Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Guaranteed calorific value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

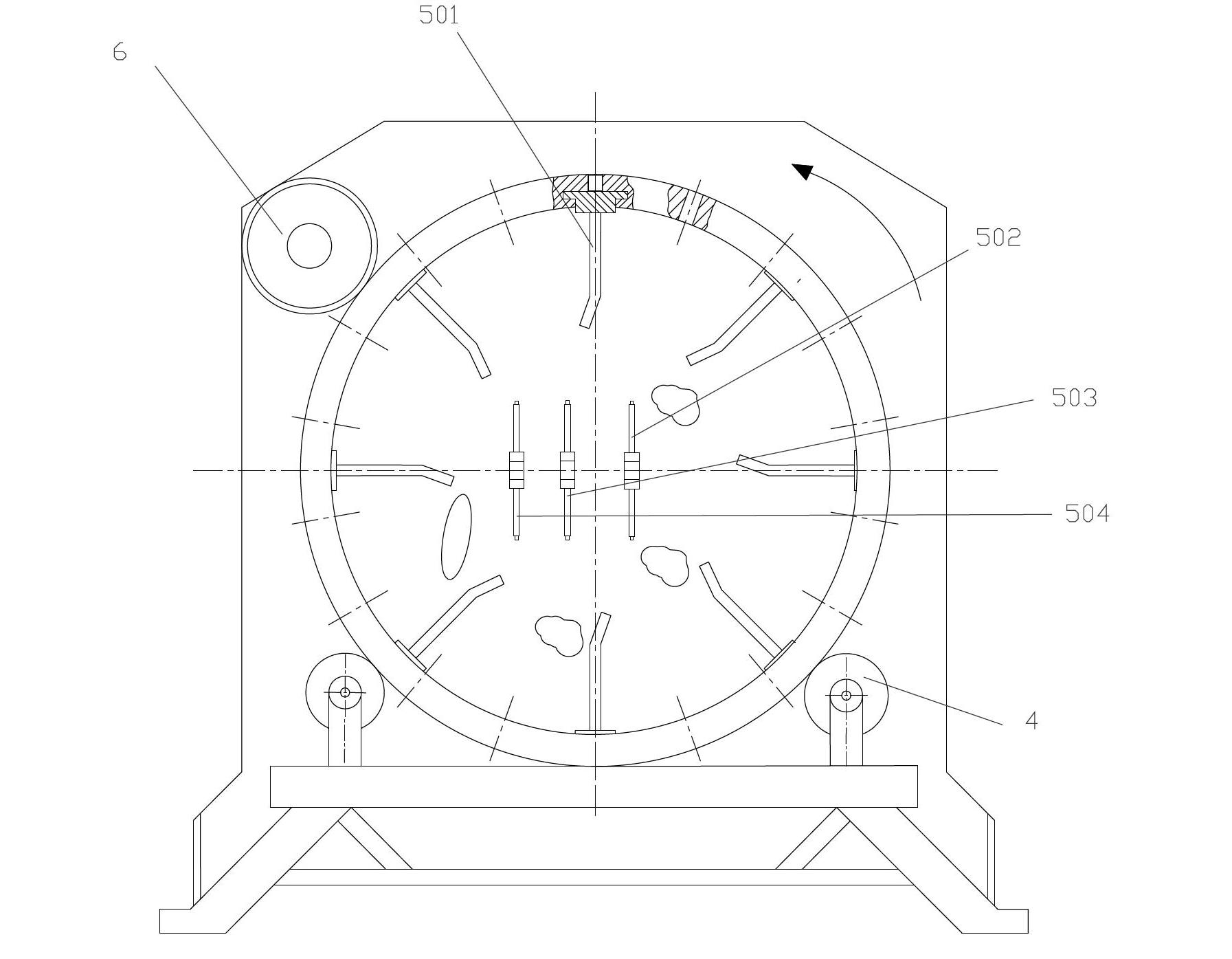

Sludge treatment method for drying sludge by using coal grinding machine and using sludge for electricity generation

InactiveCN101723570ALess investmentSave spaceSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationElectricityReflux

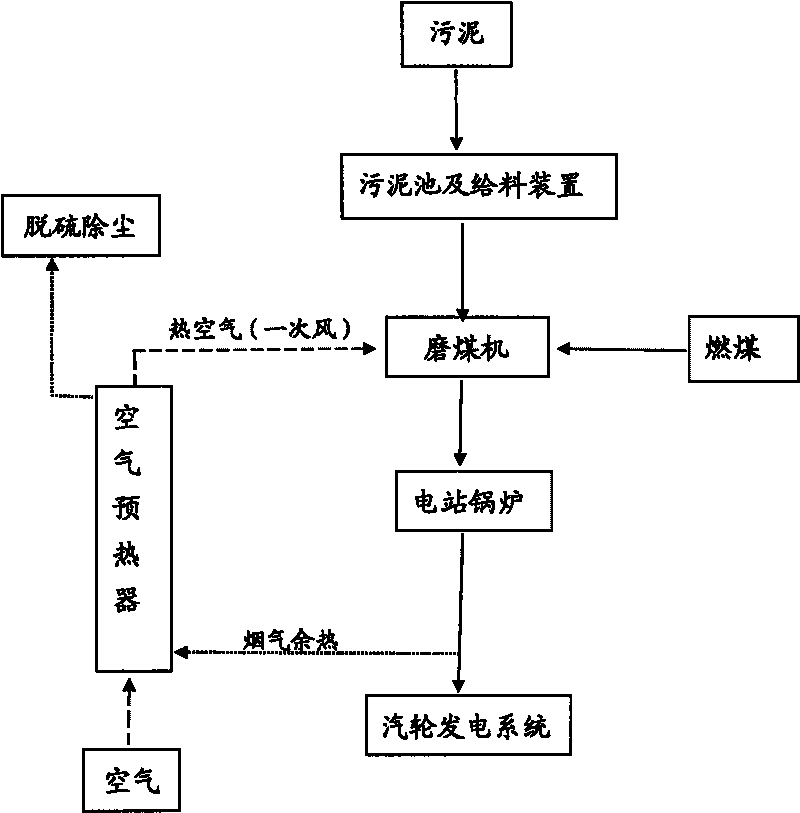

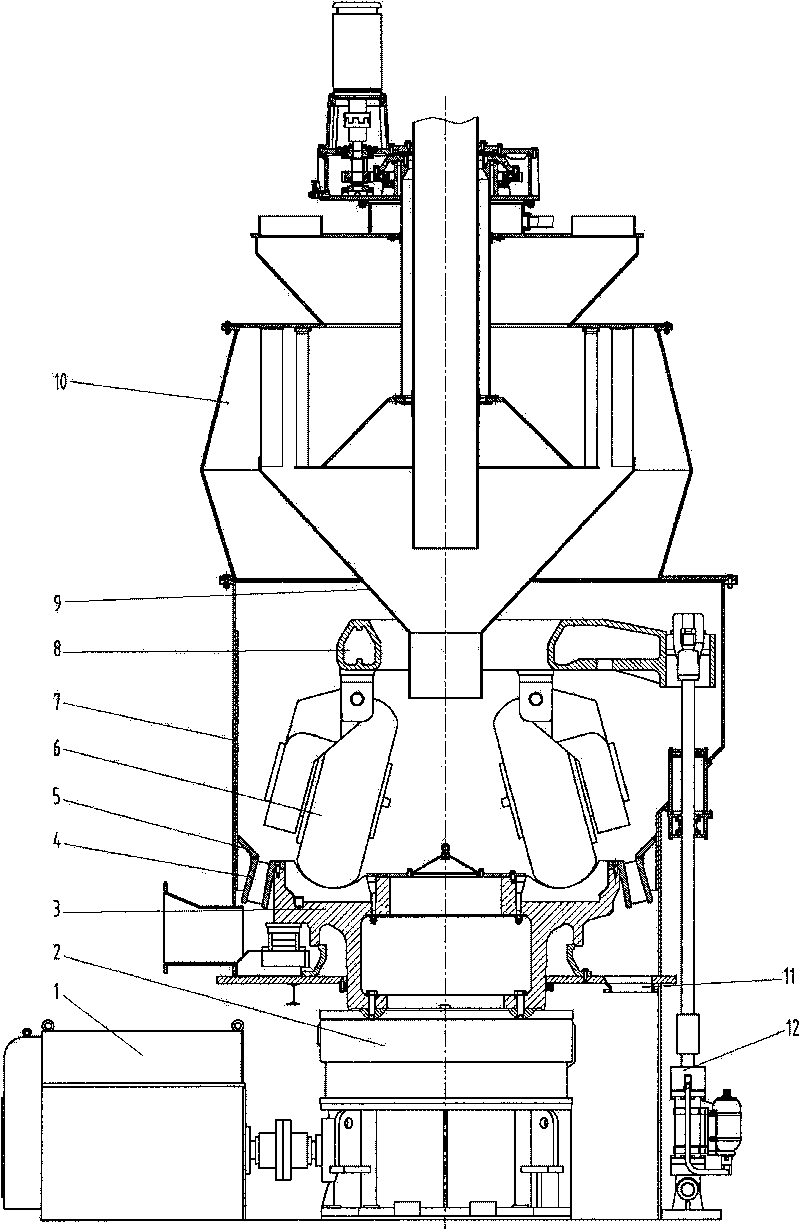

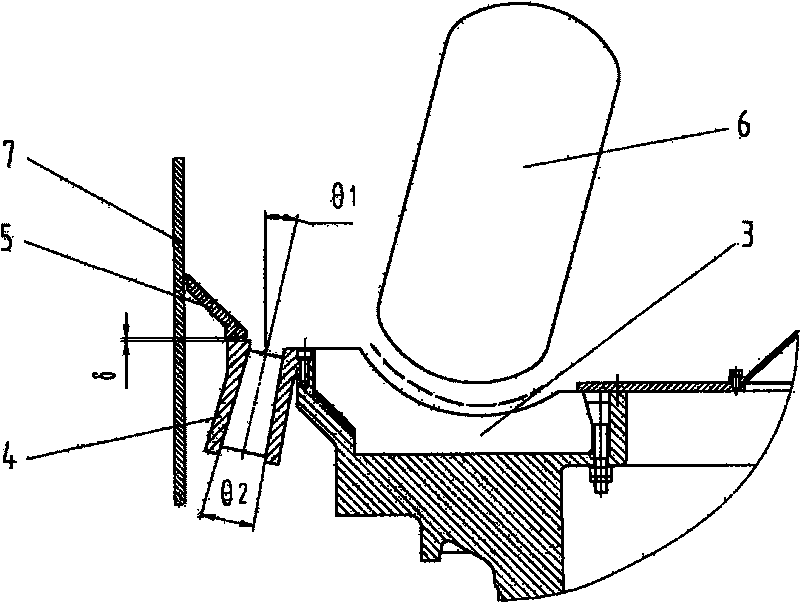

The invention discloses a sludge treatment method for drying sludge by using a coal grinding machine and using the sludge for electricity generation. The method comprises the following steps of: 1) directly introducing wet sludge with the moisture content of 70 to 90 percent into the coal grinding machine, wherein the ratio of the wet sludge is 2 to 10 percent of a fuel coal; 2) performing heat exchange between the waste heat of a utility boiler flue gas and air to generate primary air blown into the coal grinding machine, mixing the sludge with the fuel coal in the coal grinding machine, and performing grinding while drying; and 3) spraying the coal powder containing the dried sludge into the utility boiler for burning and generating electricity. The coal grinding machine which is also used as sludge drying equipment is characterized in that a hot air introduction device is a rotary type hot air nozzle ring, a powder reflux device is a through-type flow-guiding powder reflux cone, and a separating device is a rotary separator with a first separate stationary blade. The sludge treatment method makes full use of the original process of an electric power plant, makes full use of the waste heat of the flue gas and the heat value of the sludge, and acquires no additional hot resource or device for drying the sludge, and has the advantages of investment saving, low operation cost, no secondary pollution and the like.

Owner:ZHEJIANG UNIV

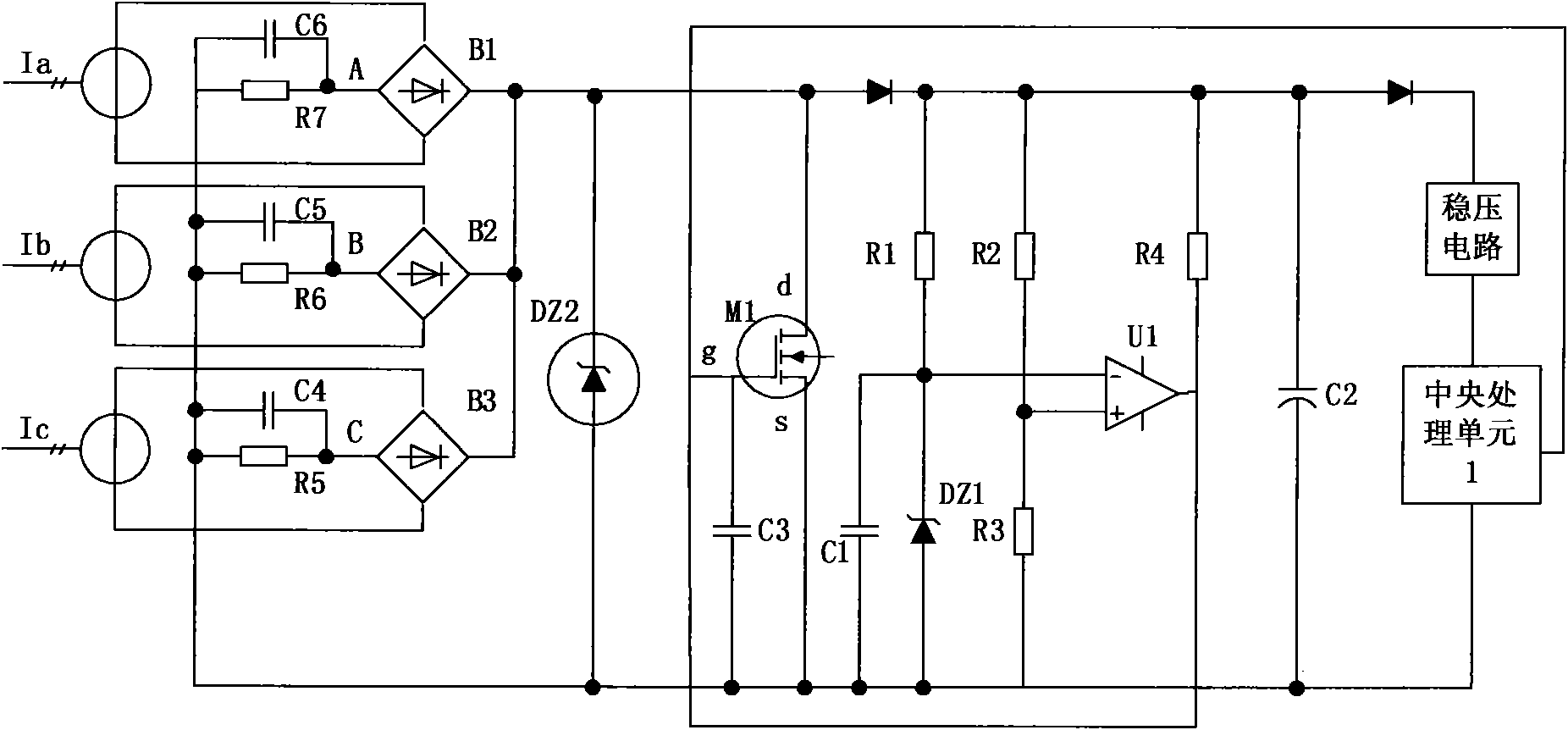

Power supply circuit of intelligent release

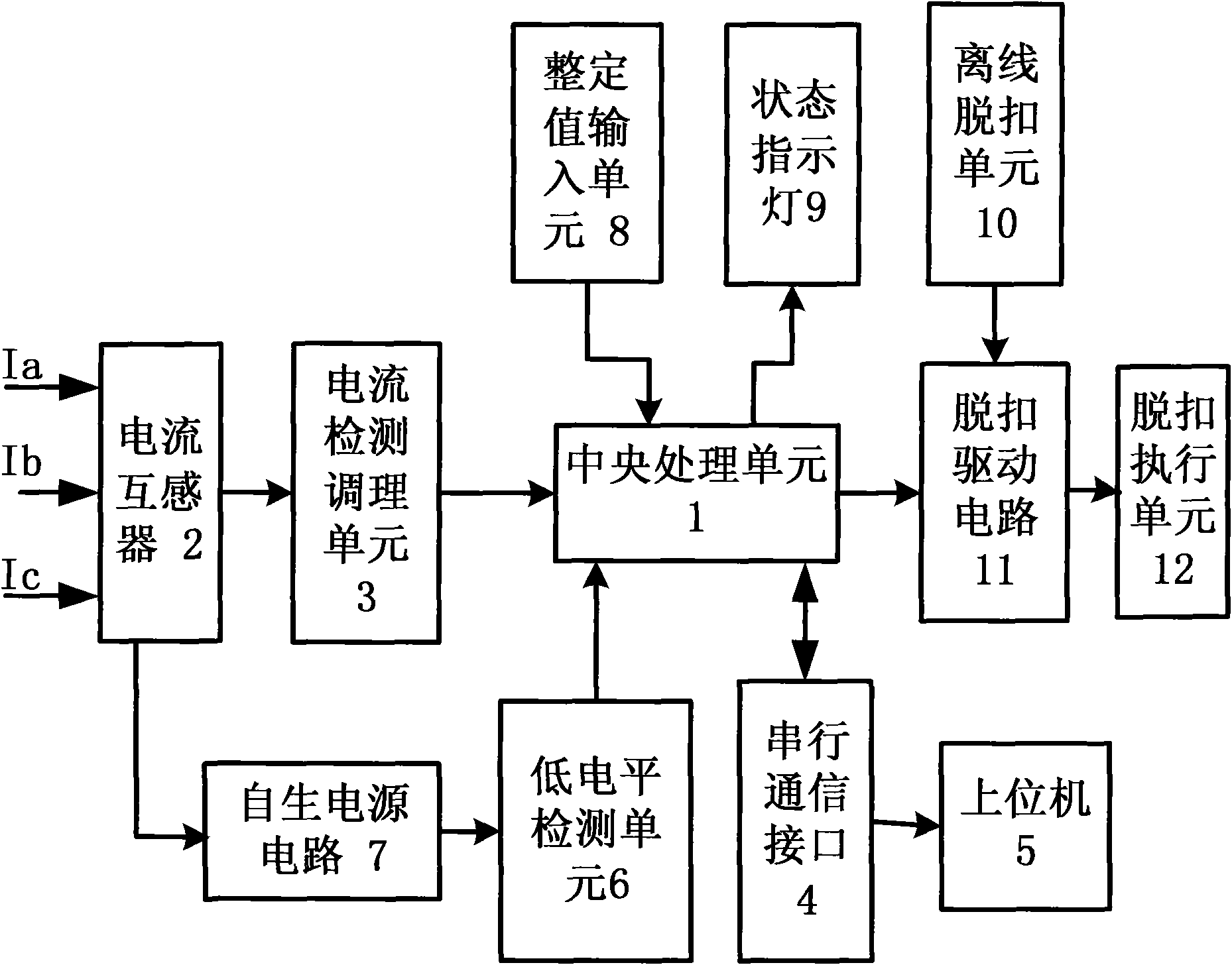

The invention relates to a power supply circuit of an intelligent release, which is powered by a self-generation power supply circuit. The power supply circuit comprises a current transformer, a current detection conditioning unit connected with the current transformer, a central control unit connected with the current detection conditioning unit, a releasing driving circuit connected with the central control unit, and a releasing execution unit connected with the releasing driving circuit. A parameter control input end of the central control unit is connected with a setting value input unit, and a communication data end of the central control unit is connected with a serial communication interface for connecting an upper computer. During operation, a singlechip performs AD conversion on a voltage signal processed by the current transformer through the current detection conditioning unit; according to a sampling value, logic operation and processing are performed, and logic level signals according with preset protection characteristics are output after the operation result and a setting value are compared; and the signals pass through the releasing driving circuit and are sent to a magnetic flux converter in the releasing execution unit to enable a breaker to trip and cut off the circuit.

