Induction brazing device and method thereof

A technology of induction brazing and induction power supply, which is used in electric heating devices, welding equipment, metal processing equipment, etc., can solve the problem that the reaction between the solder and the oxide film is not uniform and sufficient, the temperature distribution of the joint is not uniform, and the heating temperature is difficult to accurately control, etc. problems, to ensure uniform spreading, improve welding efficiency, and reduce welding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

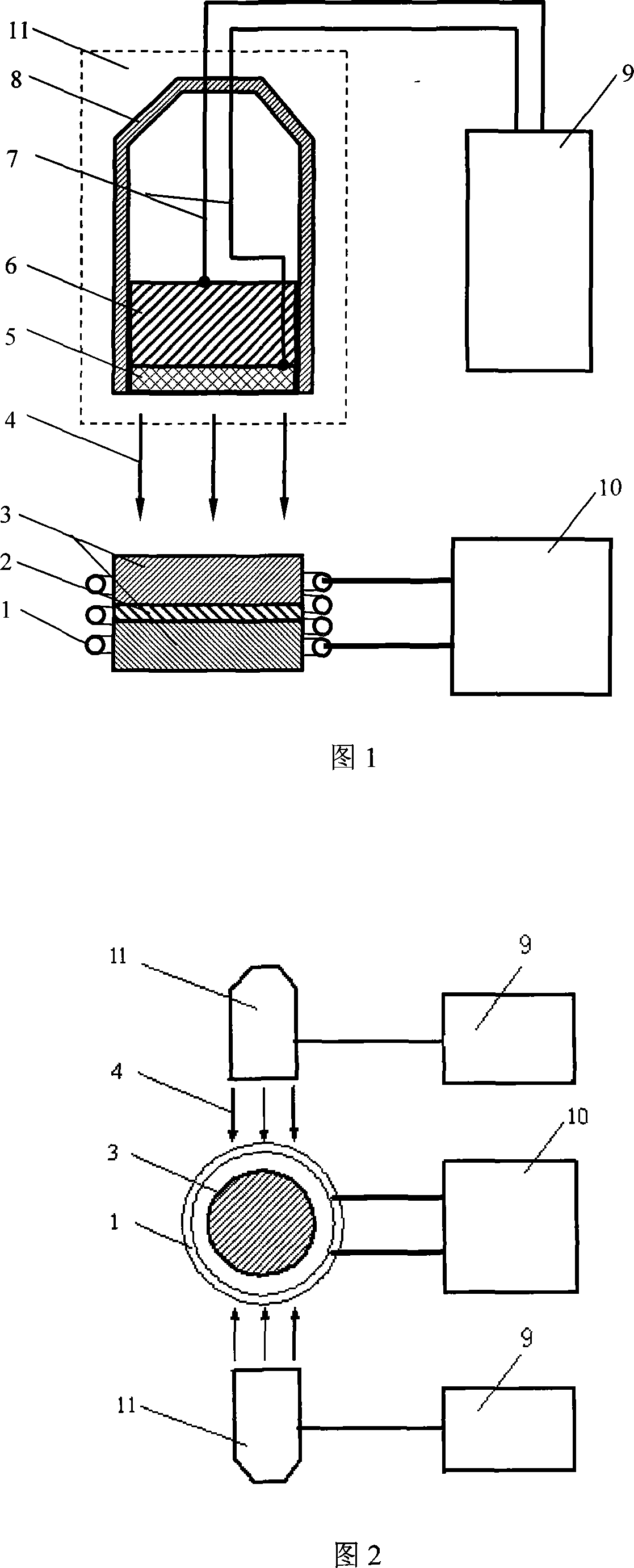

[0016] Embodiment 1: Referring to Fig. 1, it is butt brazing of two short cylindrical solid low-carbon steel weldments 3 with a thickness of Φ32 and a thickness of 8 mm, and the brazing filler metal is copper-based brazing filler metal. Place an air ultrasonic probe 11 directly above the welding section, the distance between the probe surface and the upper surface of the weldment 3 is 150 mm, the probe diameter is Φ30, the center frequency is 0.1 MHz, and the amplitude of the oscillation voltage output by the high frequency oscillator 9 is is 850V.

[0017] The welding is heated by an intermediate frequency induction power supply, and the air ultrasonic probe 11 is connected to the high frequency oscillator 9, the induction coil 1 and the intermediate frequency induction power supply 10 at the same time. After welding, the high frequency oscillator 9 and the intermediate frequency induction power supply 10 are disconnected at the same time.

[0018] After testing, welding part...

Embodiment 2

[0019] Embodiment 2: Referring to Fig. 2, it is butt brazing of two Φ25 long cylindrical solid low-carbon steel weldments 3 with a length of 150 mm, and the brazing filler metal is copper-based brazing filler metal. Place two air ultrasonic probes 11 symmetrically on the side of the welding section, the distance between the probe surface and the side of the weldment 3 is 110 mm, the probe diameter is Φ20, the center frequency is 0.1 MHz, and the amplitude of the oscillation voltage output by the high frequency oscillator 9 is 800V.

