Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4351 results about "Knife handles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

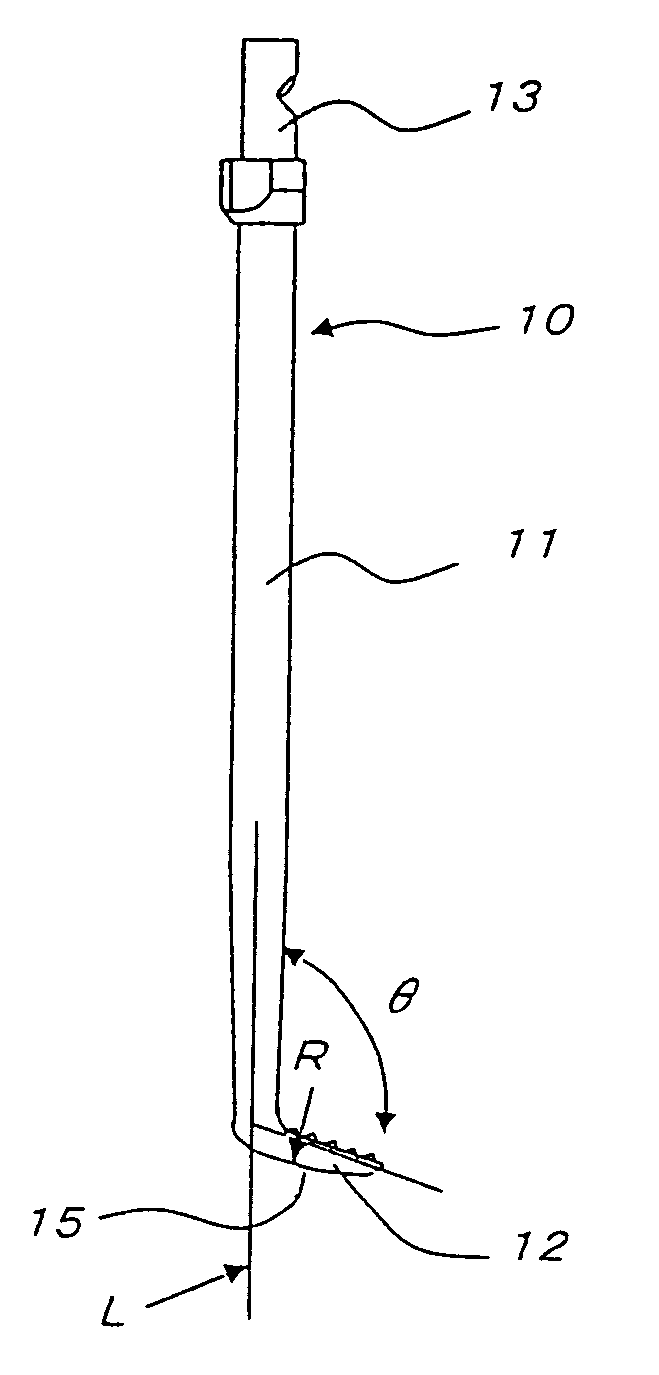

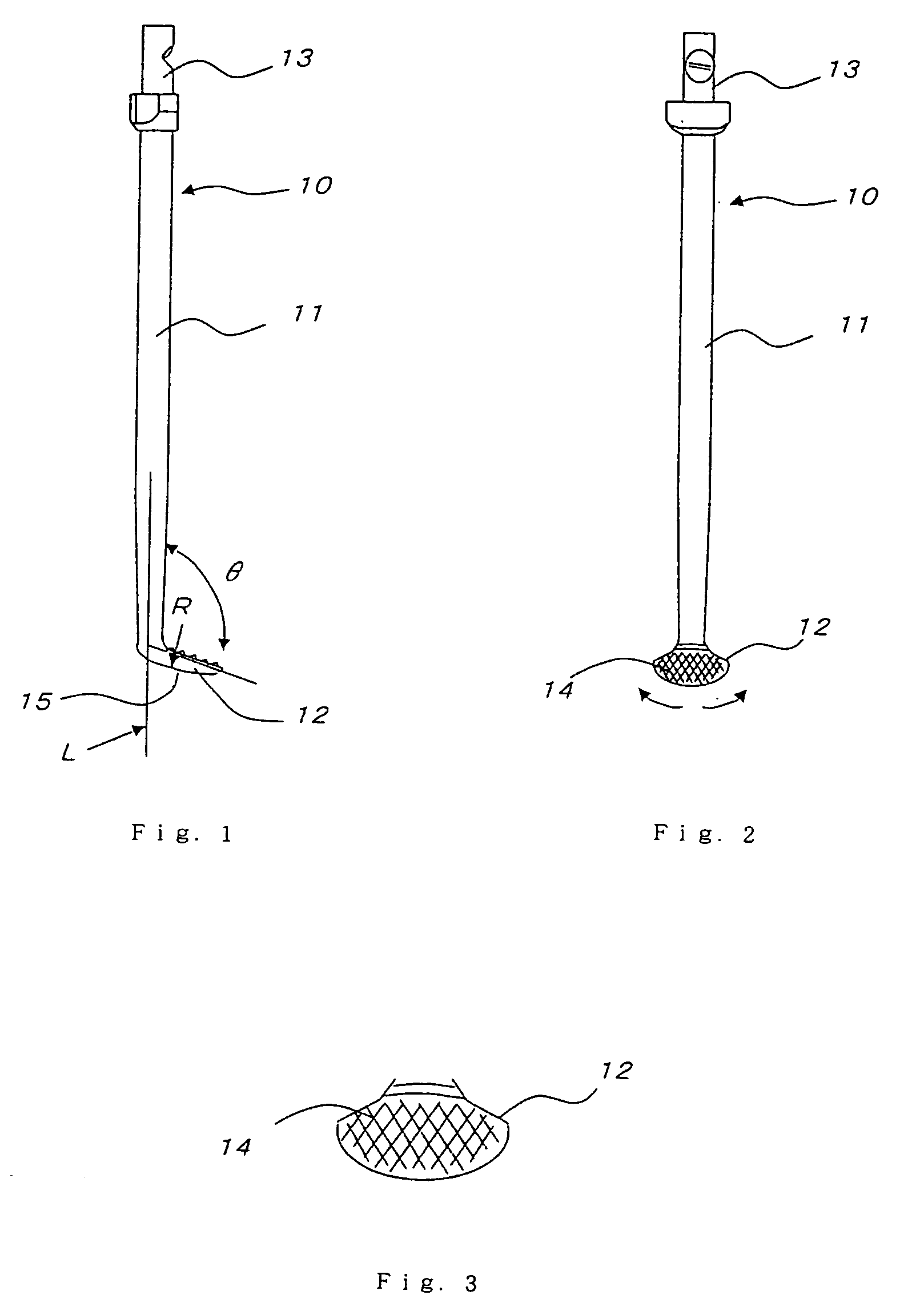

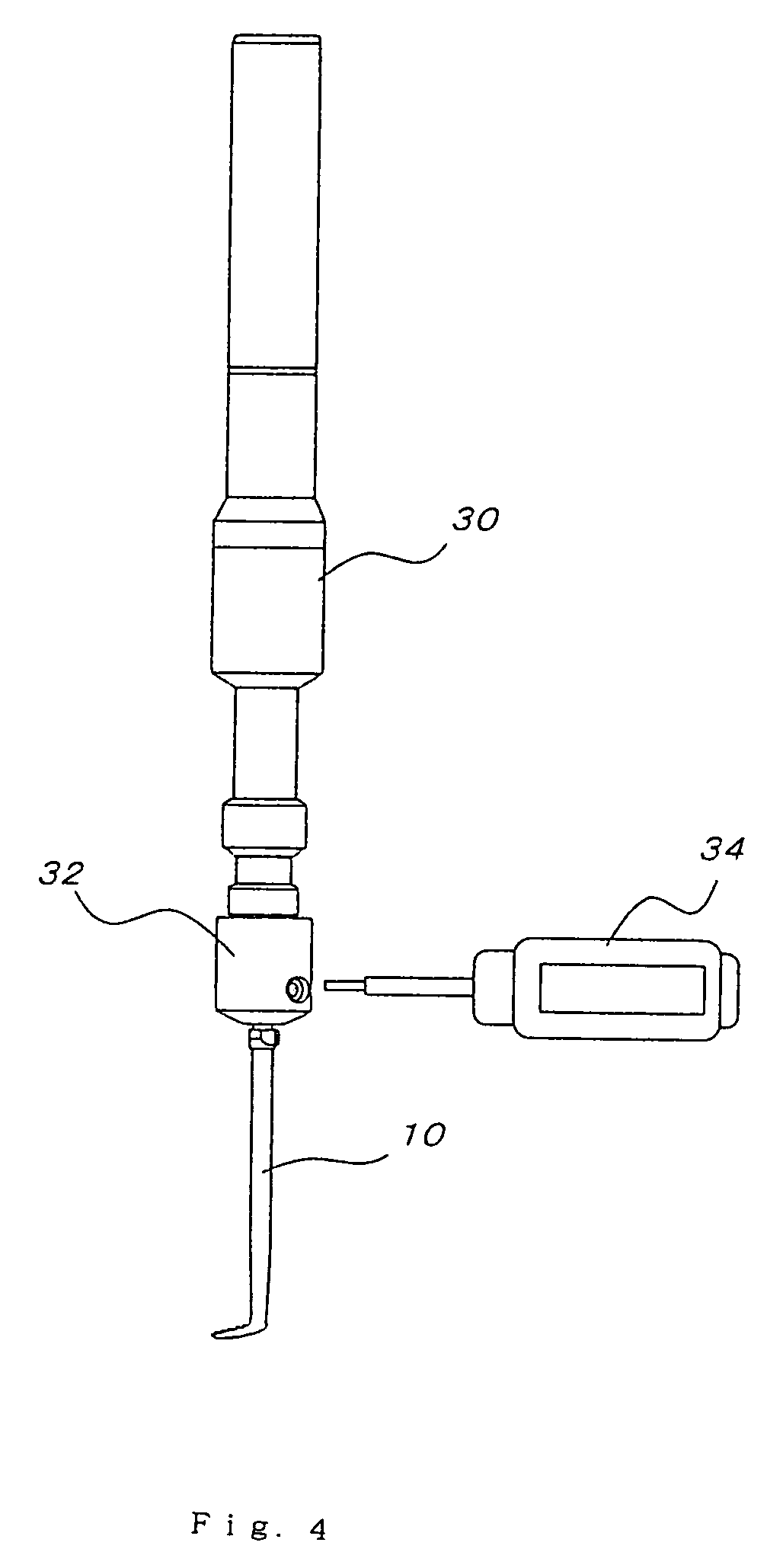

Orthopedic instrument

InactiveUS20060142776A1Safety pruningReduce in quantitySurgeryOrthopaedic devicePhysical medicine and rehabilitation

To provide an orthopedic apparatus with which a surgeon can perform a trimming operation safely without damaging blood vessels and nerves in the vicinity of an angle of jaw and without the need to make a large incision and a surgeon can perform a trimming operation by one hand with a smaller number of persons required for the operation. The orthopedic apparatus has: a shank (11); a fan-shaped member (12) which is provided at the front end of the shank (11); and a coupling (13) which is provided at the rear end of the shank and to be connected to a driving source. The fan-shaped member (12) is inclined with respect to an extension (L) of the shank (inclination angle θ); file ridges (14) are formed on the fan-shaped member (12)'s surface (reverse side) which is oriented toward the rear end of the shank; and the shank (11) is constructed so as to rotate into a clockwise direction and a counterclockwise direction continuously.