Owner:SOUTHELEC CO LTD

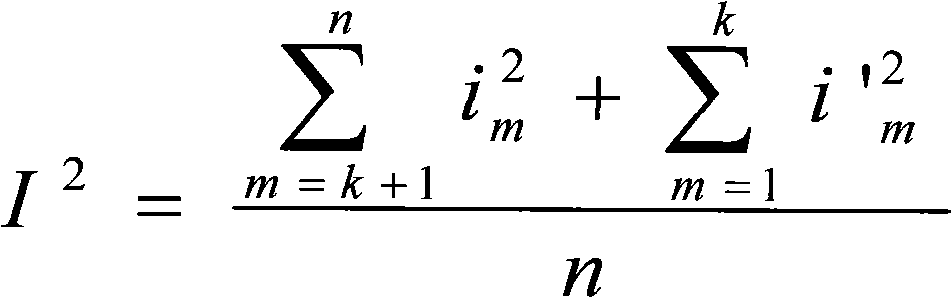

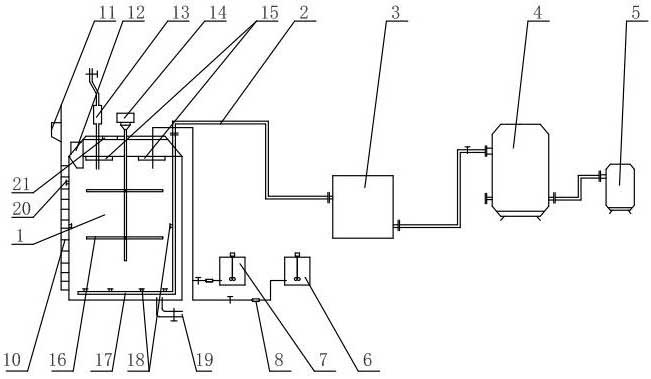

TiO2-carrying photoelectric catalyst for photoelectrocatalytic advanced treatment on sludge and method and device for TiO2-carrying photoelectric catalyst-based photoelectrocatalytic advanced treatment on sludge

ActiveCN102513108AReduce mass transfer resistanceImprove oxidation capacitySludge treatment by de-watering/drying/thickeningMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSludge

The invention discloses a TiO2-carrying photoelectric catalyst for photoelectrocatalytic advanced treatment on sludge, and a method and a device for TiO2-carrying photoelectric catalyst-based photoelectrocatalytic advanced treatment on sludge. The method provided by the invention comprises the following steps of 1, adding the TiO2-carrying photoelectric catalyst for photoelectrocatalytic advancedtreatment on sludge into sludge, 2, carrying out irradiation by an ultraviolet ray generator located at an upper part of a reactor, and feeding high-energy electrons produced by an air-carried high-energy electron generator into the sludge by an aeration pipe located a lower part of the reactor, 3, adding a composite coagulation agent into the sludge obtained by the step 2 and carrying out flocculation, and 4, carrying out press filtration of the sludge by a pressure filter. The TiO2-carrying photoelectric catalyst, the device and the method provided by the invention solve the technical problem that the sludge normal-temperature treatment technology cannot remove water absorbed by organic matter-containing sludge, realize that the content of water in residual sludge is reduced to the content below 50% by a single step under the conditions of a normal temperature and normal pressure, realize sterilization, deodorization and solidification of toxic heavy metal ions simultaneously, and realize a large sludge decrement, a low treatment cost and good treatment effects. Sludge treated by the TiO2-carrying photoelectric catalyst, the method and the device reaches the latest standard published by the state environmental protection department and is convenient for follow-up recycling application.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

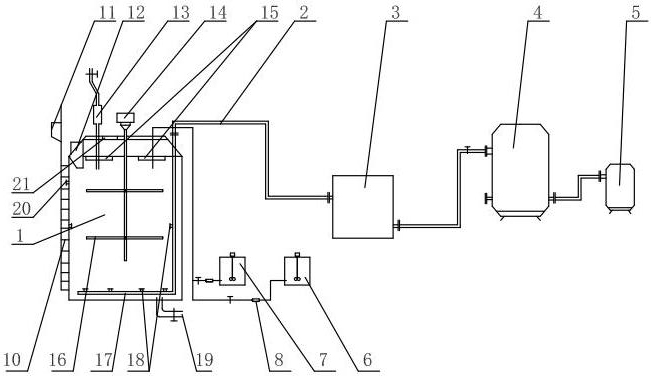

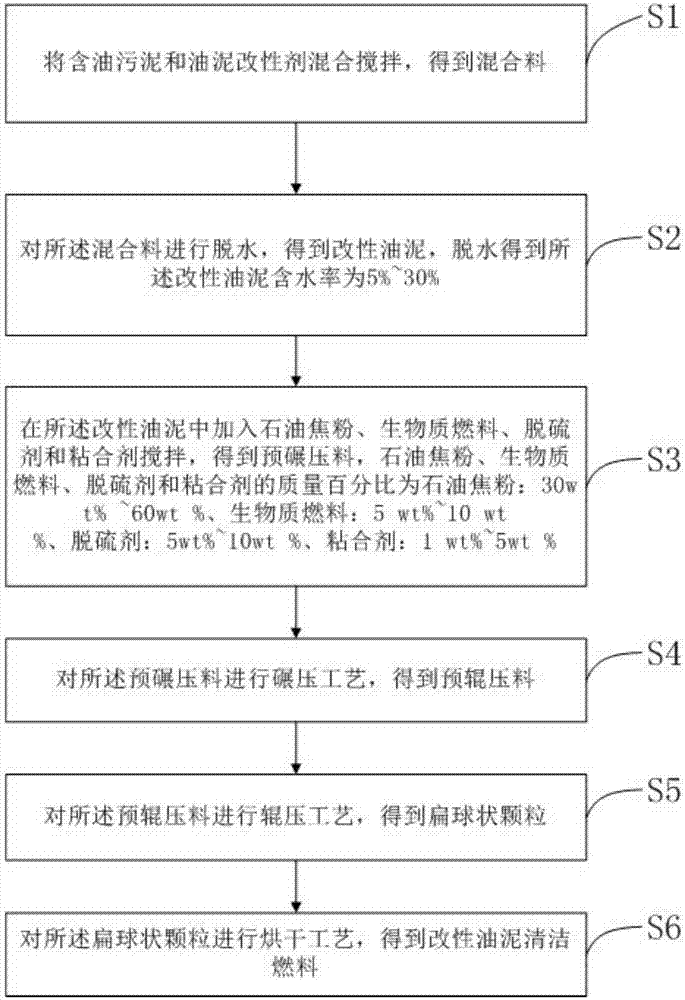

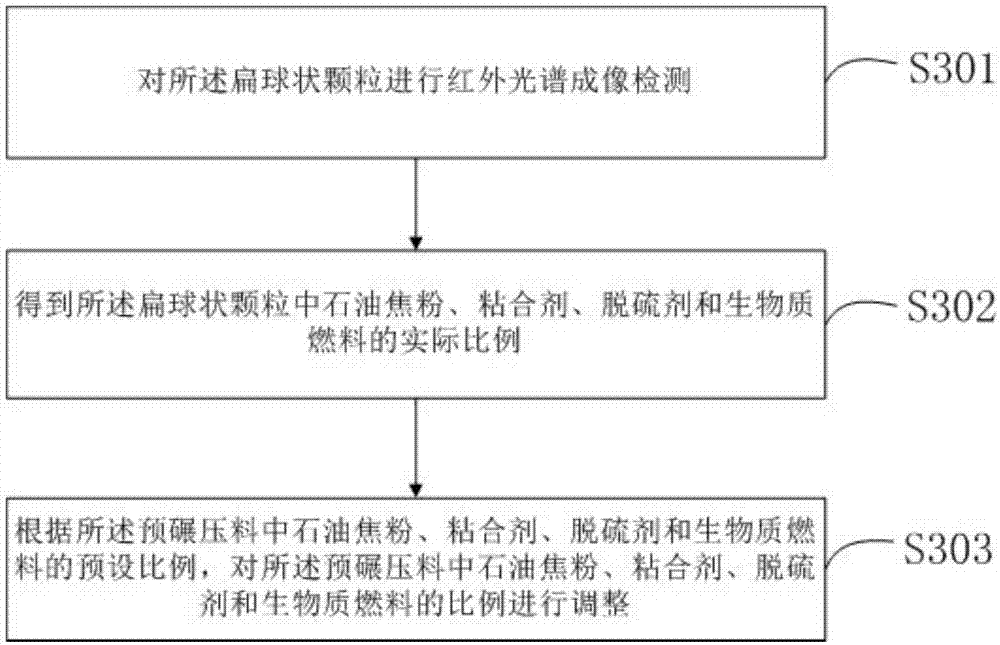

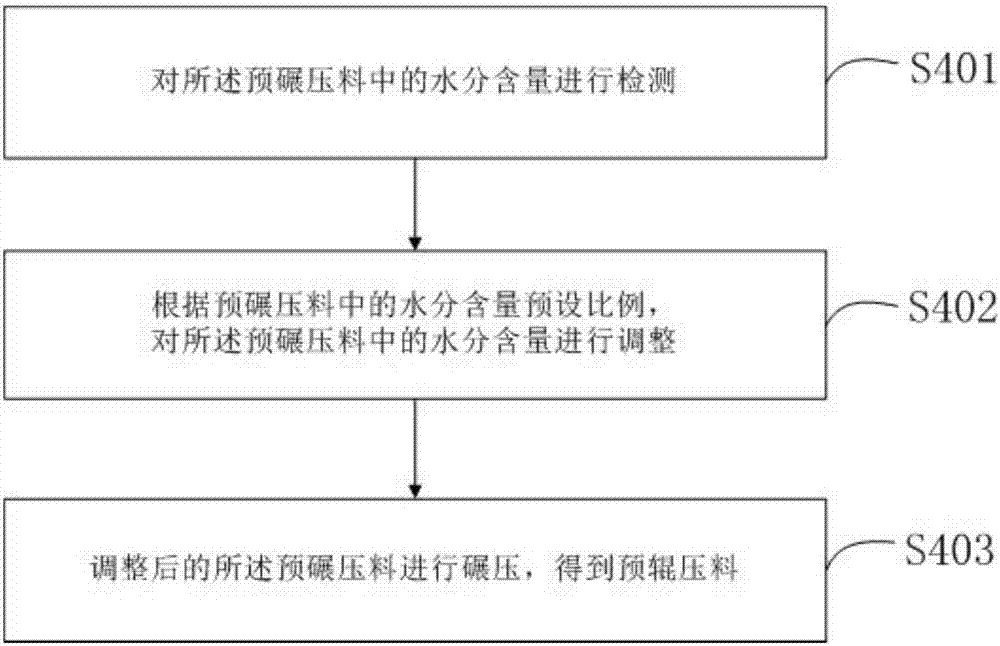

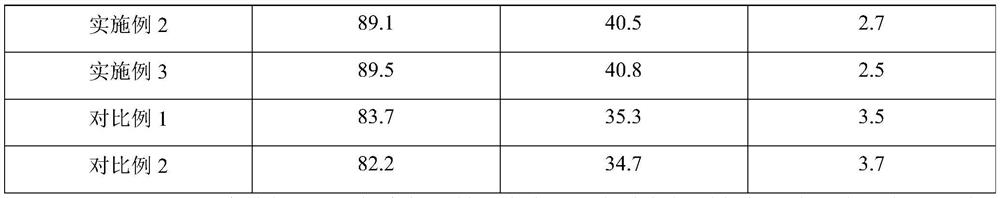

Modified oil sludge clean fuel and preparation method of modified oil sludge clean fuel

InactiveCN106967471AIncrease the calorific value of combustionCalorific value guaranteeSolid fuelsWaste based fuelAdhesiveFlue gas

The embodiment of the invention discloses a modified oil sludge clean fuel and a preparation method of the modified oil sludge clean fuel. According to the method, oil sludge and an oil sludge modifier are mixed and stirred, the activation energy of the oil sludge is reduced, and petroleum coke powder, biomass fuel, a desulfurizing agent and an adhesive are added to the uniformly stirred oil sludge. The petroleum coke powder improves the combustion heat value of the modified oil sludge; pulverized biomass improves the burn-off rate of the modified oil sludge fuel; the desulfurizing agent removes sulfide in the fuel and reduces the pollution to the air during the burning of the fuel; the adhesive is beneficial to the increasing of the molding rate of the fuel. The modified oil sludge clean fuel can be sufficiently burnt in a combustion boiler, the combustion heat value is guaranteed, the molding rate of the fuel is high, and both flue gas emission and ash emission reach the standard.

Owner:PANJIN KEANLONG TECH CO LTD

Fuel oil

InactiveCN103589466AGuaranteed not to cokeNo dustLiquid carbonaceous fuelsFuel oilOxidation stability

The invention discloses a fuel oil, which comprises dephenolized phenol oil and heavy aromatics. The invention applies dephenolized phenol oil in the field of coal chemical industry to fuel oil and utilizes the characteristic of high blending performance of the dephenolized phenol oil to prepare fuel oil with low production cost, high oxidation stability, low benzene content and standard viscosity. As the dephenolized phenol oil has wide and adequate source, the obtained fuel oil is easy to prepare, so as to solve the existing condition of the lack of fuel oil.

Owner:上海烨燃石油化工有限公司

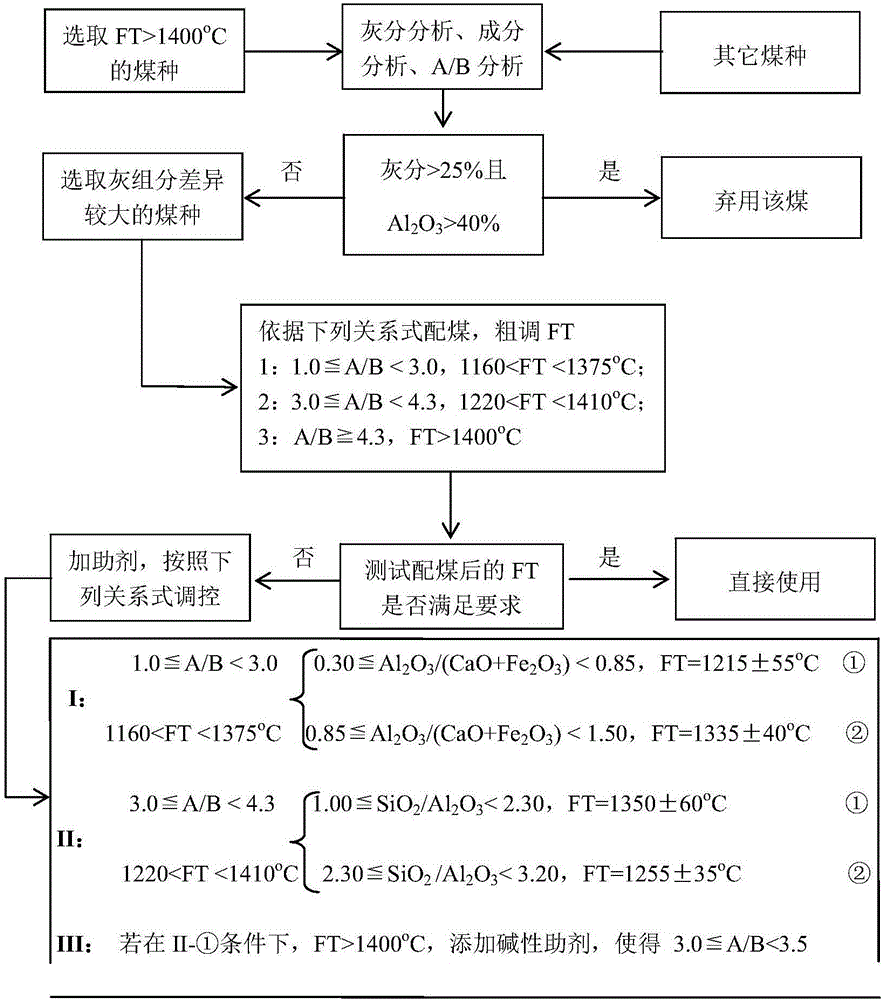

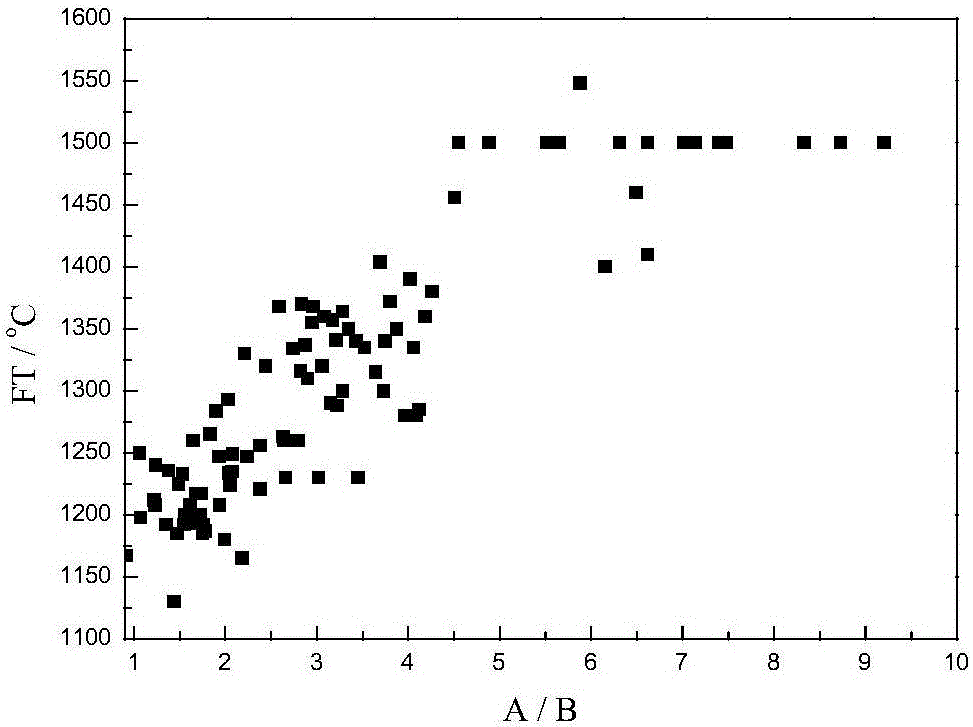

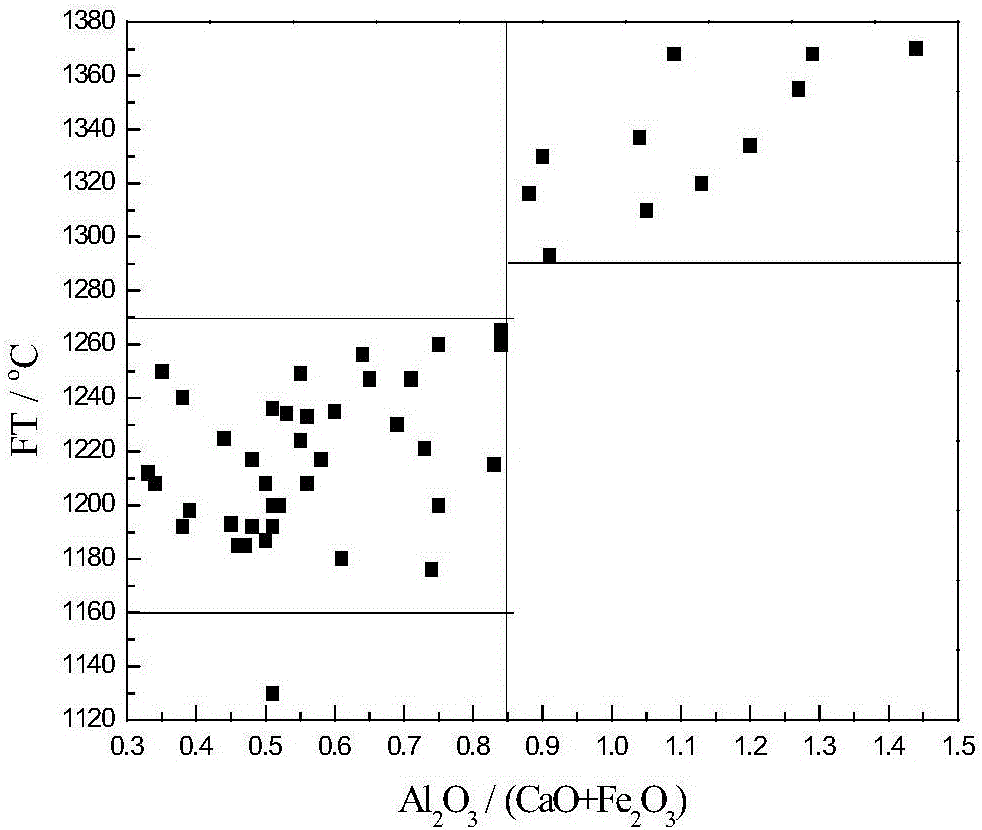

Method for regulating and controlling flowing temperature of high-melting-point coal ash

ActiveCN106675657AHighlight the pertinenceAdd lessGasification processes detailsGranular/pulverulent flues gasificationControl flowPulverized fuel ash

The invention discloses a method for regulating and controlling the flowing temperature of high-melting-point coal ash. The method comprises the following steps: measuring the ash melting point of a type of coal of which the coal ash is lower than 25 percent and the Al2O3 content in the ash is lower than 40 percent, blending a type of coal, of which the coal ash FT is larger than 1,400 DEG C since A / B is larger than 4.3, with one or more types of coal according to different masses, so that the coal ash A / B of the blended coal is less than 4.3, then ashing the blended coal, measuring blended coal ash FT, and directly using the blended coal ash if the blended coal ash FT satisfies the ideal operation temperature of a gasifying furnace; if the blended coal ash FT does not satisfy the ideal operation temperature of the gasifying furnace, further regulating and controlling the coal ash by adding an assistant. By adopting the method, the adaptability of the high-melting-point coal ash to a gasifying process of an entrained flow bed is improved, the calorific value of the blended coal is ensured, and meanwhile the adding amount of the assistant is reduced.

