Welding method of traction transformer copper conductive connection structure

A conductive connection structure, traction transformer technology, applied in the direction of connection, welding medium, welding equipment, etc., can solve the problems of poor conductivity and energy saving effect, poor weld quality, easy to cause air holes, etc., to achieve low production costs and improve Conductive efficiency and the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

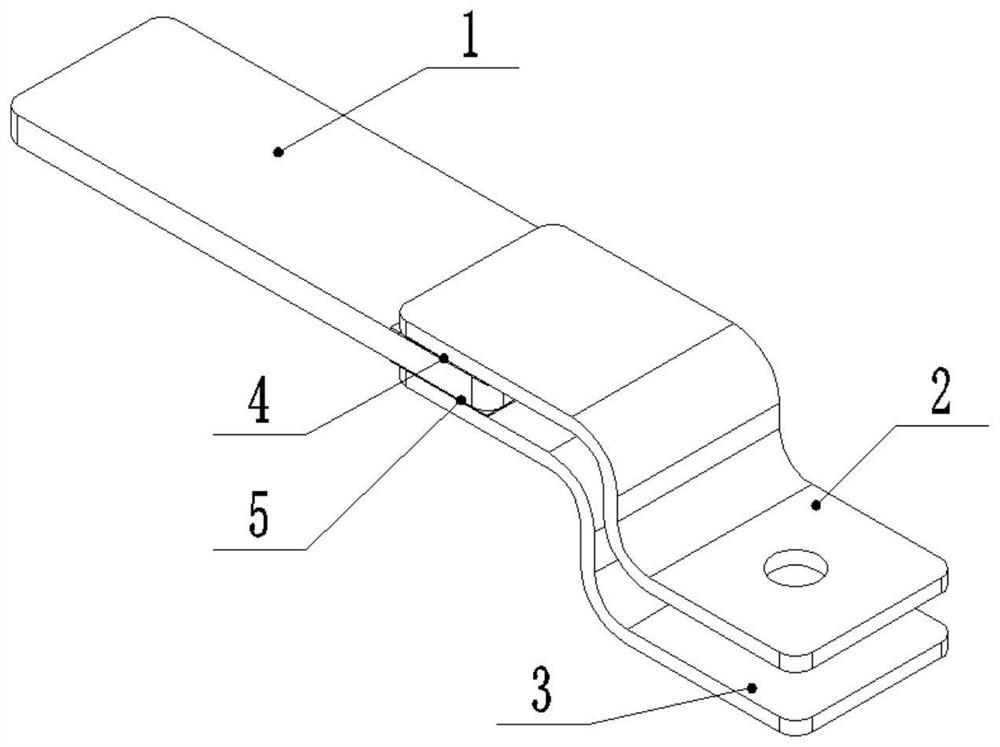

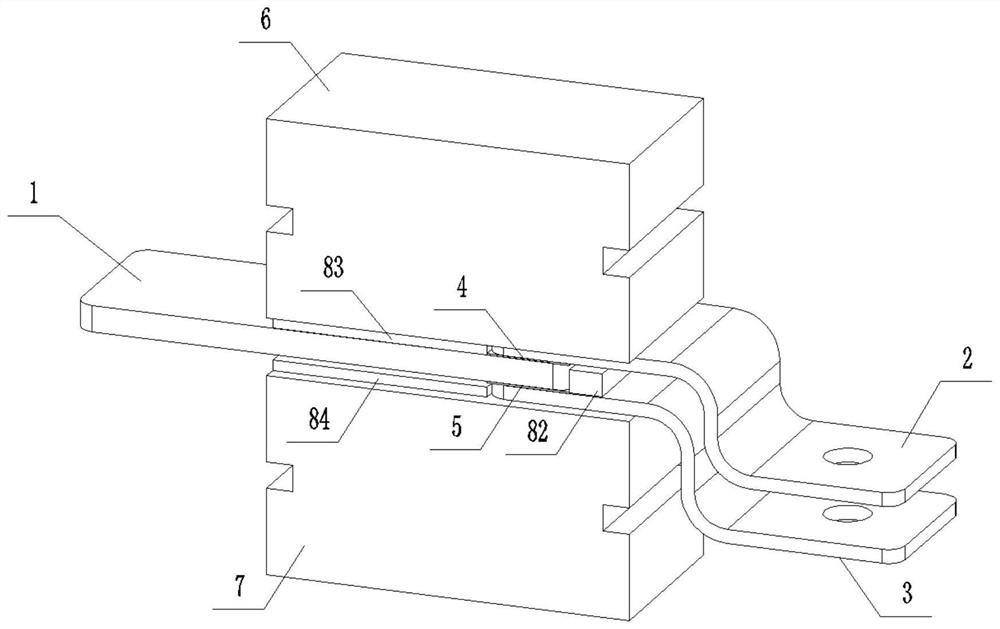

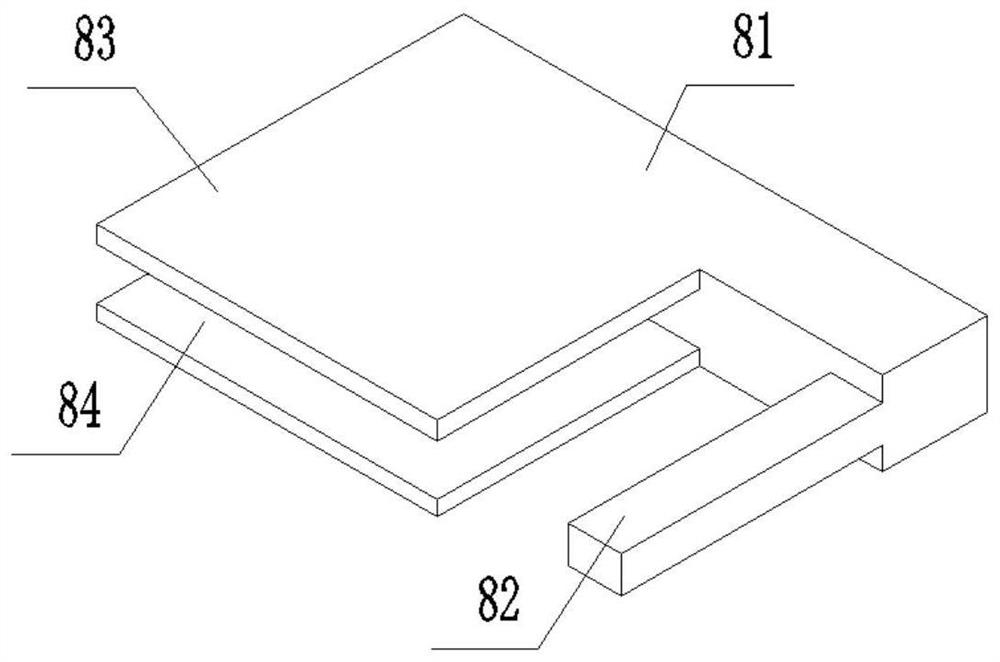

[0031] A welding method for a copper conductive connection structure of a traction transformer. The copper conductive connection structure includes a copper bar 1 and first and second copper foil flexible connectors 2 and 3. The copper bar includes copper and copper alloy rolled plates, drawn rectangular The strip, the flattened bar, the first and second copper foil flexible connectors 2 and 3 are respectively welded to the upper and lower surfaces of one end of the copper bar 1, and the upper and lower surfaces of the other end of the copper bar 1 are provided with graphite electrodes. The two copper foil flexible connectors 2, 3 are connected to the copper bar 1 through the first and second soldering pieces 4, 5 respectively, the first and second copper foil flexible connectors 2, 3 are made of multi-layer copper strips through high Molecular diffusion welding, no solder filling during welding;

[0032] The welding method of the copper conductive connection structure of the ...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, the difference lies in that the pressure range in step S4 is different.

[0041] S4 Fixing the joint: start the power device of the resistance brazing equipment in step S2, press the upper graphite electrode on the welding joint, and ensure that the welding joint is fixed, and the pressure is 10 MPa.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, except that the pressure applied in step S4 is different.

[0044] S4 Fixing the joint: start the power device of the resistance brazing equipment in step S2, press the upper graphite electrode on the welding joint, and ensure that the welding joint is fixed, and the pressure is 20 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com