Owner:NIHON UNIVERSITY

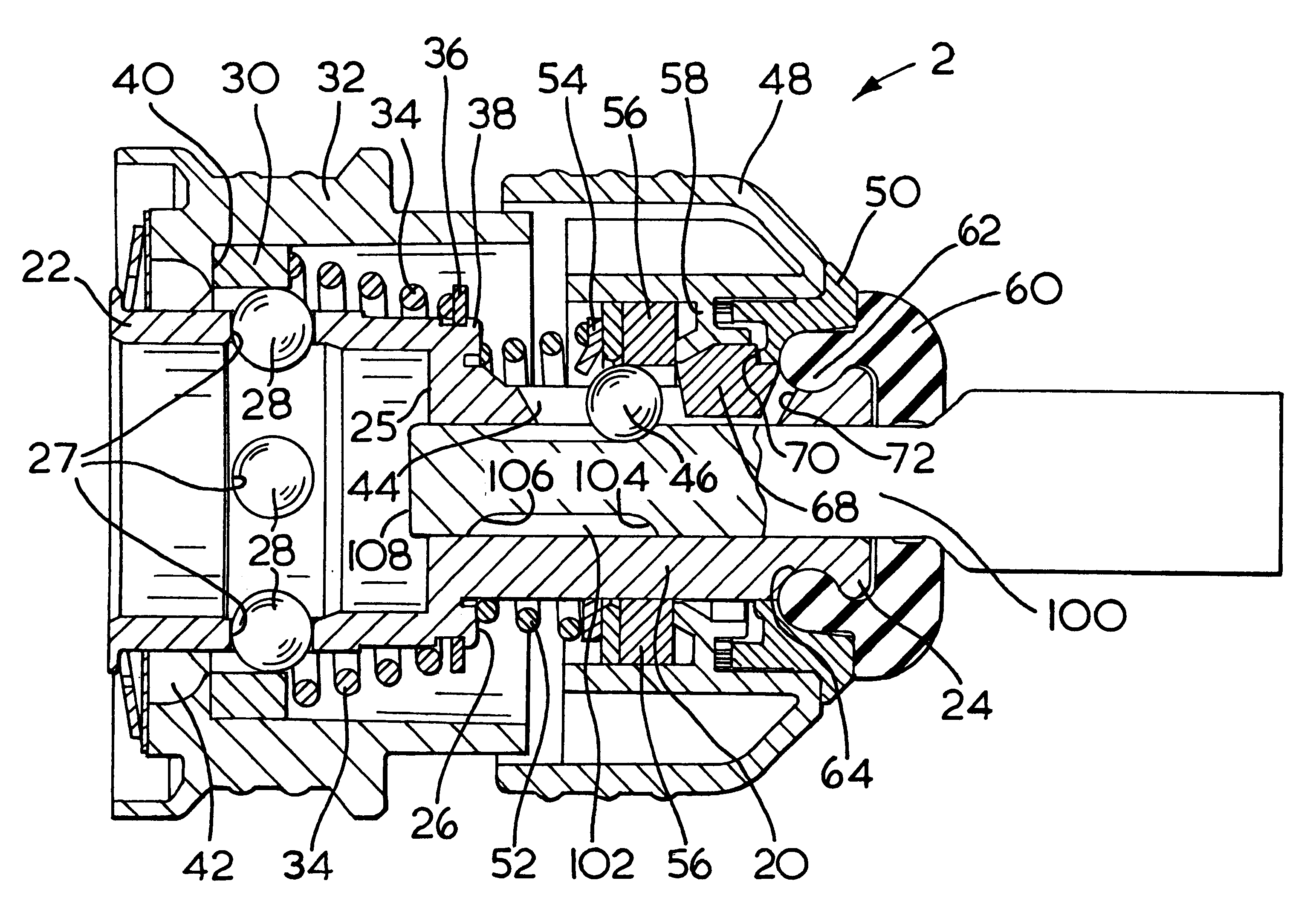

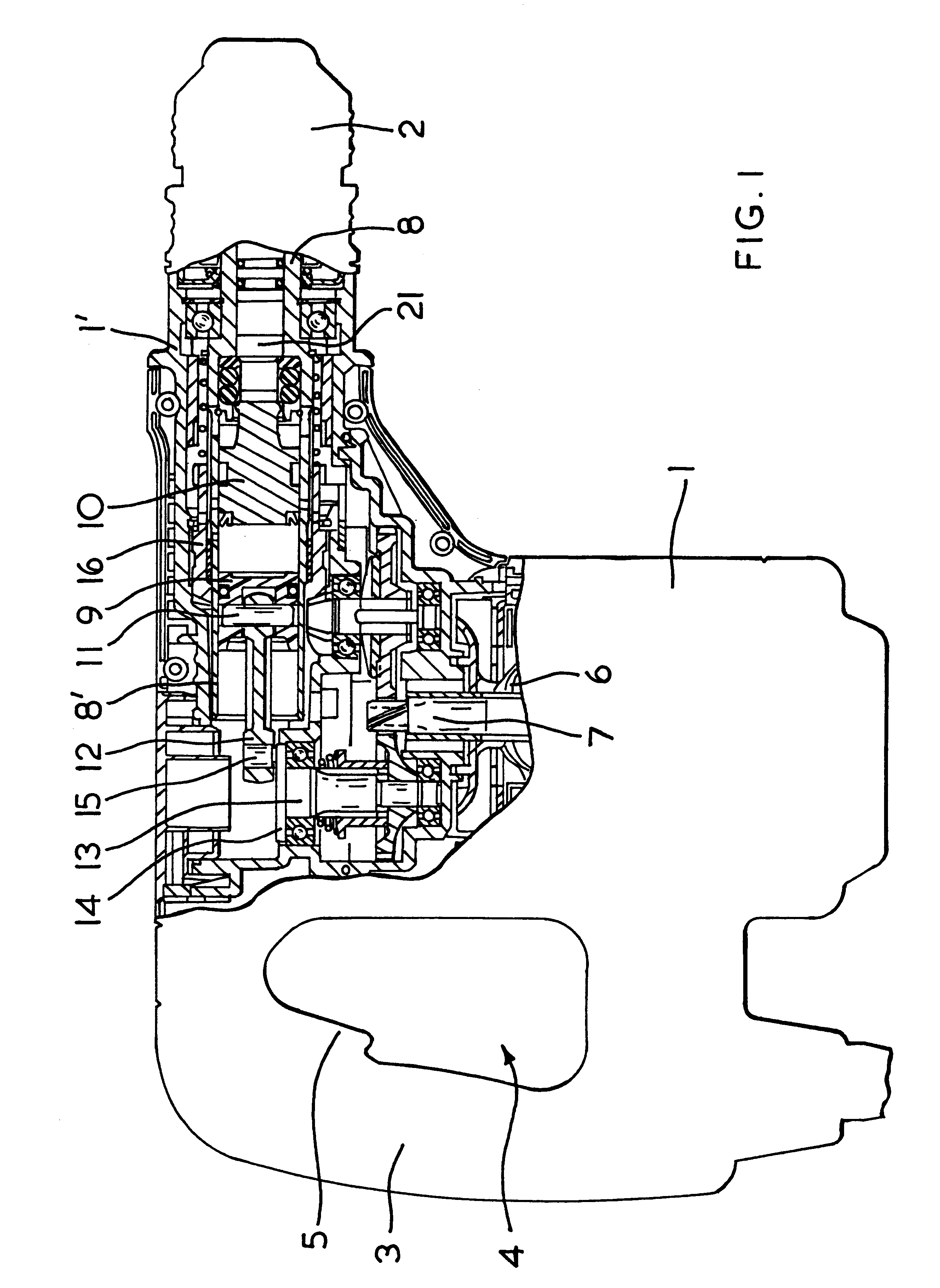

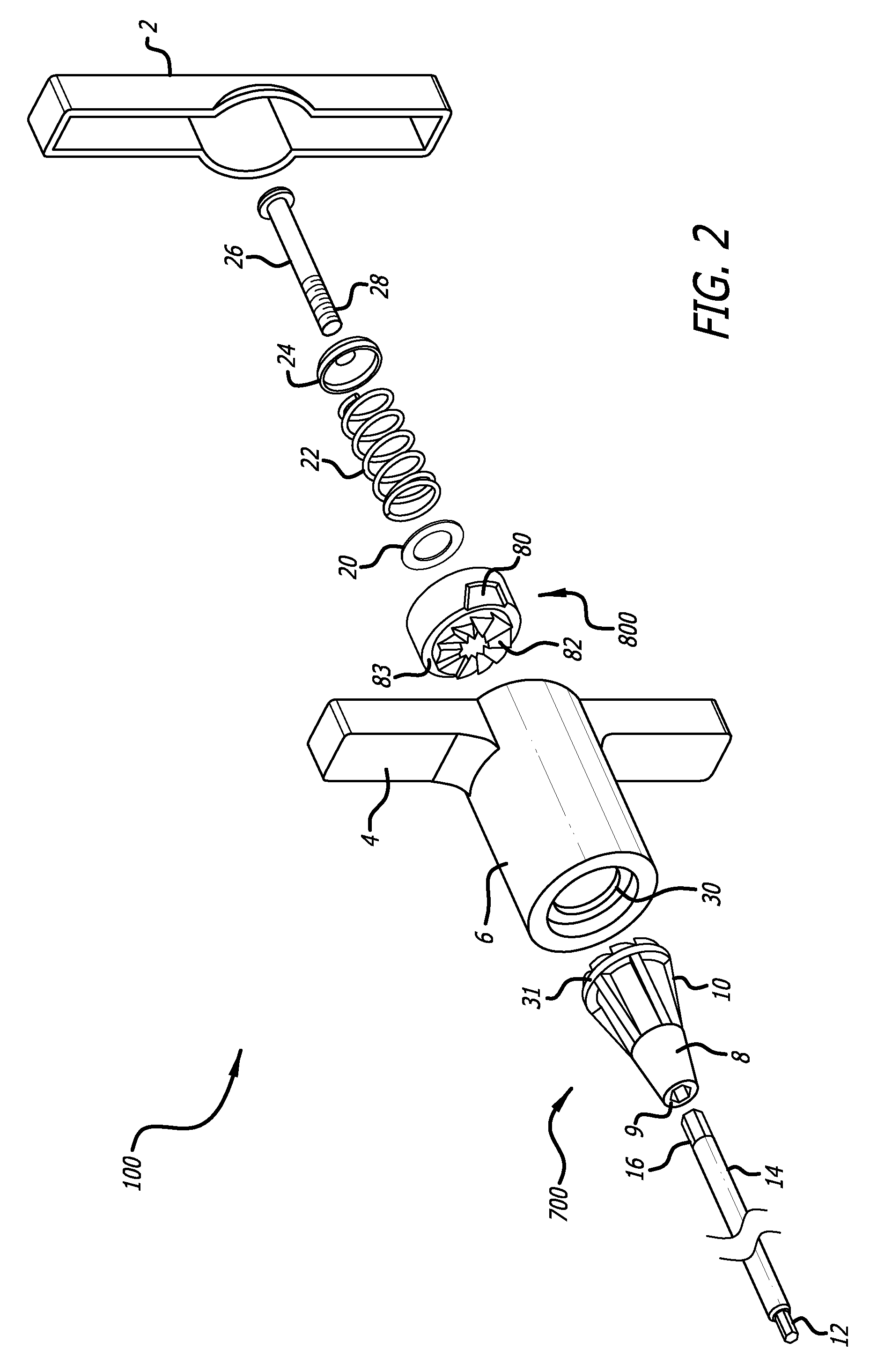

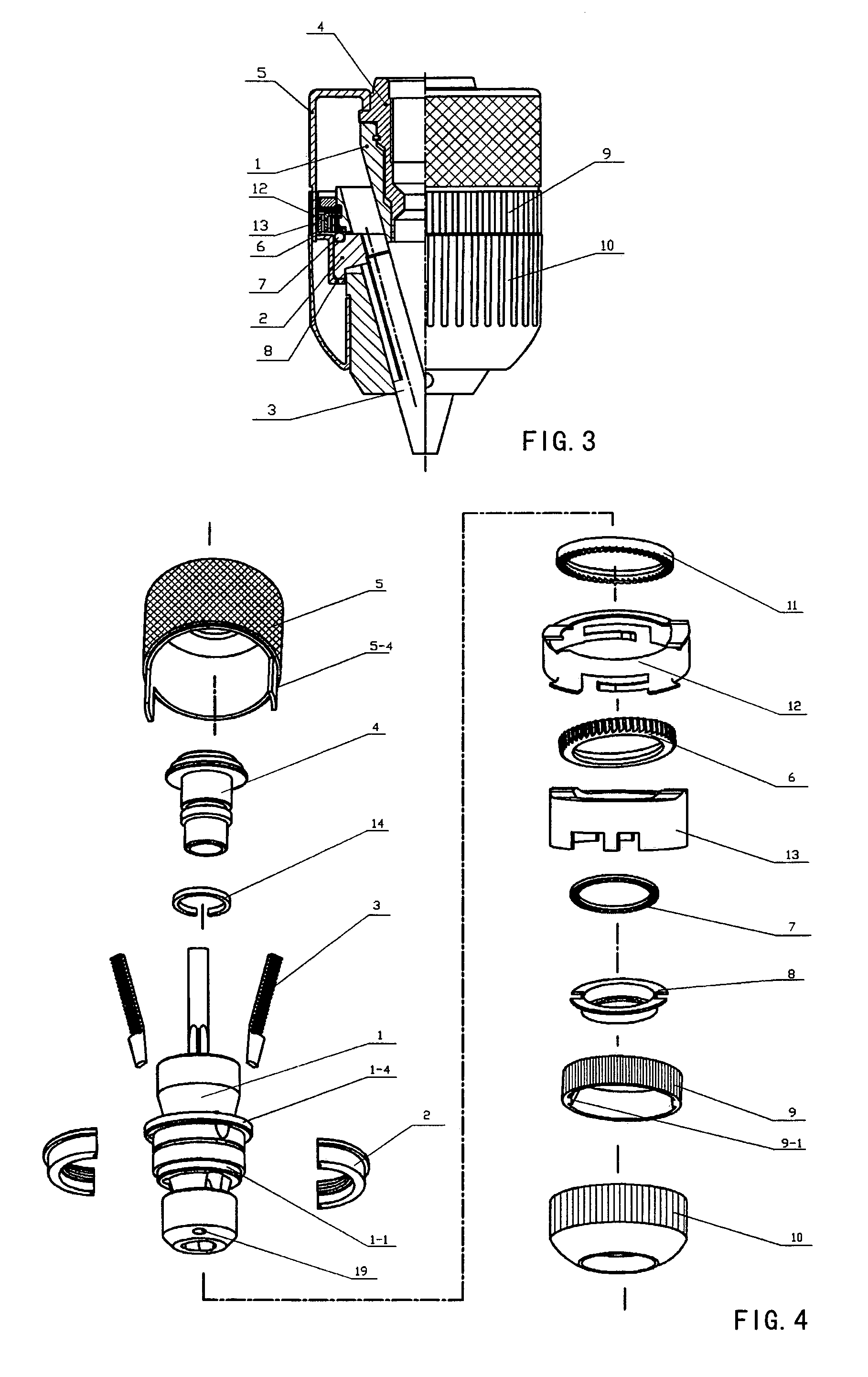

Rotary hammer

InactiveUS6241026B1Weakening rangeReduce risk of damageConstructionsChucksEngineeringFront and back ends

A tool holder attachable to a spindle of a hammer and which can receive a bit, the bit having a shank with at least one retaining groove extending along part of the shank, the retaining groove having a defined length, a front end and a rear end that limit axial movement of the bit in the tool holder, which tool holder comprises a hollow cylinder having an axis, an axial bore, a rear end that can be attached to the spindle of the hammer, and a front end that can receive the shank of the bit so that the bit is slidable within the cylinder in an axial direction, at least one retaining element that is located so that it can extend radially into the bore of the cylinder and into the at least one retaining groove of the bit so that the retaining element can be hit by the rear end of the retaining groove during the transition to idling and limit the extent of axial movement of the bit within the cylinder, at least one radial restraining element limiting movement of the retaining element in the radial direction, at least one axial restraining block limiting movement of the retaining element in the axial direction, when hit by the retaining element the axial restraining block movable to a limited