Owner:NORTHWEST UNIV(CN)

Multi-component regenerated fuel based on domestic garbage and preparation method thereof

The invention discloses a multi-component regenerated fuel based on domestic garbage and a preparation method thereof, which are suitable for resource processing of solid wastes. The regenerated fuel is formed by mixing combustible components in the domestic garbage, coal liquefaction residues, agricultural solid wastes and calcium oxide in proportion, and specifically comprises the following components in percentage by mass: 62.5%-77.0% of the combustible components in the domestic garbage, 10.0%-20.0% of the coal liquefaction residues, 5.0%-14.0% of the agricultural solid wastes and 4.5%-7.5% of the calcium oxide. The preparation method comprises the following steps: firstly separating the combustible components from the domestic garbage; then performing drying, crushing and other pretreatment on the combustible components in the domestic garbage, the coal liquefaction residues and the agricultural solid wastes; further mixing all the components according to the ratio, and uniformlystirring; and finally shaping. The regenerated fuel has the advantages of higher calorific value, stable combustion and low secondary pollution, and can realize resource utilization of the urban domestic garbage and the industrial and the agricultural solid wastes.

Owner:四川川润环保能源科技有限公司 +1

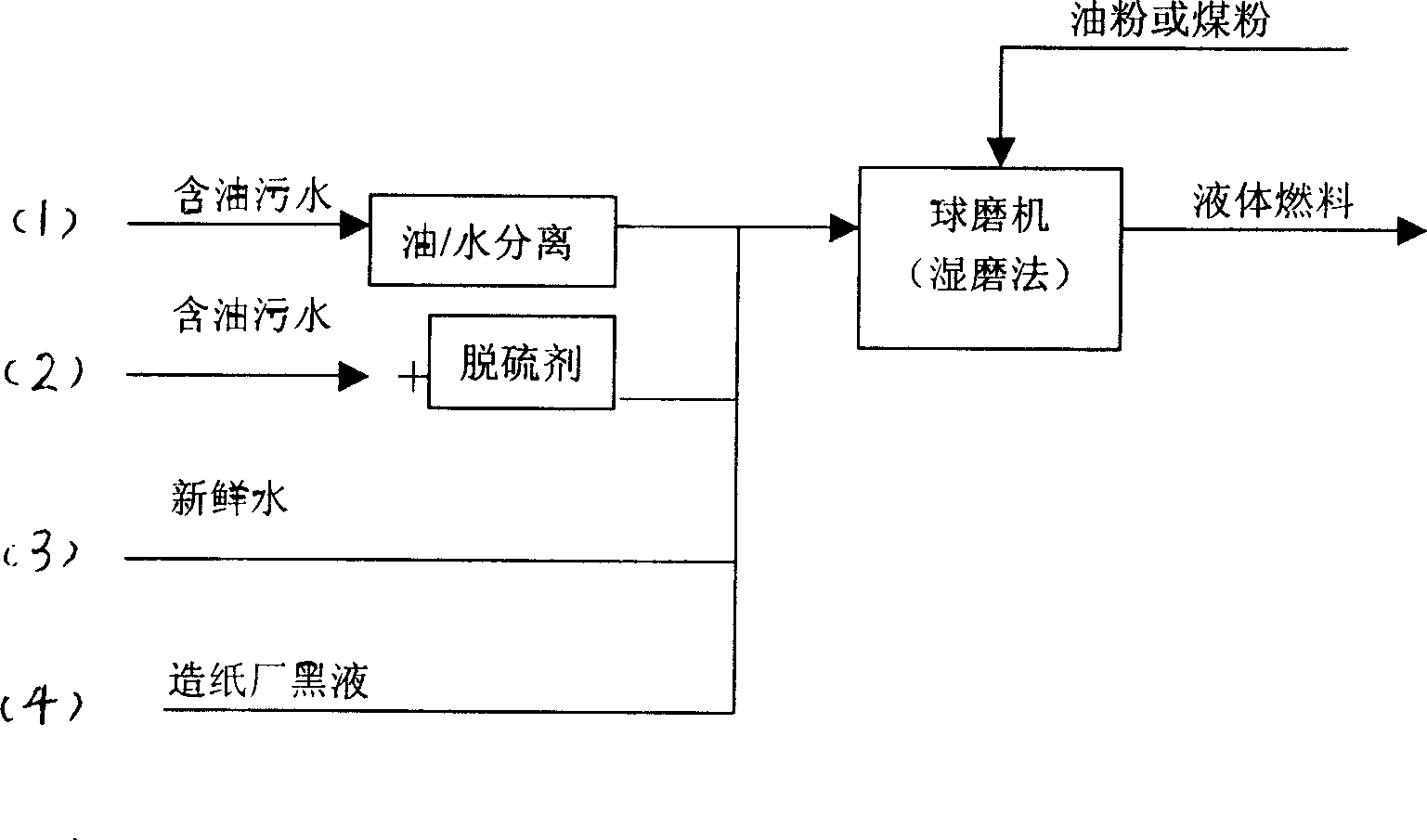

Process for treating industrial sewage

InactiveCN1837070AHigh combustion valueReduce burning oilFatty/oily/floating substances removal devicesLiquid separationFresh waterLiquid fuel

Disclosed is a process for treating industrial sewage characterized by using industrial sewage as water for the preparation of coke water slurry or water coal slurry liquid fuel in place of fresh water. The invention realizes the integration of industrial sewage treatment and the preparation of coke water slurry and water coal slurry.

Owner:淄博天工石化工程咨询有限公司

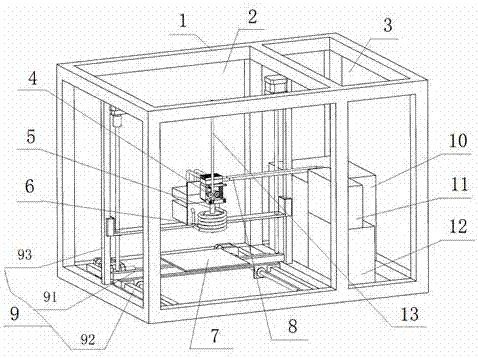

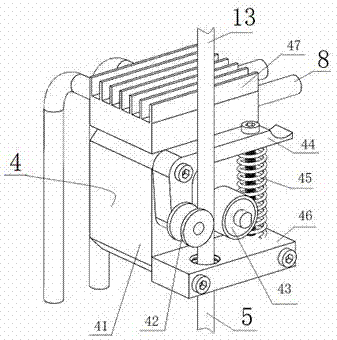

3D (three-dimension) printer for printing vitreous body and printing method

InactiveCN107285609ABroaden your optionsControl feedAdditive manufacturing apparatusGlass shaping apparatusHigh energyControl system

The invention relates to a 3D (three-dimension) printer for printing a vitreous body and a printing method. The 3D printer is composed of a frame, a printing silo and a control cooling silo; the printing silo is connected with the control cooling silo and arranged in the frame; the inner part of the printing silo is provided with a delivering mechanism, a nozzle printing mechanism, a sensing heating device, a printing bottom plate, a cooling medium guide flow pipe and a three-dimensional movement mechanism; the inner part of the control cooling silo is provided with a cooling device, a control system and a power supply. By applying the 3D printer for printing the vitreous body and the printing method, the selection scale of the printing raw material is enlarged; the sensing heating method has the significant advantages of high working efficiency, high energy utilization rate, quick temperature rise, control easiness, small equipment volume, pollution free and others; besides, the printer and the printing device have the advantages of simple and reliable structure, high automatic degree, control easiness, strong practicability and others.

Owner:贵州云上左岸科技有限公司

Briquette for gas producer produced by high volatile bituminous coals and method

InactiveCN101805650AIncrease cold strengthNo reduction in fixed carbon contentSolid fuelsBulk chemical productionFixed bedAnthracite

The invention relates to a briquette for a gas producer produced by high volatile bituminous coals and a method. The briquette can meet the requirements of the two-stage fixed bed gas producer for coal quality. The briquette is characterized in that: aiming at the characteristics of high bituminous coal forming elasticity, anthracite coal with the weight 10-20% of that of the bituminous coal is added by weight percentage and is taken as a carbon skeleton, thereby improving the cold strength of the briquette formed by the bituminous coals; modified clay with the weight 4-6% of that of the bituminous coal is added by weight percentage and is taken as a thermal intensifier, and simultaneously a sodium humate binder with the weight 4-6% of that of the bituminous coal is formed by cold pressing, thereby not only improving the cold strength of the briquette, but also not reducing the fixed carbon content of the briquette so as to ensure the heating value and gas production quantity of the briquette; and a small amount of modified clay is added to improve the thermal strength and thermal stability of the briquette, and can be used as a catalyst in the gasification process simultaneously,thereby improving the gasification activity of the briquette.

Owner:河南中美铝业有限公司

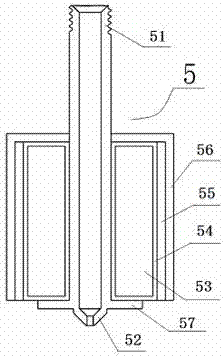

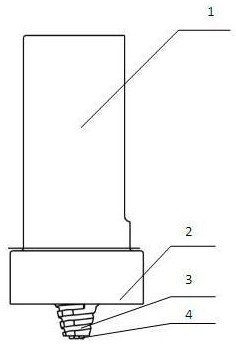

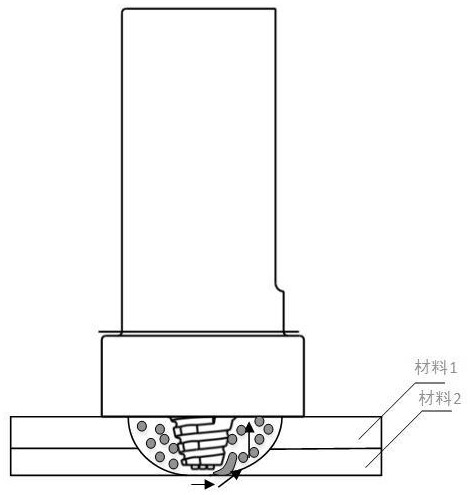

Dissimilar material friction-stir welding tool

PendingCN111843177AImprove wear resistanceGuaranteed calorific valueNon-electric welding apparatusEngineeringMaterials science

The invention discloses a dissimilar material friction-stir welding tool which comprises a cutter handle, a shaft shoulder part and a stirring needle connected sequentially. The stirring needle is provided with at least one group of lug bosses on the bottom part of a needle tip, and is arranged in a circular truncated cone shape; and the diameter of the stirring needle is gradually reduced from the part connected with the shaft shoulder part to the direction far away from the shaft shoulder part. One group or multiple groups of lug bosses is connected to the bottom part of the stirring needle,a single group is presented in an eccentric way, and the multiple groups are presented in a way of uniformly distributing around the axis of the stirring needle, so that the flow characteristic and the heating amount of materials on the lower part are ensured. The dissimilar material friction-stir welding tool solves the problem of differences in flow characteristics and temperature characteristics of the materials during dissimilar material (aluminum, steel; aluminum, organic composite materials and the like) friction-stir welding, and is particularly suitable for overlap welding of upper and lower dissimilar materials.

Owner:AEROSPACE ENG EQUIP SUZHOU CO LTD

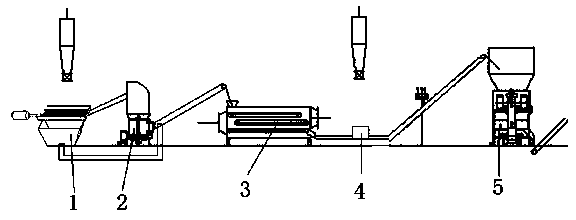

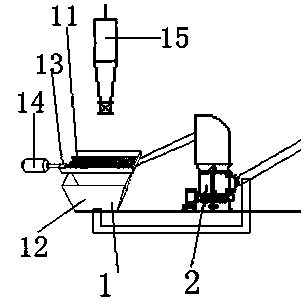

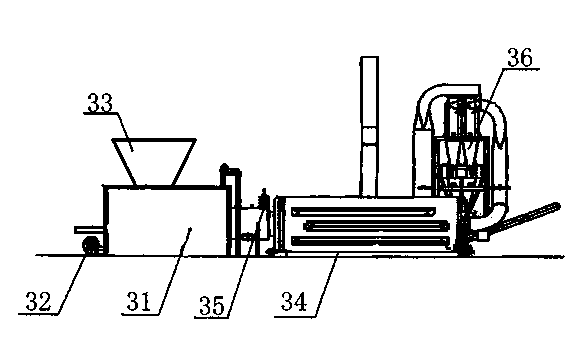

Production equipment for biomass wood pellet fuel

InactiveCN103992837AHigh calorific valueIncrease burn rateBiofuelsSolid fuelsPulp and paper industryPellet fuel

The invention discloses production equipment for a biomass wood pellet fuel. The production equipment comprises a saw dust pulverizer, a roller dryer and an extrusion forming granulator which are sequentially connected, wherein a material storage room is arranged between the roller dryer and the extrusion forming granulator and is used for transferring a wood pellet raw material and detecting moisture content of the wood pellet raw material. The wood pellet is taken as the raw material for producing the biomass wood pellet fuel, so that the production method is simple in process and is applicable to industrial production; the prepared biomass wood pellet fuel has high heat value, combustion ratio and heat efficiency.