[0020] Welding is heated by an intermediate frequency induction power supply. The two air ultrasonic probes 11 are connected to their respective high frequency oscillators, induction coils 1 and intermediate frequency induction power supply 10 at the same time. After welding is completed, the high frequency oscillator and intermediate frequency induction power supply are disconnected at the same time. 10.

[0021] After testing, welding parts wit...

Embodiment 3

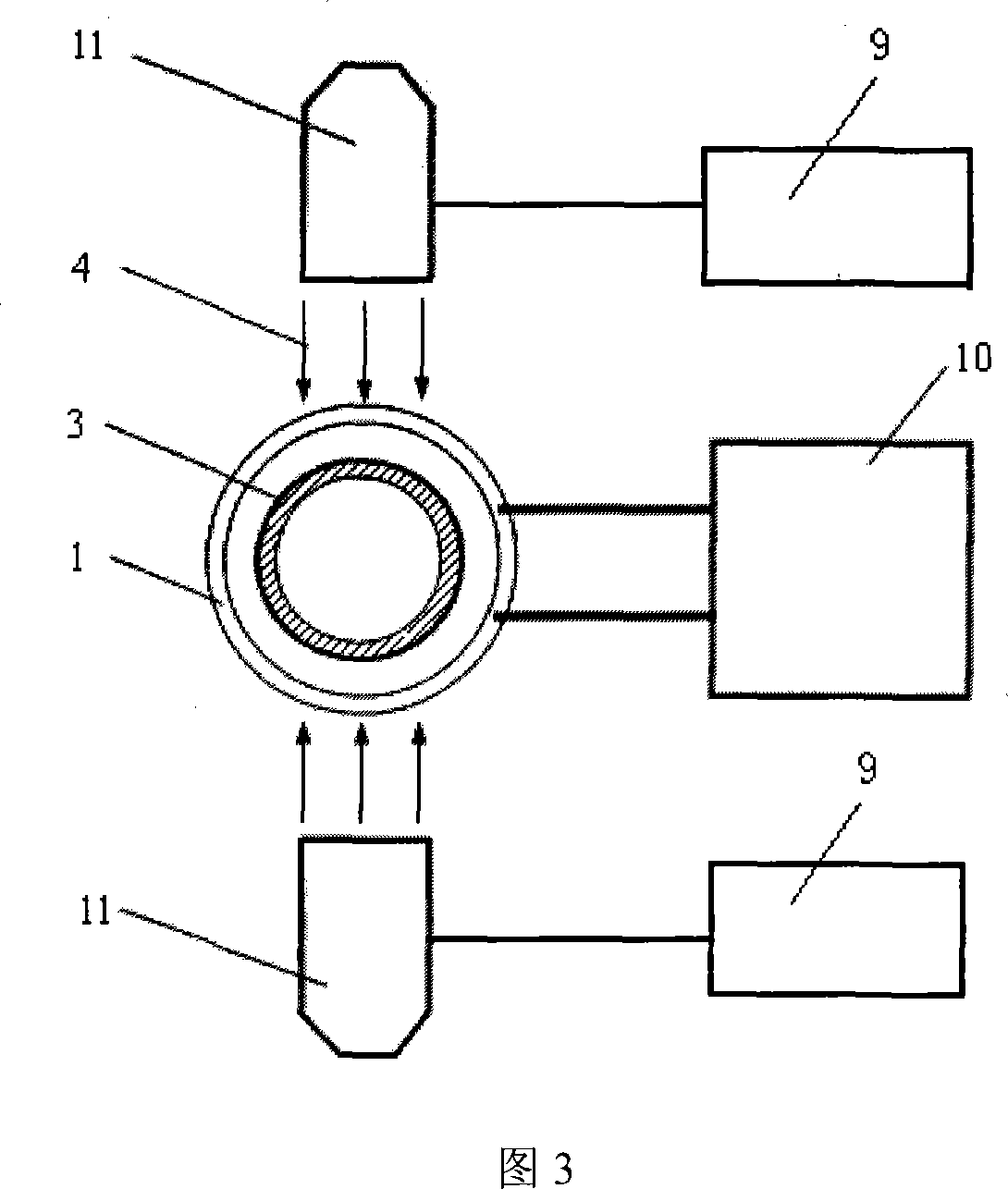

[0022] Embodiment 3: Referring to Fig. 3, it is the butt brazing of two tubular low-carbon steel weldments 3 with an outer diameter of Φ25mm, a wall thickness of 3mm, and a length of 150mm, and the brazing filler metal is copper-based brazing filler metal. Place two air ultrasonic probes 11 symmetrically on the side of the welding section, the distance between the probe surface and the side of the weldment 3 is 100 mm, the probe diameter is Φ20, the center frequency is 0.1 MHz, and the amplitude of the oscillation voltage output by the high frequency oscillator 9 is 850V.

[0023] Welding is heated by high-frequency induction power supply, and the two air ultrasonic probes 11 are connected to their respective high-frequency oscillators, induction coil 1 and high-frequency induction power supply 10 at the same time. After welding is completed, the high-frequency oscillator and high-frequency Frequency induction power supply 10.

[0024] After testing, welding parts with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com