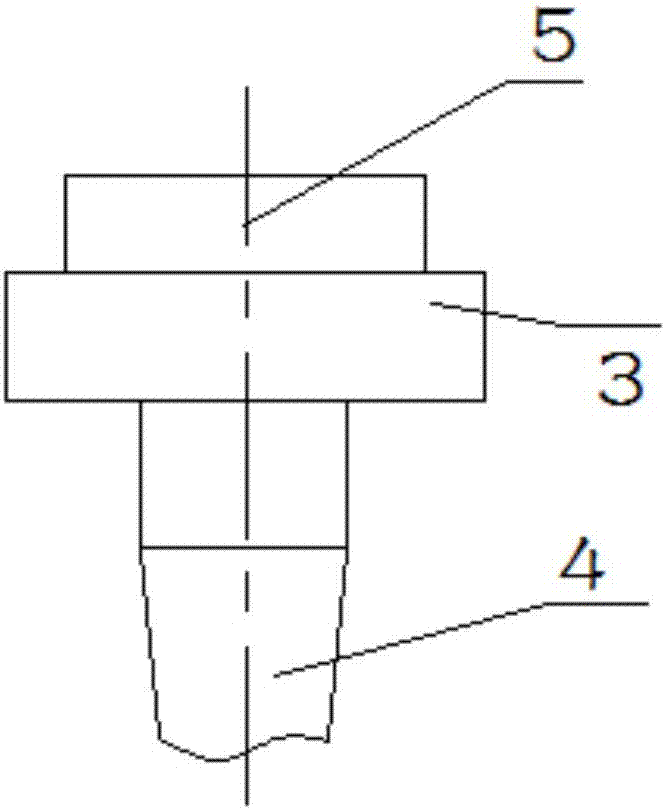

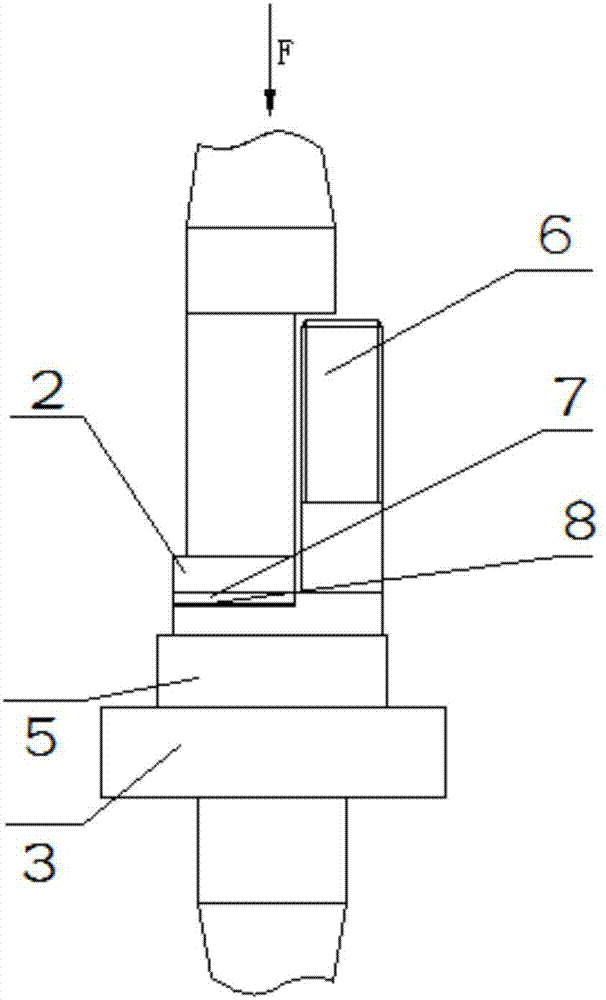

Induction brazing device and method thereof

InactiveCN101200012ASpread evenlyImprove brazing rateHeating appliancesVoltage amplitudeElectrical connection

The invention discloses an induction brazing device, comprising an induction power supply and induction coil. The invention is characterized in that an air-medium Ultrasonic probe is at least included; the air-medium ultrasonic probe is in electrical connection with a high frequency oscillator. The invention also discloses a high frequency braze welding method which uses the induction brazing device, and comprises the steps as follows: select at least one air-medium ultrasonic probe with different diameters according to the size of the connection area or complex degree; adjust the center frequency of the air-medium ultrasonic probe, the oscillating voltage amplitude of the high frequency oscillator output, and the distance between the air-medium ultrasonic probe and weld assembly connector; meanwhile connect the air-medium ultrasonic probe with the oscillator, and connect the induction coil with the induction power supply to complete the welding. Comparing with the dependant use of induction coil and induction power supply when welding the same diameter welding parts, the current output value of the induction power supply and the welding time are all reduced by 10 to 20 percent after being tested; the energy is saved and the welding efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

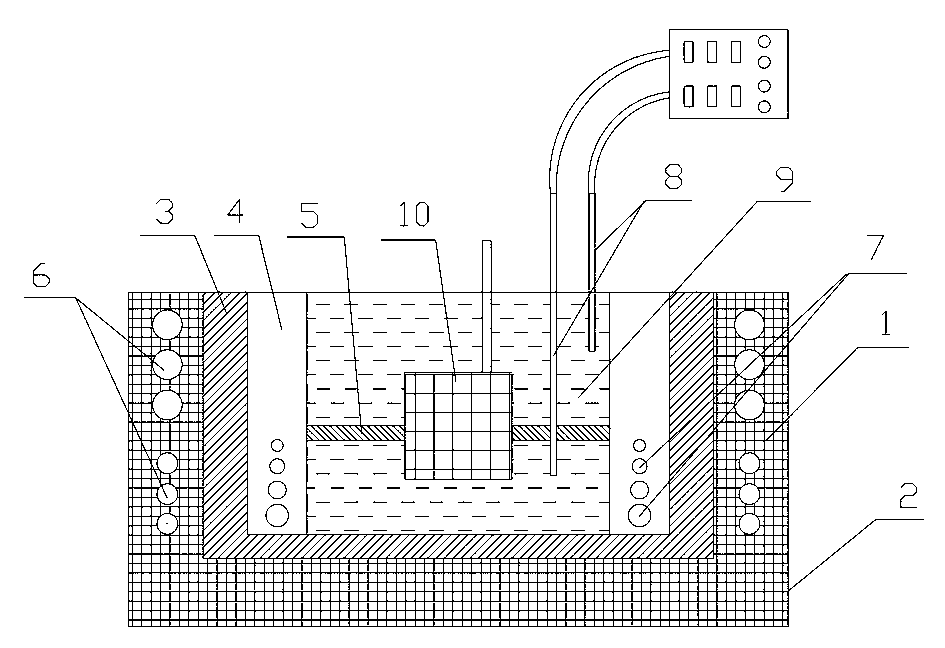

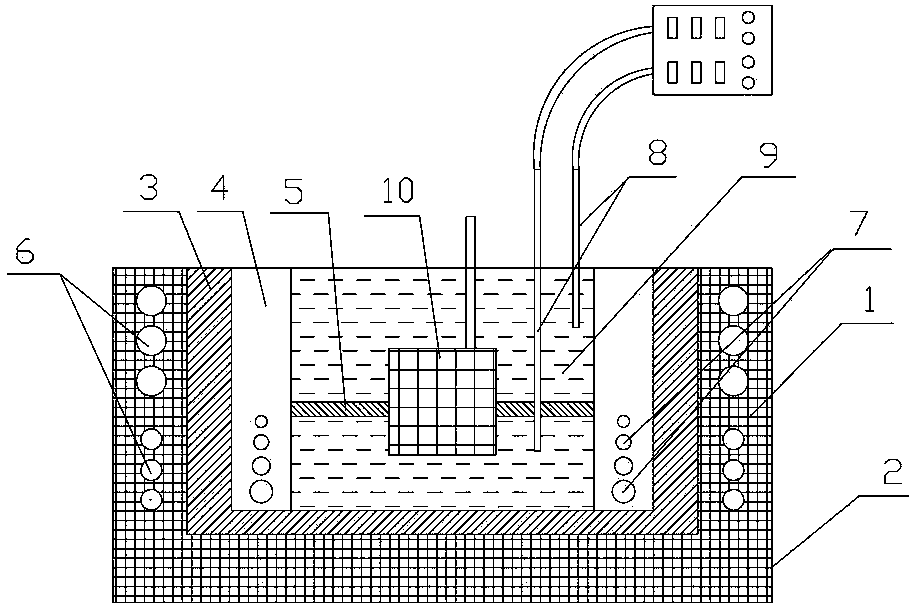

Dip brazing method with a preset temperature gradient and special brazing furnace