Owner:DEQING FUSENLI ENERGY SAVING TECH

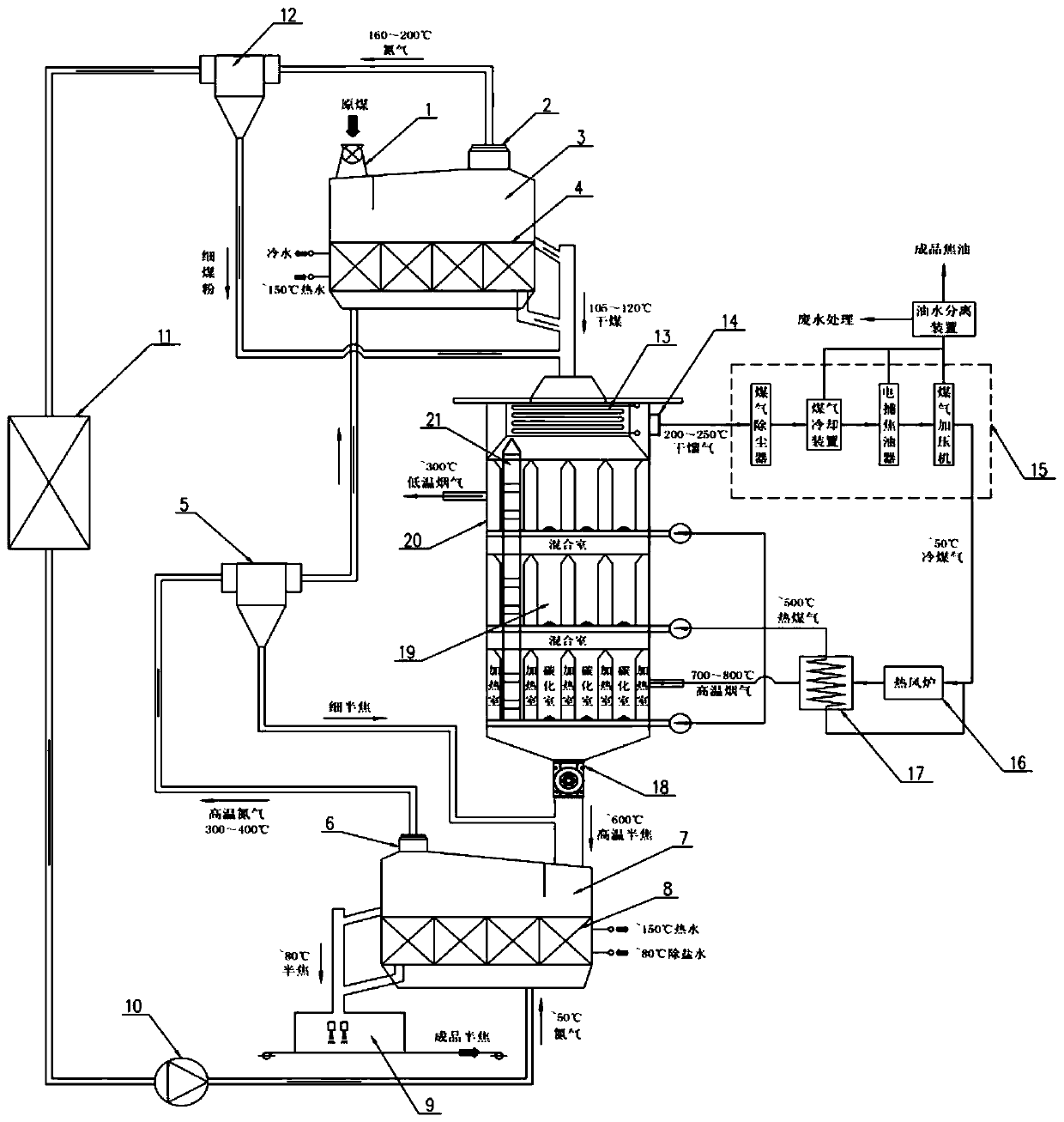

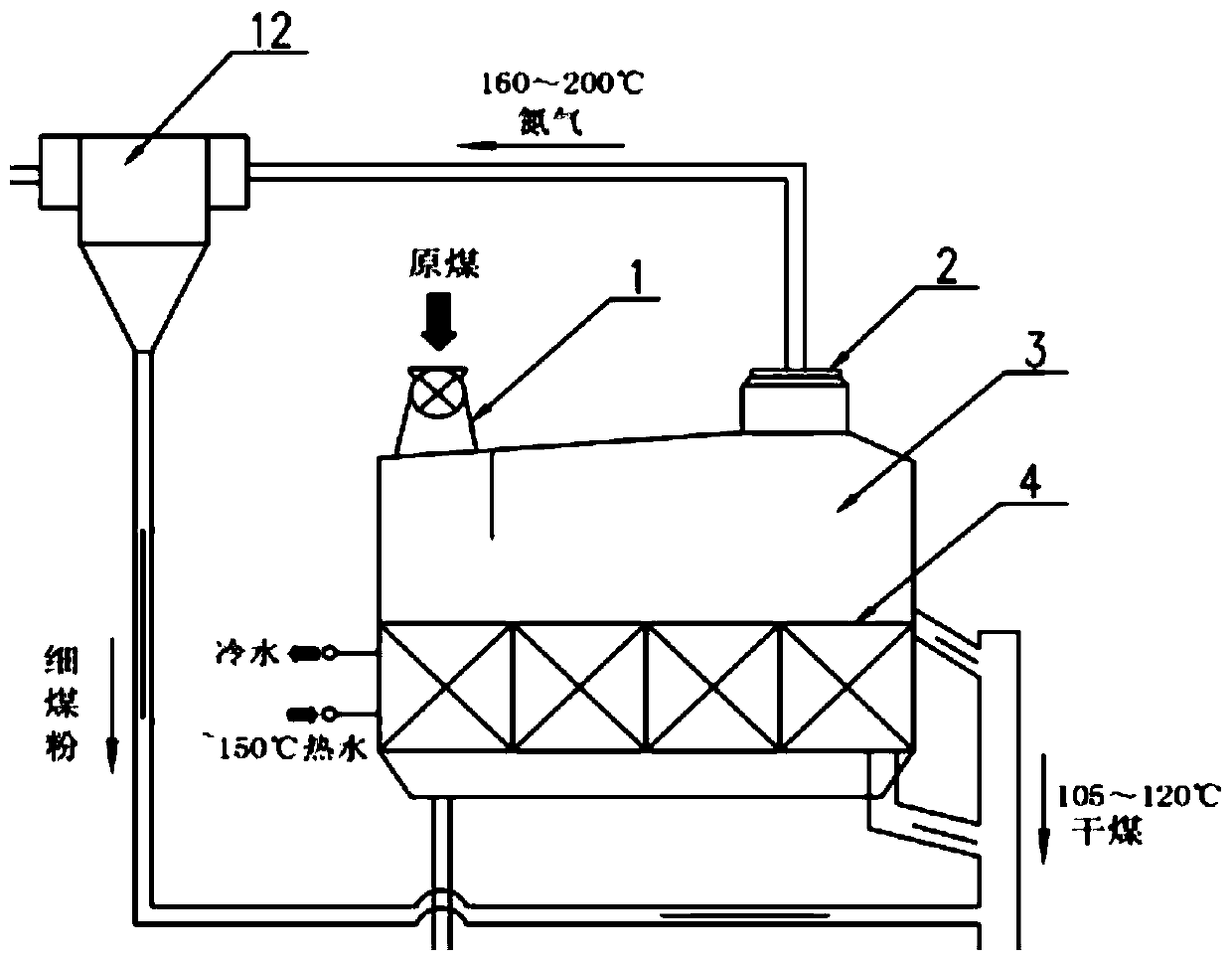

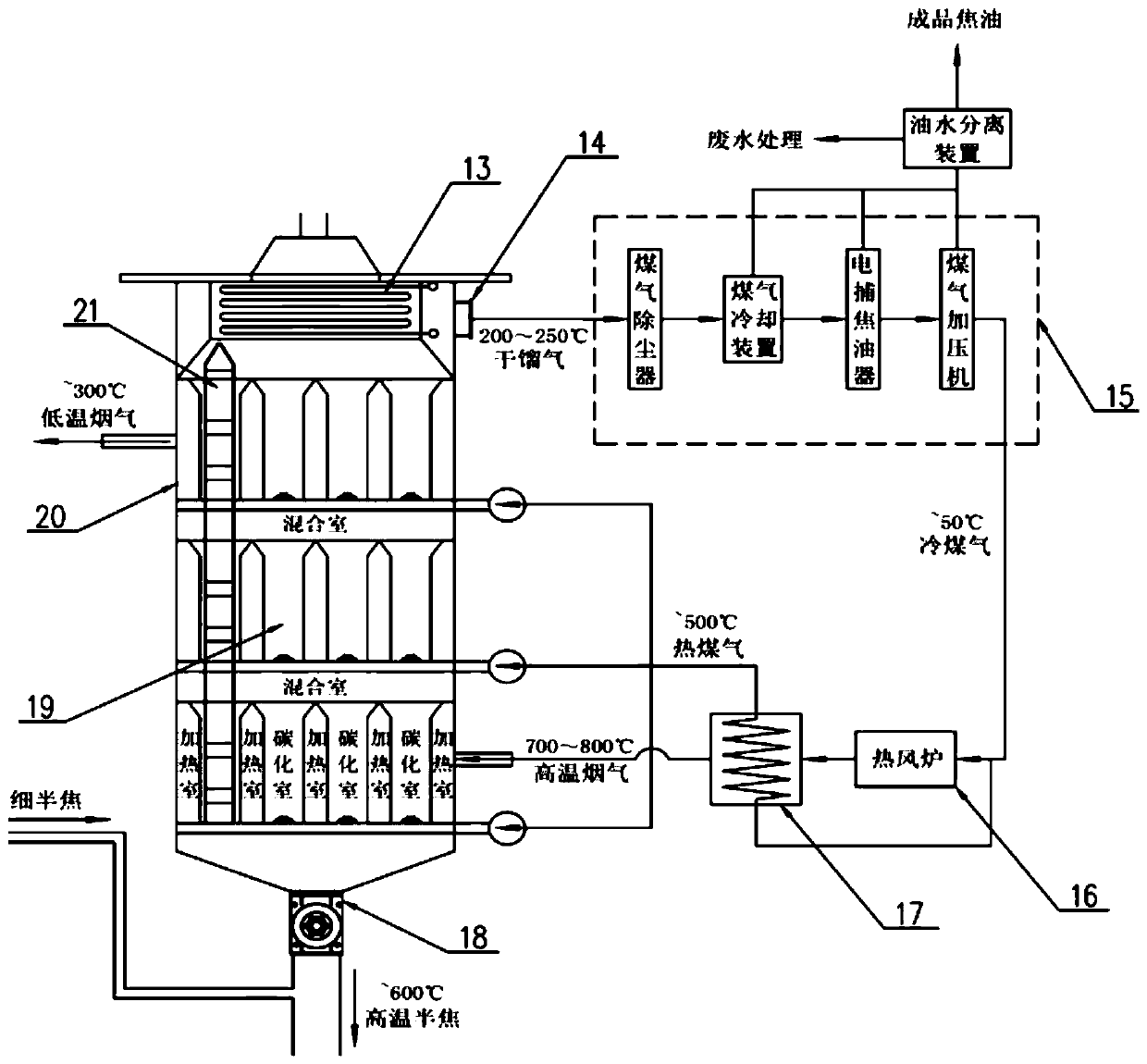

Dual-heat-source low-rank-coal low-temperature-carbonization pyrolysis technology system

PendingCN110117497AIncrease the speed of dry distillation pyrolysisGuaranteed calorific valueIndirect and direct heating destructive distillationEnergy inputCarbonizationNitrogen gas

The invention discloses a dual-heat-source low-rank-coal low-temperature-carbonization pyrolysis technology system. The dual-heat-source low-rank-coal low-temperature-carbonization pyrolysis technology system comprises a fluidized-bed raw-coal drying dehydration device, a low-rank-coal low-temperature-carbonization pyrolysis device, a fluidized-bed semi-coke cooling device, a nitrogen circulatingsystem and a dual-heat-source system; the dual-heat-source system comprises a pyrolysis-coal-gas heat supplying pipe system adopting one part of pyrolysis coal gas generated by the low-rank-coal low-temperature-carbonization pyrolysis device as a first heat source and one part of pyrolysis coal gas generated by the low-rank-coal low-temperature-carbonization pyrolysis device as a second heat source, the pyrolysis coal gas of the first heat source is burned into high-temperature flue gas through a fuel-gas hot air furnace in an external heating mode to become an external heat source of the low-rank-coal low-temperature-carbonization pyrolysis device, and purified pyrolysis coal gas of the second heat source is heated into hot coal gas through a coal gas reheater to directly enter a coal layer of the low-rank-coal low-temperature-carbonization pyrolysis device to participate a carbonization pyrolysis reaction. According to the dual-heat-source low-rank-coal low-temperature-carbonizationpyrolysis technology system, through recycling of waste heat of the technology system, energy consumption is reduced, the purity, a heat value and the coal-carbonization-pyrolysis finished-product recovery rate of output coal gas are increased, and the coking technology wastewater quantity is decreased.

Owner:WUXI YIEN TECH

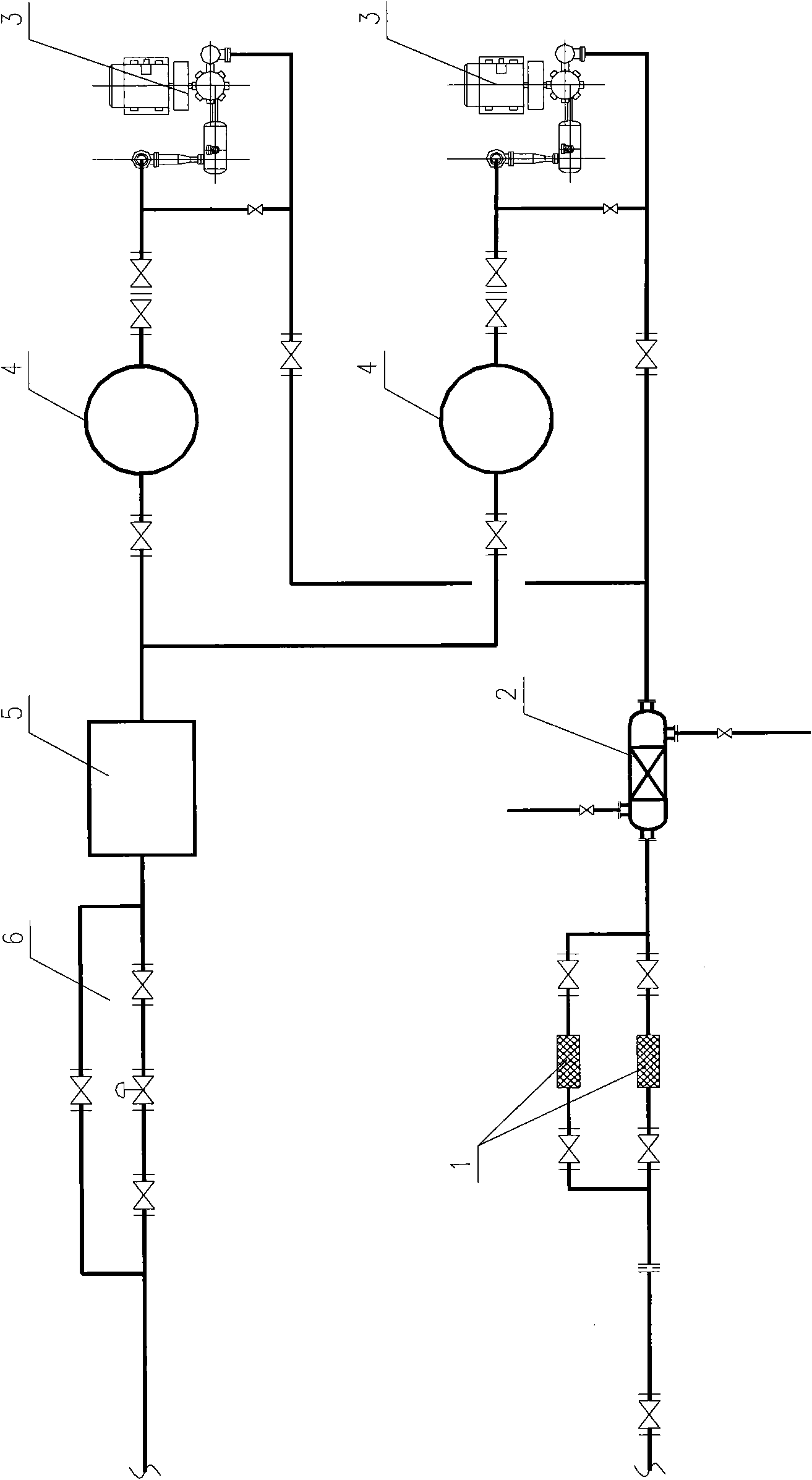

Process for backblowing and deashing through bag-type dust remover by blast furnace dry method

The invention relates to a process for backblowing and deashing through a bag-type dust remover by a blast furnace dry method. The pure blast furnace gas after the dust removal by the bag-type dust remover is used as a gas source to perform backblowing on the bag-type dust remover; and before the backblowing, the pure blast furnace gas after the dust removal by the bag-type dust remover is further deashed by a filter, and then is subjected to steps of temperature reduction, pressurization, dehydration and pressure regulation to meet the requirement of gas required by the bag body backblowing and deashing. The dust removal method of the process reduces requirements on nitrogen in the bag-type dust removal technology, and avoids the problem of bag backblowing caused by unstable pressure and insufficient supply of nitrogen. The process has pollution-free operation, applies temperature swing adsorption, saves energy, reduces emission, simultaneously reduces the consumption of the nitrogen, safely and effectively reduces the cost of a blast furnace gas bag in the operation, and can be mainly applied to the bag-type dust removal of the gas of a large-sized blast furnace.

Owner:BERIS ENG & RES CORP

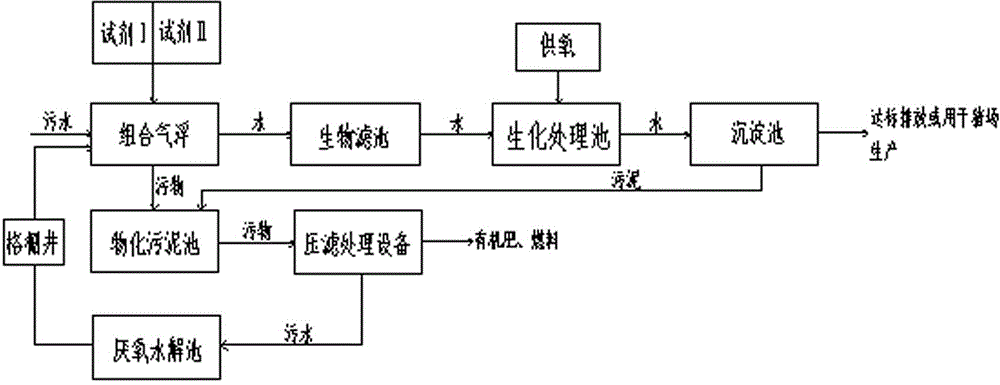

Processing system and processing method for high concentration sewage in pig farm

InactiveCN103601333APromote the development of a virtuous ecological cycleEasy to handleMultistage water/sewage treatmentHigh concentrationPig farms

The invention discloses a processing system and a processing method for high concentration sewage in a pig farm. The processing system for the high concentration sewage in the pig farm comprises combined air flotation, a biological filter and a biochemical processing pool with a spherical membrane therein. The processing method for the high concentration sewage in the pig farm comprises two steps of primary physicochemical treatment and aerobic biochemical treatment. The processing system and the processing method have the beneficial effects that dry dirt can be used as an organic fertilizer to promote benign ecological circle development of pork production and drive optimization and adjustment of agricultural structures; the sewage in the pig farm is treated by the primary physicochemical treatment and the aerobic biochemical treatment, i.e., an A2O+MBBR method, so that expensive treatment cost can be reduced and the method is convenient for popularization; the high concentration sewage in the pig farm can be treated efficiently so as to meet a national discharge standard; recycled water is used for recovering the treated sewage, so that water source is saved; due to the application of an emulsion PAM, the content of organic materials in the sludge is increased while heat value of the sewage is kept; objects of sludge reduction and harmless treatment can be achieved; a sustainable development road is reserved for sludge resources; and paths of biochemical sludge utilization are broadened.

Owner:HAIMEN SHENHAO ECOLOGICAL AGRI

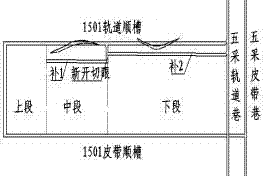

Complex geological condition fully-mechanized working face split-close type fault crossing method

InactiveCN107060759AReduce the degree of impactImprove resource recoveryUnderground miningSurface miningResource recoveryCoal

The invention provides a complex geological condition fully-mechanized working face spilt-close type fault crossing method, and relates to the field of coal mine production. The method comprises the steps: (1) building a roadway and bypassing a fault at the location near a track trough before the production of a working face; (2) removing equipment of a shrinking face when an upper working face is advanced to the fault while backstopping; (3) installing equipment at a new cut hole; (4) closing the face of the working face. According to the technical scheme, the method has the advantages that a guarantee is provided for the comprehensive and efficient advancement of the fully-mechanized working face; the coal resource recovery rate is increased; the additional construction costs of the moving expenses are reduced; the damage of the working face equipment caused by crossing fault is avoided; the coal heating value is ensured; the economic efficiency is improved; the practicality is good.

Owner:SHANDONG DONGSHAN XINYI COAL MINE CO LTD

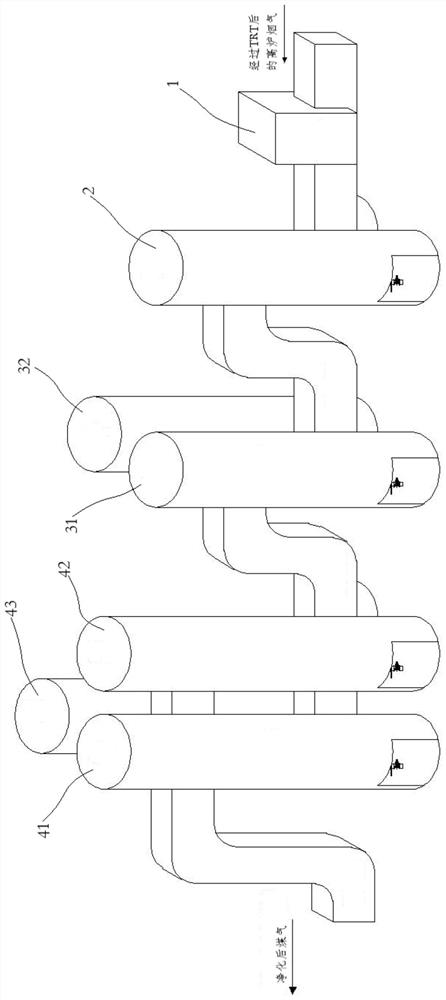

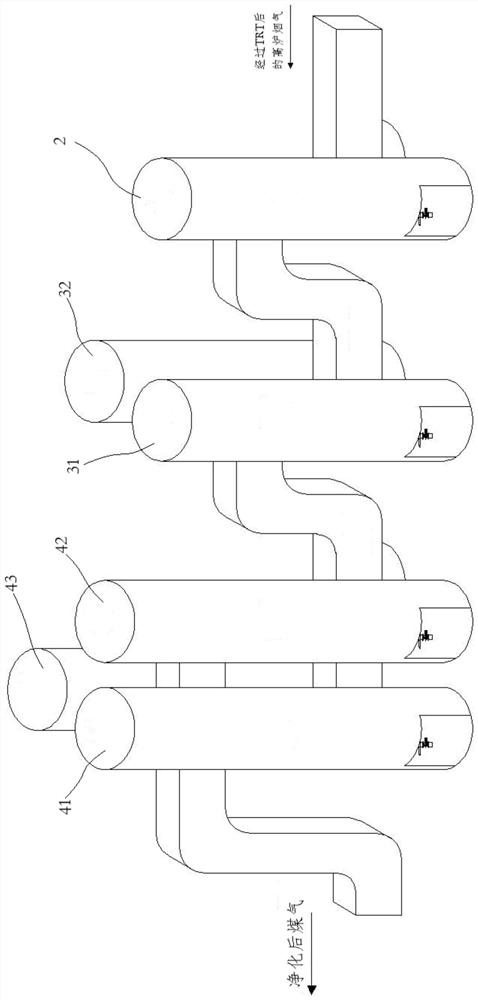

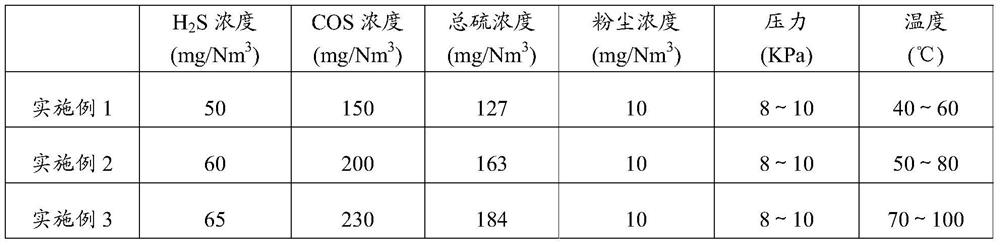

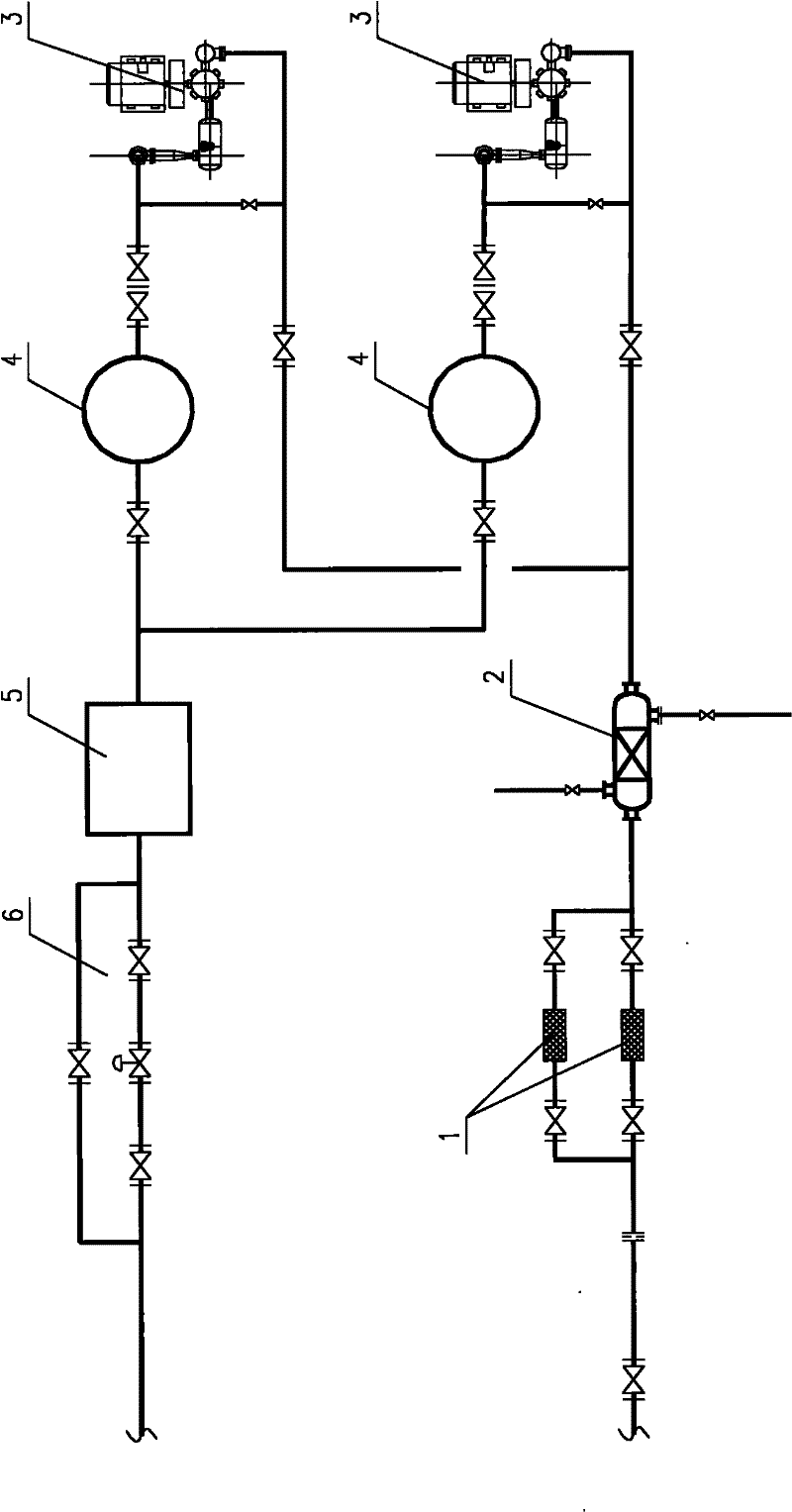

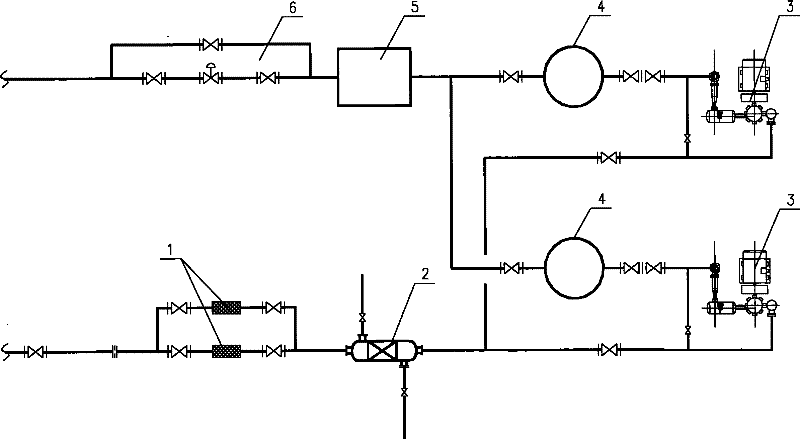

Blast furnace gas desulfurization process

PendingCN113372965AGuaranteed calorific valueReduce acidic and corrosive substancesGas purification by catalytic conversionGas contaminants removalPtru catalystHydrolysis

