Thick metal plate large-area butt joint braze welding method

A brazing method and metal plate technology, applied in metal processing, metal processing equipment, welding equipment, etc., can solve the problems of poor solder filling, difficult gas discharge, low brazing rate, etc., and achieve high brazing rate and heating time. Short, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

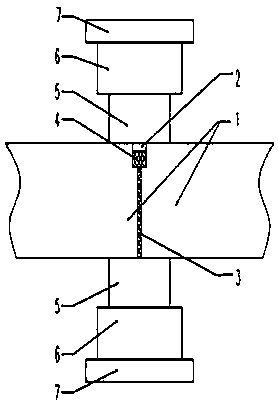

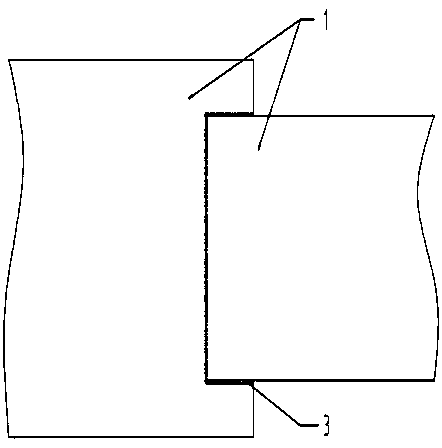

[0022] The two thick metal plates 1 are made of T2 copper, and the selected foil-shaped brazing material 3 and the preset brazing material 4 in the U-shaped groove 2 are BAg45CuZn, and the brazing joint surface of the two T2 copper plates 1 is a U-shaped surface. to combine figure 1 and image 3 Note that the method described in this embodiment is implemented by the following steps.

[0023] In the first step, the thickness of the two pieces of T2 copper plate 1 is processed to 38mm. The width of the T2 copper plate with a U-shaped surface is 140mm, and the width of the T2 copper plate inserted into the U-shaped groove is 99.7mm. The welding surface and the upper surface of the two pieces of copper plate 1 A U-shaped groove 2 with a width of 4 mm and a height of 3 mm is processed at the joint.

[0024] The second step is to place 0.15mm thick foil-like BAg45CuZn brazing material 3 in the gap between the 1U-shaped contact surfaces of the two T2 copper plates, and use a clamp ...

Embodiment 2

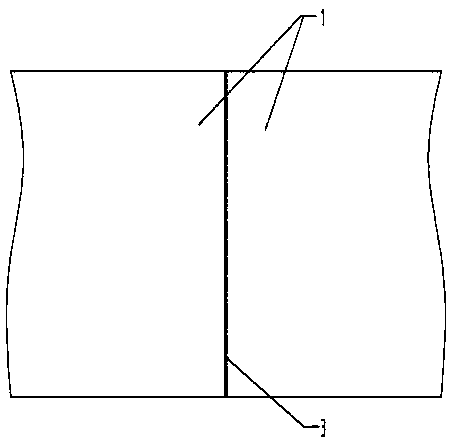

[0029] One of the two thick metal plates 1 is made of H65 brass, and the other is made of 1Cr18Ni9Ti stainless steel plate. The selected foil-shaped brazing material 3 and the preset brazing material 4 in the U-shaped groove 2 are BAg45CuZn, H65 brass The brazing joint surface of plate 1 and 1Cr18Ni9Ti stainless steel plate 1 is plane, and the joint figure 1 and figure 2 Note that the method described in this embodiment is implemented by the following steps.

[0030] The first step is to process the thickness of H65 brass plate 1 and 1Cr18Ni9Ti stainless steel plate 1 to 23mm and the width to 100mm, and process a width of 3mm and a height of 3mm at the connection between the welding surface of H65 brass plate 1 and 1Cr18Ni9Ti stainless steel plate 1 and the upper surface The U-shaped groove 2.

[0031] The second step is to place a 0.1mm thick foil-shaped BAg45CuZn brazing material 3 in the gap between the butt joint contact surfaces of the H65 brass plate 1 and the 1Cr18Ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com