ActiveCN103008813AEliminate stomatal defectsImprove brazing rateMetal working apparatusSoldering auxillary devicesMetallurgyEnergy consumption

The invention discloses a dip brazing method with a preset temperature gradient. The dip brazing method comprises the following steps that firstly, a circular separating plate is horizontally arranged in a brazing furnace, and the inside of the brazing furnace is divided into at least two relatively independent spaces by the circular separating plate; the upper part and the lower part of the brazing furnace are respectively heated by heating bodies in different power, fusion brazing material in the brazing furnace forms a temperature gradient that the temperature is gradually raised from bottom to top, a workpiece is dipped into the fusion brazing material to be brazed, and the temperature each part of the workpiece is the same as the temperature of the fusion brazing material in contact with the workpiece; and the workpiece is slowly moved out, the brazing material at the bottom of the brazed workpiece is firstly solidified, then the brazing material is gradually solidified in an upward sequencing way, and gas in brazing seams is exhausted out in the solidifying process, so as to complete the brazing process. The invention also discloses a special brazing furnace. The dip brazing method and the special brazing furnace have the advantages that the problems of multiple gas holes, low brazing efficiency, instable quality of the product, large energy consumption and the like in the brazed workpiece during dip brazing are well solved; and the structure of the brazing furnace is simple, the operation is convenient, different temperature gradients can be set according to different process requirements, and the brazing requirements of different brazed workpieces are met.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Silver-based brazing filler metal alloy, preparation method of silver-based brazing filler metal alloy, and preparation methods of foil strip and wire

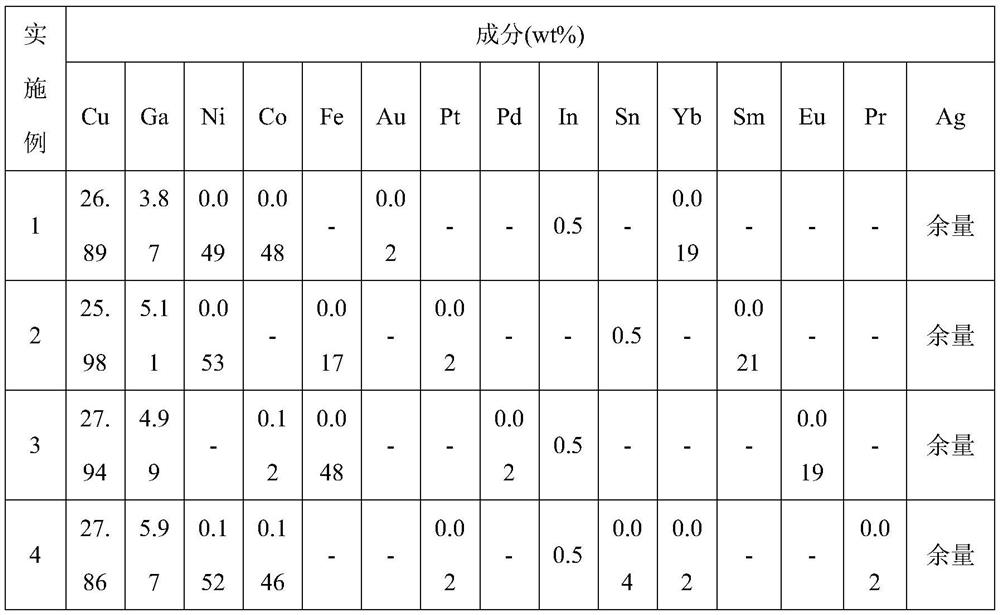

ActiveCN112059468ASolve the problem of high welding temperature and inconsistent melting pointEliminates nickel plating processWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses a silver-based brazing filler metal alloy. The silver-based brazing filler metal alloy comprises the following components of, in percentage by mass, 26%-28% of Cu; 3.5%-5.5% ofGa; at least two of the following elements of 0.001%-0.5% of Ni; 0.001%-0.5% of Co; 0.001%-0.5% of Fe; at least one of the following elements of 0.001%-0.5% of Au; 0.001%-0.5% of Pt; 0.001%-0.5% of Pd; at least one of the following elements of 0.001%-0.5% of In; 0.001%-0.5% of Sn; at least one of the following elements of La, Ce, Pr, Nd, Sm, Eu, Er, Yb, Y and Sc; and the balance Ag. The inventionfurther provides a preparation method of the silver-based brazing filler metal alloy and preparation methods of a foil strip and a wire. When the silver-based brazing filler metal alloy is used for welding a vacuum electronic device, a nickel plating process is omitted, and environmental pollution is prevented; meanwhile, the problems of high welding temperature and inconsistent melt flow pointsof Ag-28Cu-xNi alloy are solved; and the brazing filler metal alloy is good in brazing manufacturability and good in wettability, the brazing rate of kovar alloy, stainless steel and the like is higher than 95%, and the shear strength sigma b of a brazed joint is larger than or equal to 285 MPa.

Owner:KUNMING INST OF PRECIOUS METALS

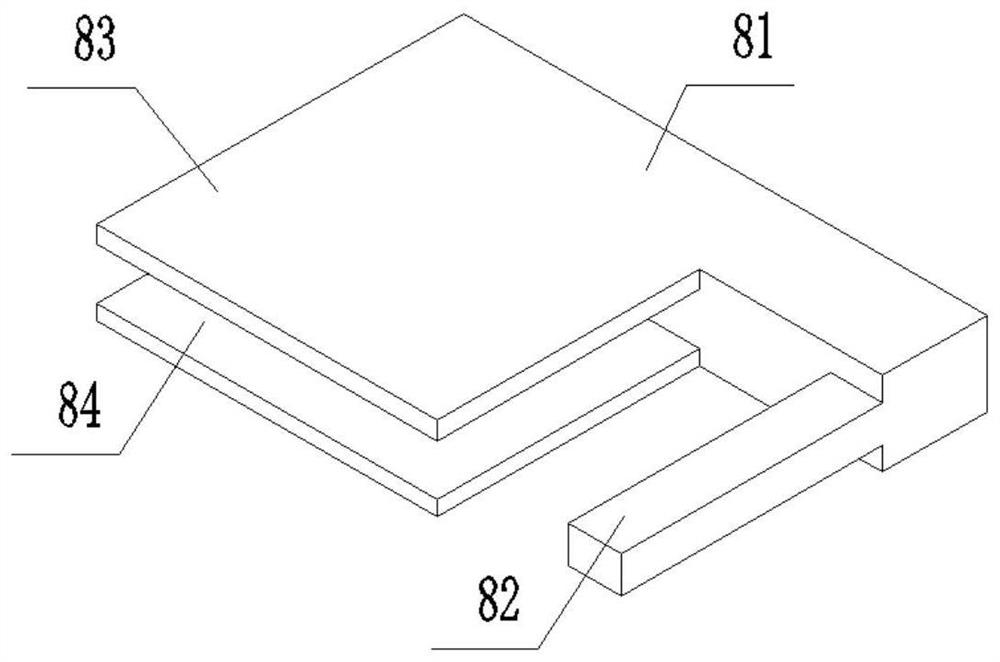

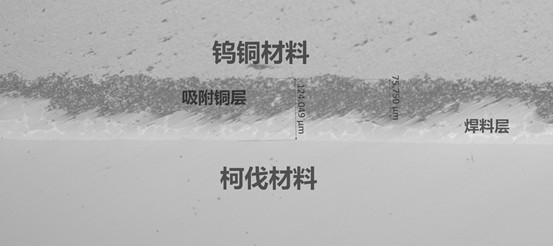

A method for improving the brazing strength of tungsten-copper parts

The invention discloses a method for improving the brazing strength of tungsten-copper parts, which comprises the following steps: S1 pressing a tungsten billet; S2 forming: putting the pressed tungsten billet into a graphite crucible, and putting copper to be infiltrated on the tungsten billet block, and then use corundum powder to bury and compact it to obtain a pre-sintered part; S3 sintering: put the formed pre-sintered part into an atmosphere-protected molybdenum wire furnace for high-temperature sintering to obtain a tungsten-copper alloy; S4 sandblasting: sinter the sintered After the tungsten-copper alloy is out of the furnace, the surface corundum powder is removed by sandblasting, and a layer of 0.01-0.1mm copper clad layer is naturally formed on the surface of the tungsten-copper alloy; S5 vacuum brazing: the sandblasted tungsten-copper alloy and stainless steel or Kovar alloy are subjected to vacuum Brazing. The method of the present invention adopts an ultra-thin copper-clad layer of 0.01-0.1mm infiltrated on the surface of the tungsten billet, which effectively improves the welding strength between the tungsten-copper alloy and stainless steel or Kovar alloy, improves the brazing rate, and effectively avoids the Welding defects due to non-wetting of tungsten copper material.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