The invention discloses a blast furnace gas desulfurization process. The blast furnace gas desulfurization process comprises the following steps: (1) to-be-treated blast furnace gas passing through a TRT or a pressure regulating valve group passes through a pretreatment reactor to remove acidic corrosives so as to form pretreated gas, wherein a calcium-based absorbent serving as a pretreating agent is arranged in the pretreatment reactor, and the temperature of the blast furnace gas to be treated is 70-120 DEG C; (2) enabling the pretreated coal gas to pass through a hydrolysis tower, and converting organic sulfur into hydrogen sulfide to form hydrolyzed coal gas, wherein an alumina-based hydrolysis catalyst is arranged in the hydrolysis tower; and (3) enabling the hydrolyzed coal gas to pass through a desulfurization reactor to form purified coal gas; wherein the desulfurization reactor is filled with an iron oxide absorbent. According to the process, the desulfurization efficiency can be improved on the premise of reducing equipment corrosion.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

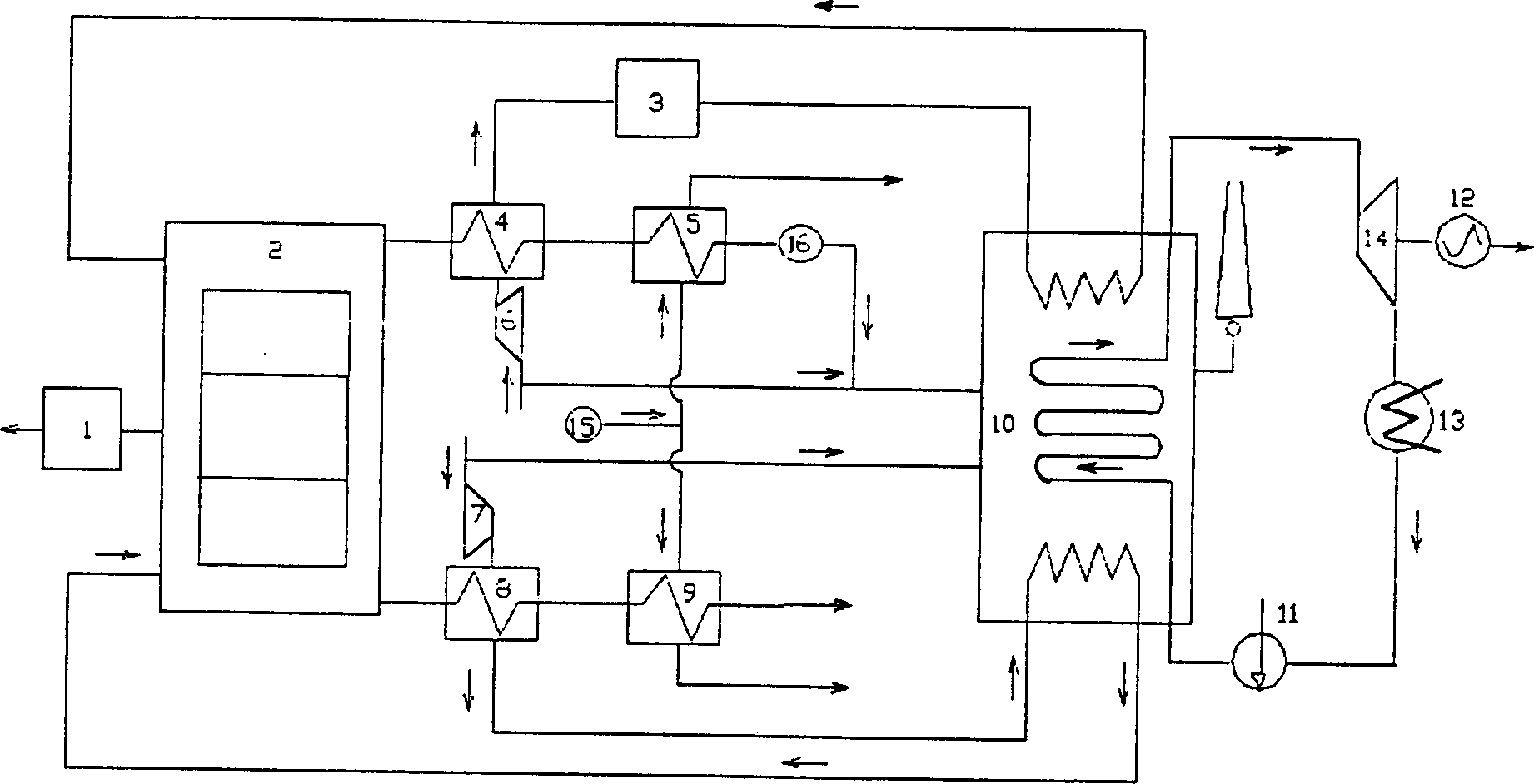

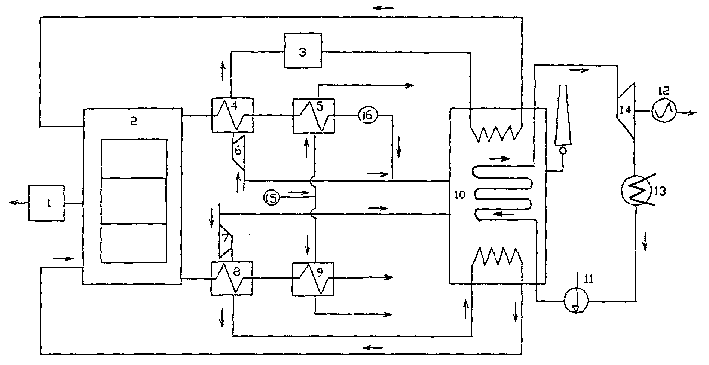

Electric generation system combining solid oxide fuel battery with turbogenerator

InactiveCN1151575CIncrease temperatureGuaranteed calorific valueFuel cell heat exchangeGas turbine plantsElectrochemical responseEngineering

A solid oxide fuel cell and steam turbine combined generating system uses a jointly circulated generating mode with solid oxide fuel cells and steam turbine, among which after the fuel gas is boosted by a fuel-gas fan, heated by a heat-exchanger, and desulfurized by a desulfurizer, it is sent to a steam boiler to be preheated, then to the fuel cell anode for electrochemical reaction, the electric energy generated is sent to the users via outdoor circuit. The exhaust from the anode is sent to the heat exchanger for fuel preheating and water supply, then to the steam boiler via carbon dioxide removal device to be burnt together with part of natural gas to heat water to generate high-temperature and high-pressure steam to push the steam turbine to rotating and drive the generator to generate electric energy.

