Ultrasonic-assisted high-frequency induction brazing device for electric contact system

A high-frequency induction brazing and ultrasonic technology, used in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems of short resistance brazing time, discount on the performance and life of electrical contacts, and uneven thickness of the brazing seam. Improve the brazing rate, welding strength and life, high-quality automatic brazing, and the effect of taking into account the quality of brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

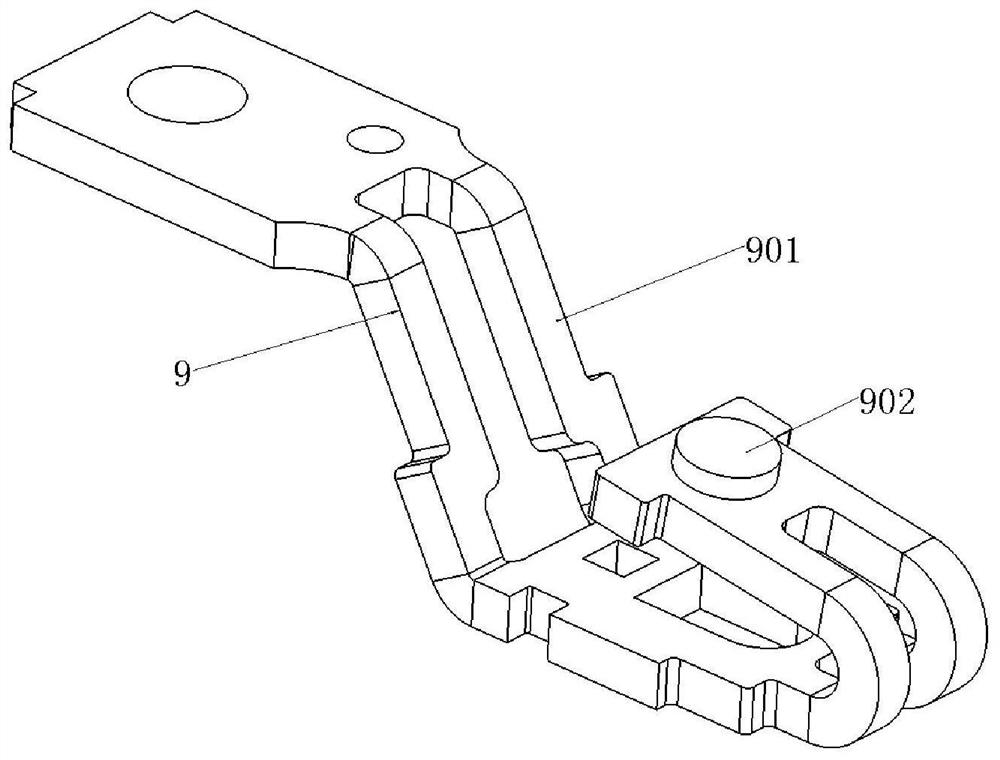

[0039] The electric contact workpiece 9 that the present invention aims at is as figure 1 As shown, it is composed of a special-shaped contact bridge 901 and a contact 902. The present invention effectively improves the electrical contact through automatic devices such as loading and unloading, assembly, testing, and ultrasonic-assisted high-frequency induction brazing, combined with an optimized welding process. The speed of system welding, the brazing rate and shear tensile strength of welded joints.