A method for preparing copper-tungsten composite contacts using copper-tungsten mixed powder 3D printing

ActiveCN112792354BImprove brazing rateImprove conductivityAdditive manufacturing apparatusElectric switchesPunchingCopper–tungsten

The invention discloses a method for preparing a copper-tungsten composite contact by using copper-tungsten mixed powder 3D printing, which mainly includes the following steps: preparation of copper powder and tungsten powder, preparation of copper-tungsten mixed powder, 3D printing, and final treatment of samples. In the method, the specific method of copper-tungsten composite contact is to connect and print copper-tungsten parts on the stamped copper parts, which can save manufacturing costs, and the printed parts and composite interface are fine and free of holes, and the printed copper-tungsten end parts are dense and uniform in composition , excellent performance, and at the same time, this method supports personalized customization and small batch production, which just fits the market development trend of continuous reduction in product cost and continuous improvement in performance and appearance.

Owner:陕西斯瑞铜合金创新中心有限公司

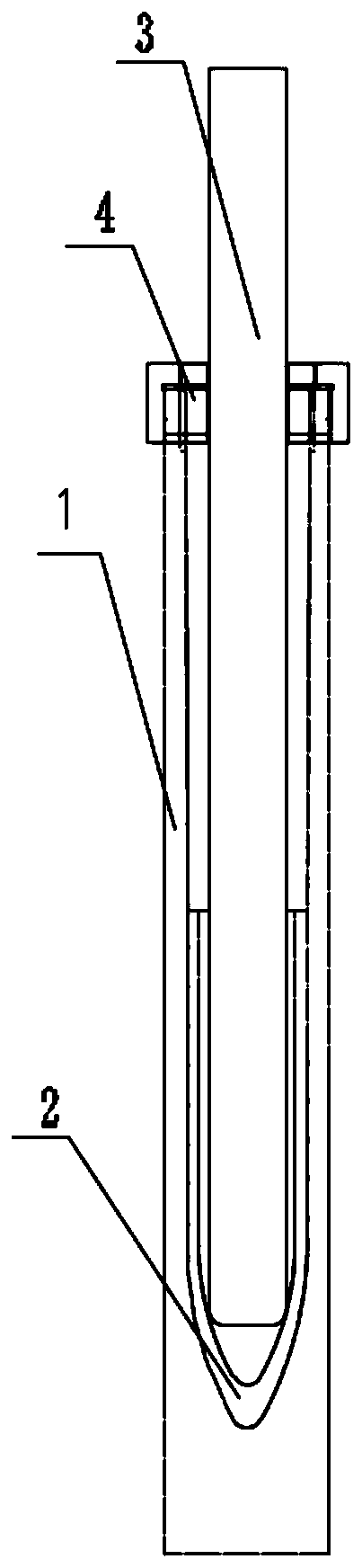

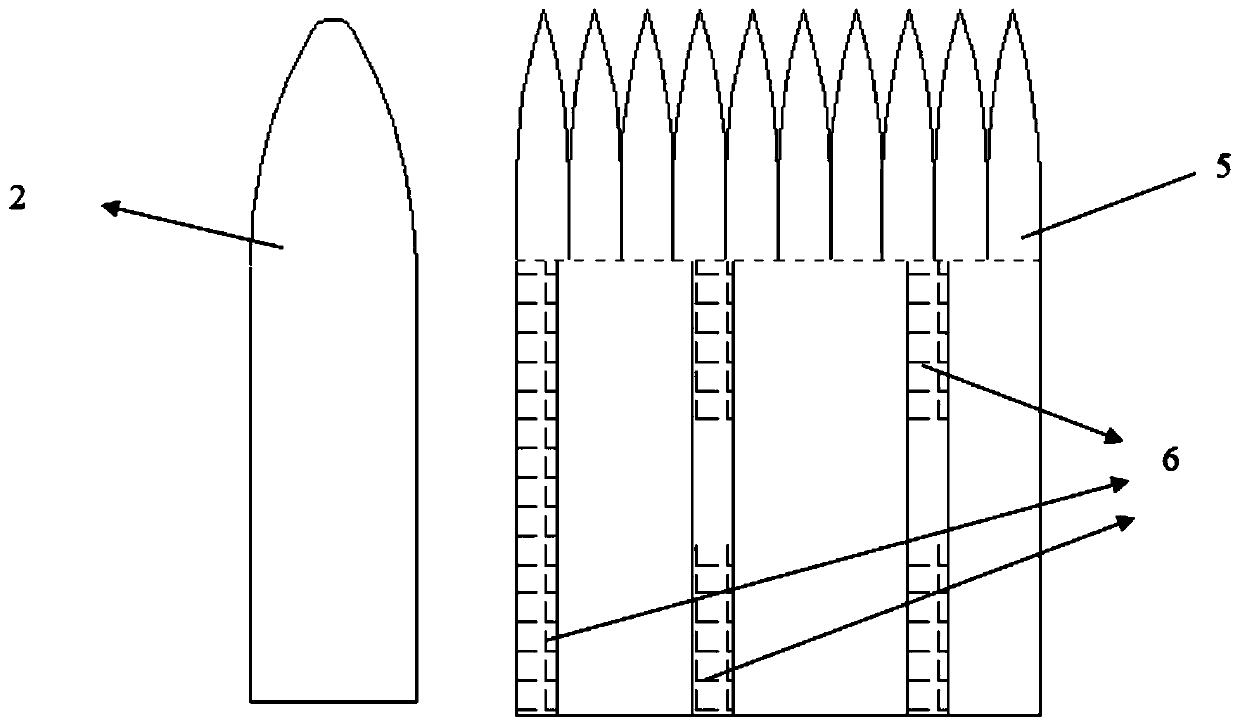

Brazing method for capillary tube and joint

ActiveCN112025018AHeating evenlyImprove brazing rateHeating appliancesSoldering auxillary devicesCorrosionEngineering

The invention discloses a brazing method for a capillary tube and a joint. The method includes the following steps that S1, the capillary tube and the joint are assembled; S2, welding flux is added tothe connecting plane of the capillary tube and the joint; and S3, the periphery of a brazing foot is sleeved with a heating coil, heating is conducted, and brazing is completed. According to the brazing method for the capillary tube and the joint, the brazing rate is remarkably increased, corrosion of the wall of the capillary tube is effectively avoided, and the welding blockage rate is greatlyreduced.