Owner:SHANGHAI JIAO TONG UNIV

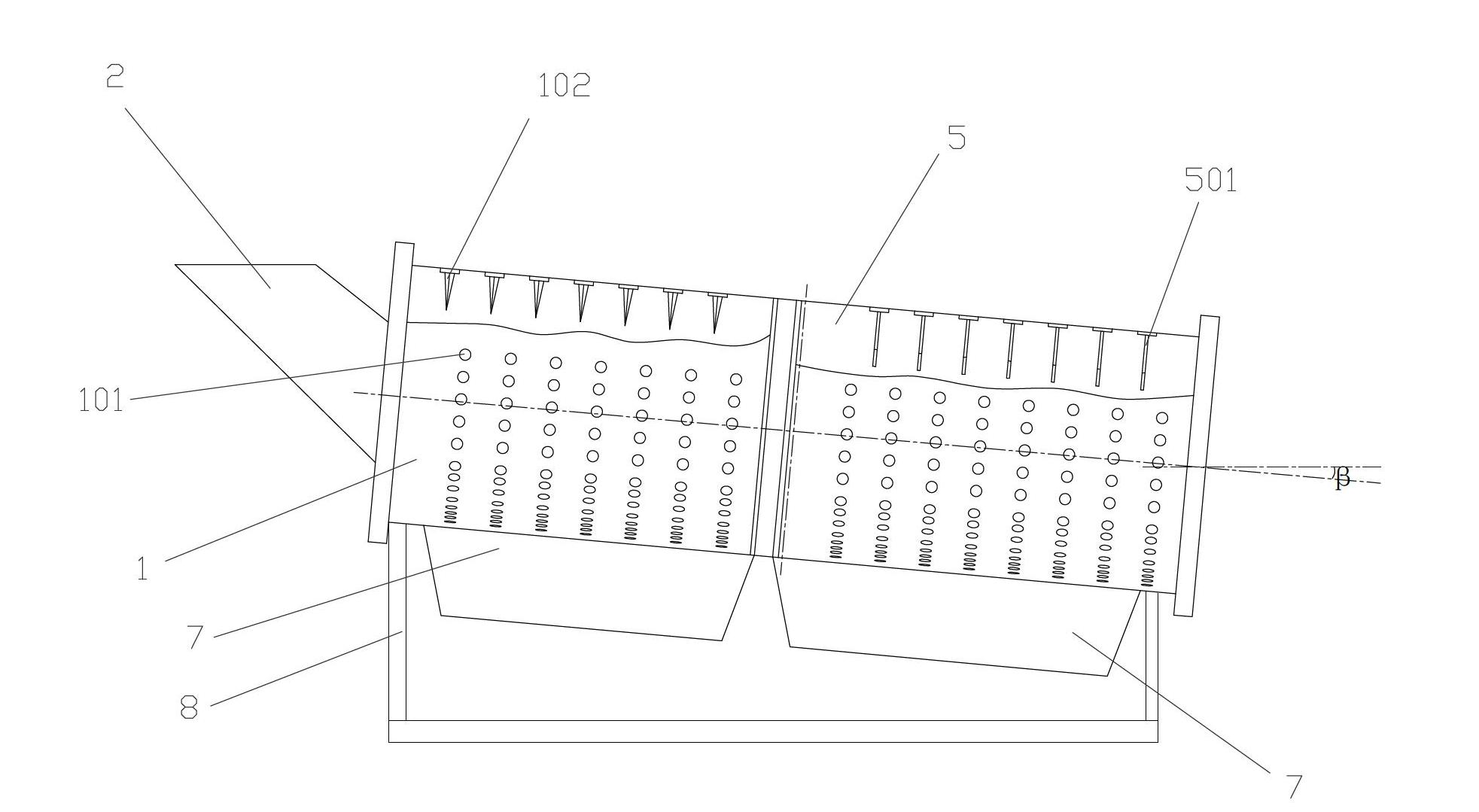

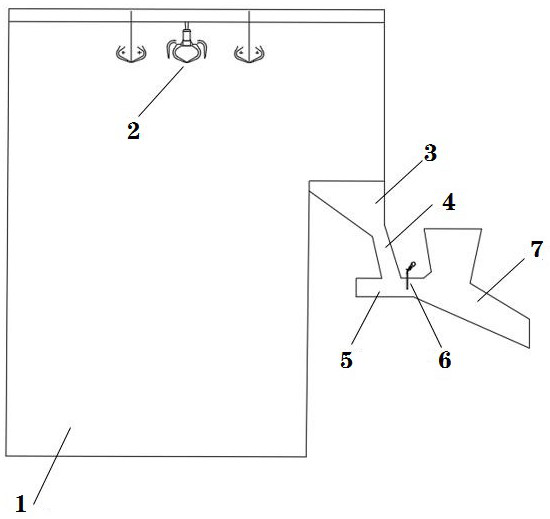

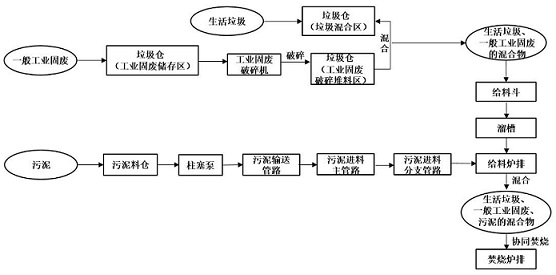

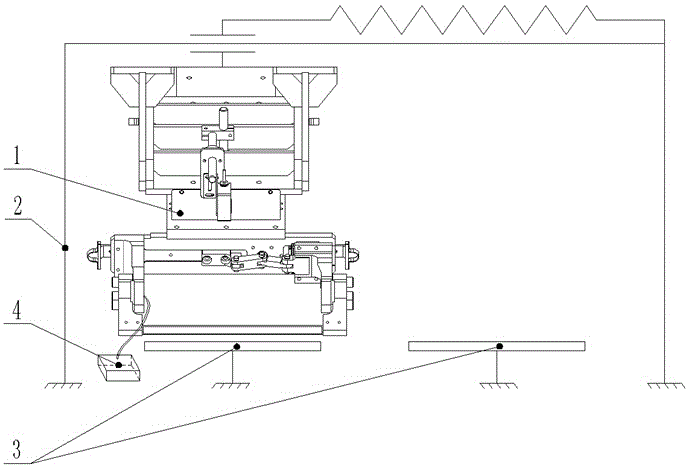

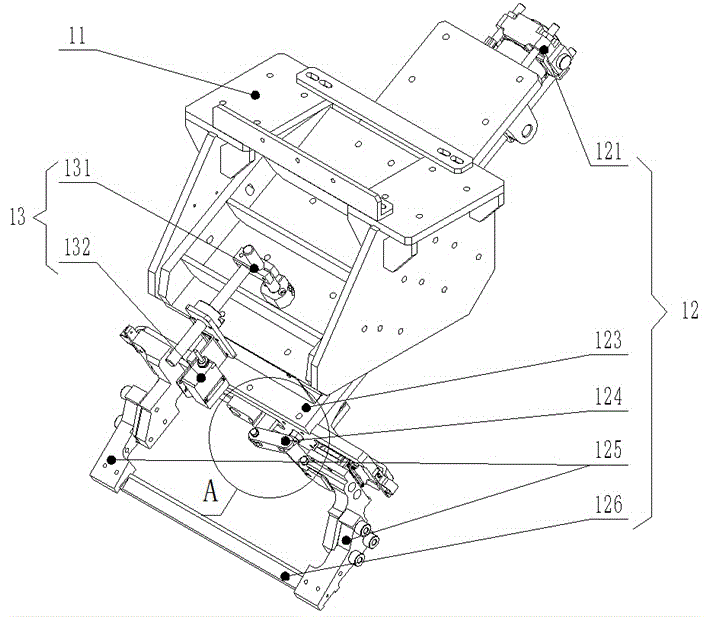

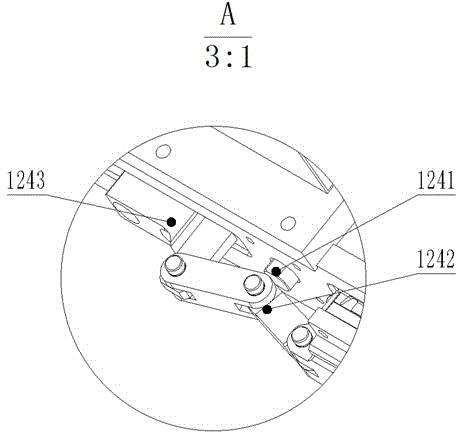

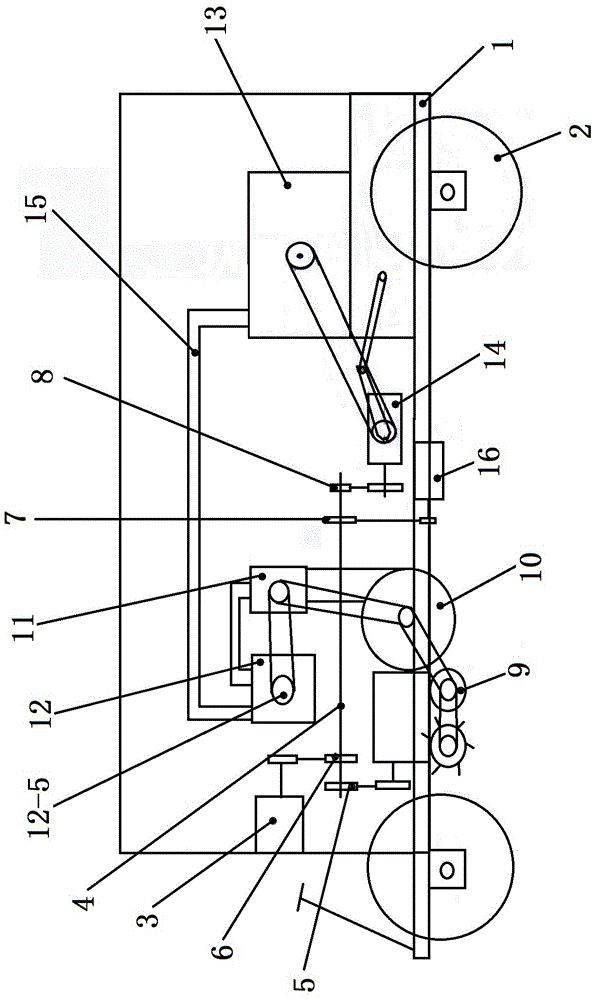

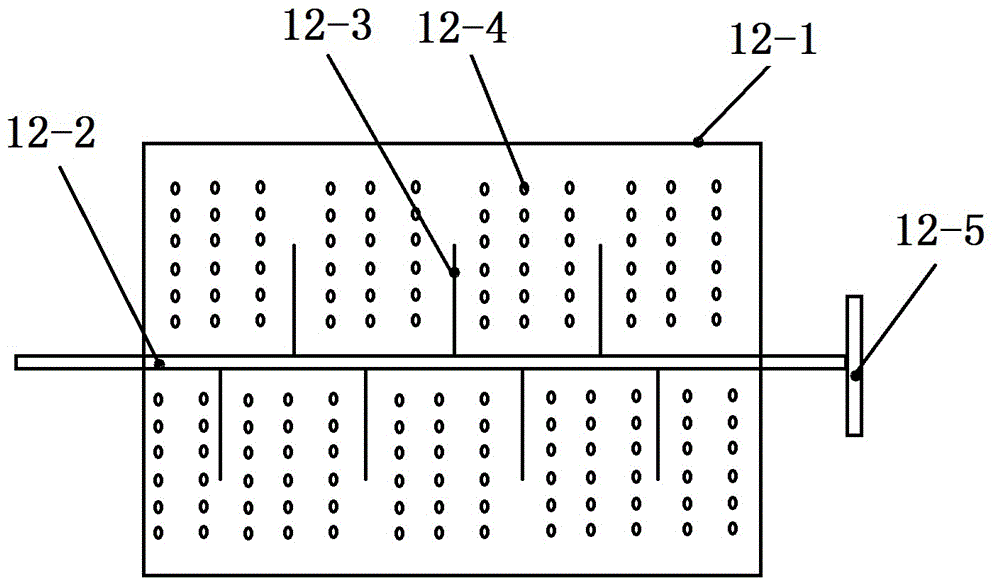

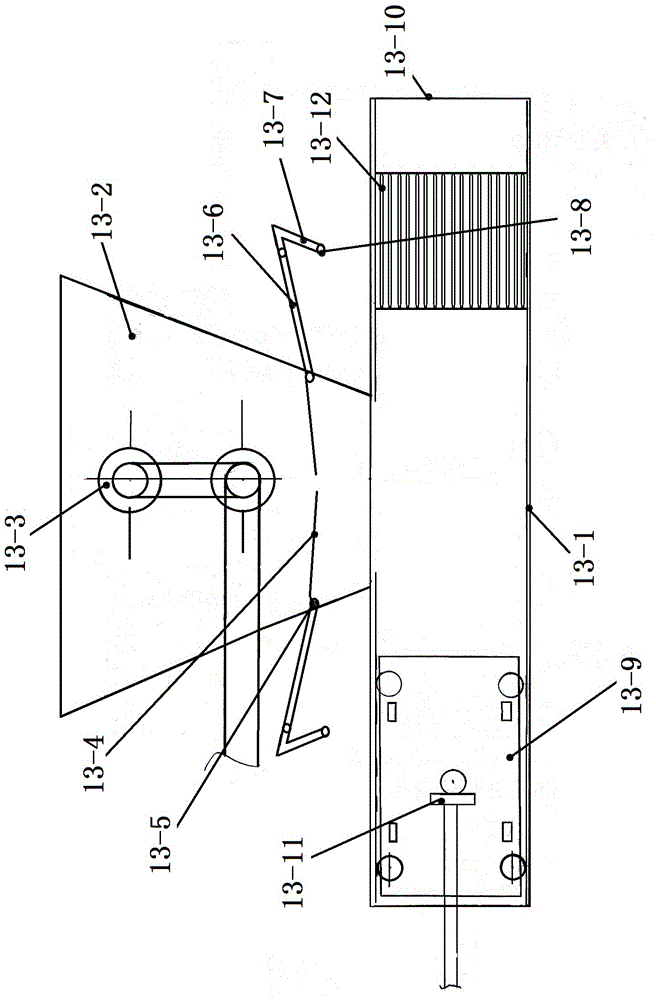

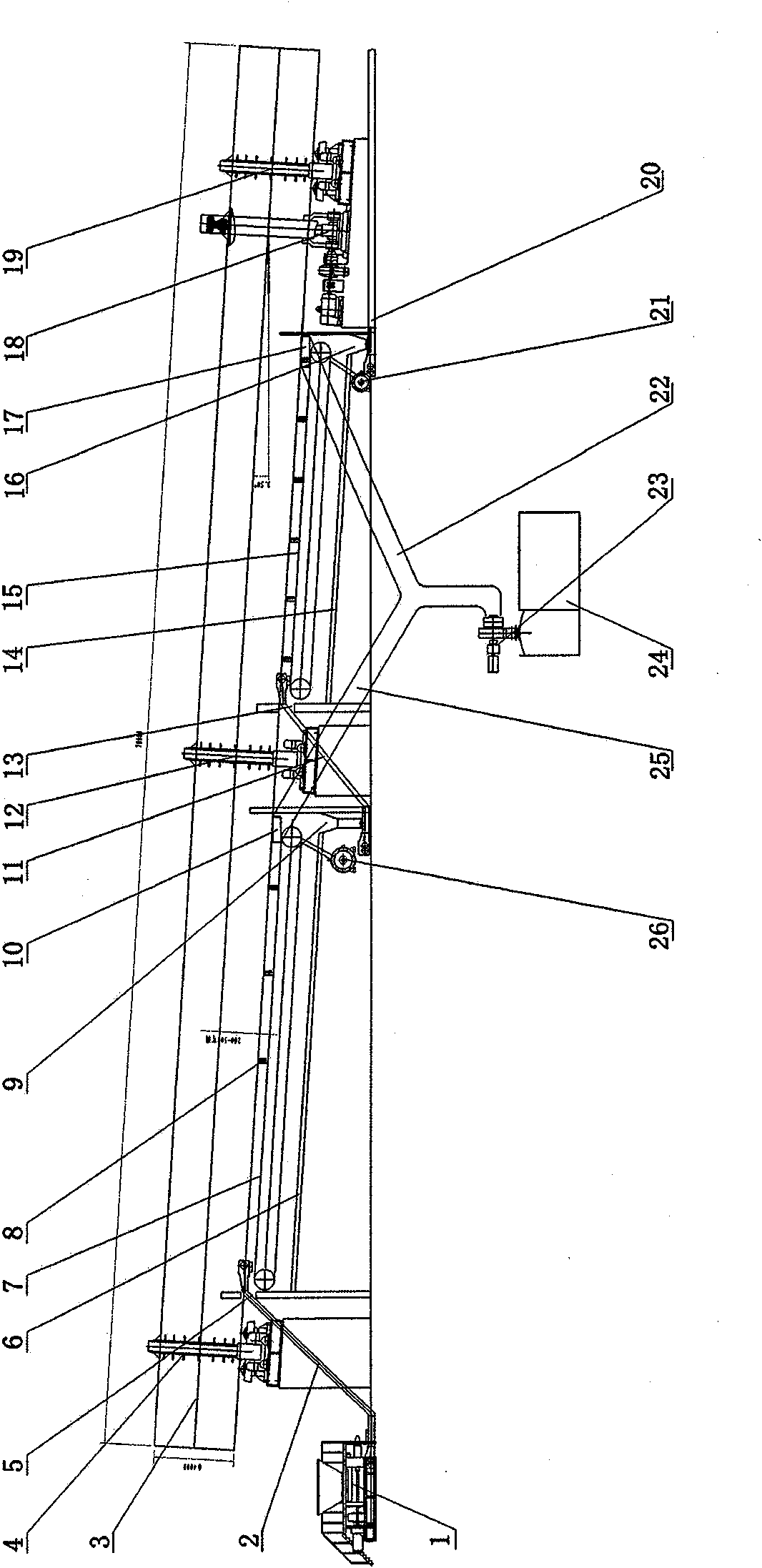

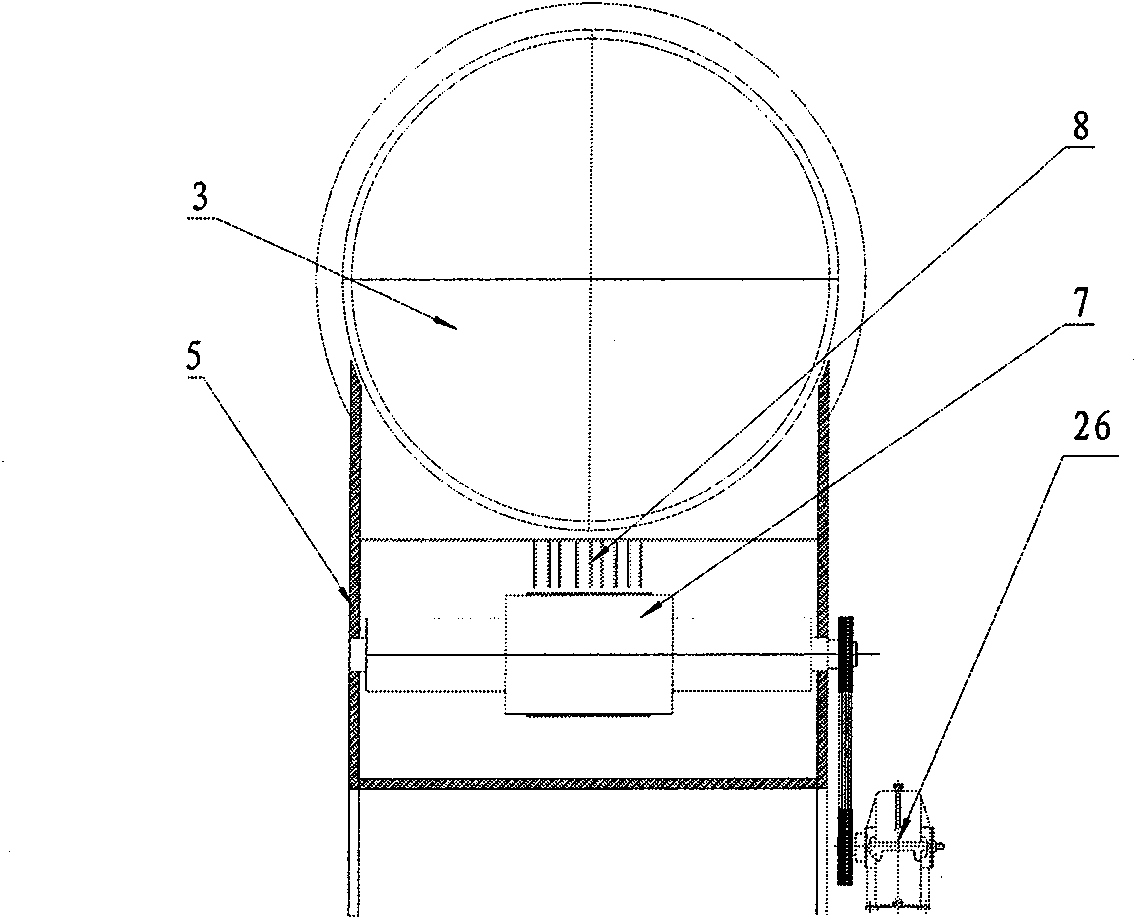

Feeding system for collaborative incineration of household garbage, general industrial solid waste and sludge

PendingCN113339809AWell mixedAvoid uneven calorific valueIncinerator apparatusSludgeRefuse Disposals

The invention discloses a feeding system for collaborative incineration of household garbage, general industrial solid waste and sludge, and belongs to the technical field of garbage treatment. The feeding system comprises a garbage bin, a garbage grab bucket, a feeding hopper, a chute, a feeding fire grate, a sludge feeding pipeline and an incinerator fire grate, wherein the garbage grab bucket is arranged at the top of the garbage bin; the top of the feeding hopper is communicated with the garbage bin; the bottom of the feeding hopper is communicated with the chute; the feeding fire grate is arranged at the bottom of the chute; the sludge feeding pipeline is arranged above the feeding fire grate; an inlet of the incinerator fire grate is communicated with an outlet of the feeding fire grate; an industrial solid waste storage area, an industrial solid waste crushing area, an industrial solid waste crushing and stacking area and a garbage mixing area are sequentially arranged in the garbage bin; an industrial solid waste crusher is arranged in the industrial solid waste crushing area; and a sliding way is arranged at the bottom of the industrial solid waste crusher and used for conveying crushed general industrial solid waste to the industrial solid waste crushing and stacking area. According to the feeding system, the three wastes can be uniformly mixed, and stable combustion is promoted.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD +2

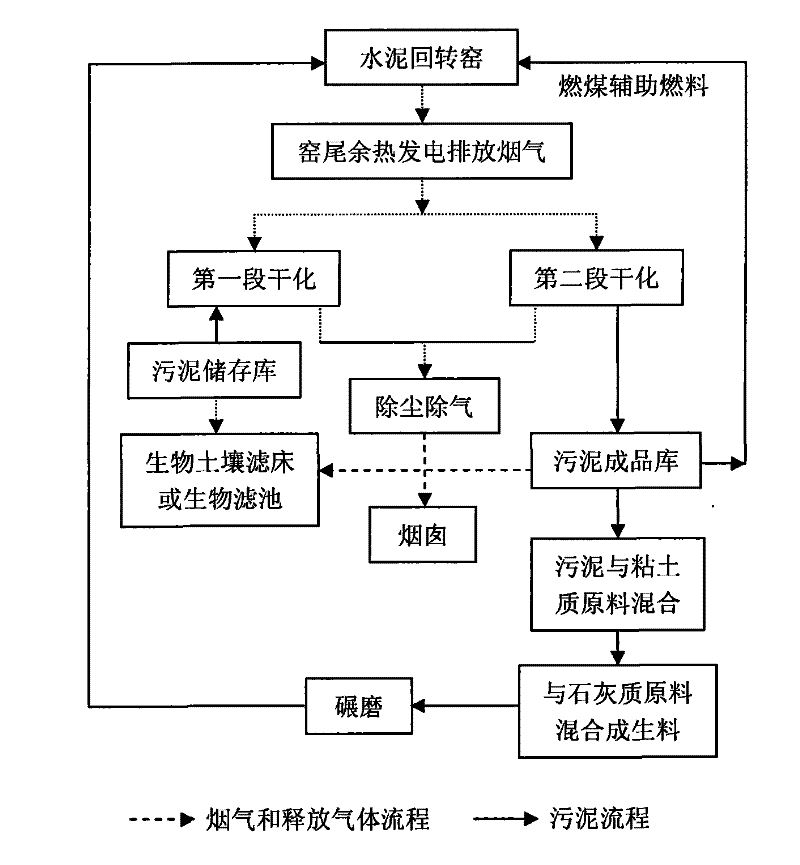

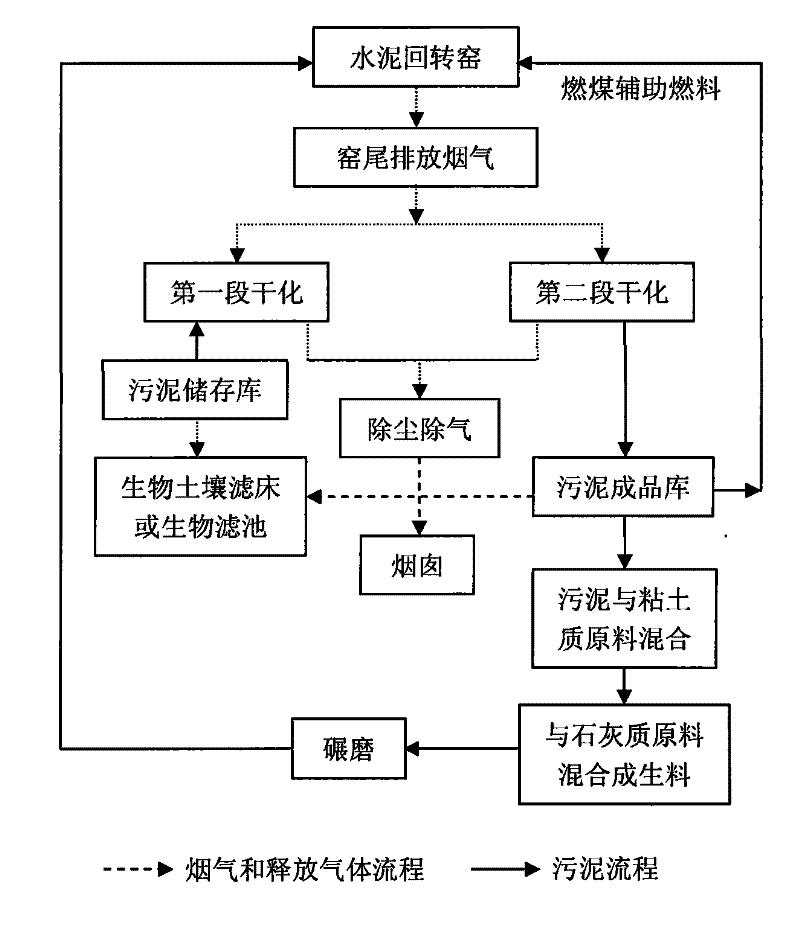

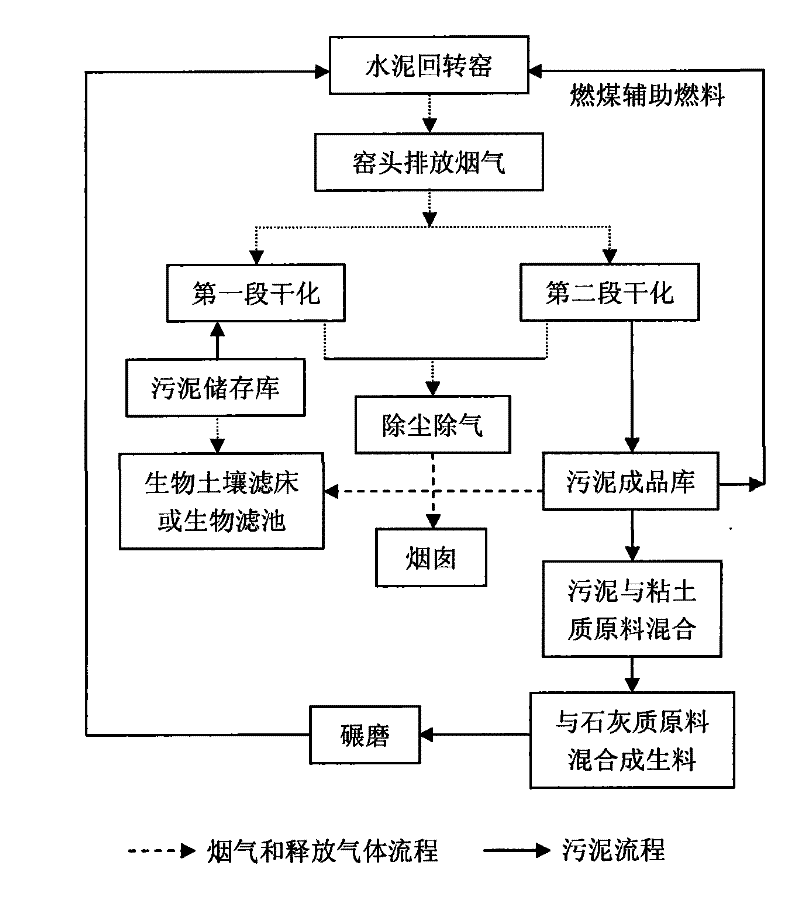

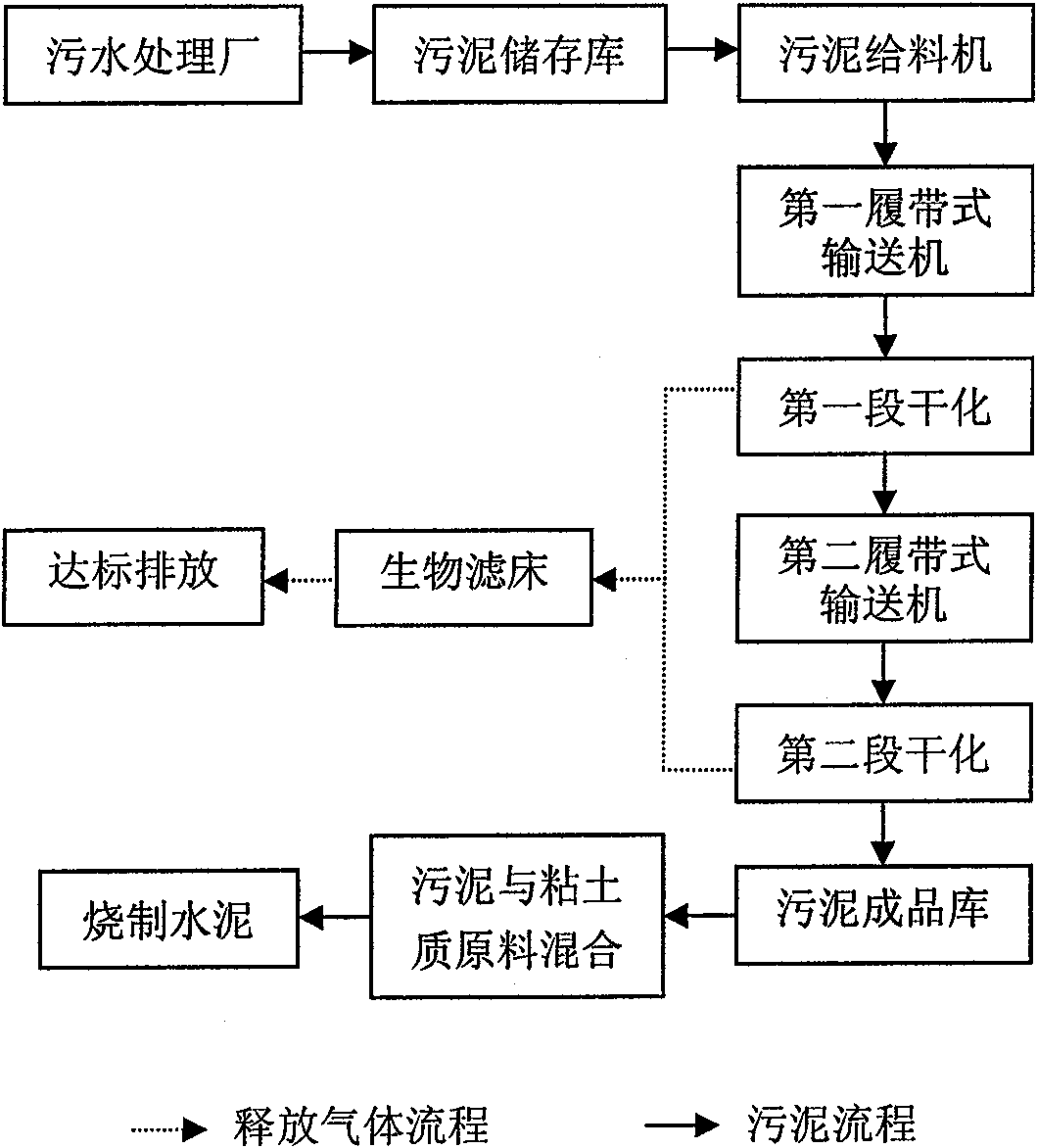

Method for utilizing fume afterheat of cement plant to heat-dry sludge and prepare cement by firing sludge

ActiveCN101643307BReduce moisture contentWill not affect normal operationSludge treatment by de-watering/drying/thickeningCement productionEnvironmental effectSludge

The invention discloses a method for utilizing fume afterheat of a cement plant to heat-dry sludge and prepares cement by firing sludge. The method comprises the following steps of: respectively sending the fume afterheat discharged by a cement rotary kiln to a first sludge drying and granulating device and a second sludge drying and granulating device, for purpose of two-stage sludge drying; 2) stacking urban sludge in a sludge storage warehouse and carrying out pretreatment prior to the drying; 3) using a component-type feeder to send the pretreated sludge into the first sludge drying and granulating device, for purpose of first-stage sludge drying; 4) using a conveyor to send the sludge after the first-stage sludge drying into the second sludge drying and granulating device, for purpose of second-stage sludge drying; and 5) mixing the sludge subject to two-stage sludge drying with clay and lime material to form raw material, and obtaining the cement by grinding, calcining, cooling and powdering the raw material. In the method, waster materials are used for treating waster materials, so that the urban sludge is harmlessly treated and recycled, and remarkable social and environmental effects can be generated.

