Dip brazing method with a preset temperature gradient

A technology of dip brazing and preset temperature, applied in the field of brazing furnaces, can solve the problems of unstable product quality, increased energy consumption and environmental pollution, poor brazing seam density, etc., to ensure quality and stability, eliminate Stomatal defects, the effect of meeting the requirements of brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

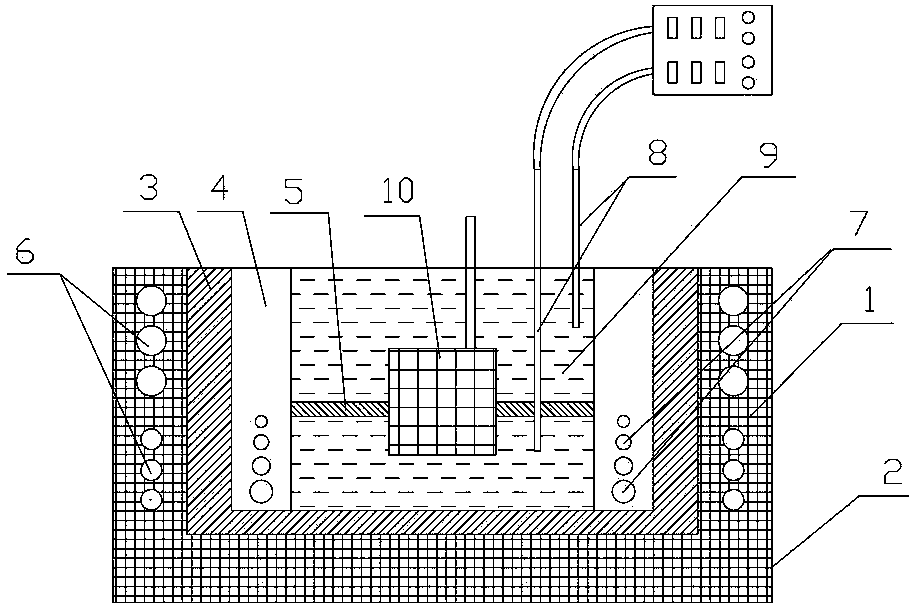

[0017] The dip brazing method of the preset temperature gradient of the present invention comprises the following steps:

[0018] In the first step, according to the volume of the workpiece to be brazed, choose to place at least one layer of annular partitions horizontally in the inner cavity of the brazing furnace, so that the inner cavity of the brazing furnace forms at least two relatively independent spaces. If the size is large, the ring-shaped partition can be placed in multiple layers, and the middle aperture of the ring-shaped partition should be able to put the brazing workpiece;

[0019] In the second step, according to the process requirements, use heating bodies with different powers (the heating body can be an induction heating body or an electrode heating body) to heat the upper and lower parts of the brazing furnace separately, so that the molten solder or molten salt in the furnace The spatial distribution divided by the annular partition forms a temperature gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com