Owner:郑州郑飞机电技术有限责任公司

Machining method of injector partition plate cavity

The invention relates to the field of spacecraft machining, and discloses a machining method of an injector partition plate cavity. The machining method of the injector partition plate cavity comprises the following steps that A1, a fan-shaped groove and a wedge-shaped vertical groove are cutted on the inner circumference of an annular body; an upper cover plate, a lower cover plate and a wedge-shaped insert are machined, the upper cover plate and the lower cover plate is assembled at the fan-shaped groove, finish machining is carried out on the wedge-shaped insert, the wedge-shaped insert is assembled at a vertical groove, and vacuum brazing is carried out to obtain a partition plate cavity body assembly: A2, a ring groove piece is assembled at the inner circumference of the partition plate cavity body assembly, and fixing and brazing are achieved; wire cutting, assembling and brazing are performed on a hollow plate and a corrugated plate to obtain a partition plate; an adapter is wire cutted and assembled with the partition plate to obtain a honeycomb assembly: A3, the upper end of the wedge-shaped insert and the upper end of the annular groove piece are milled to form a sinking table surface, and a compensation block is finish-milled; a square groove is milled in the middle of a reinforcing plate, and brazing filler metal grooves are milled in the two sides of the square groove and the outer end face of the reinforcing plate; the partition plate cavity body assembly, the reinforcing plate, the honeycomb assembly and the compensation block are assembled, fixed and brazed; and finish machining is carried out after discharging, and argon arc welding is carried out on a water connector at a water inlet hole to obtain an injector partition plate cavity.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

A connection method between pdc and cemented carbide

ActiveCN106270883BIncrease moistureReduce intensitySoldering apparatusWelding/soldering/cutting articlesCarbideAlloy

Owner:宁波中机松兰刀具科技有限公司

Welding method of traction transformer copper conductive connection structure

PendingCN113571988AReduce manufacturing production costsImprove assembly and installation efficiencyLine/current collector detailsVehicle componentsGraphite electrodeTraction transformer

The invention discloses a welding method of a traction transformer copper conductive connecting structure. The conductive connecting structure comprises a copper bar, a first copper foil flexible connecting piece and a second copper foil flexible connecting piece; the first copper foil flexible connecting piece and the second copper foil flexible connecting piece are respectively welded on the upper and lower surfaces of one end of the copper bar, and graphite electrodes are arranged on the upper and lower surfaces of the other end of the copper bar; the first and second copper foil flexible connecting pieces are respectively connected with the copper bar through a first soldering lug and a second soldering lug. The welding method of the traction transformer copper conductive connection structure comprises the following steps: S1, preparing a graphite electrode; S2, installing a graphite electrode; S3, assembling a welding joint; S4, fixing the joint; S5, performing heating and welding; S6, performing cleaning after welding. By adopting the structure that the two copper foil flexible connecting pieces are welded at one end of one copper bar, two flexible output connecting ends can be obtained after one-time welding on one copper bar, so that the manufacturing and production cost of the transformer is lower, the part assembling and mounting efficiency is higher, and the conductive efficiency and the structure optimization are greatly improved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Method for improving brazing strength of tungsten-copper part

The invention discloses a method for improving the brazing strength of a tungsten-copper part. The method comprises the following steps of S1, pressing of a tungsten blank; S2, forming, wherein the pressed tungsten blank is placed in a graphite crucible, a copper block needing infiltration is placed on the tungsten blank, then emery powder is adopted for filling and is tamped, and a pre-sintered part is obtained; S3, sintering, wherein the formed pre-sintered part is put into an atmosphere protection molybdenum wire furnace to be sintered at a high temperature, and a tungsten-copper alloy is obtained; S4, sand blasting, wherein after the sintered tungsten-copper alloy is discharged out of the furnace, sand blasting is carried out to remove the emery powder on the surface, and a copper-clad layer of 0.01-0.1 mm is naturally formed on the surface of the tungsten-copper alloy; and S5, vacuum brazing, wherein vacuum brazing is conducted on the tungsten-copper alloy obtained after sand blasting and stainless steel or a Kovar alloy. According to the method, the ultrathin copper-clad layer of 0.01-0.1 mm is infiltrated on the surface of the tungsten blank, the welding strength between the tungsten-copper alloy and the stainless steel or the Kovar alloy is effectively improved, the brazed rate is increased, and the welding defect caused by non-infiltration of a tungsten-copper material is effectively avoided.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Phosphor copper welding rod and preparation method thereof

ActiveCN104028915AReduce processing requirementsSolve with silverWelding/cutting media/materialsSoldering mediaChemical industryElectrolysis

The invention discloses a phosphor copper welding rod prepared by taken electrolytic copper, phosphorite and Yunnan tin as main raw material. The phosphor copper welding rod comprises the following elements in percentage by weight: 46.22 percent of copper, 50.53 percent of phosphorus, 2.73 percent of tin and 0.52 percent of other metal. The invention further discloses a preparation method of the phosphor copper welding rod. The phosphor copper welding rod has the benefits that the problems that an existing silver welding rod uses a large quantity of silver, the cost is high, and the environment is polluted are solved, and the phosphor copper welding rod has the advantages of relatively low melting point, high brazed rate and high welding precision and can be widely applied to the industrial manufacturing fields of refrigeration, festoon lightings, hardware appliance, instruments and meters, chemical industry, aerospace and the like.

Owner:YUEQING BOTE WELDING MATERIAL

Novel flux-cored silver solder

InactiveCN110936065AGood moisture absorptionImprove liquidityWelding/cutting media/materialsSoldering mediaDipotassium hydrogen phosphateTetrafluoroborate

The invention discloses a novel flux-cored silver solder, which belongs to a soldering material in the fields of metal materials and metallurgy. The novel flux-cored silver solder is prepared by coating soldering flux powder with a BAg18CuZnSn silver solder strip. And the BAg18CuZnSn silver solder strip is prepared from metal silver, copper, zinc and tin. The coating brazing flux powder is composed of potassium bifluoride (KHF2), potassium fluoride, boric acid, cesium carbonate, potassium carbonate, potassium silicate, sodium silicate, dipotassium hydrogen phosphate and potassium tetrafluoroborate (KBF4). Soldering flux powder in the flux-cored silver solder has excellent flowability and moisture absorption resistance, in the tape winding and drawing process of the flux-cored silver solder, the flux-cored silver solder does not have the phenomenon of wire breakage, the soldering flux powder cannot adhere to a roller, and the drawing diameter of the flux-cored silver solder can be reduced to 0.4 mm or below so as to meet the requirement for precise soldering.