extent in the axial direction with respect to the radial restraining element, and a resilient element located forward of the axial restraining block and arranged so as to attenuate the impact transmitted through the axial restraining block from the retaining element.

Owner:BLACK & DECKER INC

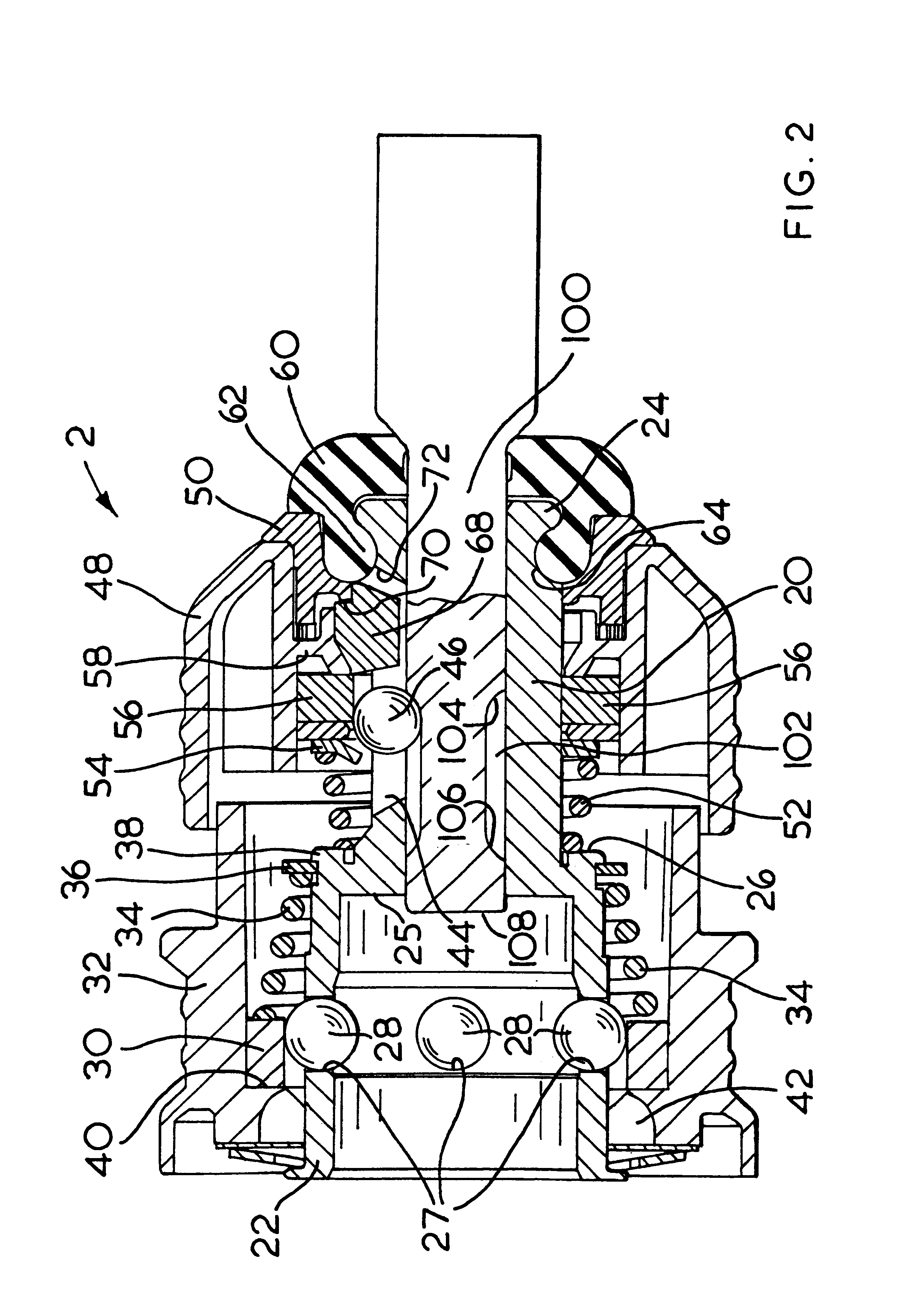

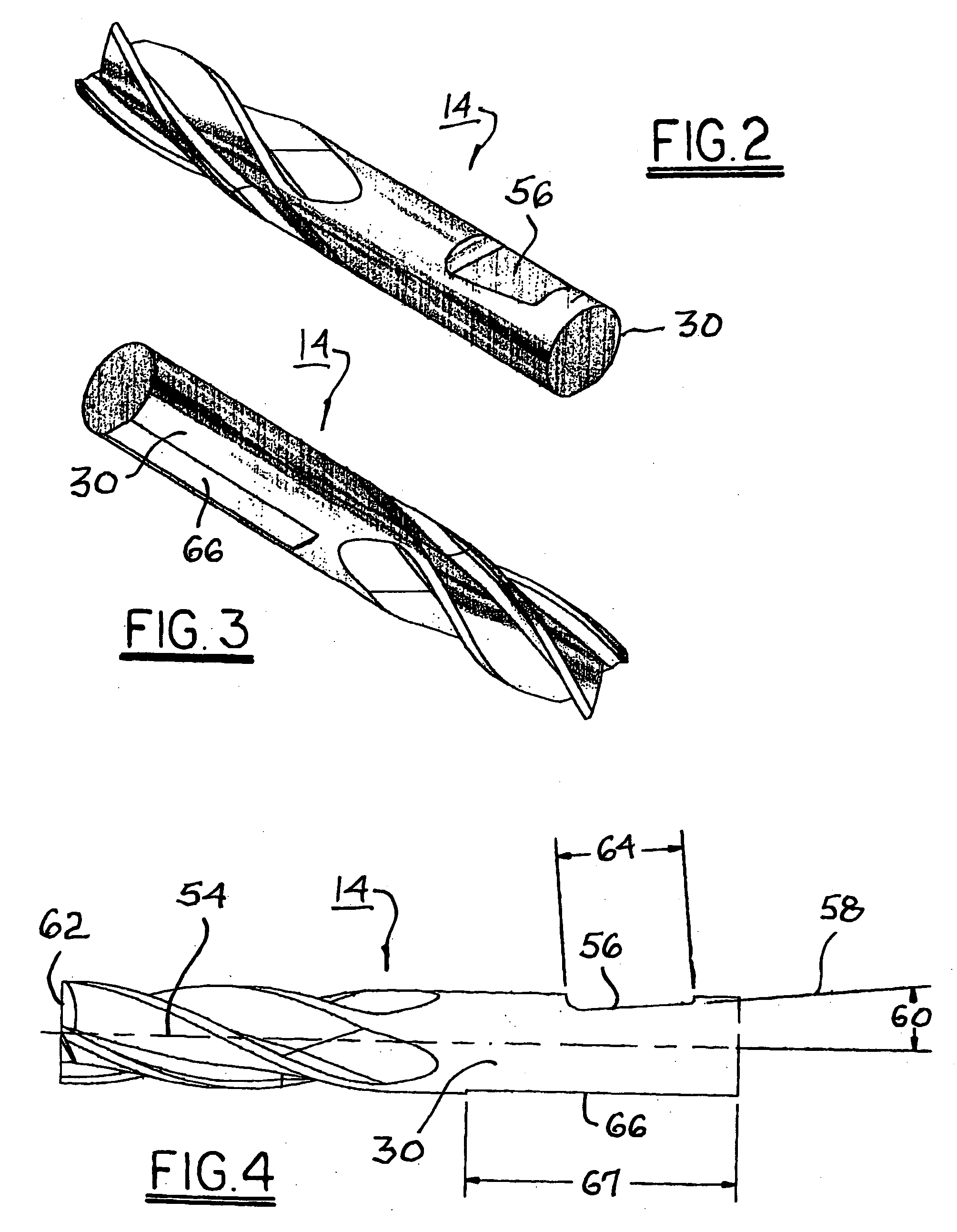

System for mounting a machine tool in a tool holder

InactiveUS20050238451A1Accurate centerAvoid turningSleeve/socket jointsTransportation and packagingSet screwEngineering

A system for mounting a tool in a tool holder combining a means for high-precision centering of the tool and a means for positive restraint of the tool from rotation within the tool holder. The tool holder includes a cylindrical aperture having a diameter slightly less than the diameter of the shank of a cylindrical tool. The tool is installed into the tool holder by heating the tool holder to a temperature sufficient to increase the pocket diameter sufficiently to accept the tool shank. In a first shrink-fit embodiment, the tool shank is further provided with an angular flat for engagement with a set screw to prevent the tool from being turned in the holder in use. In a second shrink-fit embodiment, a groove extending partially around the tool receives a tangential pin through a passage in the tool holder. The tool is rotated in the holder until the pin binds in the groove, thus preventing any further rotation of the tool in the holder during use.