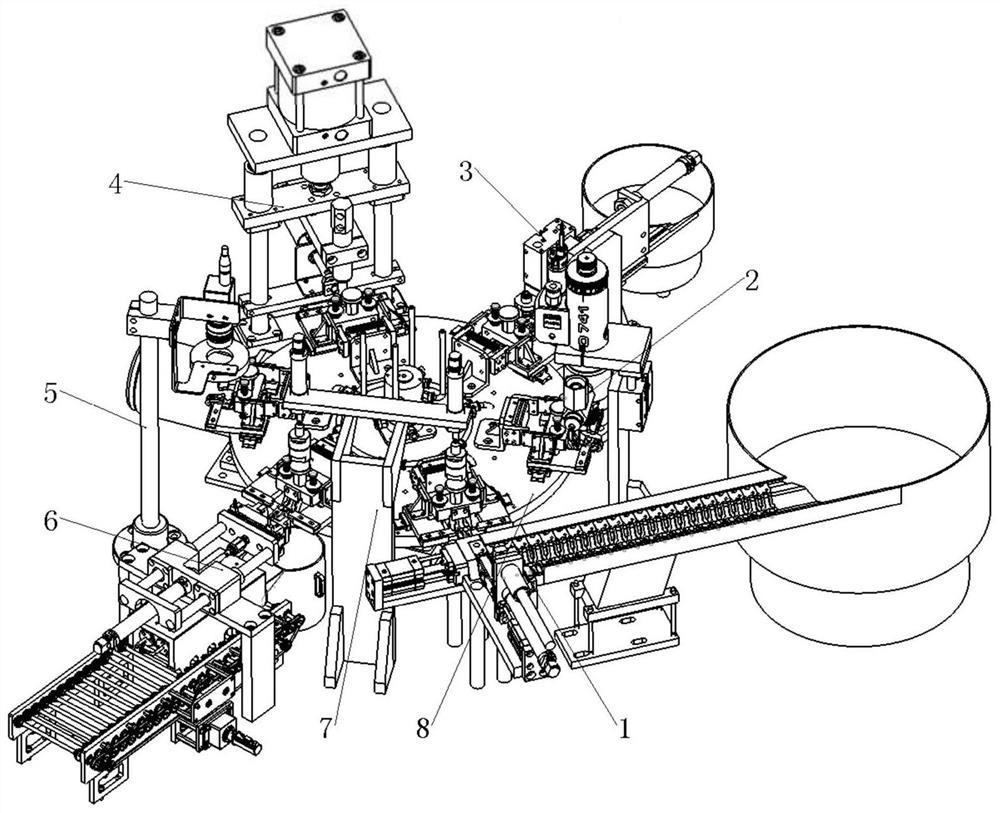

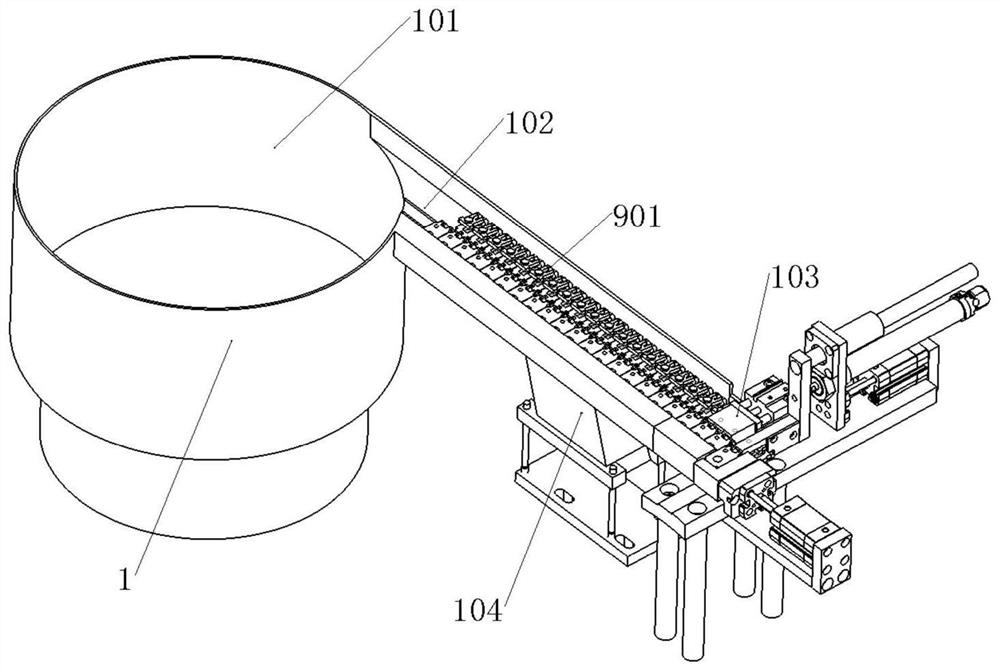

[0040] Such as Figure 2-14 As shown, the present invention provides an ultrasonic-assisted high-frequency induction brazing device for an electric contact system, the main body of which is driven by a six-degree cam divider, and six assembly processing stations are sequentially arranged on the periphery of the cam divider workbench....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com