Owner:ZHEJIANG YONGWANG WELDING MATERIALS CO LTD

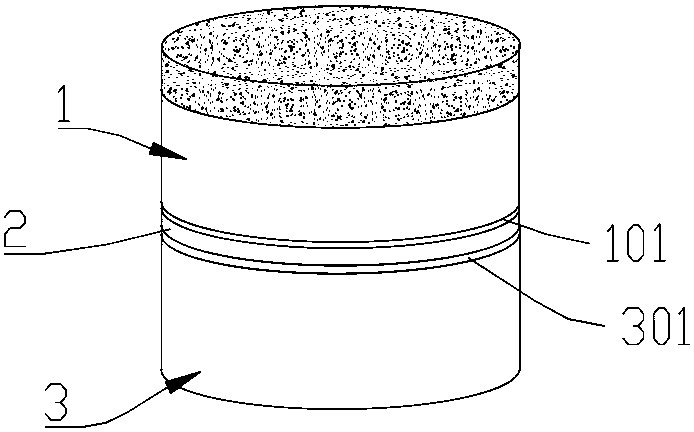

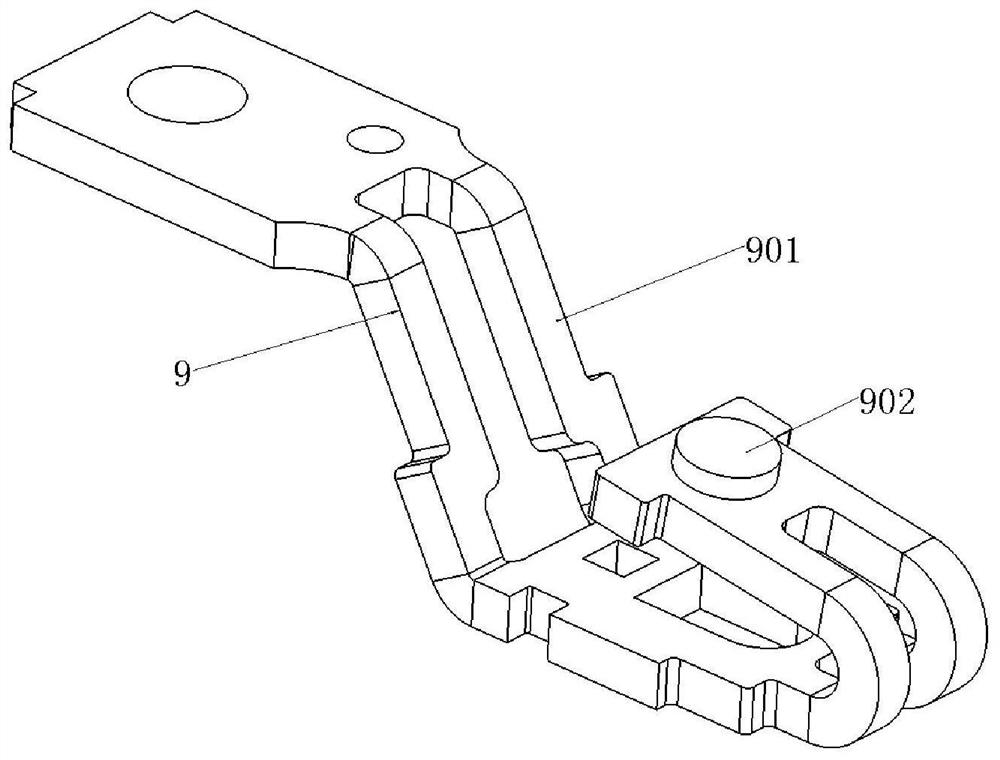

Contactor binding post assembly and brazing connecting method

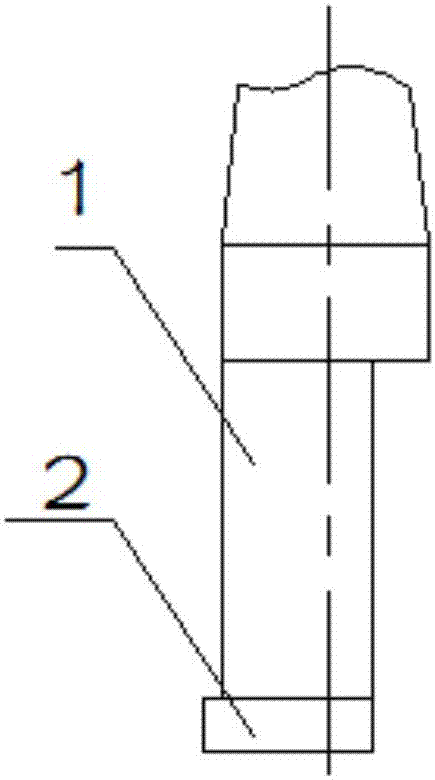

InactiveCN107498162AEasy to spreadImprove brazing rateLine/current collector detailsSoldered/welded conductive connectionsEngineeringBinding post

The invention provides a contactor binding post assembly which comprises an upper electrode, a binding post and a lower electrode. The upper end of the binding post is connected with the upper electrode, and the lower end of the binding post is connected with the lower electrode; the upper electrode comprises an upper-level electrode arm and an upper-level electrode head, and the upper-level electrode head is arranged on the lower portion of the upper-level electrode arm; the lower electrode comprises a lower-level electrode head, a lower-level electrode arm and a resistance heat source, the upper end of the lower-level electrode head is connected with the resistance heat source, and the lower end of the lower-level electrode head is connected with the lower-level electrode arm; and the upper-level electrode head of the upper electrode is connected with the binding post through a contact point and a brazing material, and the lower-level electrode head of the lower electrode is connected with the binding post through the resistance heat source. According to the contactor binding post assembly, spreading of the brazing material is improved, the brazed rate of a brazing seam of the contact point and the binding post is increased, and the impact of brazing flux residues on a product is completely eradicated, so that the use property and reliability of the contactor product are improved, and high-end development of the product is promoted.

Owner:GUIZHOU TIANYI ELECTRICAL

A production process of silver-tungsten carbide compound silver-nickel-copper electric contact

A production process of a silver-tungsten carbide and silver-nickel-copper compounded electric contact includes: mixing, namely mixing Ag powder, C powder and Wc powder to form AgWc12C3 powder, and mixing Ag powder, Ni powder and Cu powder to form Ag, Ni and Cu alloy powder; sintering and pelleting; namely sintering and pelleting the AgWc12C3 powder and the Ag, Ni and Cu alloy powder; pre-pressing, spreading the sintered Ag, Ni and Cu alloy particles and AgWc12C3 particles into two layers and using a die for compression moulding; sintering, placing the pressed blank formed by pre-pressing into a sintering furnace and sintered in an anaerobic environment; and re-pressing, using the die for compression moulding according to requirements of products. Ag powder in the prior art is substituted by the Ag, Ni and Cu alloy powder, nickel and copper are added, silver content in a composite layer is saved, and brazing rate is increased after modification, and bonding strength is improved.

Owner:ZHEJIANG TIANYIN ALLOY TECH

A kind of phosphor copper welding rod and preparation method thereof

ActiveCN104028915BReduce processing requirementsReduce pollutionWelding/cutting media/materialsSoldering mediaChemical industryElectrolysis

Owner:YUEQING BOTE WELDING MATERIAL

A kind of silver-based solder alloy and its preparation method, the preparation method of foil strip material and wire material

ActiveCN112059468BGuaranteed cleanlinessEasy to realize industrial productionWelding/cutting media/materialsSoldering mediaUltimate tensile strengthKovar

The invention discloses a silver-based solder alloy, which comprises: Cu, 26-28%; Ga, 3.5-5.5%; at least two of the following elements: Ni, 0.001-0.5%; Co, 0.001- 0.5%; Fe, 0.001-0.5%; at least one of the following elements: Au, 0.001-0.5%; Pt, 0.001-0.5%; Pd, 0.001-0.5%; at least one of the following elements: In, 0.001-0.5% %; Sn, 0.001-0.5%; at least one of the following elements: La, Ce, Pr, Nd, Sm, Eu, Er, Yb, Y and Sc; the balance is Ag. The invention further provides a preparation method of silver-based solder alloy and a preparation method of foil strip and wire. The silver-based solder alloy of the present invention saves the nickel-plating process in welding vacuum electronic devices, preventing it from polluting the environment; at the same time, it solves the problems that the welding temperature of the Ag-28Cu-xNi alloy is high and the melting point is inconsistent; the solder The material alloy brazing process is good, has good wettability, the brazing rate of Kovar alloy, stainless steel, etc. is higher than 95%, and the shear strength of the brazed joint is σ b ≥285MPa.

Owner:KUNMING INST OF PRECIOUS METALS

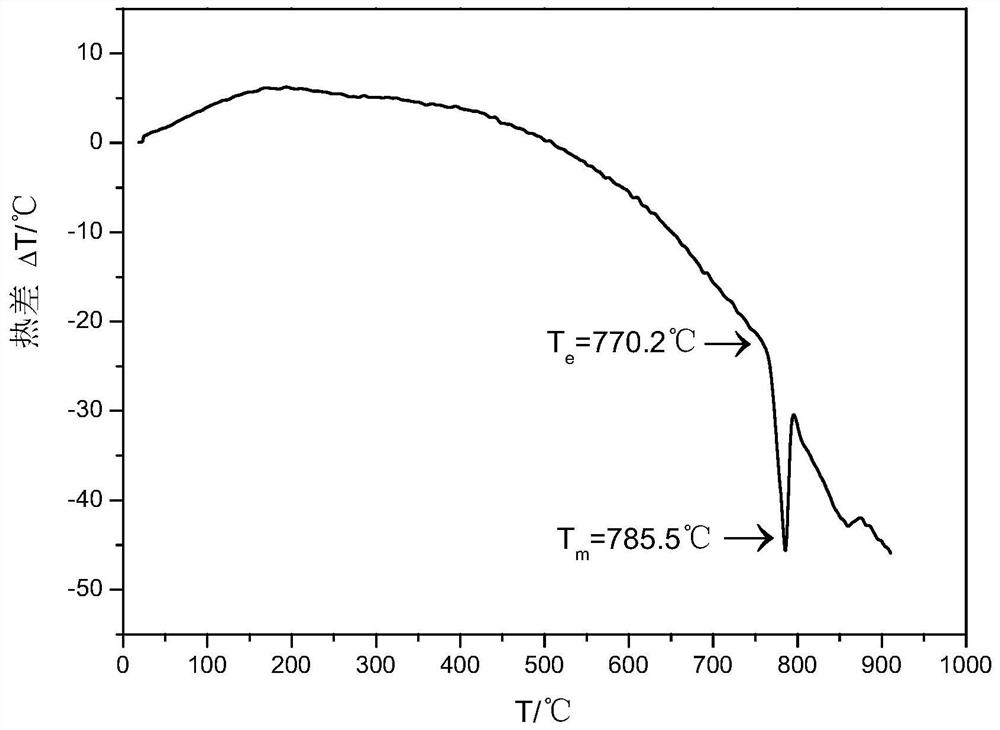

A kind of low-silver solder for vacuum electronic device sealing and preparation method thereof

ActiveCN107855679BLow vapor pressureSave resource costWelding/cutting media/materialsSoldering mediaVacuum electronicsMelting temperature

