Multifunctional sprue spreader system for solving positioning and exhausting of sand core

A shunt cone, multi-functional technology, applied in the direction of core, mold composition, casting and molding equipment, etc., can solve the problems of difficult sand core exhaust, low production qualification rate of motorcycle wheels, large deviation of product wall thickness, etc. Solve product size deviation and air hole problems, eliminate wheel hub air hole defects, and eliminate the effect of large size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with example the present invention will be further described.

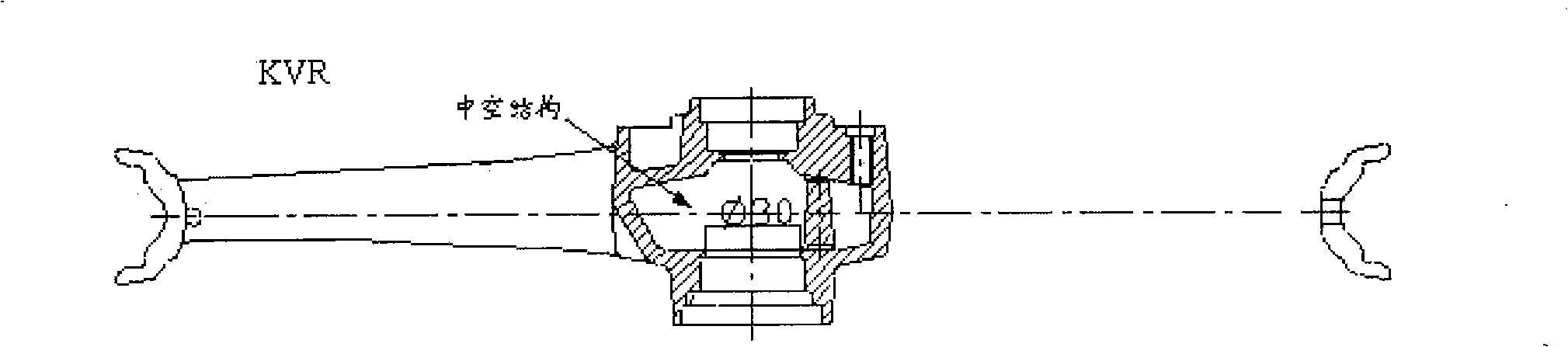

[0023] KVR wheel products have a hollow structure due to the middle hub, such as image 3 Shown, the assembly sketch map of product mold and splitter cone and sand core in the prior art is as Figure 4 shown.