Owner:杭州新源环境工程有限公司

Micro-mist dust suppression method based on coal cutter cutting dust sources

ActiveCN111101938AImprove the effect of dust suppressionStrong targetingSlitting machinesThermodynamicsMechanical engineering

The invention relates to a micro-mist dust suppression method based on coal cutter cutting dust sources. Coal cutter cutting dust generation is divided into four different dust sources, and differentmist spraying modules are installed at corresponding positions of a coal cutter to conduct dust suppression on the dust sources. Mist fluid is sprayed by the mist spraying modules, and according to atomization parameters, the mist spraying amount and the dust concentration, particle size distribution, dispersion degree and dust generation amount of dust generated by different dust sources, a dustsource area is misted, so that the dust generated by coal cutter cutting is collided with mist drops of the mist fluid, coagulated and captured and settles in the initial state, and the capacity of capturing inhalable dust with the particle size of 10 micron or below is especially improved. The method fully considers a body structure, movement features and use conditions of the coal cutter, and adesigned dust suppression system has a certain anti-smashing performance and is reliable in use and convenient to maintain.

Owner:北京中矿兴宝环保科技有限公司

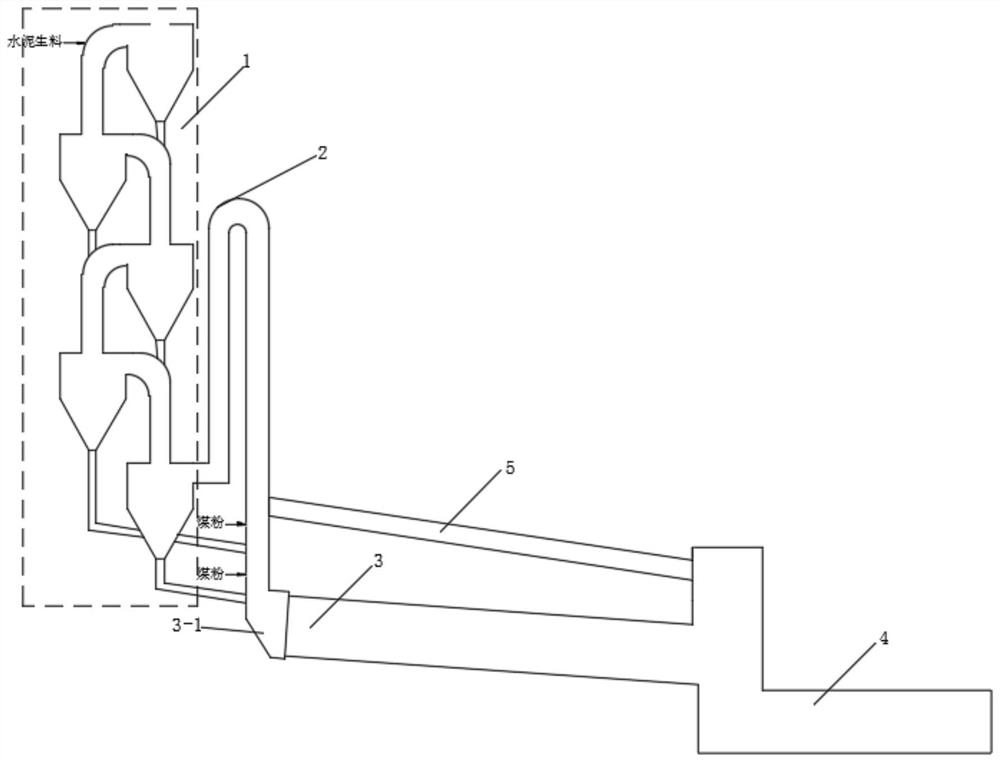

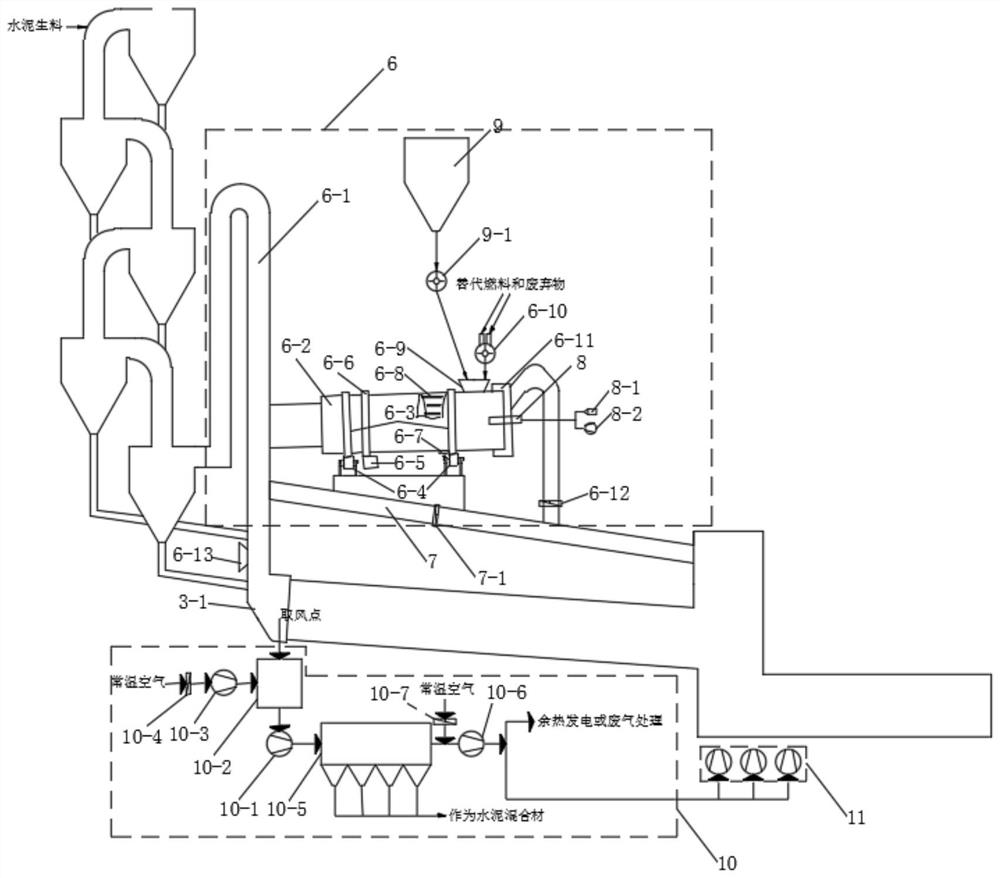

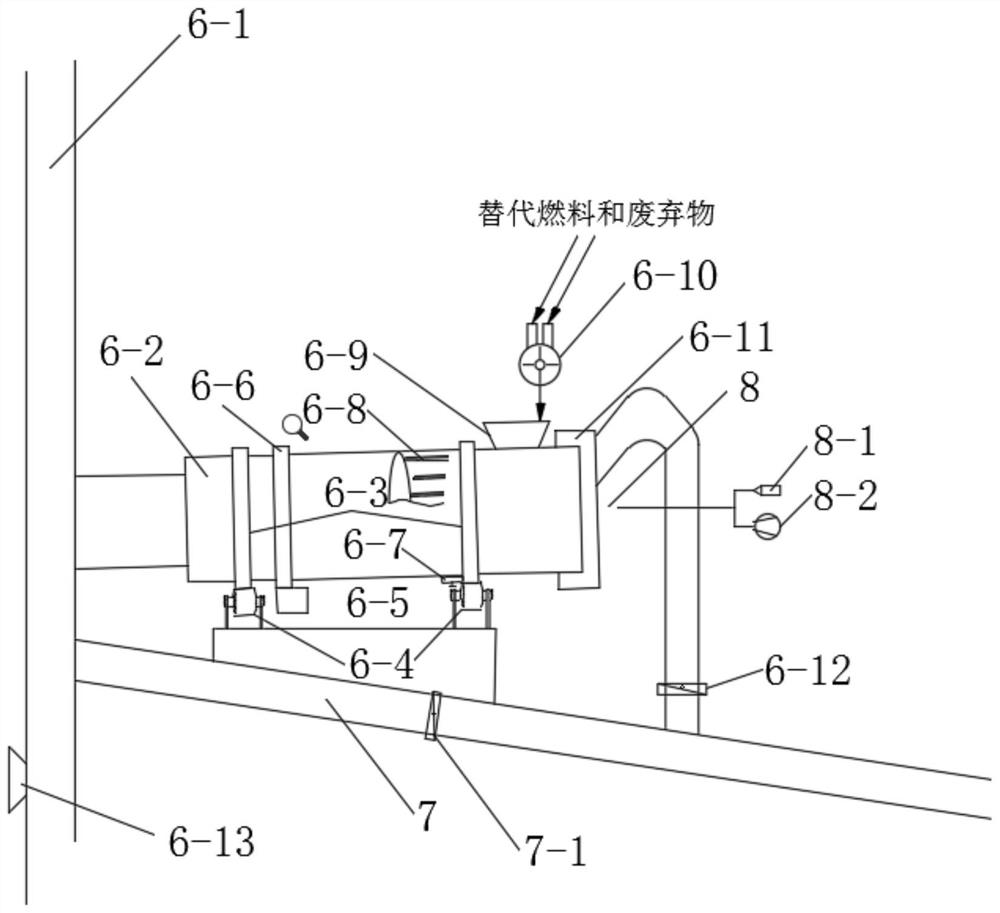

Cement raw material decomposition system using alternative fuel

PendingCN114216336AEasy disposalReduce use costFurnace typesWaste heat treatmentProcess engineeringAlternative fuels

The invention discloses a cement raw material decomposition system using alternative fuel. The cement raw material decomposition system comprises a cement raw material decomposition reactor and a rotary drum type reactor mounted on the cement raw material decomposition reactor, the rotary drum type reactor is respectively communicated with a decomposition reactor on the cement raw material decomposition reactor and a tertiary air pipe; the rotary drum type reactor comprises a rotating mechanism rotationally connected with the decomposition reactor, a supporting mechanism is fixedly installed on the tertiary air pipe and is in contact connection with the rotating mechanism, the supporting mechanism is fixedly connected with a transmission mechanism, the transmission mechanism is in transmission connection with the rotating mechanism, and the rotating mechanism is rotationally connected with a feeding mechanism. And the feeding mechanism is fixedly connected with the tertiary air pipe. According to the method, under the conditions that the sources of the alternative fuel and the waste are unstable and the homogenization effect cannot be effectively guaranteed in the pretreatment process, the waste can be reliably, safely and conveniently treated and the alternative fuel can be effectively used under the condition that the production is not influenced.

Owner:KHD洪堡威达克有限公司

Double-station electric heating cutter device for materials

The present invention discloses a double-station electric heating cutter device for materials. The double-station electric heating cutter device comprises an electric heating cutter device body, a portal frame, double-station workbenches and an electric heating control component, wherein the electric heating cutter device body is connected to the portal frame in a sliding manner; the double-station workbenches are arranged under the portal frame; the electric heating control component is connected to the electric heating cutter device body through a circuit; an electric heating cutter mechanism in the electric heating cutter device body is fixed under a connecting support, so that the cutting operation can be achieved through an actuating cylinder; an electric heating knife rest connected to a cutter can be used for instant heating, so that the cutter can reach a high temperature within a short time in order to facilitate cutting of soft materials; a temperature sensor fixedly connected to an upper part of the connecting support can feed the actual temperature of the cutter back, so that the cutting action of the actuating cylinder is controlled; and the electric heating cutter device body can be switched between the double-station workbenches. The double-station electric heating cutter device has the advantages of simple structure, high production efficiency and capability of achieving automation of a cutting process.

Owner:DINGHAN TECH XIAMEN

Machine integrating straw picking, soil dust removing and straw processing

The invention relates to a machine integrating straw picking, soil dust removing and straw processing and mainly aims to solve the problem that an existing straw picking and processing machine cannot remove soil dust. The machine comprises a frame, wheels, an engine and a transmission shaft, wherein the sprocket of the engine is connected with a second sprocket through a chain, a first sprocket is connected with the sprocket of a picker through a chain, the sprocket of the picker is connected with one sprocket of a straw cutter through a chain, and the other sprocket of the straw cutter is connected with one sprocket of a rubbing machine through a chain; the spindle of a dust remover is provided with centrifugal teeth, the cylinder of the dust remover is provided with dust removing holes, and the sprocket of the dust remover is connected with the other sprocket of the rubbing machine through a chain; a third sprocket is connected with the sprocket of a gearbox through a chain, and a fourth sprocket is connected with the sprocket of a rocker reducer through a chain; a packaging machine comprises a shell, a stirring roller and a turning plate are arranged in a hopper, the turning plate is connected with a pull rod, the sprocket of the rocker reducer is connected with the sprocket of the stirring roller through a chain, and a corrugated box connected with a rocker is connected with a pulley. The machine can remove soil dust during straw processing.