Owner:PARLEC

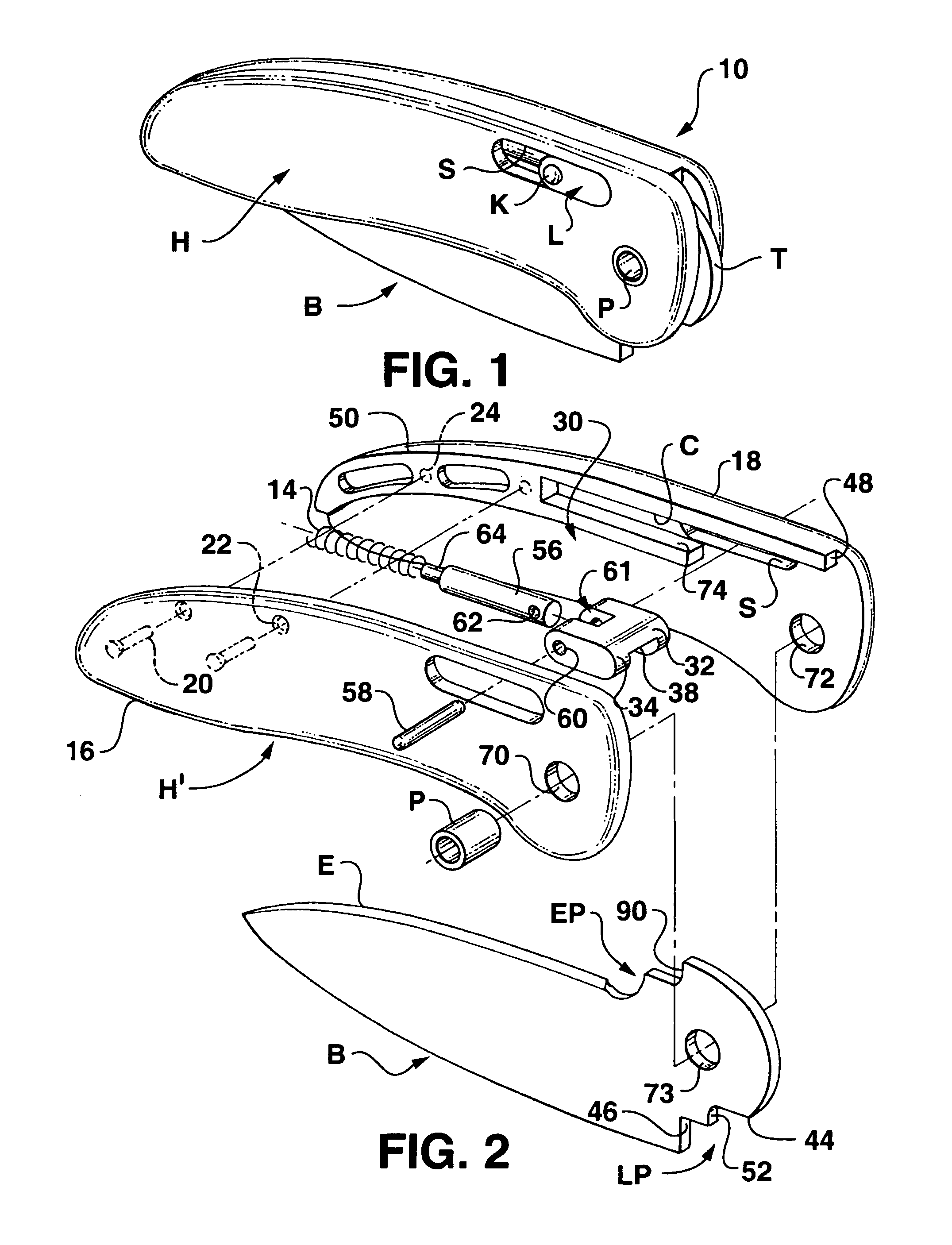

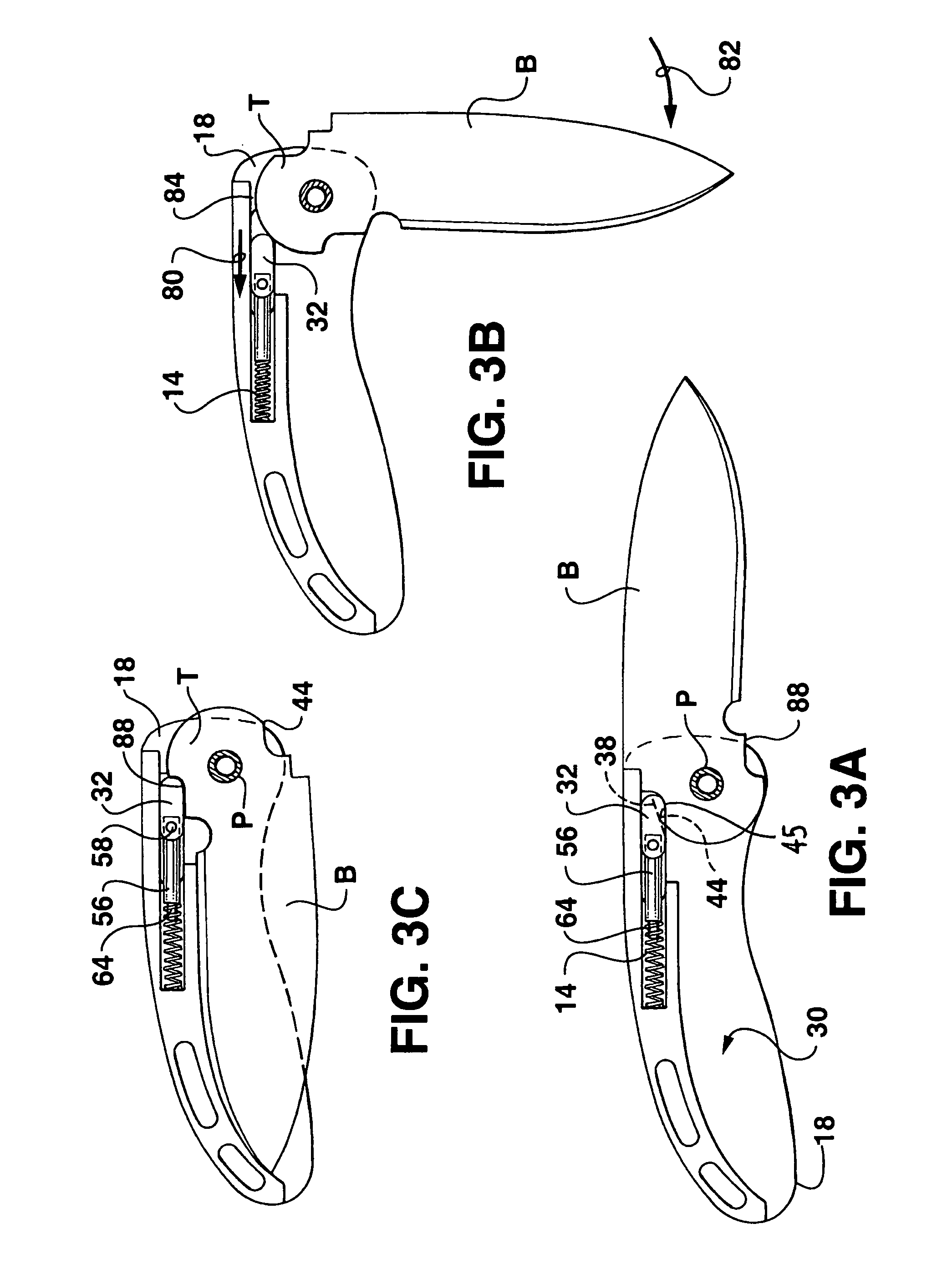

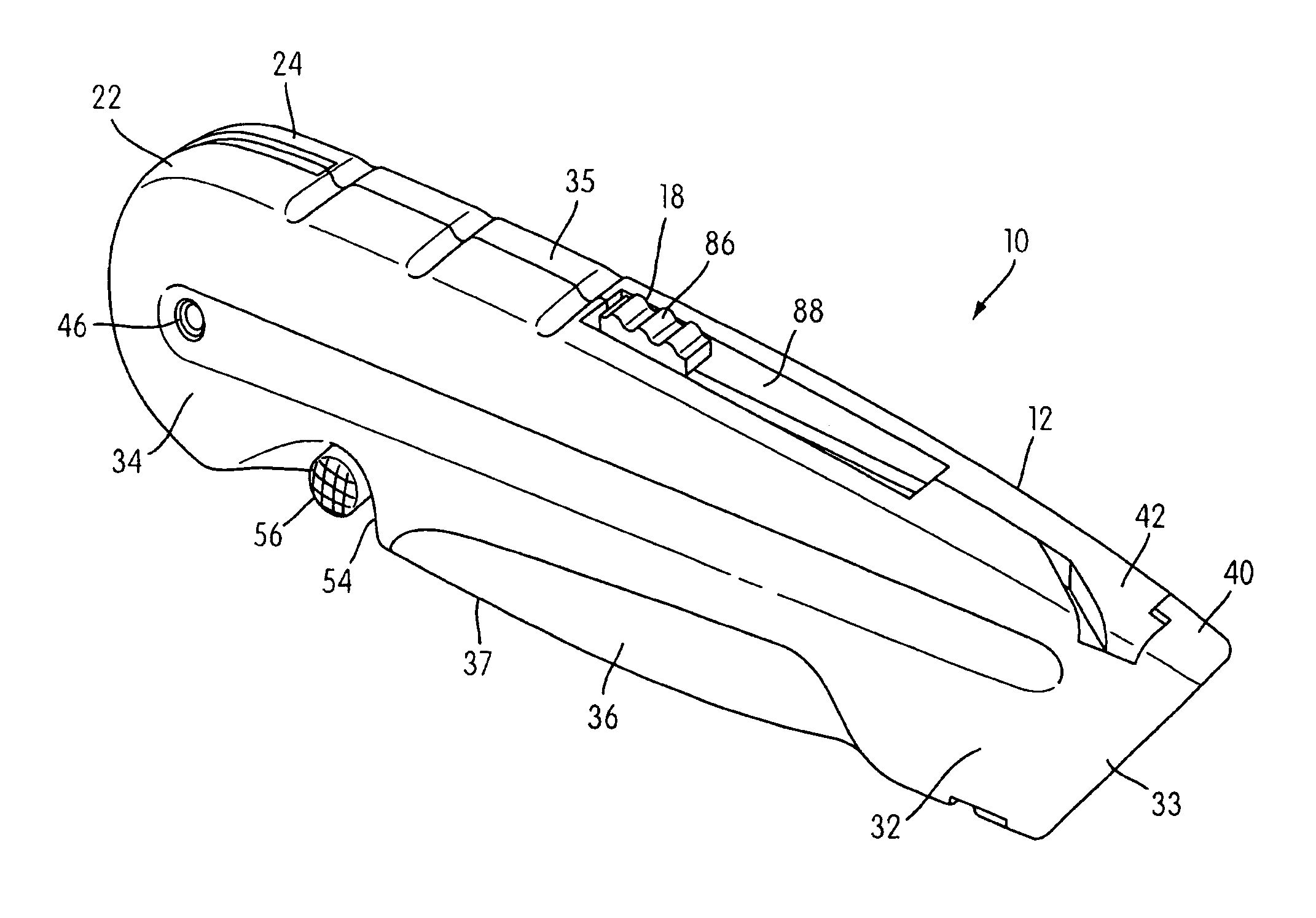

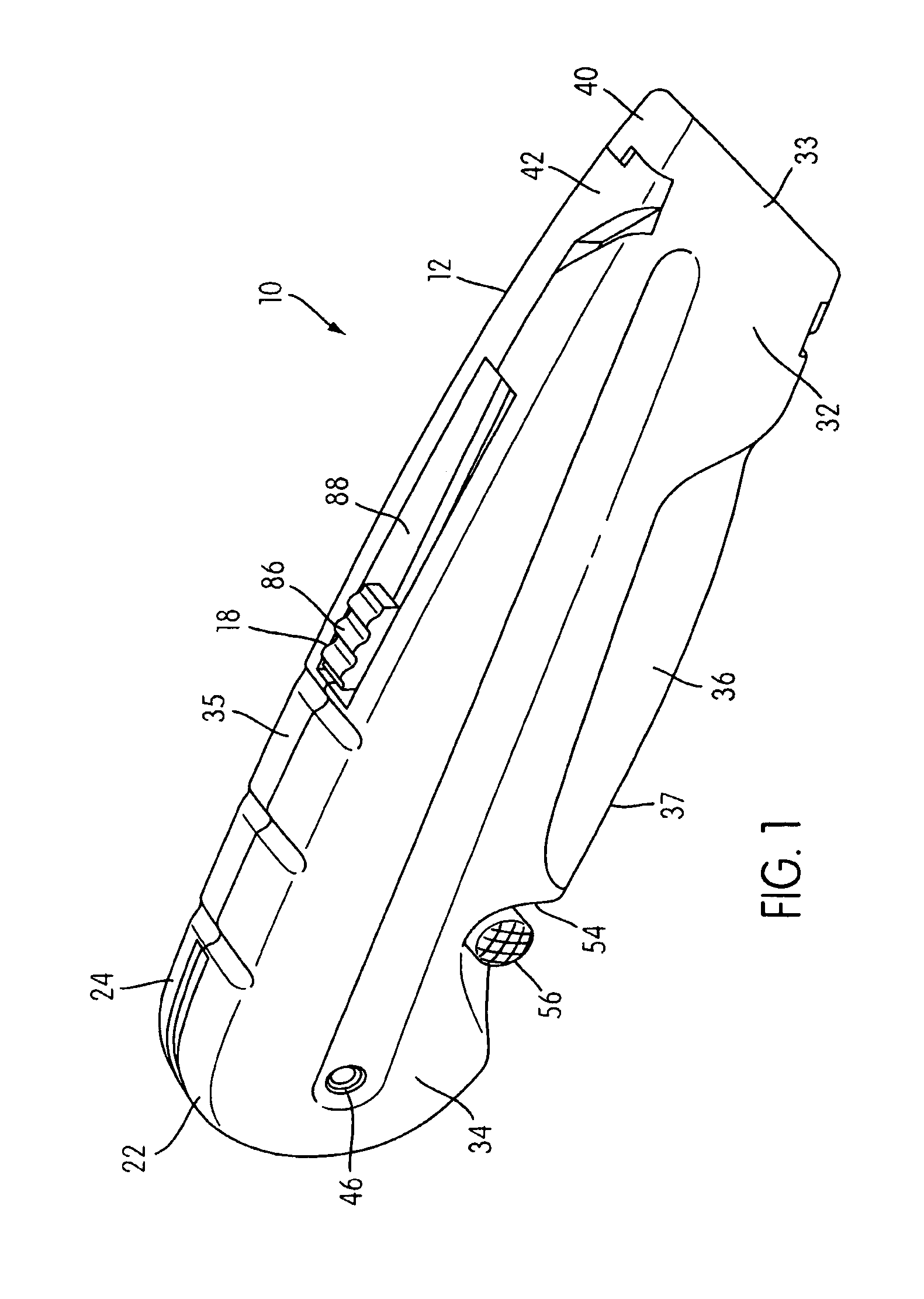

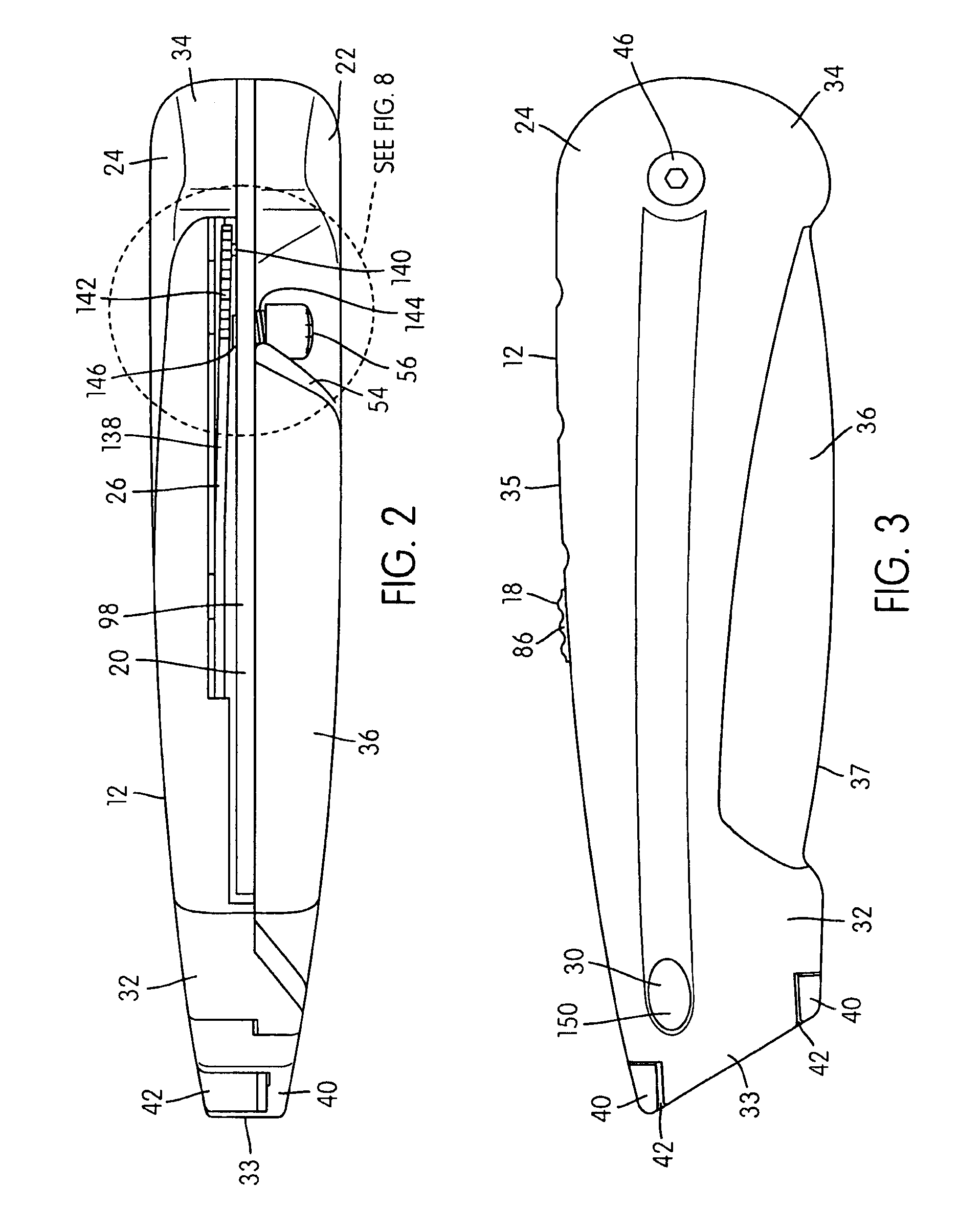

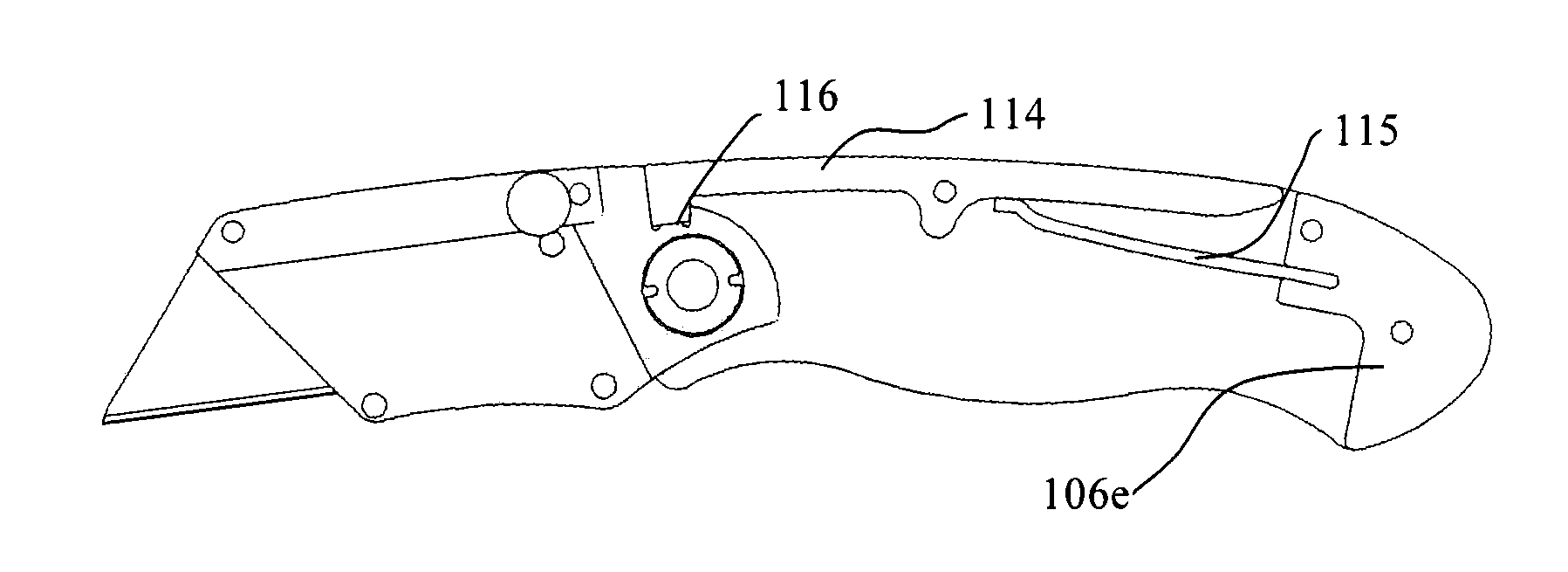

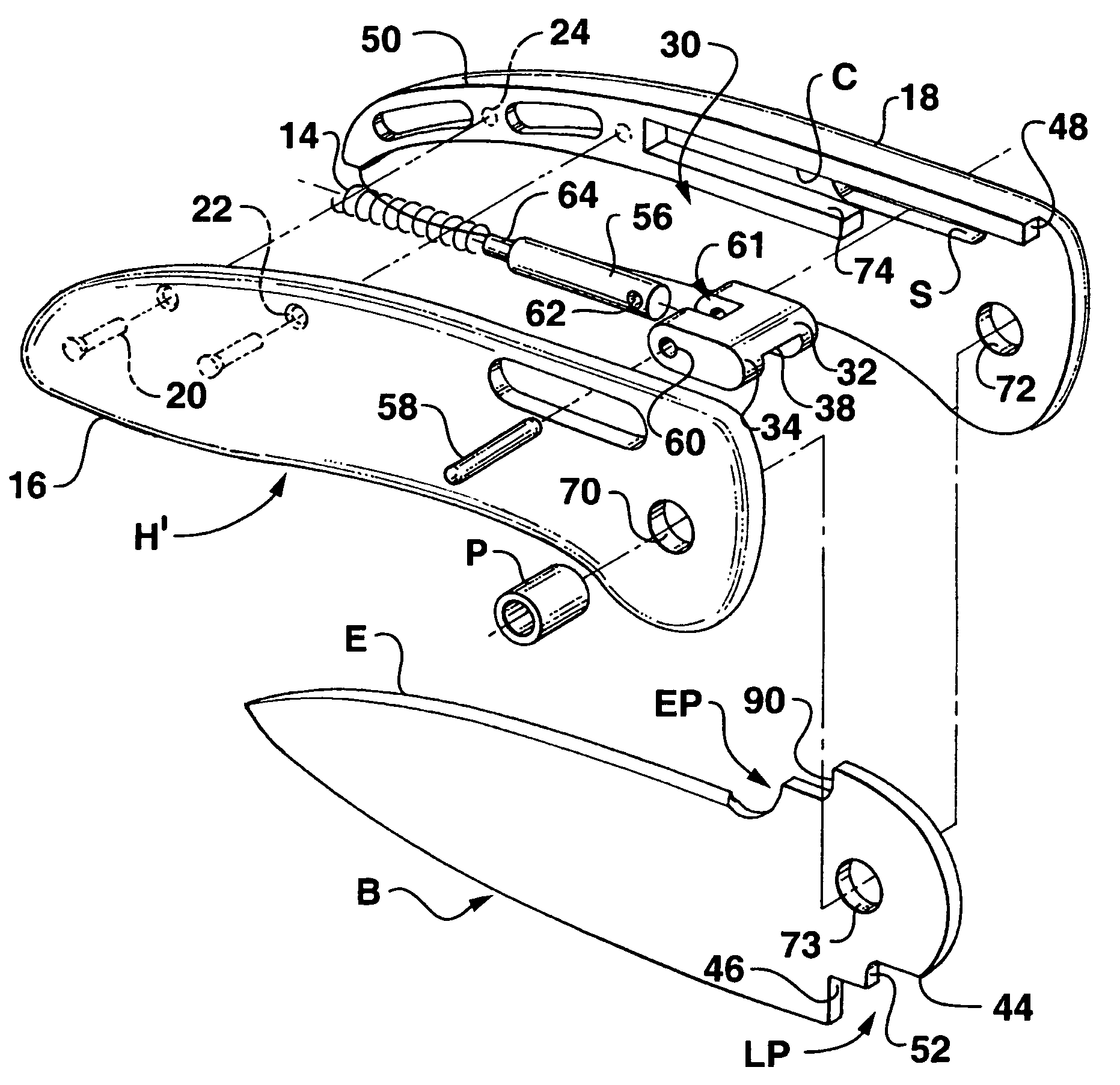

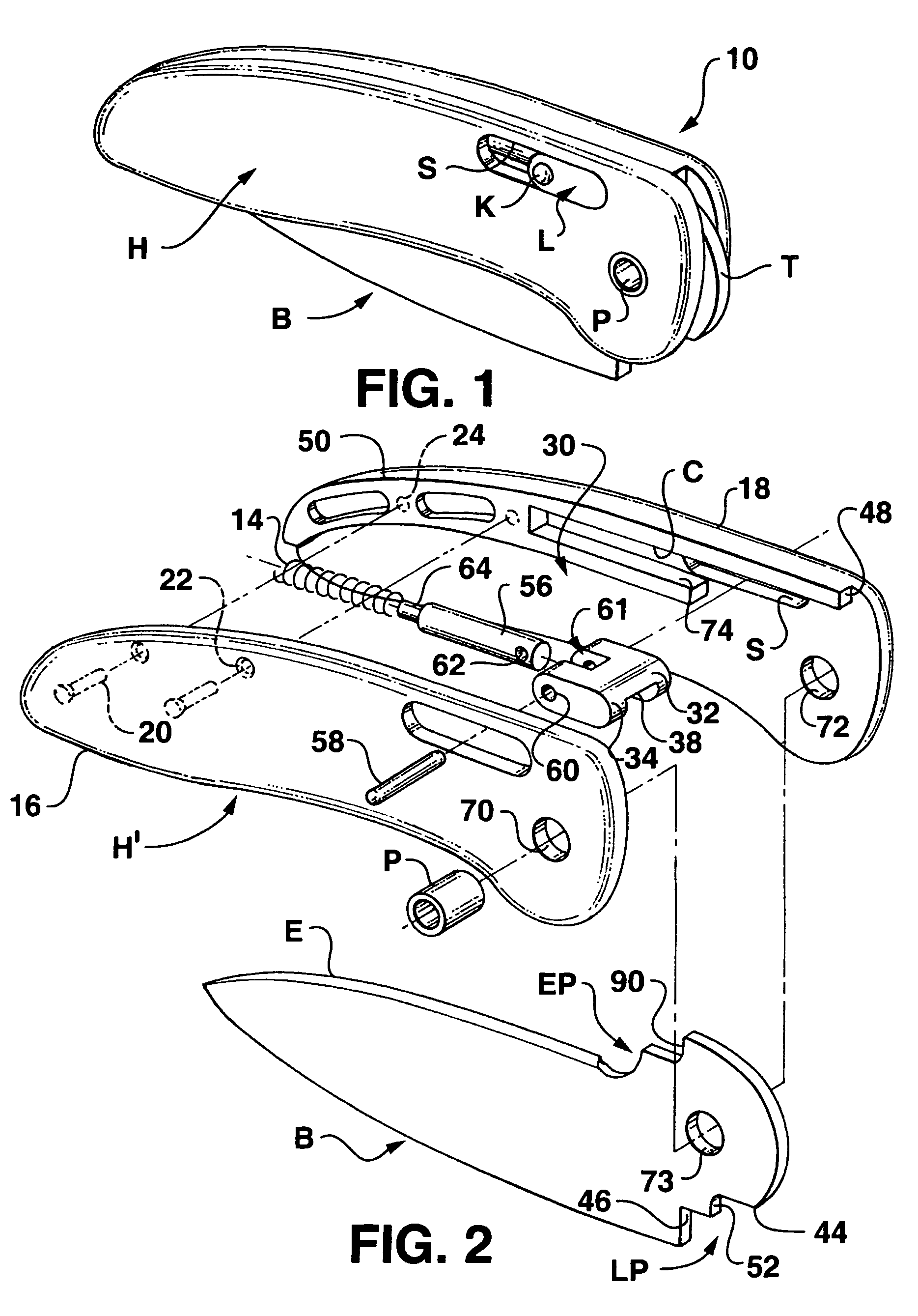

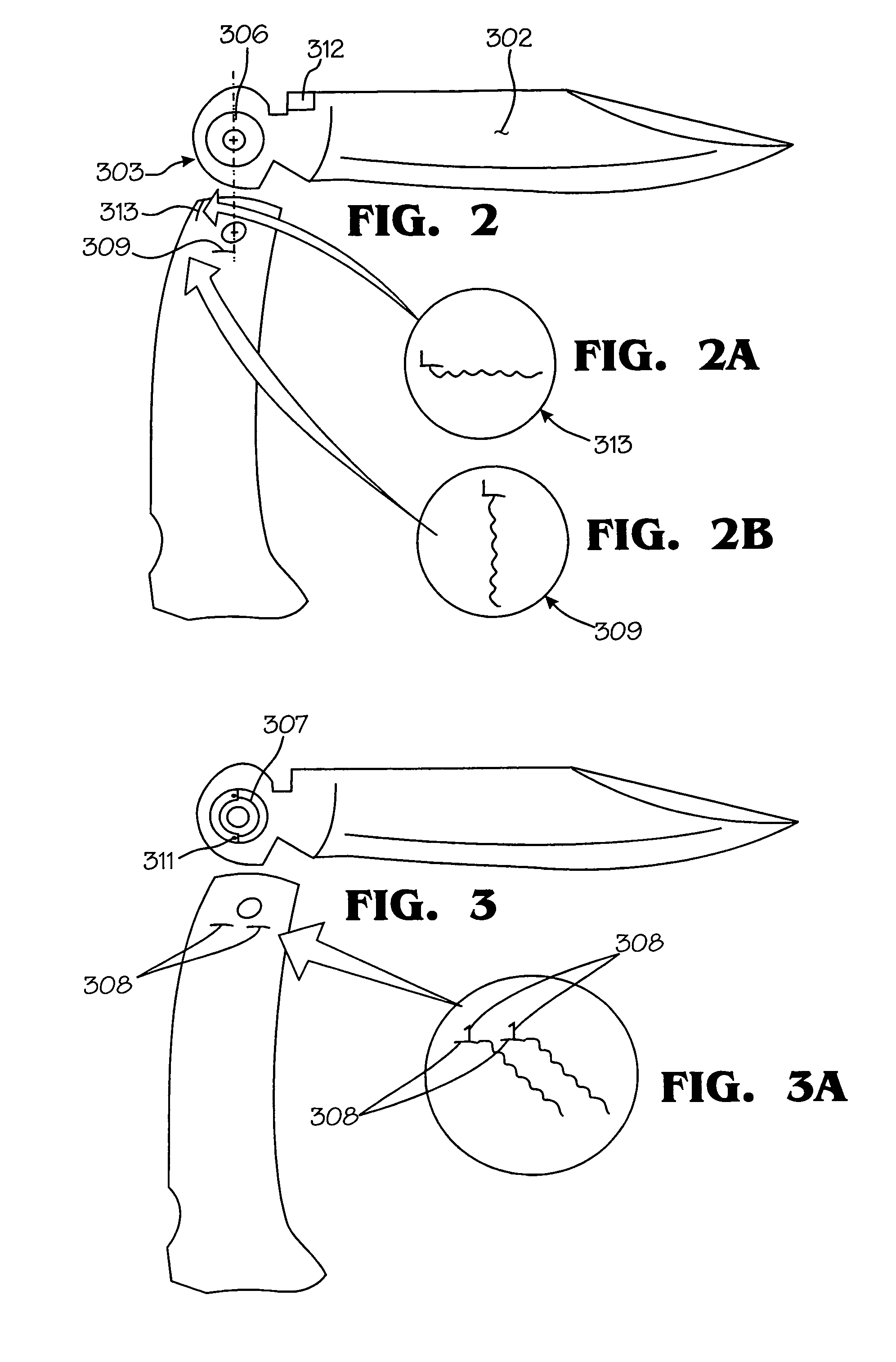

Folding knife with locking blade

InactiveUS7032315B1Improved blade locking mechanismOpen fastThrusting weaponsWeapon componentsEngineeringKnife blades

A folding knife having a blade locking member carried for sliding movement within a channel defined in the handle, the locking member being movable to a blade locking position when the blade is in an extended position. A spring, or other biasing structures, such as an opposing magnet arrangement, provide a spring-like biasing of the locking member towards a blade locking. In one embodiment, the locking member extends substantially the full width of the handle and is accessible from either side of the knife handle. The locking member includes a ramp on the underside thereof for contacting a projection, or bump, on the rearward portion of the blade tang. An adjustable bushing is provided which allows for adjustment of the blade within the handle to provide for both ease of pivoting of the blade, while reducing any lateral play in the blade within the handle.