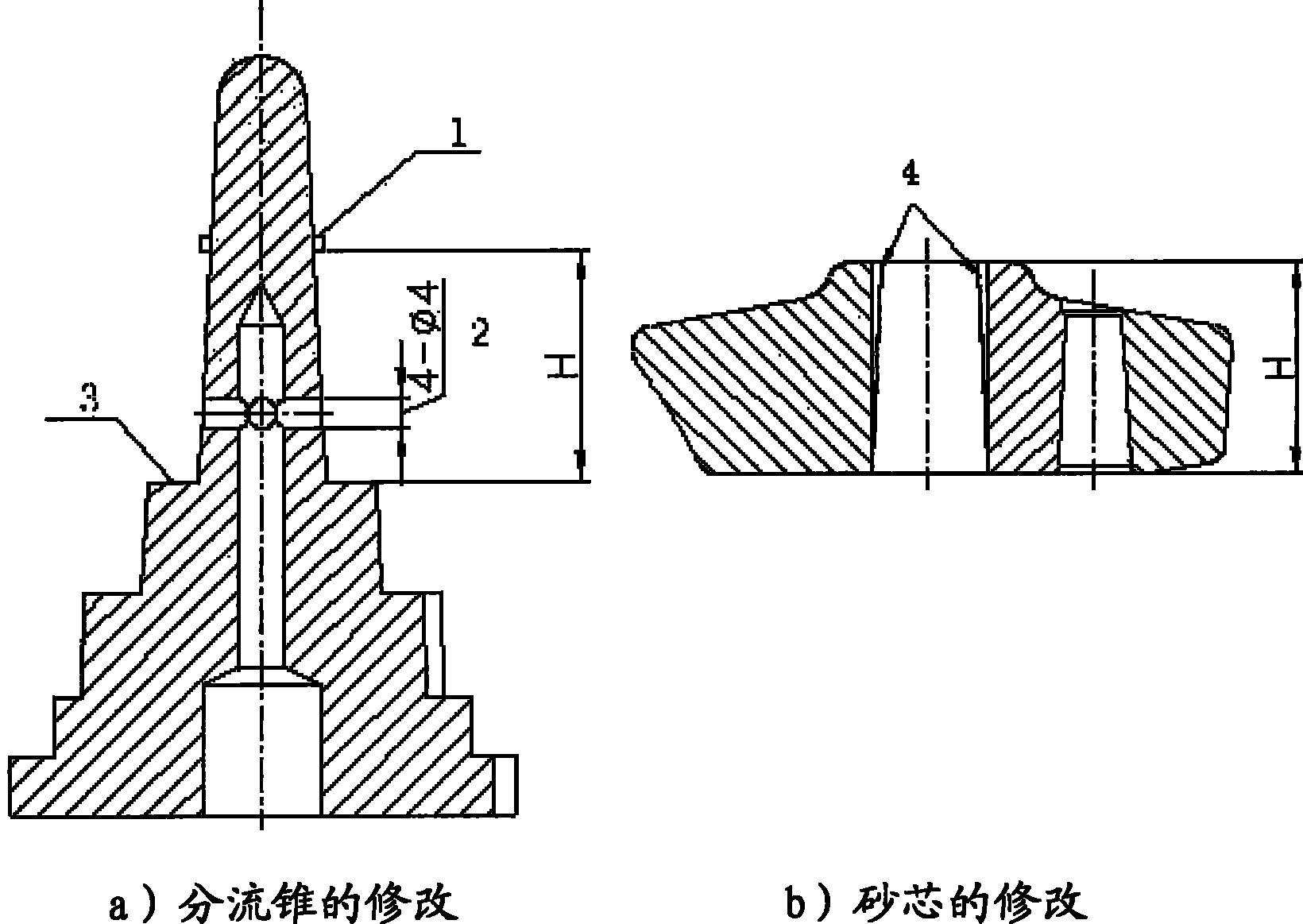

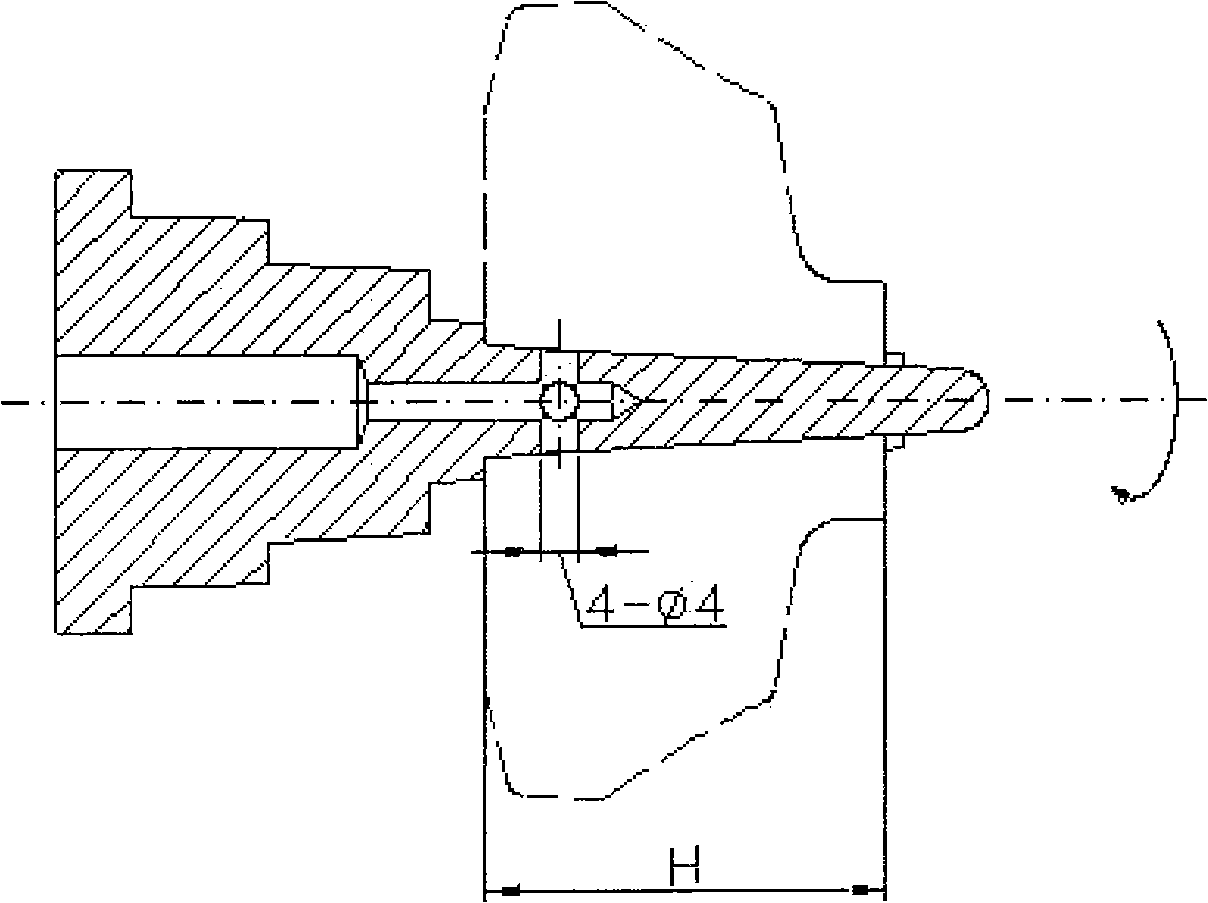

[0024] The hollow structure of the middle hub of the wheel should be molded with a sand core, but because the diameter of the end surface of the through hole of the lower bearing is φ30mm, the contact surface between the sand core and the splitter cone is too small, and there is not a large enough positioning surface (such as Figure 4 The middle red mark indicates the assembly drawing of the diverter cone and the sand core), and the inaccurate positioning of the sand core leads to a large deviation in the wall thickness of the product. In addition, the material of the wheel casting is A356.2, and the density is 2.63g / cm 3 Left and right, the density is higher than that of the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com