The invention discloses a low-silver brazing material for vacuum electronic device sealing and a preparation method thereof, belonging to the technical field of brazing materials. In terms of mass percentage, the composition is: Ag 42.0%-48.0%, Ga 3.0%-5.0%, Ni 0.1%-2.0%, and the balance is Cu. Using the method of "vacuum continuous casting-solution heat treatment-rolling-on-line stretching and straightening heat treatment-finish rolling", a wide and extremely thin strip with a thickness of 20 μm and a width of 250 mm can be prepared. The preparation method is simple and conducive to mass production. The melting temperature of this low-silver solder is equivalent to that of AgCuNi solder. It has good brazing processability, good wettability, low silver content, low vapor pressure, etc., and the soldering rate to oxygen-free copper, nickel and other materials is higher than 99 %; weld tensile strength σ b ≥150MPa; used for sealing vacuum devices such as vacuum tubes, the package leakage rate is ≤1.0×10 ‑11 Pam 3 / s.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Dip brazing method with a preset temperature gradient

ActiveCN103008813BEliminate stomatal defectsImprove brazing rateMetal working apparatusSoldering auxillary devicesMetallurgyEnergy consumption

The invention discloses a dip brazing method with a preset temperature gradient. The dip brazing method comprises the following steps that firstly, a circular separating plate is horizontally arranged in a brazing furnace, and the inside of the brazing furnace is divided into at least two relatively independent spaces by the circular separating plate; the upper part and the lower part of the brazing furnace are respectively heated by heating bodies in different power, fusion brazing material in the brazing furnace forms a temperature gradient that the temperature is gradually raised from bottom to top, a workpiece is dipped into the fusion brazing material to be brazed, and the temperature each part of the workpiece is the same as the temperature of the fusion brazing material in contact with the workpiece; and the workpiece is slowly moved out, the brazing material at the bottom of the brazed workpiece is firstly solidified, then the brazing material is gradually solidified in an upward sequencing way, and gas in brazing seams is exhausted out in the solidifying process, so as to complete the brazing process. The invention also discloses a special brazing furnace. The dip brazing method and the special brazing furnace have the advantages that the problems of multiple gas holes, low brazing efficiency, instable quality of the product, large energy consumption and the like in the brazed workpiece during dip brazing are well solved; and the structure of the brazing furnace is simple, the operation is convenient, different temperature gradients can be set according to different process requirements, and the brazing requirements of different brazed workpieces are met.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

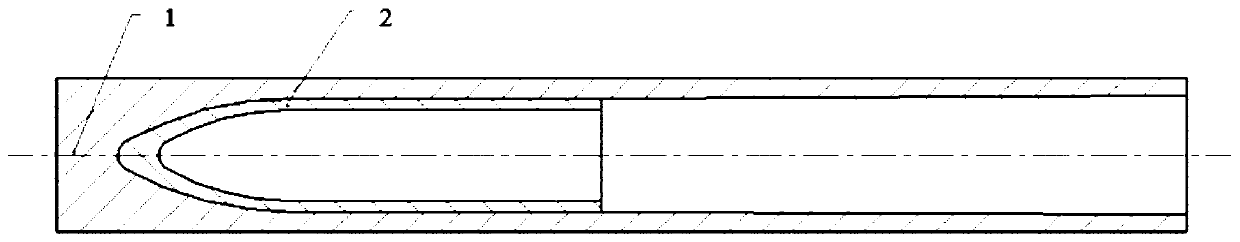

A method for brazing inner holes of ultra-high strength steel and tungsten alloy

ActiveCN107717156BImprove reliabilityHigh strengthSoldering apparatusFurnace typesHigh intensityUltimate tensile strength

The invention discloses an ultrahigh-strength steel and tungsten alloy inner hole brazing method. The method comprises the following steps of: tailoring a brazing sheet, fixing the brazing sheet to the outer surface of a liner, wherein the liner can be wrapped by the brazing sheet to be placed in an inner hole of a shell, putting a combination of a shell and the liner filled with the brazing sheetin a brazing furnace, setting the brazing temperature to be above the brazing sheet melting point, heating the brazing sheet continuously for a period of time, wherein the brazing sheet is fully melted, and the brazing sheet fully fills the gap between welding surfaces of the liner and the shell to finish a normalizing process; performing annealing processing on the combination of the shell and the liner filled with the brazing sheet; and raising the temperature of the brazing furnace till the brazing material is melted, and quenching an ultrahigh-strength steel and tungsten alloy weldment. The method provided by the technical scheme combines high-temperature brazing, quenching and tempering, so that a special material brazing process and a shell material thermal treatment are combined fully to obtain a high-strength high-welded-rate brazing joint and meanwhile, the high strength and toughness of the shell are guaranteed.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

Ultrasonic-assisted high-frequency induction brazing device for electric contact system

ActiveCN110355437BImprove brazing rateImprove welding strengthMetal working apparatusSoldering auxillary devicesUltrasonic assistedUltrasonic vibration

The invention provides an electrical contact system ultrasonic-assisted high-frequency induction brazing device. A body of the device adopts a six-index cam divider for driving, six assembling and machining stations are arranged on the periphery of a cam divider workbench in sequence, and a same positioning mould is arranged on each assembling and machining station. The electrical contact system ultrasonic-assisted high-frequency induction brazing device specifically comprises a contact bridge feeding assembly, a soldering paste dripping assembly, a contact feeding assembly, a high-frequency induction brazing assembly, a CCD industrial camera assembly, a discharging assembly, an electric chuck assembly 7 and a cam divider assembly. According to the device, through ingenious and reasonablestructural design, a high-frequency induction heat source and ultrasonic vibration double compound energy field is integrated in a compact space; through process procedure design, the welding positions are optimized before, during and after welding correspondingly; and the automation degree is high, and both the machining efficiency and the brazing quality are taken into consideration.

Owner:山东承坤信息科技有限公司

Brazing alloy prefilling process in vacuum brazing

ActiveCN102179587BThe mechanical properties do not changeSolve the limitation of capillary action not exceeding 10mmSoldering apparatusBraze alloyUltimate tensile strength

The invention discloses a brazing alloy prefilling process in vacuum brazing, which comprises the following steps of: clamping a brazing alloy and a parent stock; casting in vacuum, and making the brazing alloy and the parent stock melted on the premise of keeping the mechanical properties unchanged, wherein the structure of the brazing alloy is not completely disintegrated, and an eutectic liquid phase appears only; and making the condensed brazing alloy and the parent stock subjected to micro metallurgical bond, wherein the bond strength sigma b is 60-120MPa and can ensure that the brazing alloy is not separated from the parent stock during finish machining. The brazing alloy prefilling process solves the problems that capillarity of the brazing alloy is limited within 10mm, the high-strength bond of the brazing alloy and the parent stock ensures that the brazing alloy can be subjected to finish machining and is not peeled, and the brazing alloy prefilling process is particularly suitable for difficulty connected, concealed and high brazed rate brazing.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

