Machining method of injector partition plate cavity

A processing method and injector technology, applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems such as low yield, inability to process, and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in combination with specific embodiments.

[0066] A method for processing an injector partition cavity, comprising the following steps:

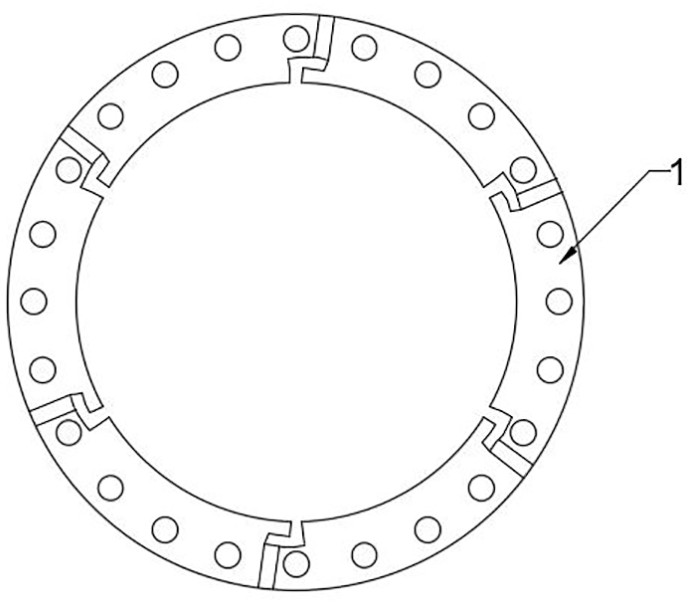

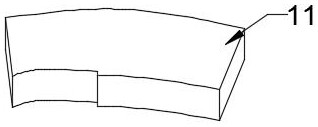

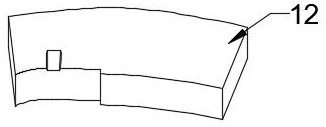

[0067] A1. If figure 1 As shown, the annular body 1 is roughly machined with 06Cr19Ni10 material, a number of reference holes are evenly rough drilled on the annular surface, and six water inlet holes are uniformly bored and milled around its circumference; 1 Cut out six fan-shaped grooves and six wedge-shaped vertical grooves on the inner circumference, and process them to form a stop at the notch; use 06Cr19Ni10 material to process and match the fan-shaped grooves, such as figure 2 The six upper cover plates 11 shown and as image 3 The six lower cover plates 12 shown are processed with 06Cr19Ni10 material to match the wedge-shaped vertical groove as Figure 4 The six wedge-shaped inserts 13 are shown; interfaces matching the six wedge-shaped inserts 13 are processed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com