Single-shuttle multi-needle overlocking apparatus

An edge banding device and sewing technology, which are applied to sewing equipment, sewing machine components, needle holders for sewing machines, etc., can solve the problems of easy discharge failure, complicated transmission structure of overlock sewing machines, and inability to complete equipment assembly and maintenance, and prevent the opening of the sewing machine. Line, reduce manufacturing production and maintenance costs, reduce the effect of processing and assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

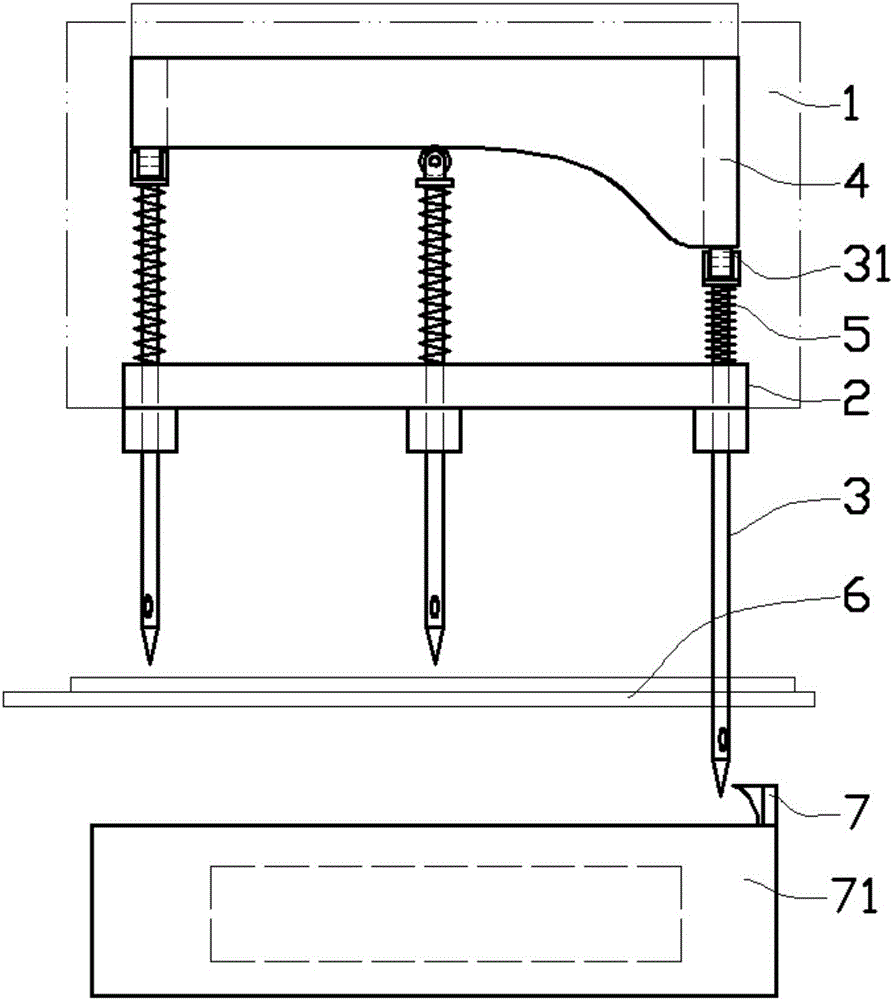

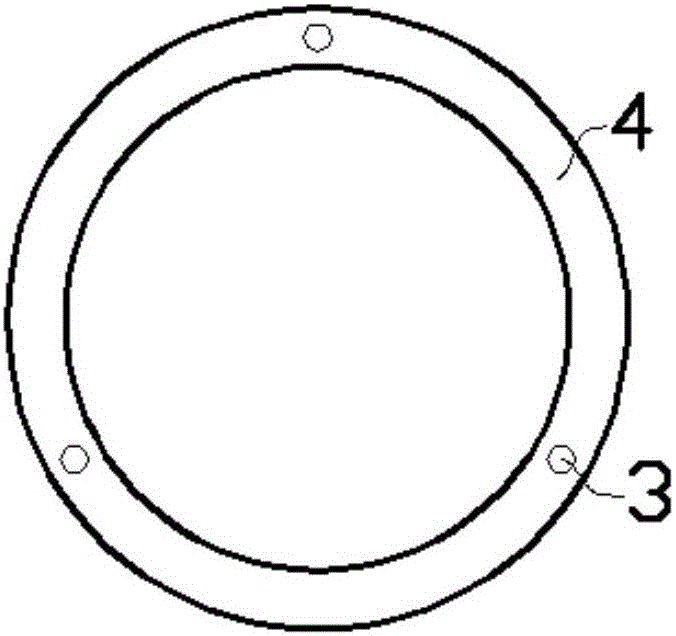

[0013] Such as figure 1 As shown in the embodiment, the one-shuttle multi-needle sewing edge banding device includes a machine head 1, the lower part of the machine head 1 is horizontally fixed with a ring-shaped fixed block 2, and the ring-shaped edge of the fixed block 2 is equipped with More than two sewing needles 3 that can slide up and down vertically, the upper part of the fixed block 2 is equipped with a ring-shaped cam 4, the cam 4 is coaxially assembled with the assembly block, and the upper part of the fixed block 2 is assembled There is a spring 5 set on the outside of the sewing needle, the upper end of the sewing needle 3 is pressed against the lower part of the cam 4 through the spring 5, and the cam 4 is driven to rotate by the transmission structure; The lower part is designed with a horizontal sewing table, which is equipped with a needle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com