Novel flux-cored silver solder

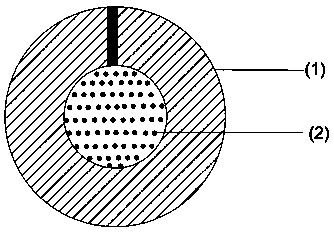

A technology of silver solder and flux core, applied in welding/cutting medium/material, welding medium, metal processing equipment, etc., can solve problems such as poor spreading, fracture of flux-cored silver solder, broken wire, etc., and achieve excellent flow properties and moisture absorption resistance, improve market competitiveness, and improve the effect of moisture absorption resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A novel flux-cored silver solder is prepared from the BAg18CuZnSn silver solder tape-coated flux powder given in claim 1. Among them, 17.0% Ag, 44.0% Cu, 2.0% Sn, and the balance is Zn.

[0027] The mass percent ratio of the coated flux powder is as follows: Potassium hydrogen fluoride (KHF 2 ) is 30%, potassium fluoride is 20%, boric acid is 33%, cesium carbonate is 0.1%, potassium carbonate is 2.0%, potassium silicate is 0.5%, sodium silicate is 0.5%, dipotassium hydrogen phosphate is 0.001% , the balance is potassium tetrafluoroborate (KBF 4 ). Wherein, the addition ratio of potassium silicate and sodium silicate is potassium silicate: sodium silicate = 1:1. The mass percentage of flux powder accounts for 18% of the whole flux-cored silver solder.

[0028] Using 4mm wide and 0.5mm thick BAg18CuZnSn silver solder strips, prepare flux cored silver solder wires with a wire diameter of 2.3mm on the flux cored wire preparation equipment, and then draw them sequentiall...

Embodiment 2

[0031] A novel flux-cored silver solder is prepared from the BAg18CuZnSn silver solder tape-coated flux powder given in claim 1. Among them, 19.0% Ag, 39.0% Cu, 2.5% Sn, and the balance is Zn.

[0032] The mass percent ratio of the coated flux powder is as follows: Potassium hydrogen fluoride (KHF 2 ) is 35%, potassium fluoride is 25%, boric acid is 30%, cesium carbonate is 0.5%, potassium carbonate is 3.0%, potassium silicate is 1.5%, sodium silicate is 1.5%, dipotassium hydrogen phosphate is 0.01% , the balance is potassium tetrafluoroborate (KBF 4 ). Wherein, the addition ratio of potassium silicate and sodium silicate is potassium silicate: sodium silicate = 1:1. The mass percentage of flux powder accounts for 28% of the whole flux-cored silver solder.

[0033] Using 8mm wide and 0.2mm thick BAg18CuZnSn silver solder strips, prepare flux cored silver solder wires with a wire diameter of 2.3mm on the flux cored wire preparation equipment, and then draw them sequentially...

Embodiment 3

[0036] A novel flux-cored silver solder is prepared from the BAg18CuZnSn silver solder tape-coated flux powder given in claim 1. Among them, 18.0% Ag, 41.0% Cu, 2.2% Sn, and the balance is Zn.

[0037] The mass percent ratio of the coated flux powder is as follows: Potassium hydrogen fluoride (KHF 2 ) is 32%, potassium fluoride is 22%, boric acid is 31%, cesium carbonate is 0.2%, potassium carbonate is 2.5%, potassium silicate is 1.0%, sodium silicate is 1.0%, dipotassium hydrogen phosphate is 0.005% , the balance is potassium tetrafluoroborate (KBF 4 ). Wherein, the addition ratio of potassium silicate and sodium silicate is potassium silicate: sodium silicate = 1:1. The mass percentage of flux powder accounts for 22% of the whole flux-cored silver solder.

[0038] Use 6mm wide and 0.4mm thick BAg18CuZnSn silver brazing material strips, prepare flux cored silver brazing material wires with a wire diameter of 2.3mm on the flux cored wire preparation equipment, and then dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com