Dissimilar material friction-stir welding tool

A technology of friction stirring and dissimilar materials, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as difficult to achieve welding effect and differences in thermal characteristics, and achieve the effect of easy replacement and increased wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

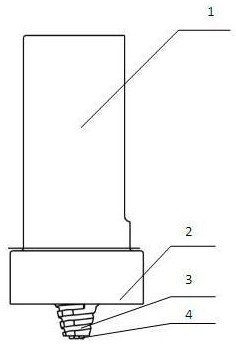

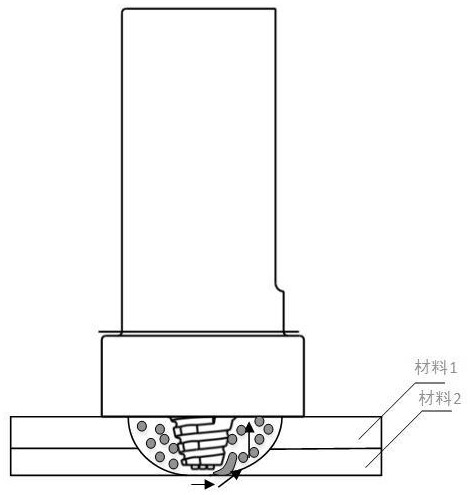

[0019] like Figure 1~2 An embodiment shown: a friction stir welding tool for dissimilar materials, including a tool handle 1, a shaft shoulder 2, and a stirring needle 3 connected in sequence, and the stirring needle is provided with at least one set of bosses at the bottom of its needle tip 4. The stirring needle is arranged as a circular table, and the diameter of the stirring needle gradually decreases from the connection with the shaft shoulder to the direction away from the shaft shoulder; The direction is opposite; the bottom of the shaft shoulder 2 is designed with a revolving groove, and the revolving direction is opposite to the rotation direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com