Contactor binding post assembly and brazing connecting method

A connection method and terminal post technology, which is applied in the direction of welding/welding connection, connection, conductive connection, etc., can solve the problems of reducing the brazing rate of brazing seams, product corrosion, and incomplete removal, etc., to improve performance and reliability, Improve the rate of brazing and improve the effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is further described below, but the scope of protection is not limited to the above.

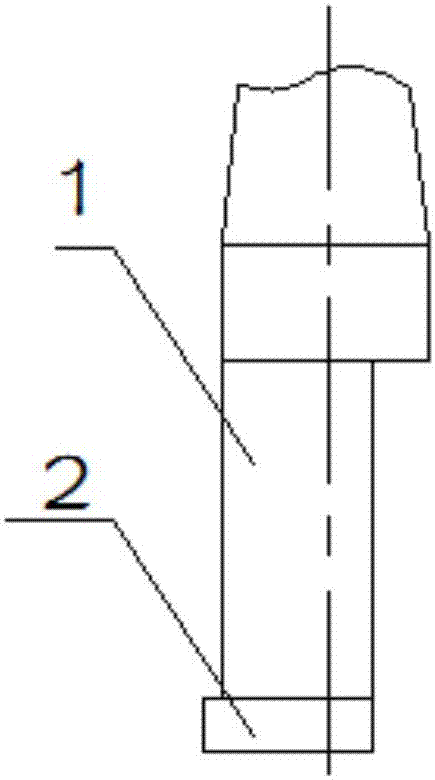

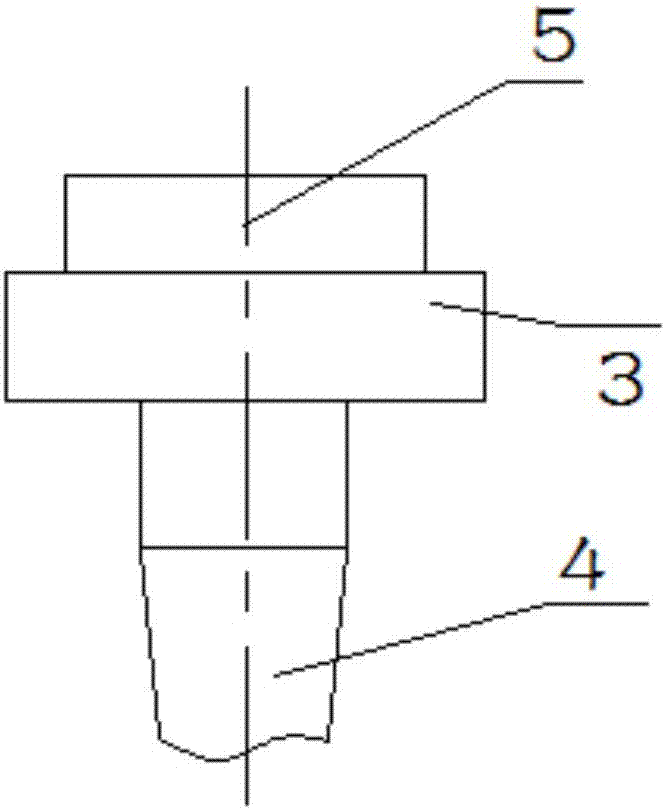

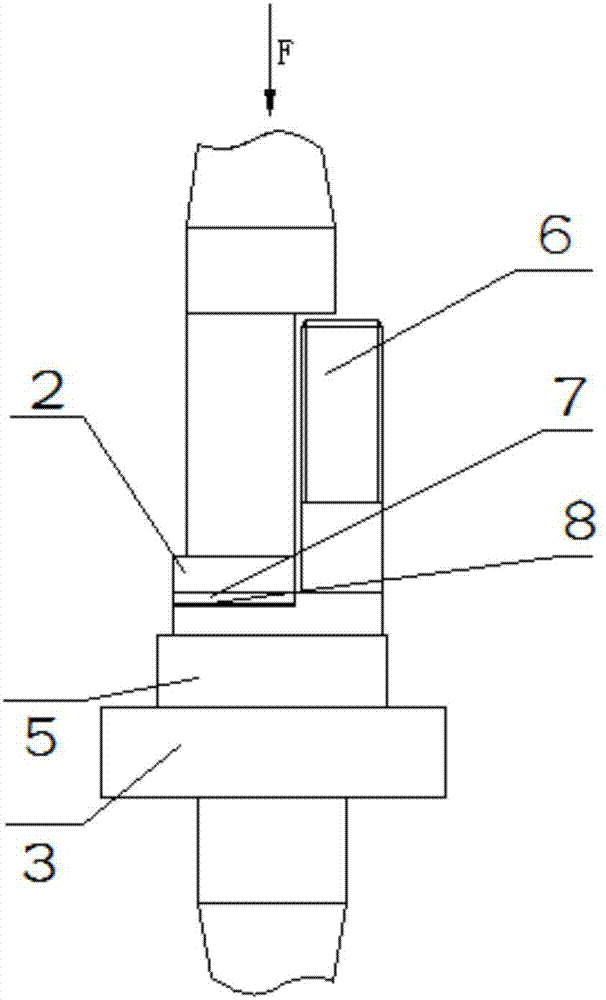

[0028] Such as figure 1 with figure 2 As shown, a contactor terminal assembly includes an upper electrode, a terminal and a lower electrode; the upper end of the terminal is connected to the upper electrode, and the lower end of the terminal is connected to the lower electrode; the upper electrode includes an upper electrode arm 1 and an upper electrode The electrical head 2, the upper electrical head 2 is arranged under the upper electrode arm 1; the lower electrode includes a lower electrode head 3, a lower electrode arm 4 and a resistance heat source 5. The upper end of the lower electrode head 3 is connected to the resistance heat source 5, and the lower end Connect the lower electrode arm 4; the upper electrode head 2 of the upper electrode is connected to the terminal through the contact 7 and the solder 8; the lower electrode tip 3 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com