Owner:LIAOYANG YONGFU NEW AGRI MACHINERY CO LTD

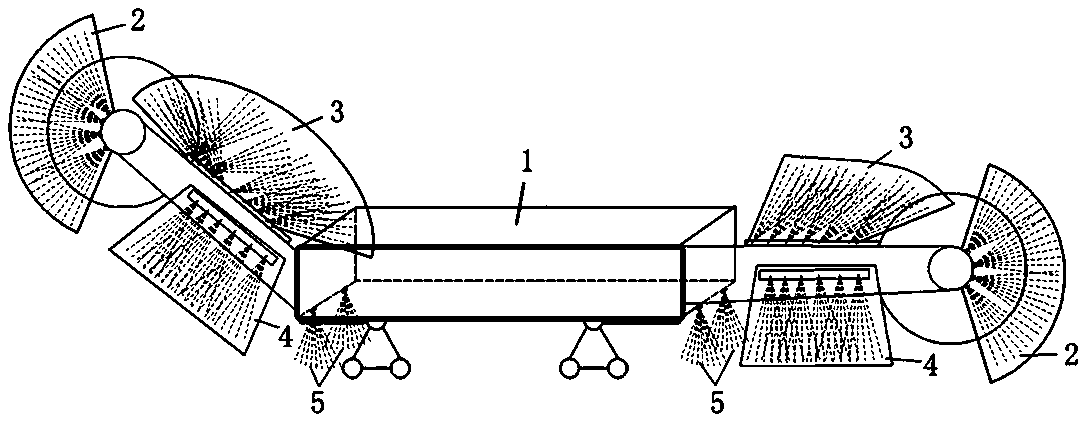

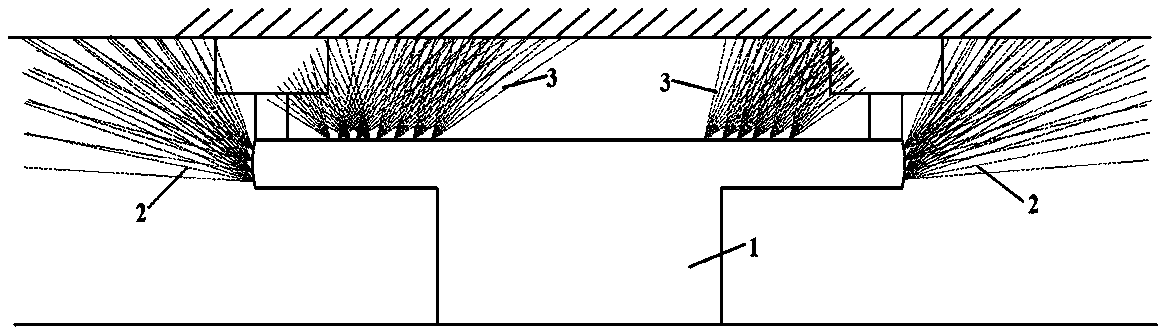

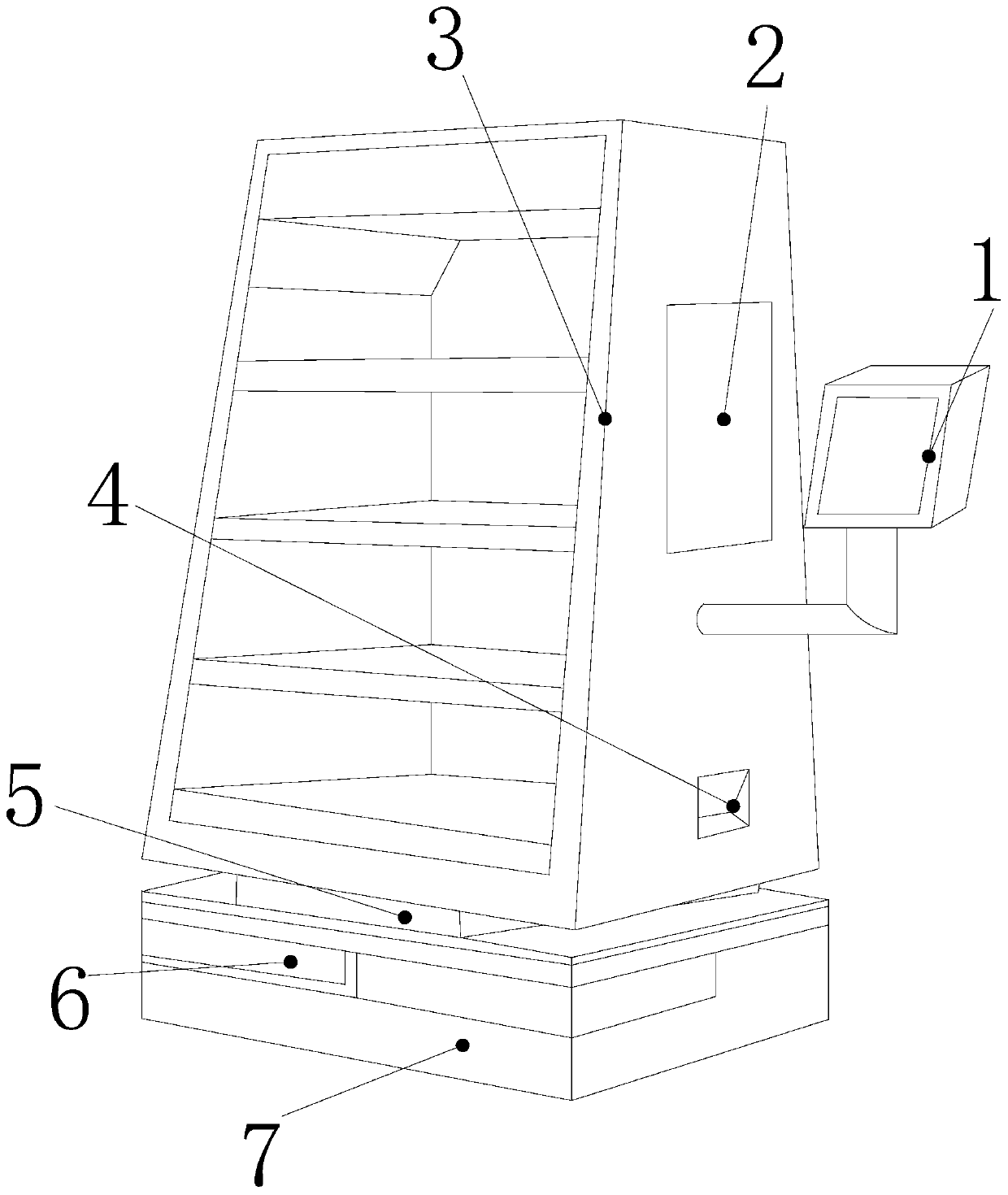

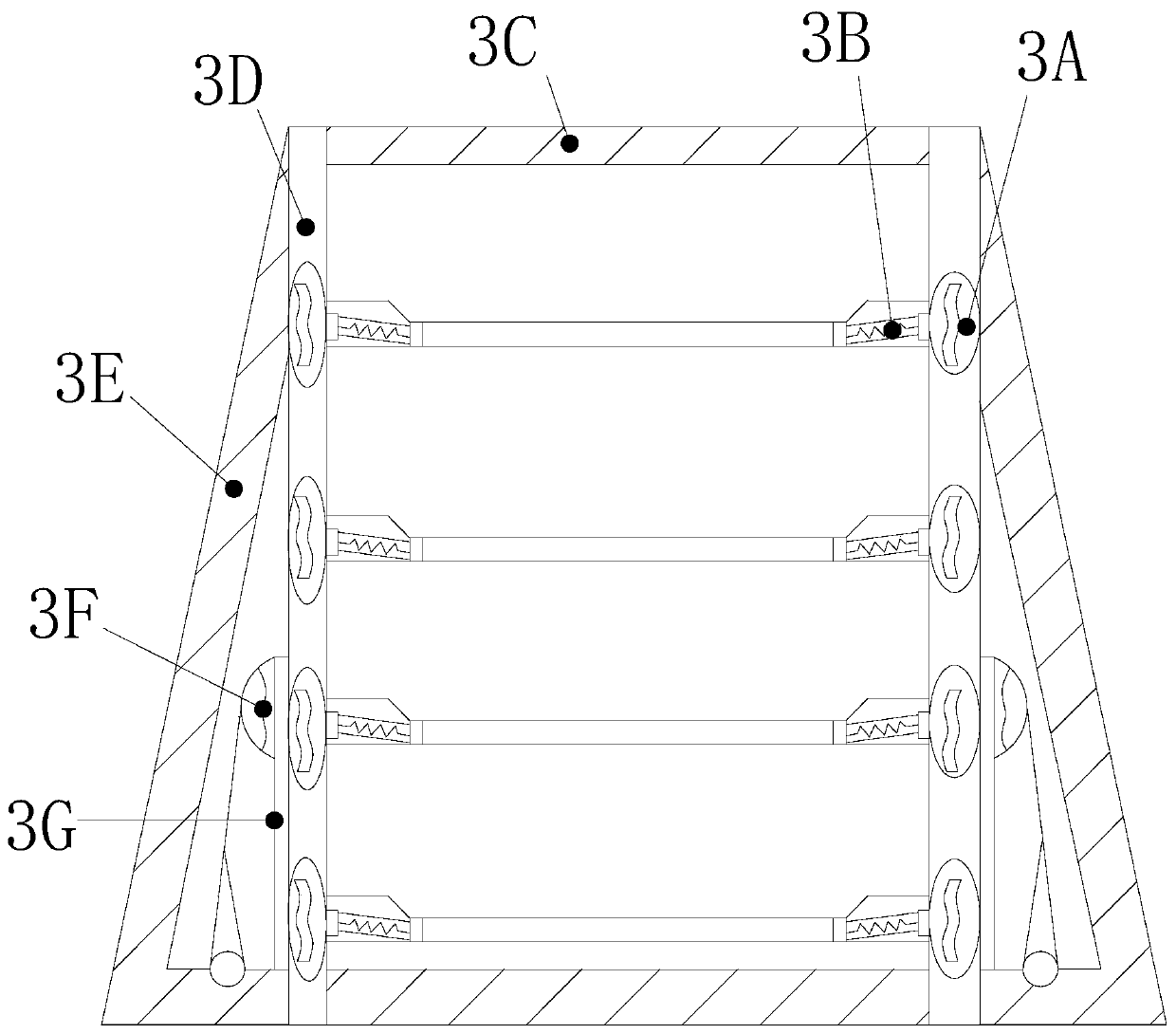

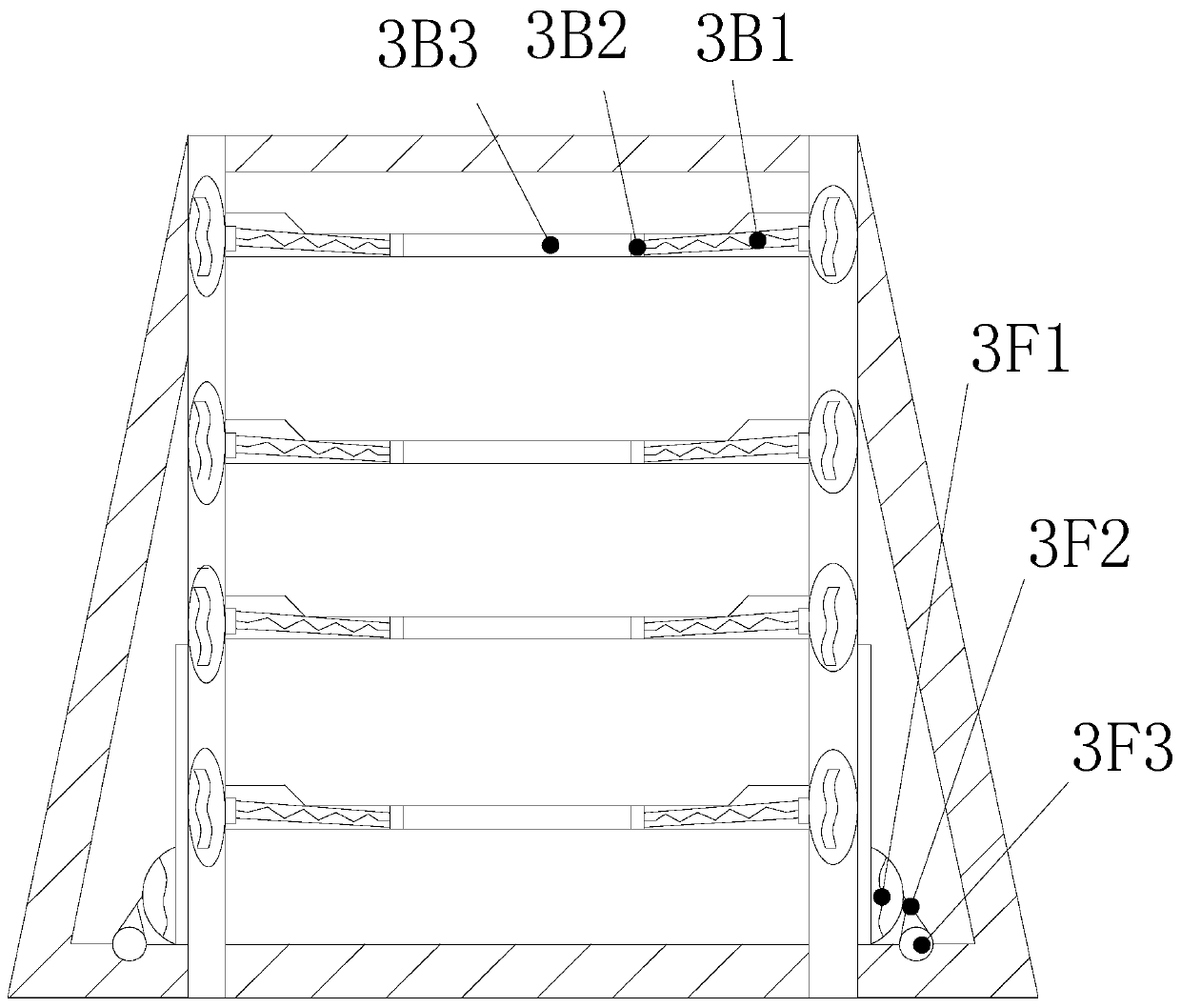

System for drying sludge by utilizing radiation heat of rotary cement kiln

InactiveCN101671105AReduce moisture contentTake advantage ofSludge treatment by de-watering/drying/thickeningSludgeBiological filter

The invention discloses a system for drying sludge by utilizing radiation heat of a rotary cement kiln, comprising a sludge feeder, a first scraper conveyor, a second scraper conveyor, a rotary cementkiln, a first closed box, a second closed box, a first closed box feed port, a second closed box feed port, a first tracked conveyor, a second tracked conveyor, a fixed rolling toothed harrow, a first closed box discharge port, a second closed box discharge port, a first ventilation opening, a second ventilation opening, a first ventilation pipe, a second ventilation pipe, a discharge conveyor, afirst transmission device, a second transmission device, an exhaust fan, a biological filter and the like. The system for drying sludge by utilizing radiation heat of a rotary cement kiln can dry sludge under the condition of low temperature by utilizing the radiation heat of the rotary cement kiln, thereby keeping the original calorific value of the sludge; and the dried sludge is used as the auxiliary material of cement, and can contribute calorific value during cement burning, so that not only the sludge in urban sewage treatment factories and river and lake dredging sludge can be thoroughly treated, but also the heat energy resource of the sludge can be largely utilized.

Owner:ZHEJIANG UNIV

Intelligent management system for step-by-step settlement of recursively racking plates in campus canteen

ActiveCN110428558ALighten the mental loadWork lessCash registersApparatus for meter-controlled dispensingHealthy dietResting time

The invention discloses an intelligent management system for step-by-step settlement of recursively racking plates in a campus canteen, and the structure of the system comprises a man-machine interface station, an observation window, a microwave recursive rack, a hand-pull catching groove, an electronic bearing seat, a digital display tube and a buffer base. The intelligent management system provided by the invention realizes the effect of forming weighting step-by-step recursively rising settlement and meal-taking through the cooperation of the man-machine interface station and the microwaverecursive rack, realizes data feedback accurate settlement, reduces works with mental load and prolonged physical exertion, ensures people's rest time and settlement comfort by humanized substitutionof intelligent equipment, realizes the effect of simultaneously placing five or six plates in the front of the queue on the traying bracket for the students to provide a break time for the students who holds the plates for a long time. At the same time, since the chilled meals can be microwaved within the rack for output, the students can rest their arm muscles to maintain the tendon of the biceps, and healthy diet of hot meals is provided for the students after the settlement to promote the development.

Owner:义乌市嘉诗电子科技有限公司

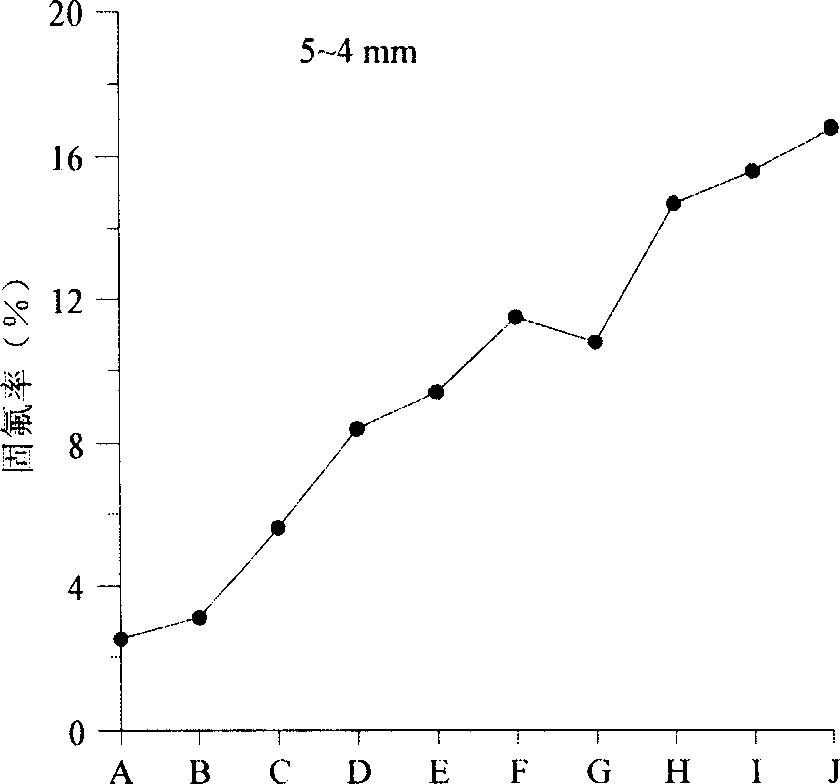

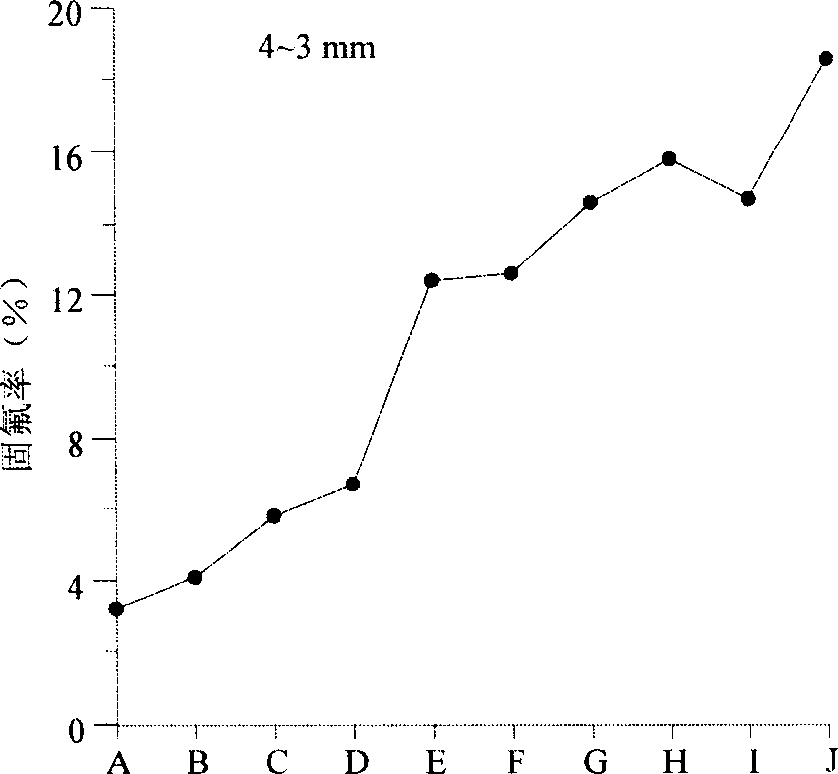

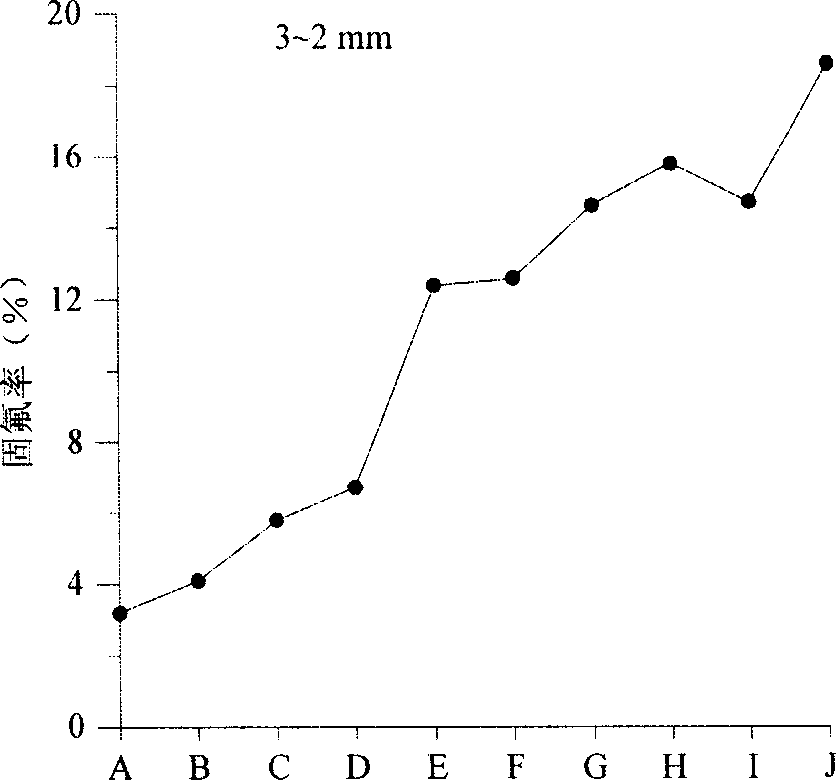

Fluoride-poisoning fluoride-retention technology with powdered coal, argic horizon, and limestone as mixed fuel

The invention discloses a fluorine-fixing technology in the Tylototriton western endemia flurosis of composite fuel based on dust coal, soil stick layer and limestone, which is characterized by the following: affirming optimum proportion of dust coal / soil stick layer / limestone at 5:1:1 and optimum grain of limestone between 0.4-0.2 mm; making fluorine-fixing rate at 92 percent; obtaining composite fuel component easily; discarding present modified technology of stove chimney; fitting for spreading widely.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

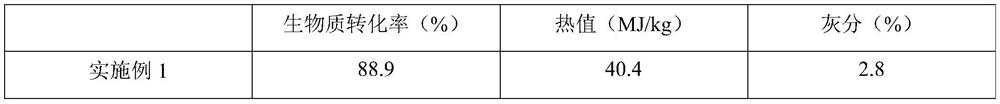

Biomass-based liquid fuel and production process thereof

InactiveCN111849527AHigh catalytic activityMany poresBiofuelsLiquid hydrocarbon mixture productionMolecular sievePtru catalyst

The invention relates to biomass-based liquid fuel and a production process thereof. According to the invention, biomass is used as a raw material and subjected to pretreatment, a pyrolytic reaction and a catalytic cracking reaction to obtain the liquid fuel; and the technical key point of the invention lies in a catalyst used in a catalytic cracking reaction, and the catalyst is prepared by mixing carrier slurry prepared from diatomite and an alpha-naphthylamine monomer with molecular sieve slurry prepared from tetraethoxysilane, a ZSM-5 molecular sieve, thiourea and the like. By means of thecatalytic action of the catalyst, a high conversion rate of biomass is achieved, the biomass is fully degraded, and the heat value of the obtained liquid fuel is high.

Owner:许洁

Process for backblowing and deashing through bag-type dust remover by blast furnace dry method

Owner:BERIS ENG & RES CORP

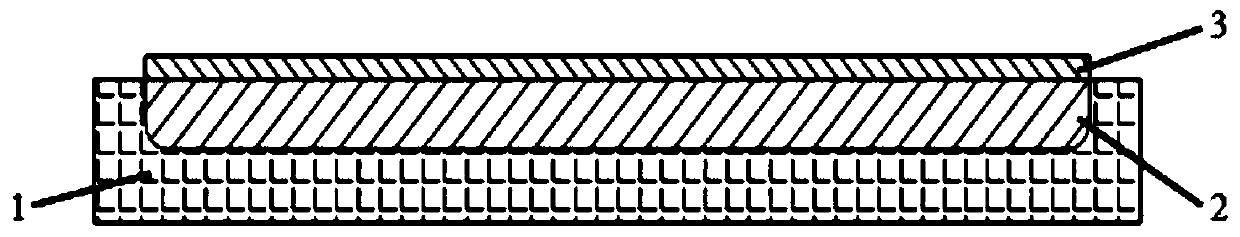

Flexible electric heat therapy patch based on liquid metal

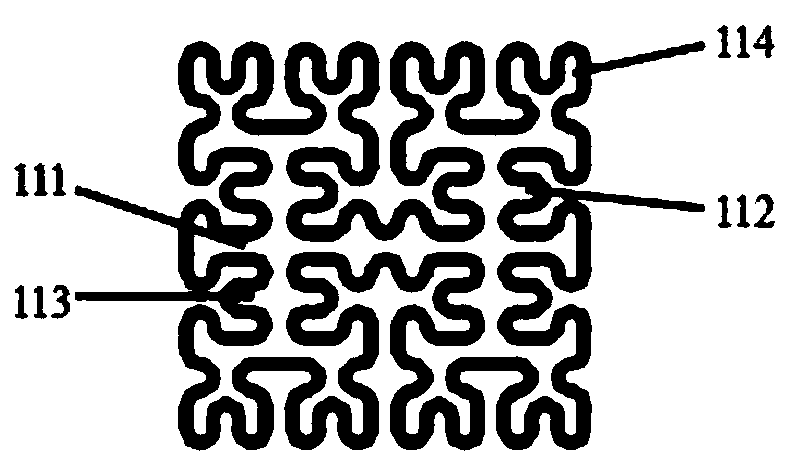

InactiveCN110559123AGuaranteed fitGuaranteed calorific valueTherapeutic coolingTherapeutic heatingElectric heatingEngineering

The present invention provides a flexible electric heat therapy patch based on liquid metal. The flexible electric heat therapy patch based on the liquid metal comprises a flexible substrate (1), liquid metal (2), a packaging layer (3), a lead (4), a switch (5) and a power supply (6). A groove (11) is formed in the flexible substrate (1), the groove (11) is filled with the liquid metal (2), and the packaging layer (3) is arranged above the groove (11); the switch (5), the power supply (6), the lead (4) and the liquid metal (2) form a closed loop; and the groove is a combined pattern consistingof an H shape (111), a Chinese character "gan" (looks like a cross with a short line above) shape (112), a Chinese character "shi" (looks like a cross with a short line below) shape (113) and an X shape (114). The provided electric heat therapy patch can be repeatedly used, is softer and foldable, has better fit degree with human body, generates heat more uniformly, and is higher in cost performance and wider in application field.

Owner:CHONGQING UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com