Brazing method for capillary tube and joint

A brazing method and capillary technology, applied to welding equipment, electric heating devices, auxiliary devices, etc., can solve the problems of insufficient solder distribution and penetration, increased solder viscosity, poor fluidity, etc., to reduce corrosion and improve The effect of brazing rate and reducing welding plugging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

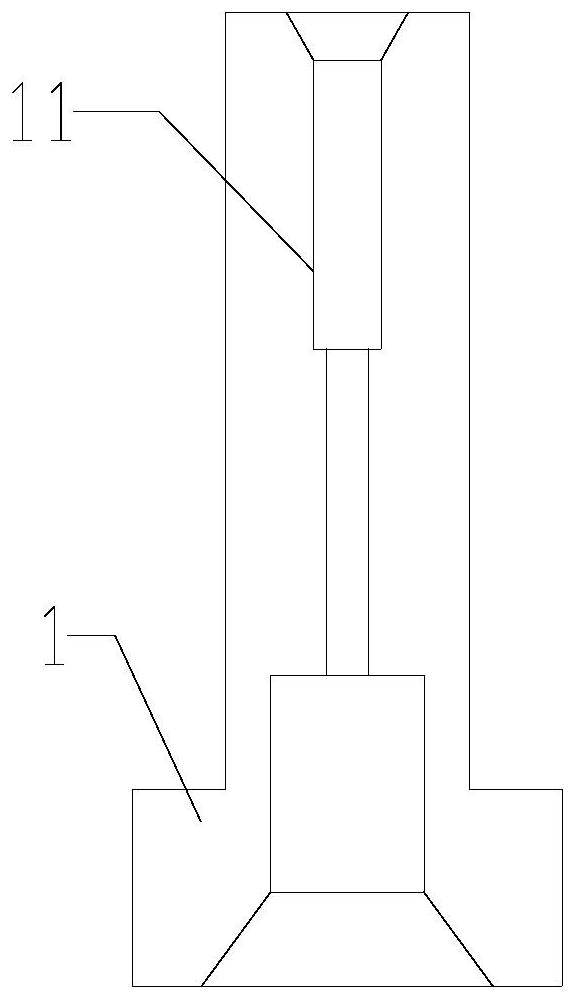

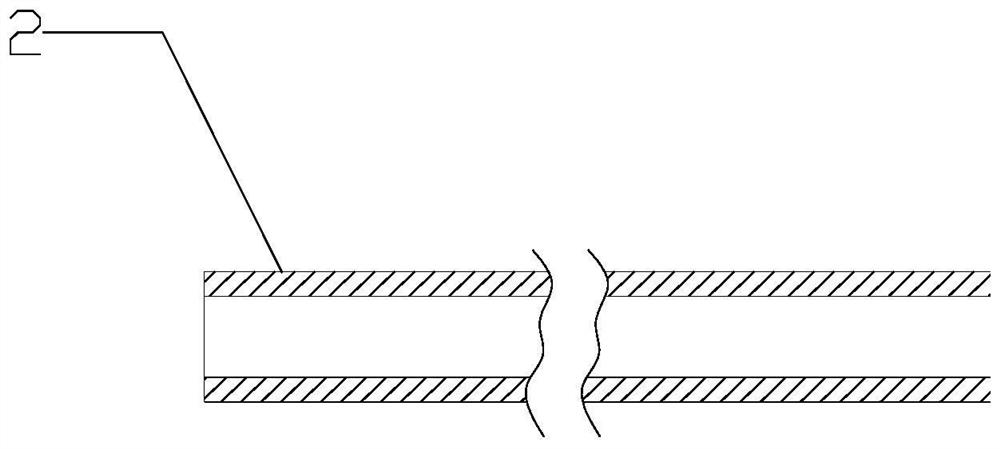

[0030] A capillary joint brazing method, comprising the following steps: S1, assembling the capillary 2 with the joint 1;

[0031] S2, adding solder 4 to the connection plane between the capillary 2 and the joint 1;

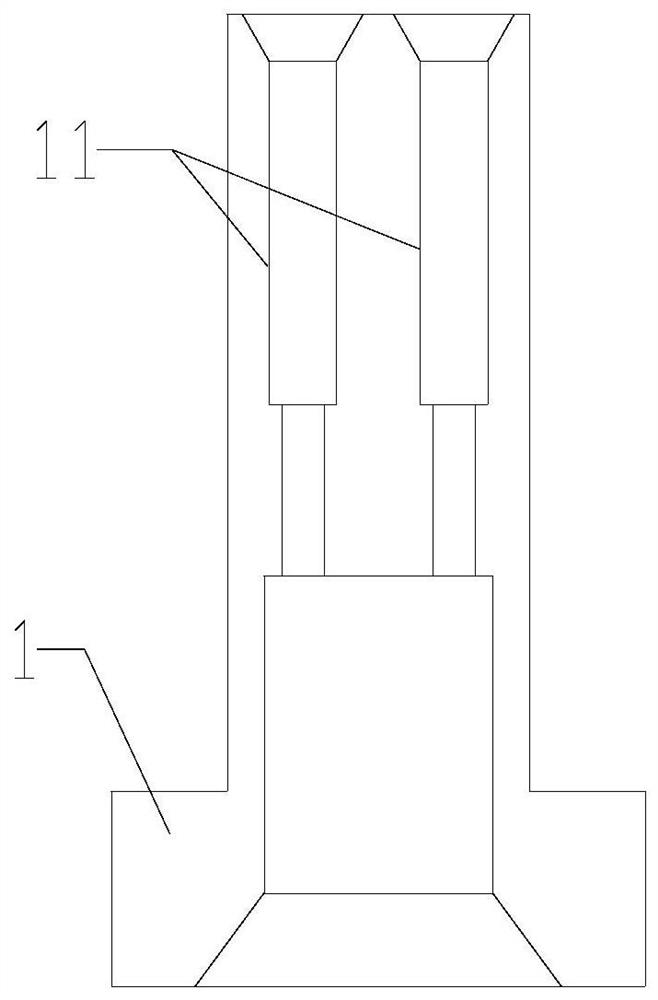

[0032] S3, set the heating coil 3 around the soldering foot for heating to complete the brazing. The heating coil 3 is a two-layer circular coil, the first layer coil 31 is a coil, and the second layer coil 32 is a three-turn coplanar coil ; The first layer of coil 31 is sleeved on the side of the capillary, and the second layer of coil 32 is sleeved on the side of the brazing joint.

[0033] The main heating part of the first-layer coil 31 is the capillary 2 , and the main heating part of the second-layer coil 32 is the welding joint. The circular coil structure can realize uniform heating along the circumference of the capillary 2 .

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that: the material of capillary 2 is 1Cr18Ni9Ti, the material of joint 1 is 1Cr18Ni9Ti, and the solder 4 is L303 silver solder welding ring.

Embodiment 3

[0037] The difference between this embodiment and Embodiment 2 is that the outer diameter of the capillary 2 is 0.9 mm, the wall thickness is 0.17 mm, the diameter of the capillary hole 11 of the joint is 1 mm, the brazing depth of a single capillary and the joint 1 is 5 mm, multiple capillary The brazing depth with joint 1 is 6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com