Induction brazing method for edge scraper of shielding tunneling machine

A technology of induction brazing and shield machine, which is applied in the direction of welding equipment, electric heating devices, auxiliary devices, etc., can solve the problems of wear resistance and fatigue resistance decline, short welding time, steel hardness reduction, etc., to increase the service life and wear resistance, low weld residual stress, and improved shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

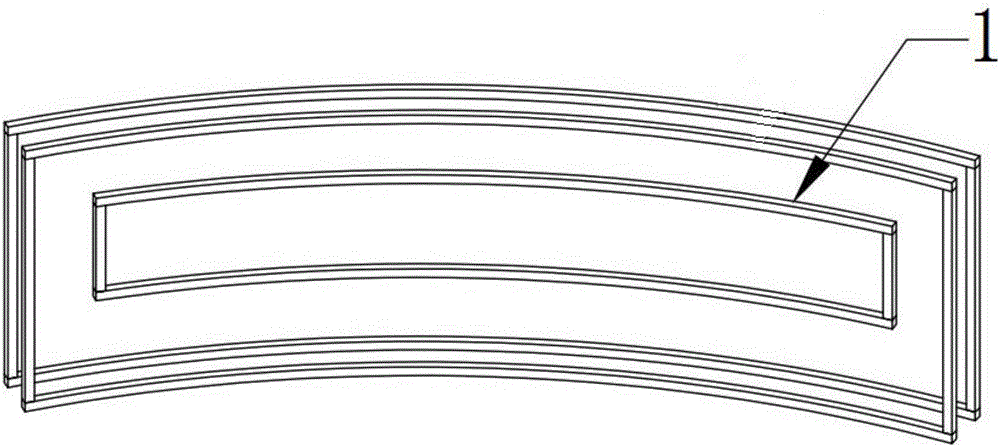

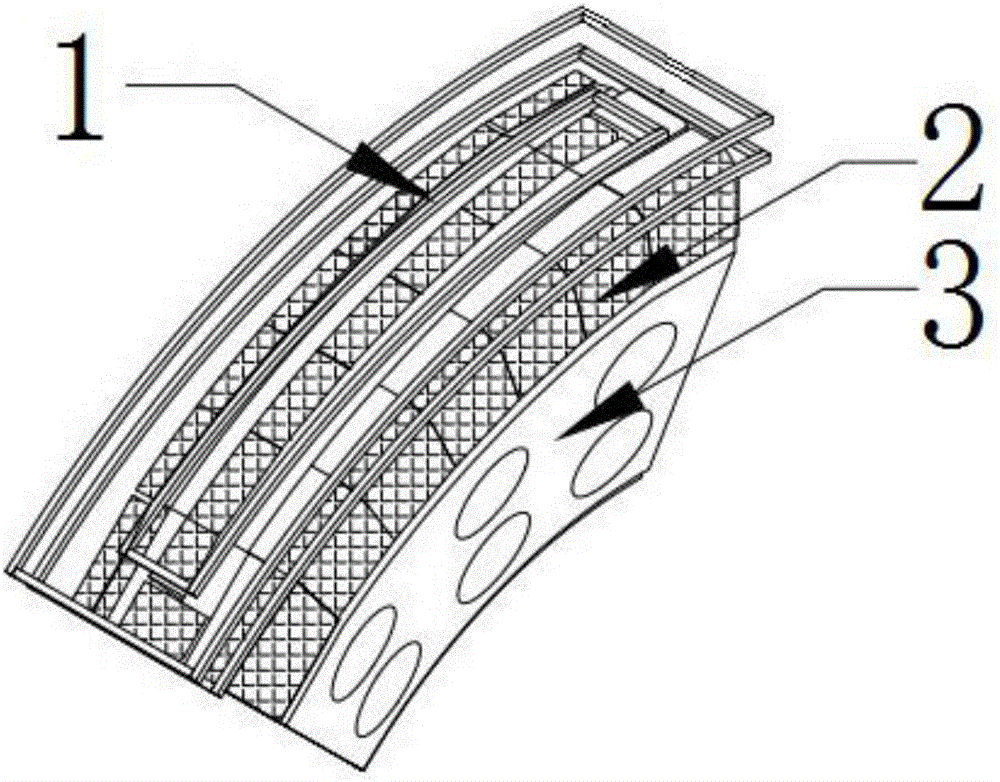

[0029] Such as figure 1 , figure 2 A shield machine edge scraper induction brazing method shown comprises the following steps:

[0030] a. Forge steel parts into arc-shaped cutter body blanks, and perform quenching and tempering treatment, and machine them into such as figure 2 Side scraper blade body 3 is shown. The cemented carbide cutter head 2 matching the side scraper is prepared by powder metallurgy, the silver-based solder is cut into a shape matching the cemented carbide cutter head 2, and then the side scraper body 3 and the cemented carbide cutter head 1 are After being assembled with silver-based solder, how to assemble is a prior art, and will not be described in detail in this embodiment.

[0031] b. Place the assembled side scraper body 3, silver-based solder, and hard alloy cutter head 2 under the profiling coil 1, adjust the position, and set the temperature measurement point of the external temperature controller to be positioned in the middle of the side...

Embodiment 2

[0042] Such as figure 1 , figure 2 A shield machine edge scraper induction brazing method shown comprises the following steps:

[0043] a. Forge steel parts into arc-shaped cutter body blanks, and perform quenching and tempering treatment, and machine them into such as figure 2 Side scraper blade body 3 is shown. The cemented carbide cutter head 2 matching the side scraper is prepared by powder metallurgy, the silver-based solder is cut into a shape matching the cemented carbide cutter head 2, and then the side scraper body 3 and the cemented carbide cutter head 1 are After being assembled with silver-based solder, how to assemble is a prior art, and will not be described in detail in this embodiment.

[0044] b. Place the assembled side scraper body 3, silver-based solder, and hard alloy cutter head 2 under the profiling coil 1, adjust the position, and set the temperature measurement point of the external temperature controller to be positioned in the middle of the side...

Embodiment 3

[0055] Such as figure 1 , figure 2 A shield machine edge scraper induction brazing method shown comprises the following steps:

[0056] a. Forge steel parts into arc-shaped cutter body blanks, and perform quenching and tempering treatment, and machine them into such as figure 2 Side scraper blade body 3 is shown. The cemented carbide cutter head 2 matching the side scraper is prepared by powder metallurgy, the silver-based solder is cut into a shape matching the cemented carbide cutter head 2, and then the side scraper body 3 and the cemented carbide cutter head 1 are After being assembled with silver-based solder, how to assemble is a prior art, and will not be described in detail in this embodiment.

[0057] b. Place the assembled side scraper body 3, silver-based solder, and hard alloy cutter head 2 under the profiling coil 1, adjust the position, and set the temperature measurement point of the external temperature controller to be positioned in the middle of the side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com