Ultrasonic vibration activation assisted microwave sintering furnace

A technology of ultrasonic vibration and microwave sintering, applied in furnaces, crucible furnaces, furnace types, etc., can solve problems such as microwave sintering applications that have not been seen, and achieve the effects of high density, low porosity, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

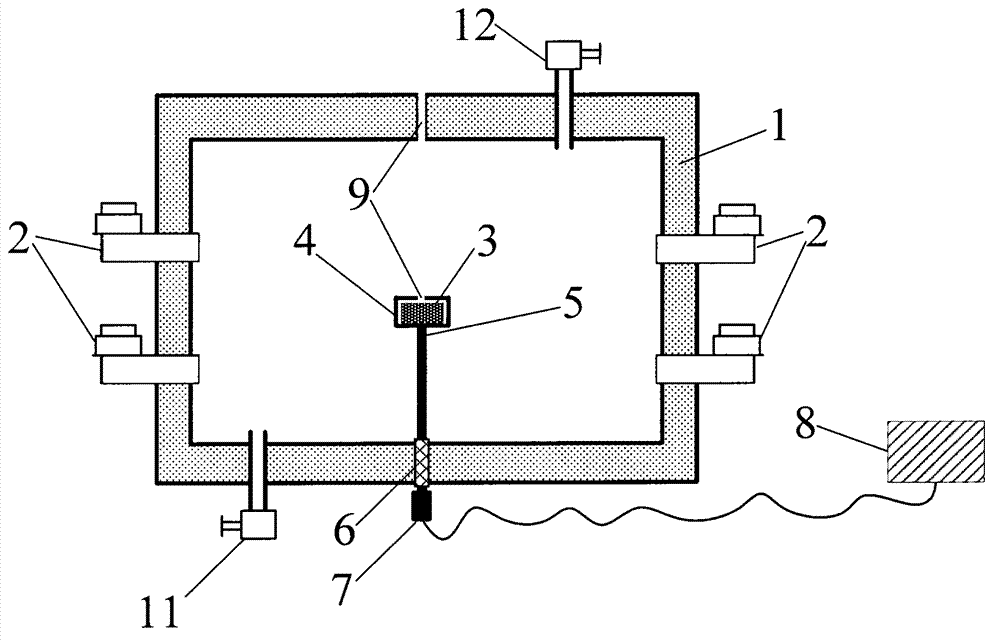

[0018] Such as figure 1 Schematic diagram of a microwave sintering furnace assisted by ultrasonic vibration activation using a wave-guiding crucible. The microwave frequency of the microwave sintering furnace assisted by ultrasonic vibration activation provided by the present invention is 2.45 GHz. In the silicon nitride wave guiding crucible 4, there are temperature measuring holes 9 for temperature monitoring through an infrared thermometer on the top of the furnace shell and the top of the silicon nitride wave guiding crucible, the center line of the two temperature measuring holes and the center of the sample to be fired lines are on the same vertical straight line, the silicon nitride wave-guiding crucible forms a wave-guiding heating chamber, the magnetron 2 passes through the furnace shell, and the microwave heats the silicon nitride wave-guiding crucible. The auxiliary sintering system activated by ultrasonic vibration is installed at the bottom. The hollow cylindrical...

Embodiment 2

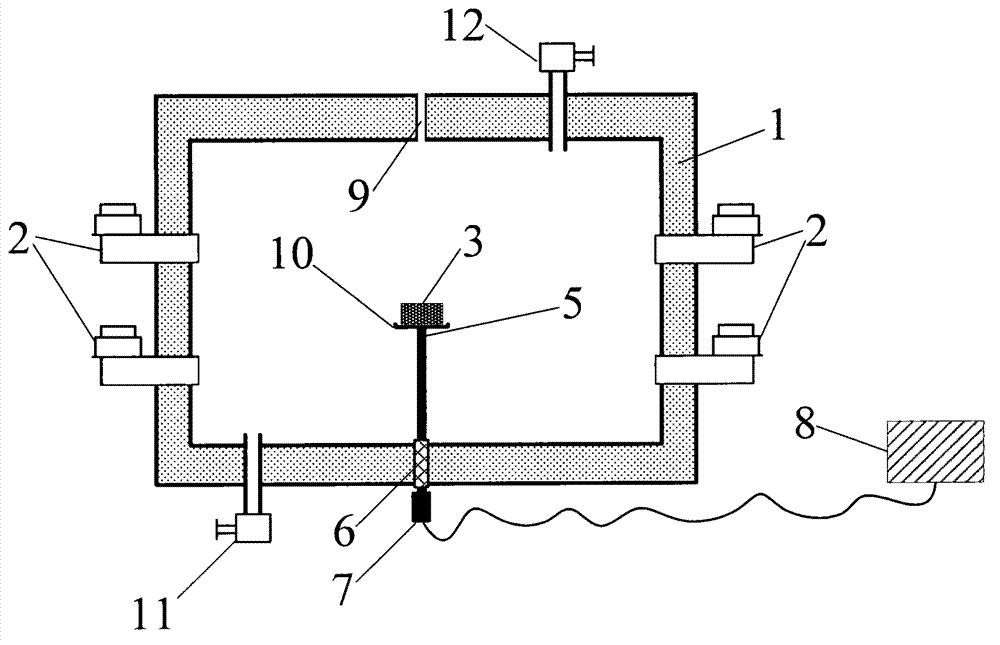

[0020] Such as figure 2 A schematic diagram of an ordinary high-temperature crucible used in the ultrasonic vibration activation-assisted microwave sintering furnace. The microwave frequency of the ultrasonic vibration-activated auxiliary microwave sintering furnace provided by the present invention is 2.45 GHz, and the MnZn ferrite block 3 with good microwave absorption is placed in an ordinary high-temperature crucible 10. There is a temperature measuring hole 9 on the top of the furnace shell for temperature monitoring through an infrared thermometer. The center line of the temperature measuring hole 9 and the center line of the sample to be burned are on the same vertical line. The magnetron 2 passes through the furnace shell, and the microwave Heat the absorbing sample to be burned. The auxiliary sintering system activated by ultrasonic vibration is installed at the bottom. The hollow cylindrical annular alumina ceramic horn support frame 6 passes through the small hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com