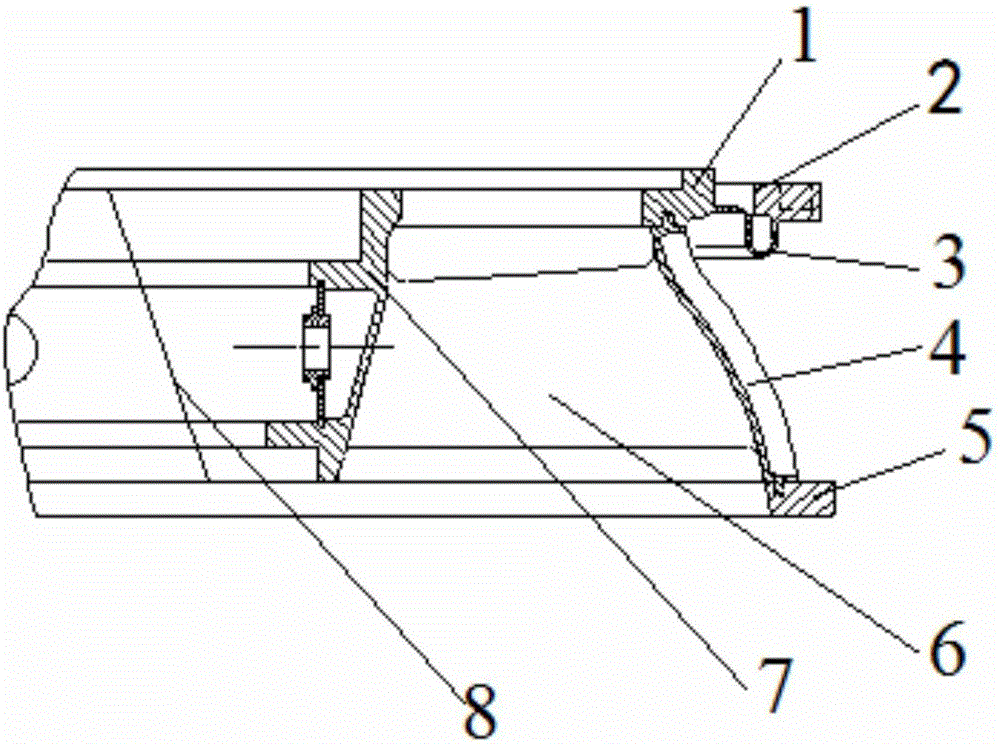

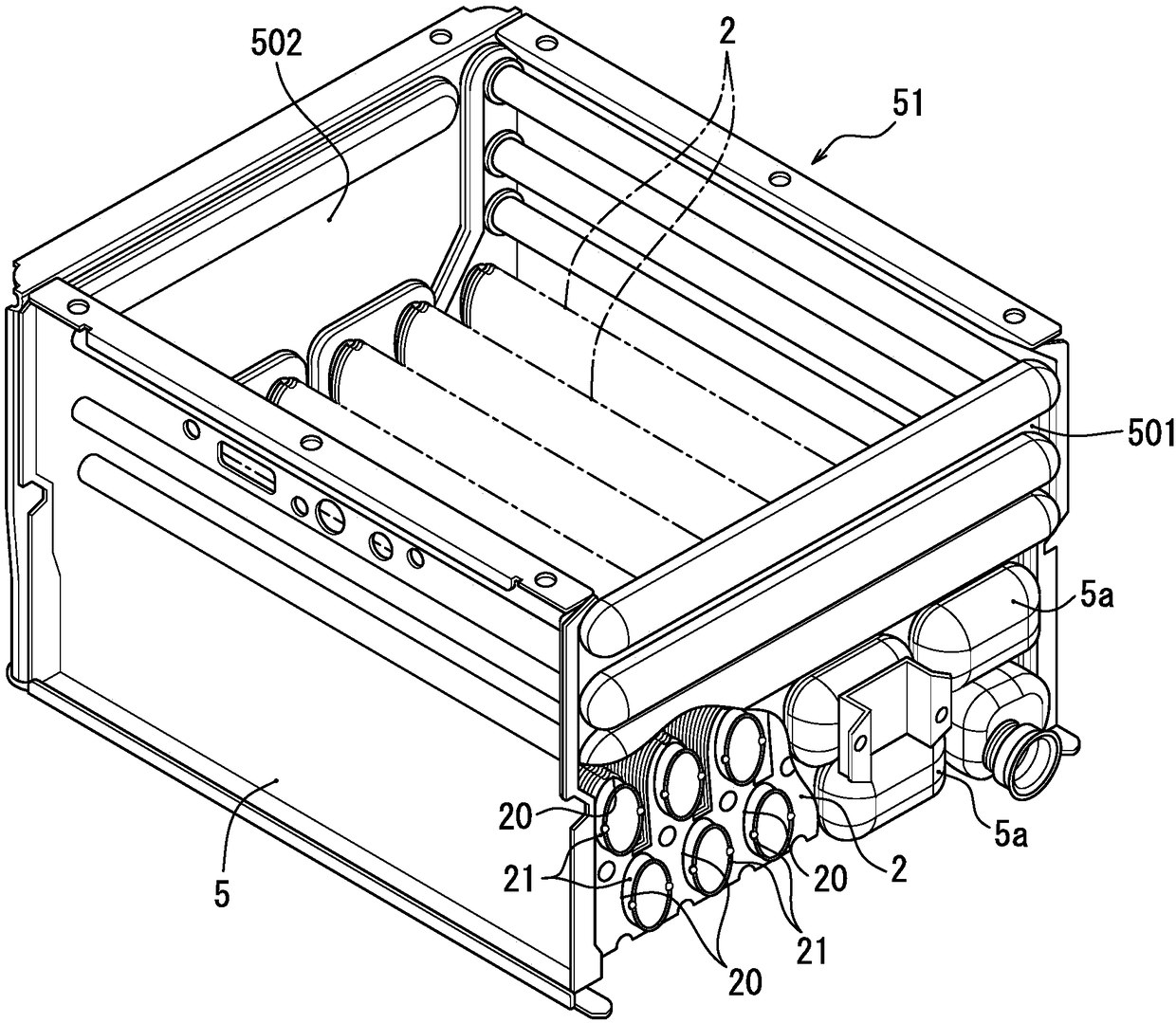

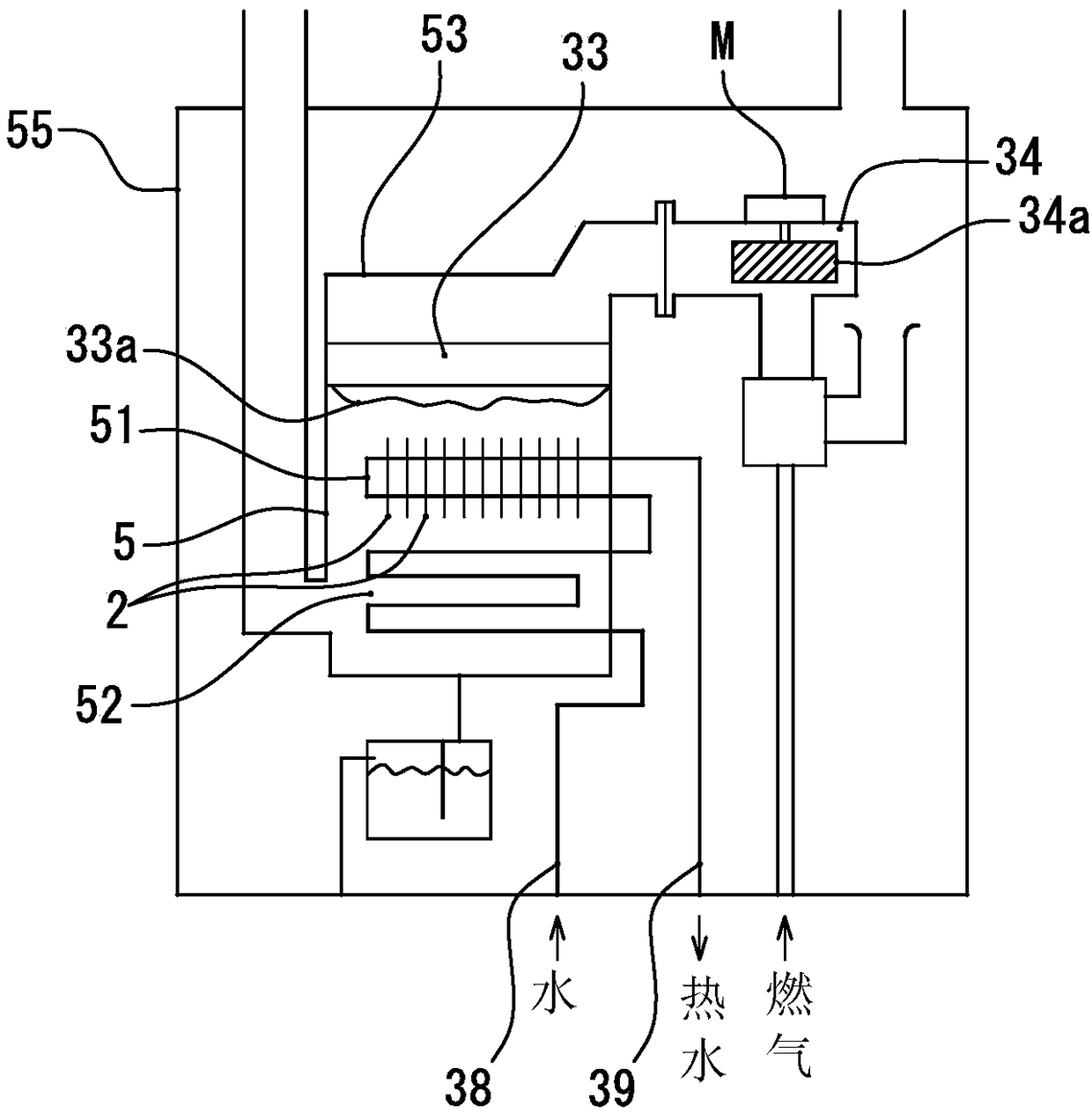

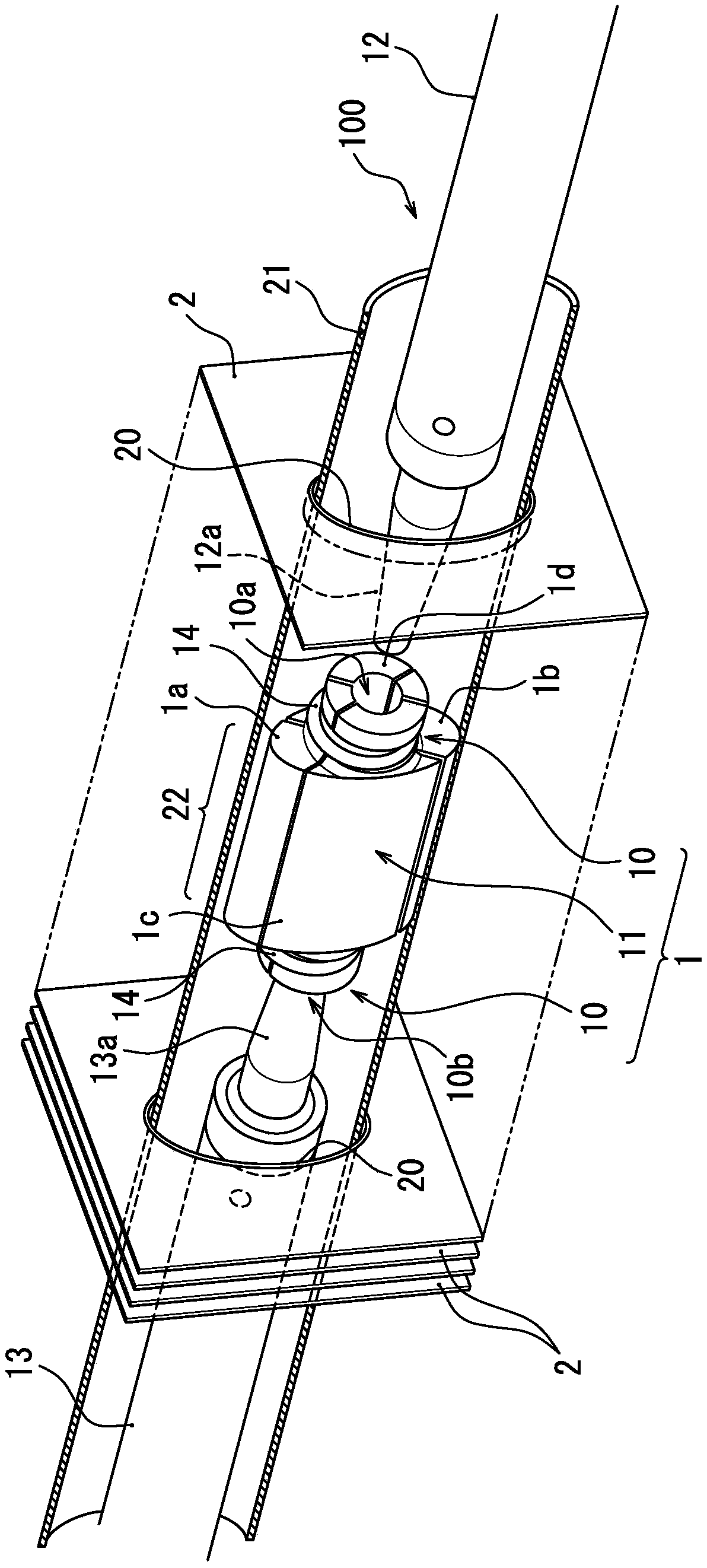

Manufacturing method of fin tube typed heat exchanger and combustion apparatus having the same

InactiveCN108981168AAchieve long lifeNo frictional heatHeat exhanger finsStationary conduit assembliesPlate heat exchangerCombustion

Provided are a method for manufacturing a fin tube type heat exchanger that may use a pipe expansion apparatus for a long time and improve productivity, and a combustion apparatus including the fin tube type heat exchanger. The method for manufacturing a fin tube type heat exchanger (51) includes: a pipe expanding process of expanding a thermoelectric pipe (21) by inserting a pipe expansion apparatus (100) into the thermoelectric pipe (21) inserted into an insertion hole (20) of a thermoelectric fin (2). The pipe expanding process includes: a first process of expanding a thermoelectric pipe (21) such that an enlarged diameter prediction range (22) to an insertion hole (20) by expanding the thermoelectric pipe (21) radially into a diameter expansion state in a state in which a pipe expansion apparatus (100) is stopped in the enlarged diameter prediction range (2) in the thermoelectric pipe (21); and a second process of moving the pipe expansion apparatus (100) to the next enlarged diameter prediction range (22) in the thermoelectric pipe (21) in an enlarged diameter state by releasing the expansion of the pipe expansion apparatus (100) in a radial direction. The first process and the second process are performed repeatedly and alternately.

