System for drying sludge by utilizing radiation heat of rotary cement kiln

A cement rotary kiln and sludge drying technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of capital occupation of land resources, expensive equipment investment, large amount and volume of sludge, etc., and achieve obvious economic benefits , the effect of reducing heat pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

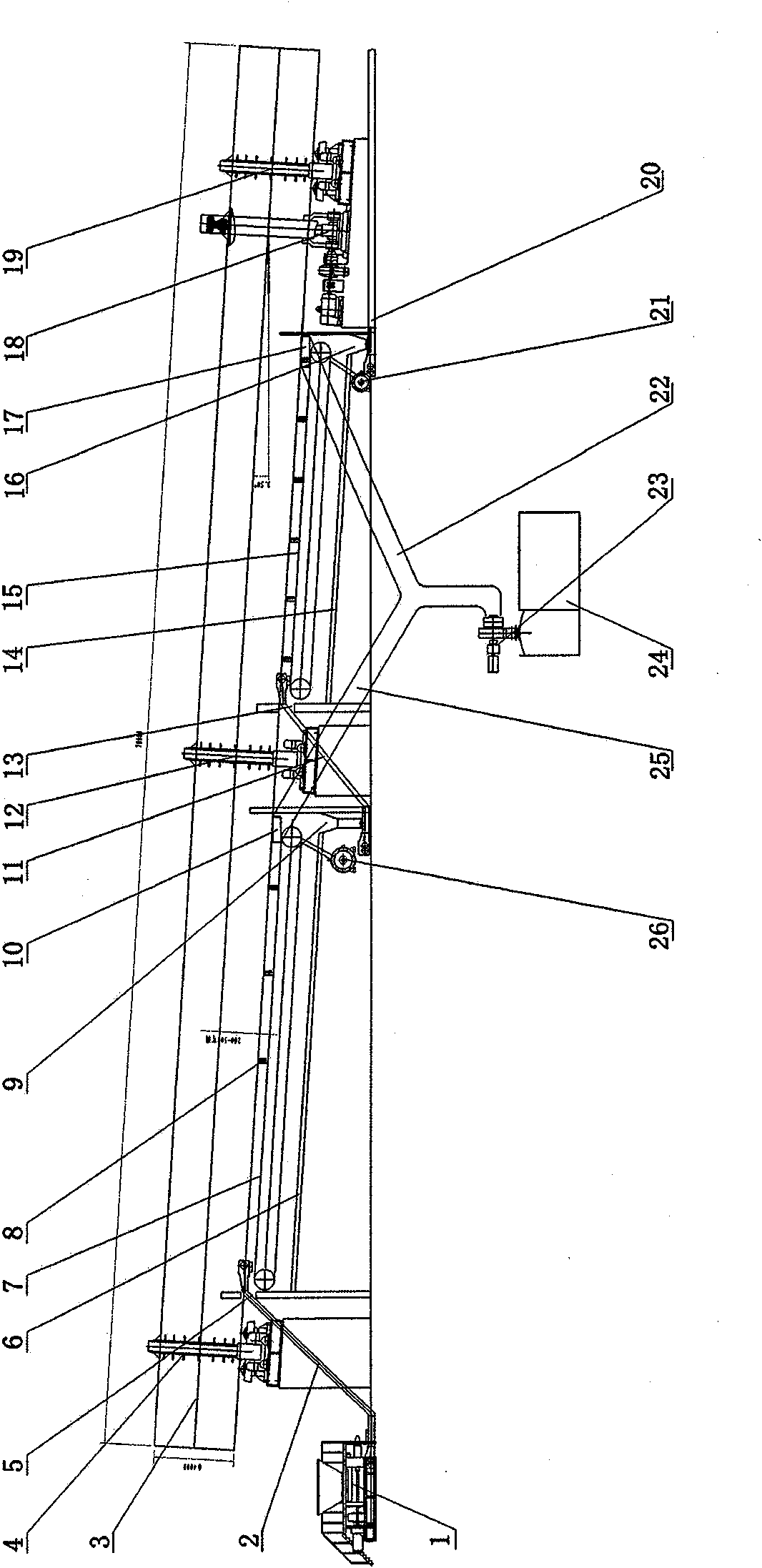

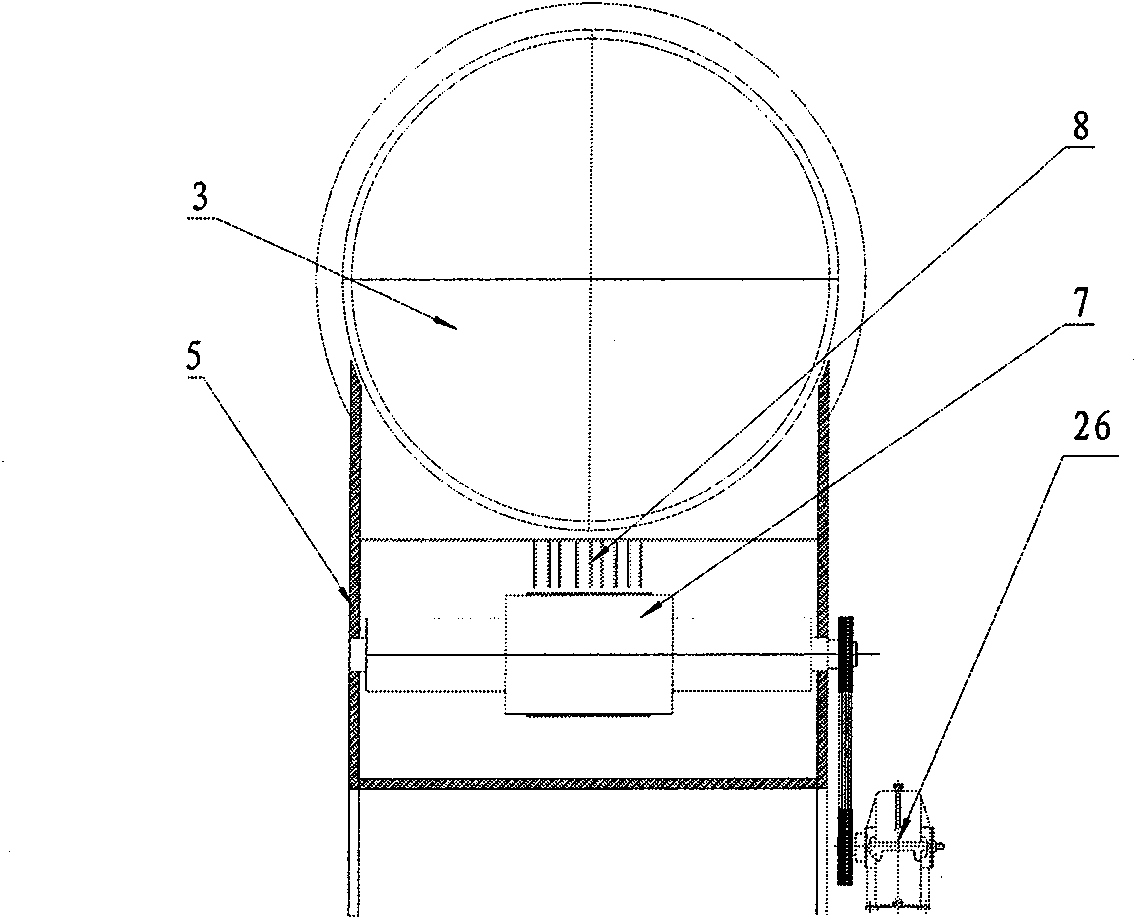

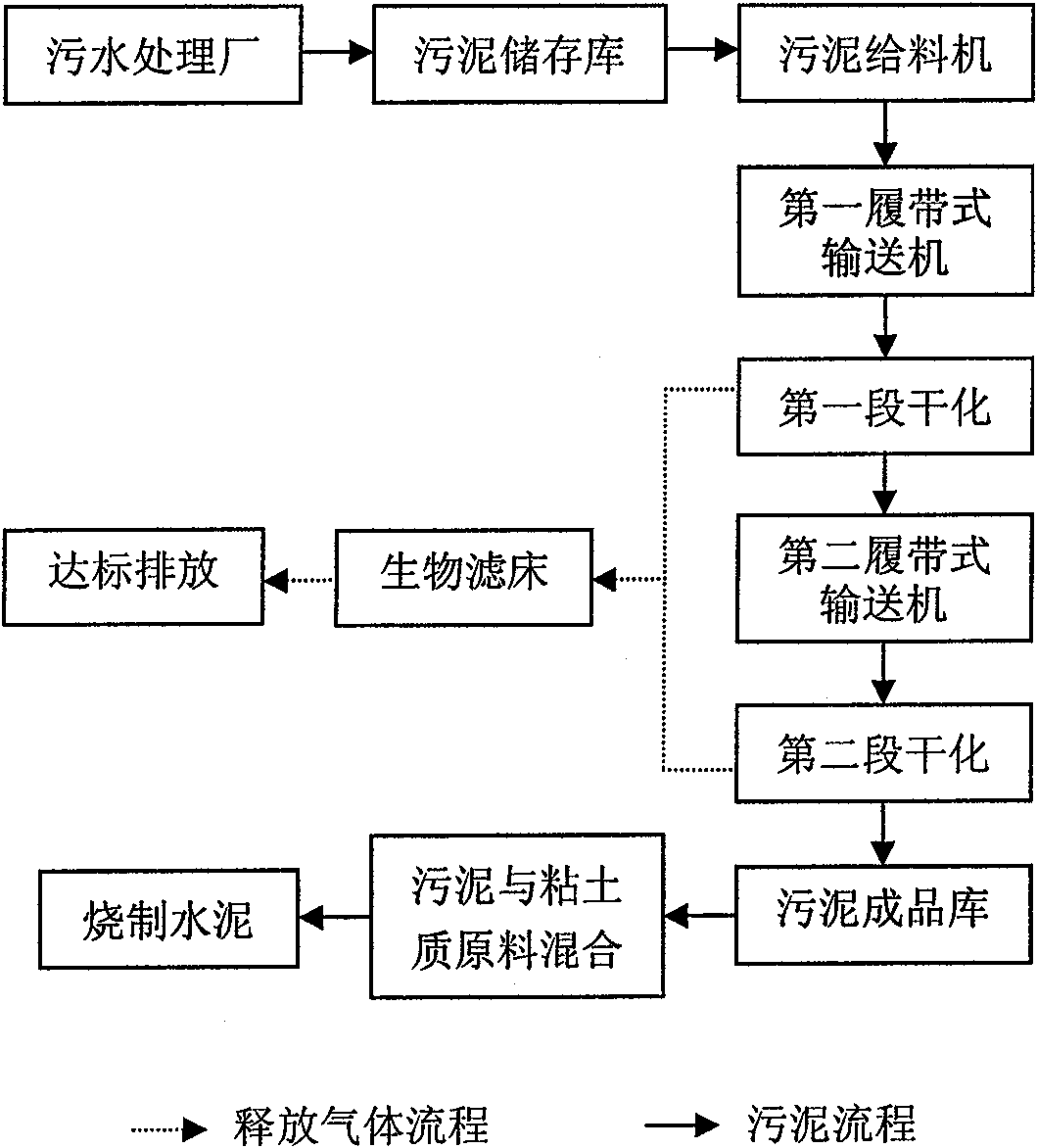

[0025] Such as figure 1 , 2 , 3, the sludge drying system using the radiant heat of the rotary kiln in a cement plant includes a sludge feeder 1, a first scraper conveyor 2, a cement rotary kiln 3, a first supporting wheel 4, and a first closed box inlet Material port 5, first closed box 6, first crawler conveyor 7, fixed rolling spike rake 8, first closed box discharge port 9, first vent 10, second scraper conveyor 11, second Supporting roller 12, second closed box feed port 13, second closed box 14, second crawler conveyor 15, second closed box discharge port 16, second ventilation port 17, cement rotary kiln transmission device 18, first Three supporting wheels 19, discharge conveyor 20, second transmission device 21, second ventilation pipe 22, exhaust fan 23, biological filter 24, first ventilation pipe 25 and first transmission device 26; cement rotary kiln 3 and cement The rotary kiln transmission device 18 is connected, and the kiln head, middle part and kiln tail of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com