Owner:RINNAI CORP

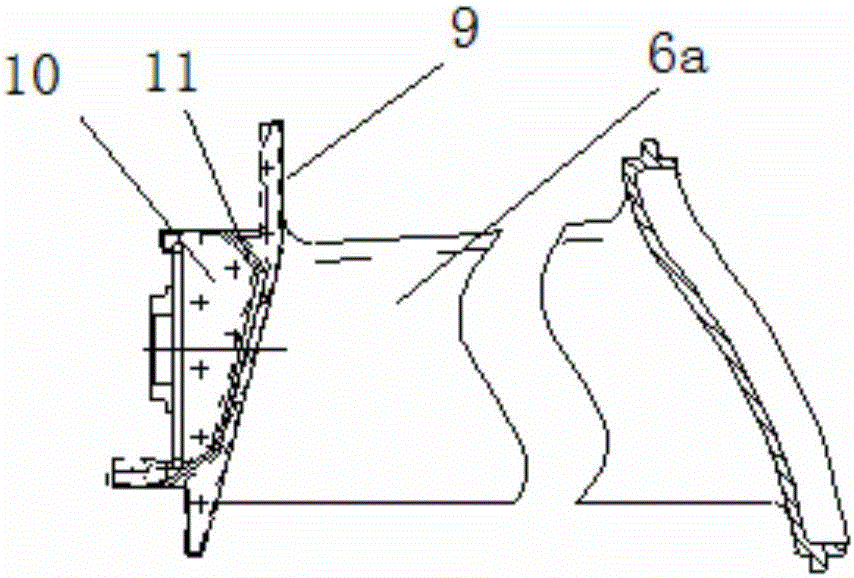

Aluminum alloy vacuum brazing method with directional magnesium vapor slow-release

ActiveCN103192151BReduce oxygen contentReduced oxidation burnSoldering apparatusSS - Stainless steelUltrasonic testing

The invention relates to an aluminum alloy vacuum brazing method with directional magnesium vapor slow-release. The method includes the specific steps: 1, placing magnesium chips into stainless steel cylinders with two ends open and open stainless steel boxes respectively by placing magnesium chips into each stainless steel cylinder and each stainless steel box; 2, placing a to-be-brazed aluminum alloy workpiece into a vacuum furnace, covering the to-be-brazed workpiece with a stainless steel process cover, placing two stainless steel boxes contained with the magnesium chips inside and outside the stainless steel cover respectively so as to decrease oxygen content in a furnace cavity and the process cover, placing more than one stainless steel cylinder nearby a brazing seam of the to-be-brazed workpiece, and enabling cylinder openings of the stainless steel cylinders to face towards the brazing seam; 3, closing a furnace door of the vacuum furnace, and heating for brazing. By the method, oxygen content in the vacuum furnace can be decreased greatly, surface oxidation and burning loss of the welded workpiece are reduced as compared with that of the prior art, brazed rate of the brazing seam is increased, and ultrasonic testing shows that cold joint area is decreased by about 20%.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com