Owner:BUSSE JERRY P

Combination utility and sporting knife

Owner:STANLEY WORKS THE

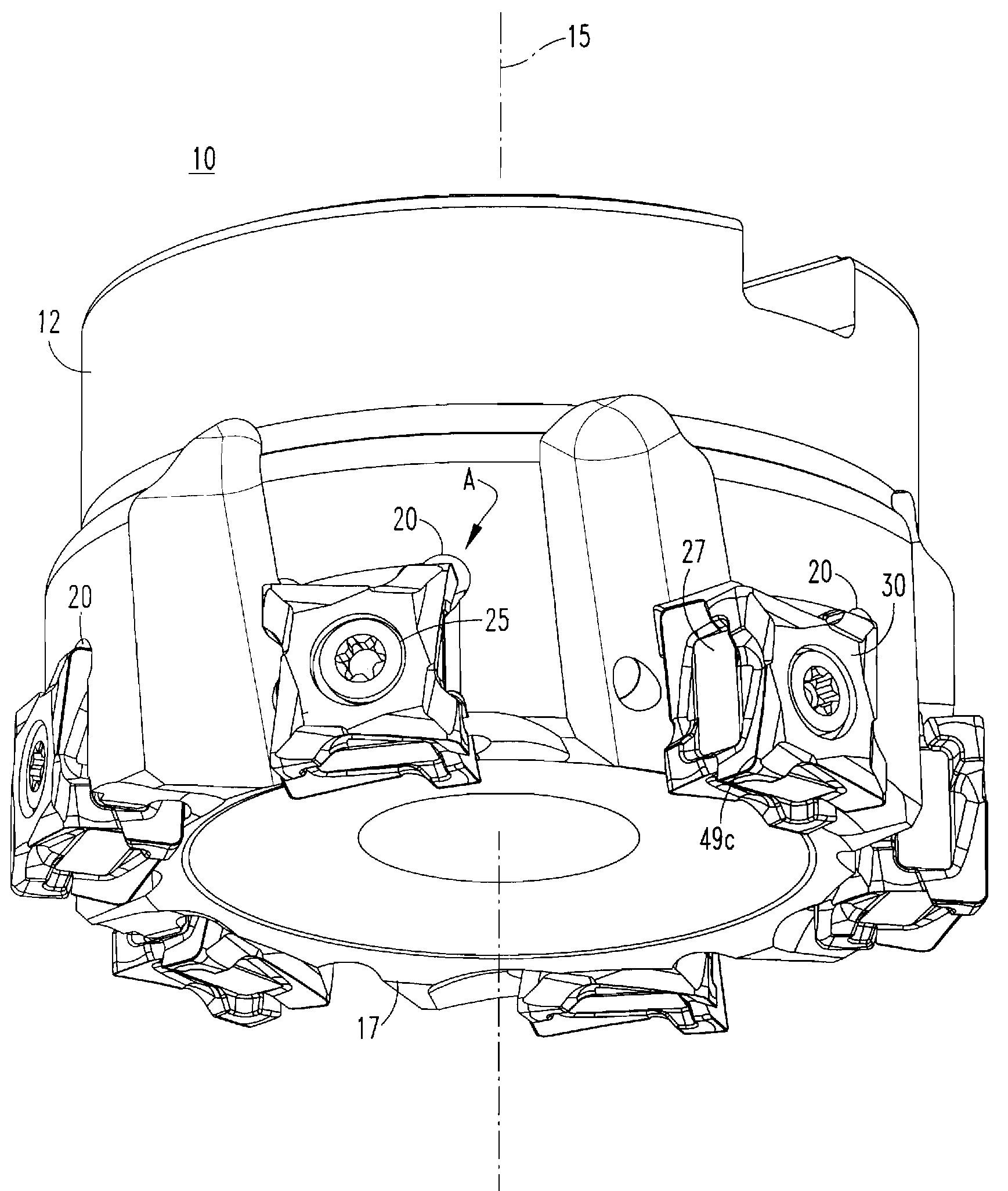

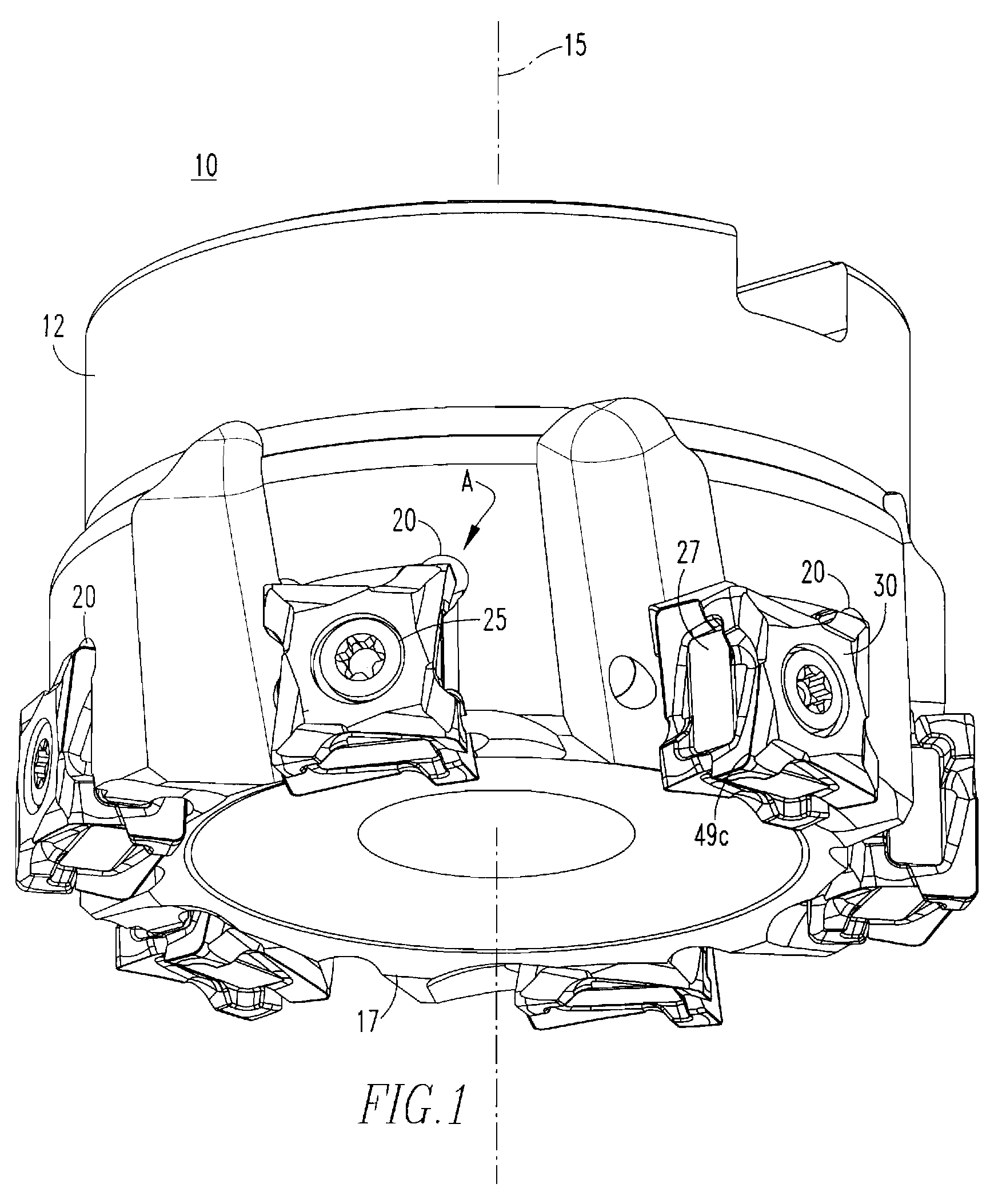

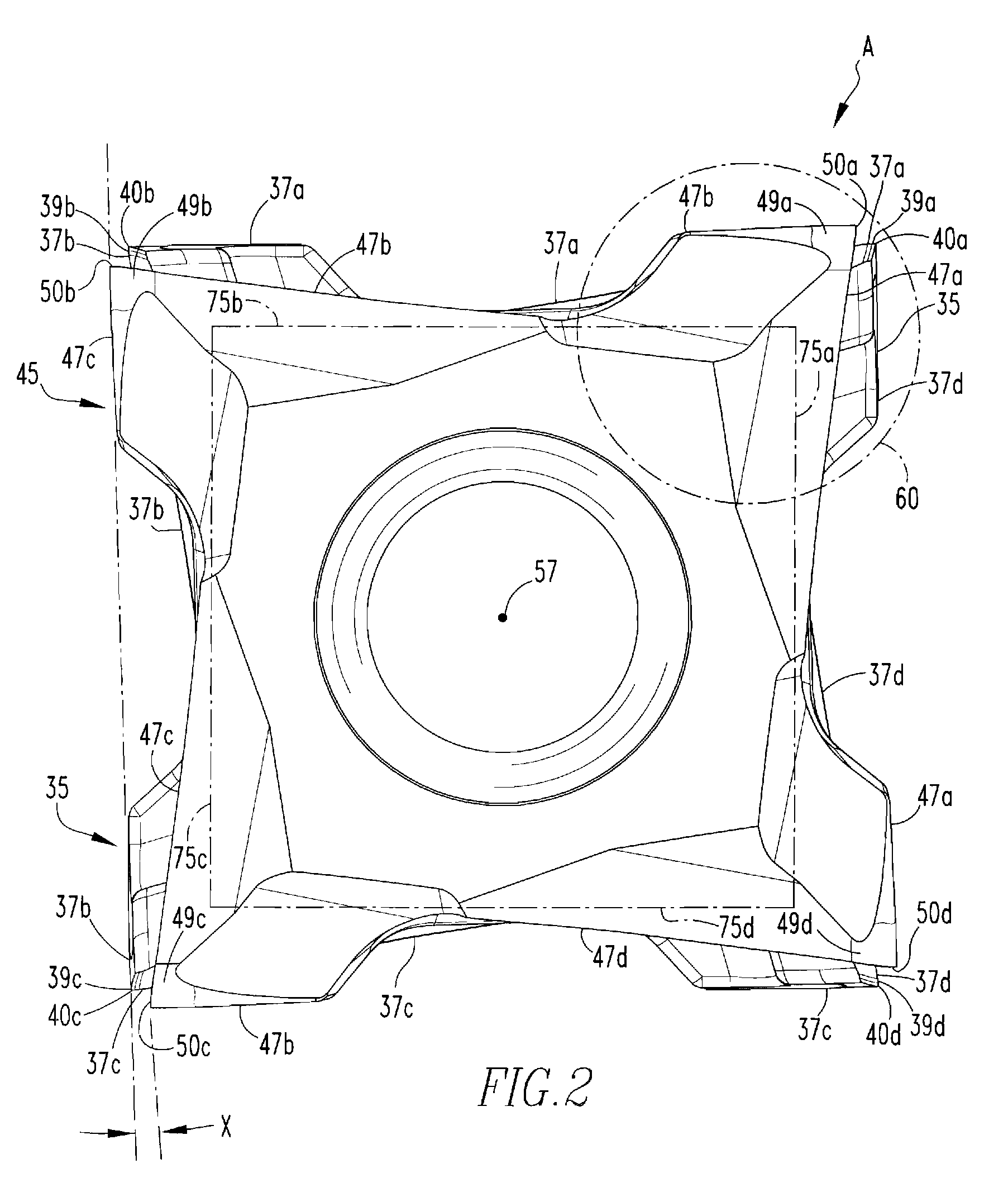

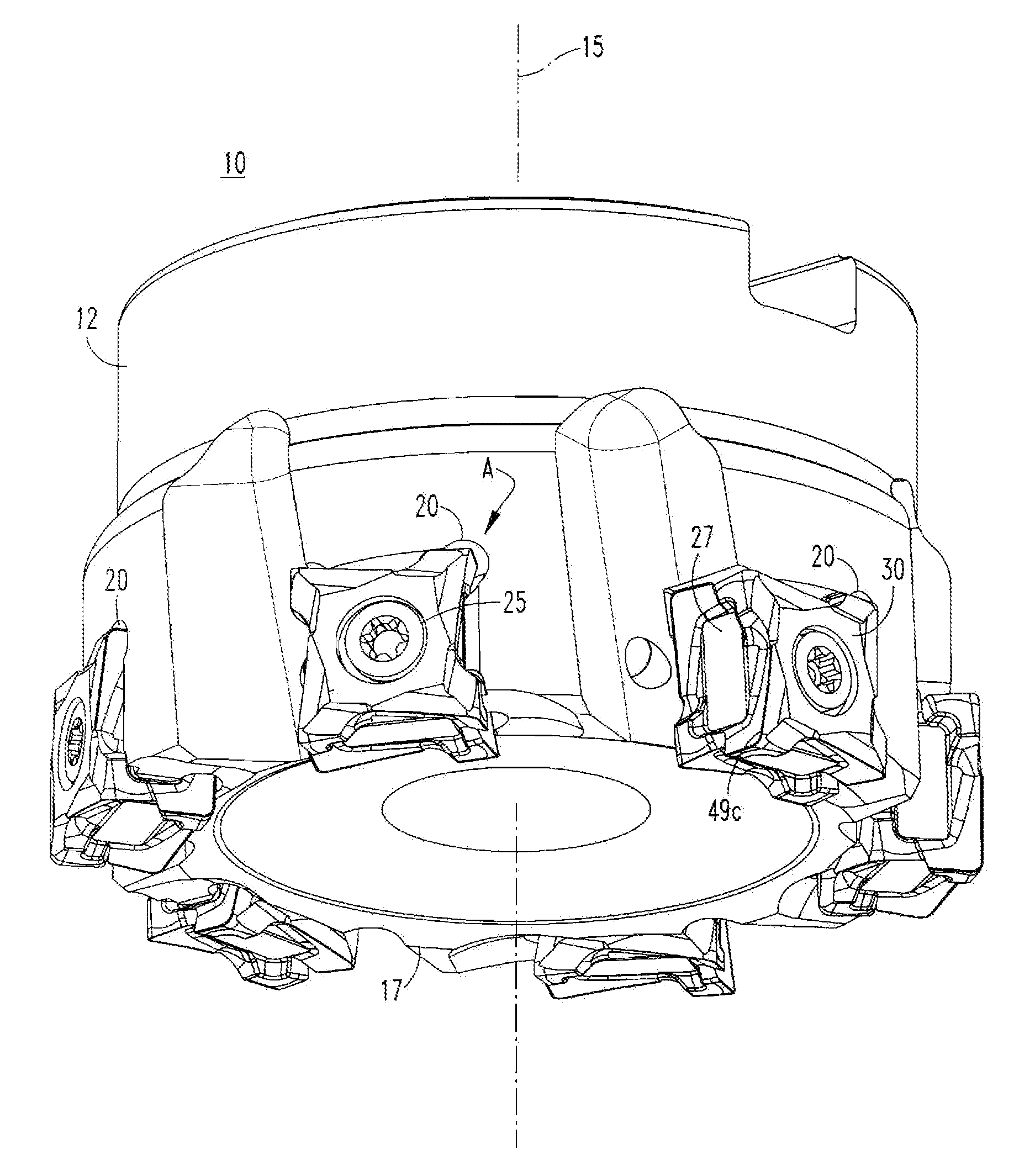

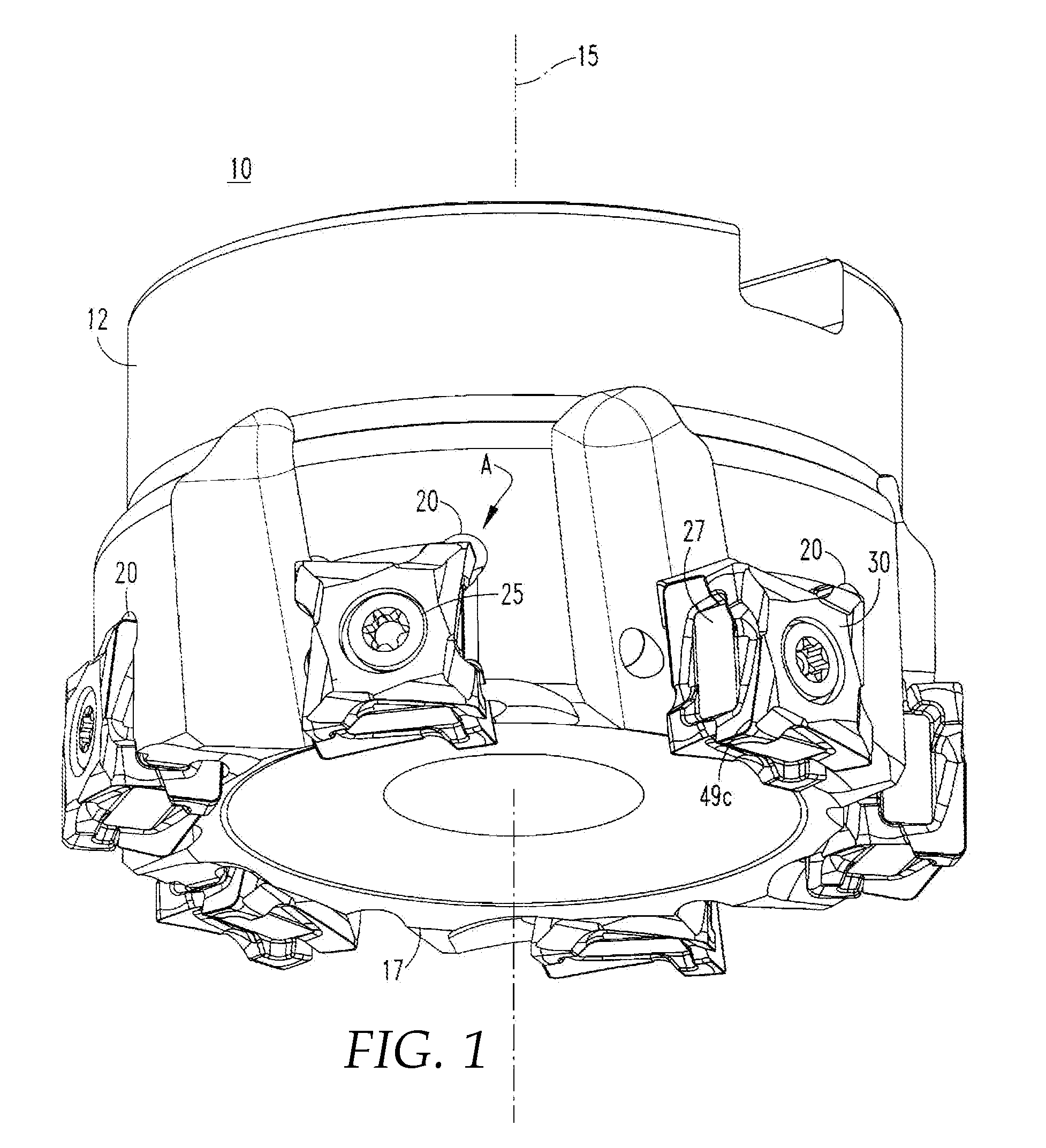

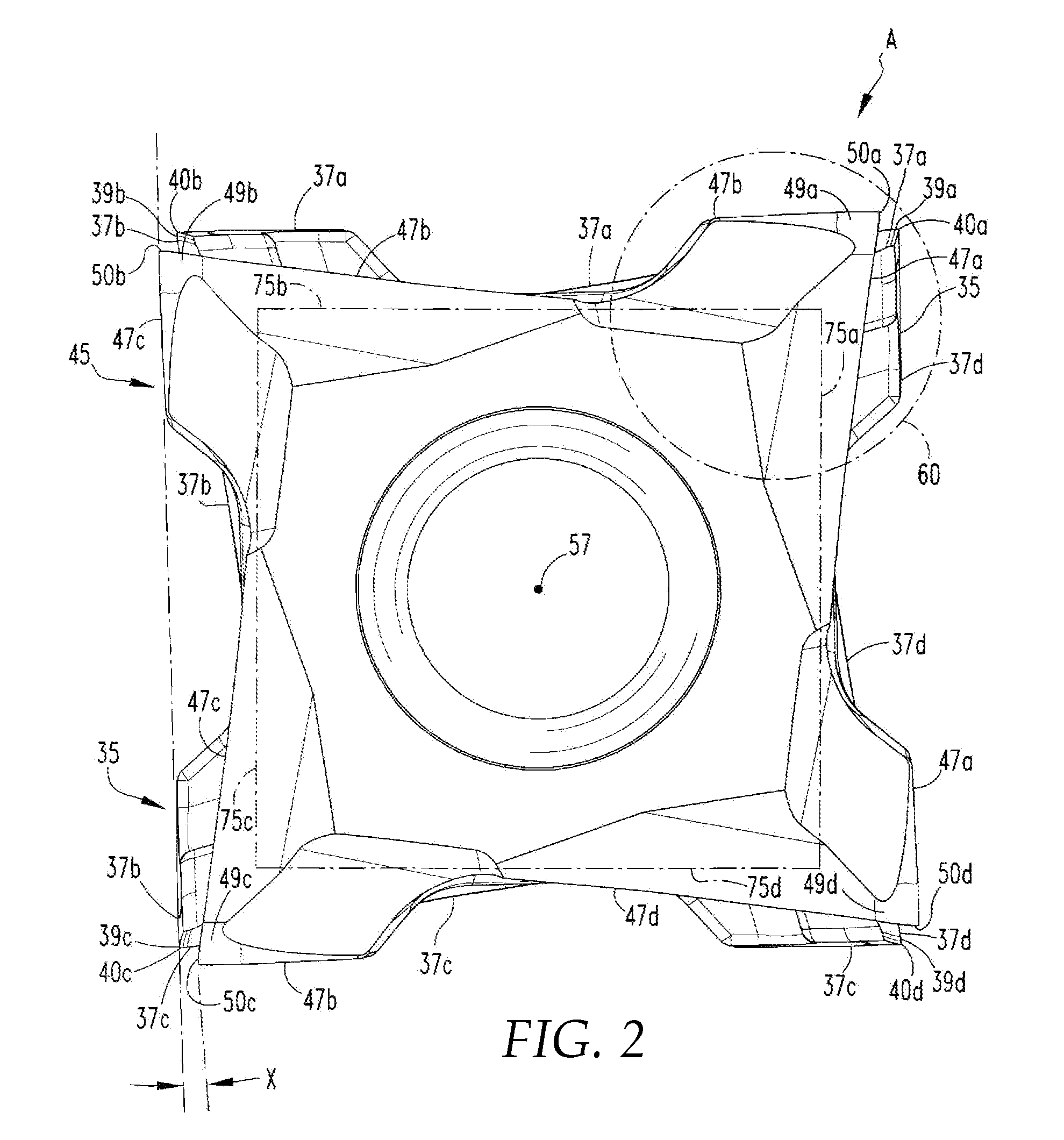

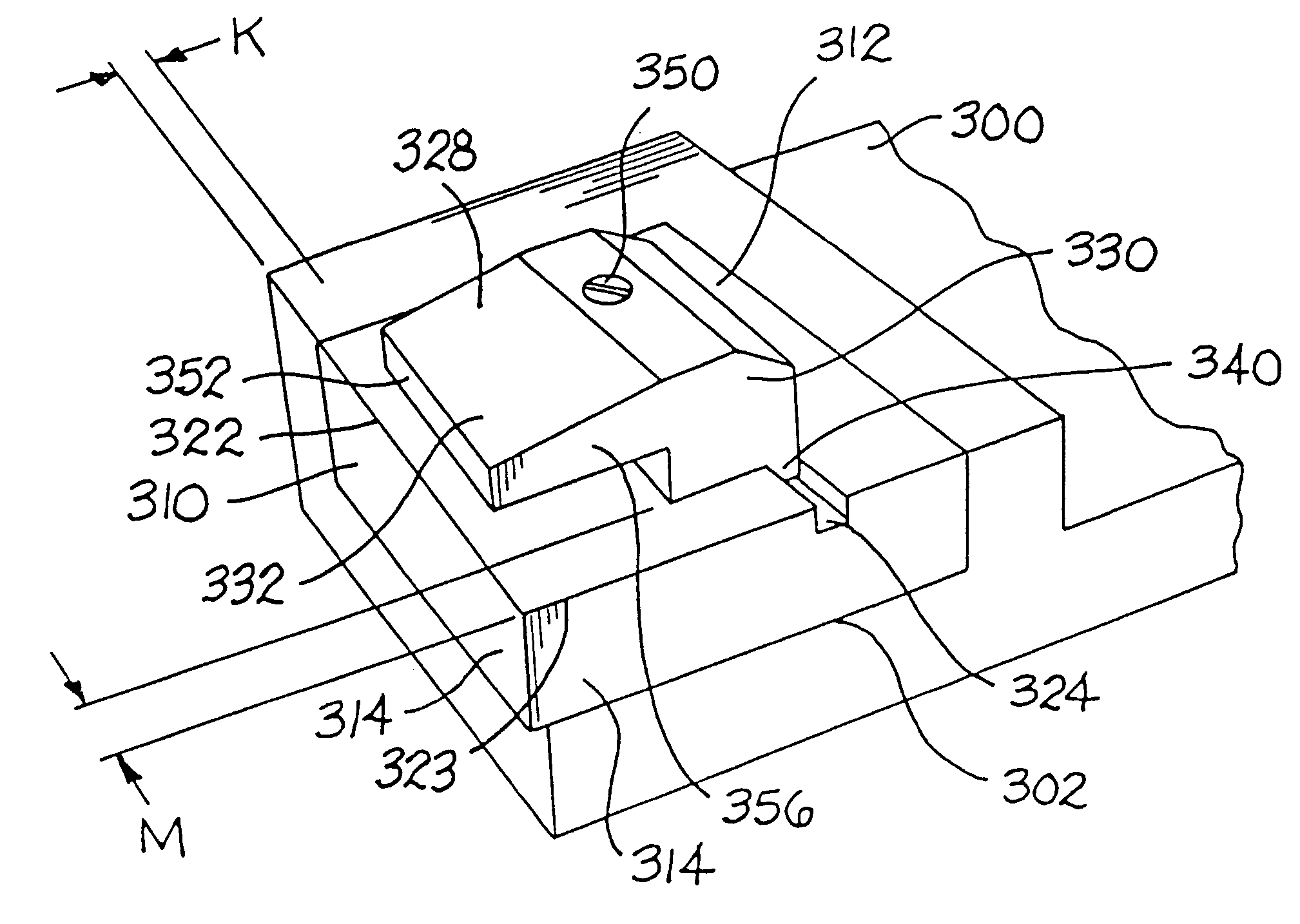

Toolholder and Toolholder Assembly with Elongated Seating pads

A toolholder has a pocket adapted to receive a double-sided on-edge cutting insert, wherein the corners of each side of the insert are radially shifted with respect to one another and has mounting pads preferably mounted about the sides of the cutting insert. The relief area for the corners of the insert is selectively fabricated to maximize the length of the support pads within the pocket of the toolholder.

Owner:KENNAMETAL INC

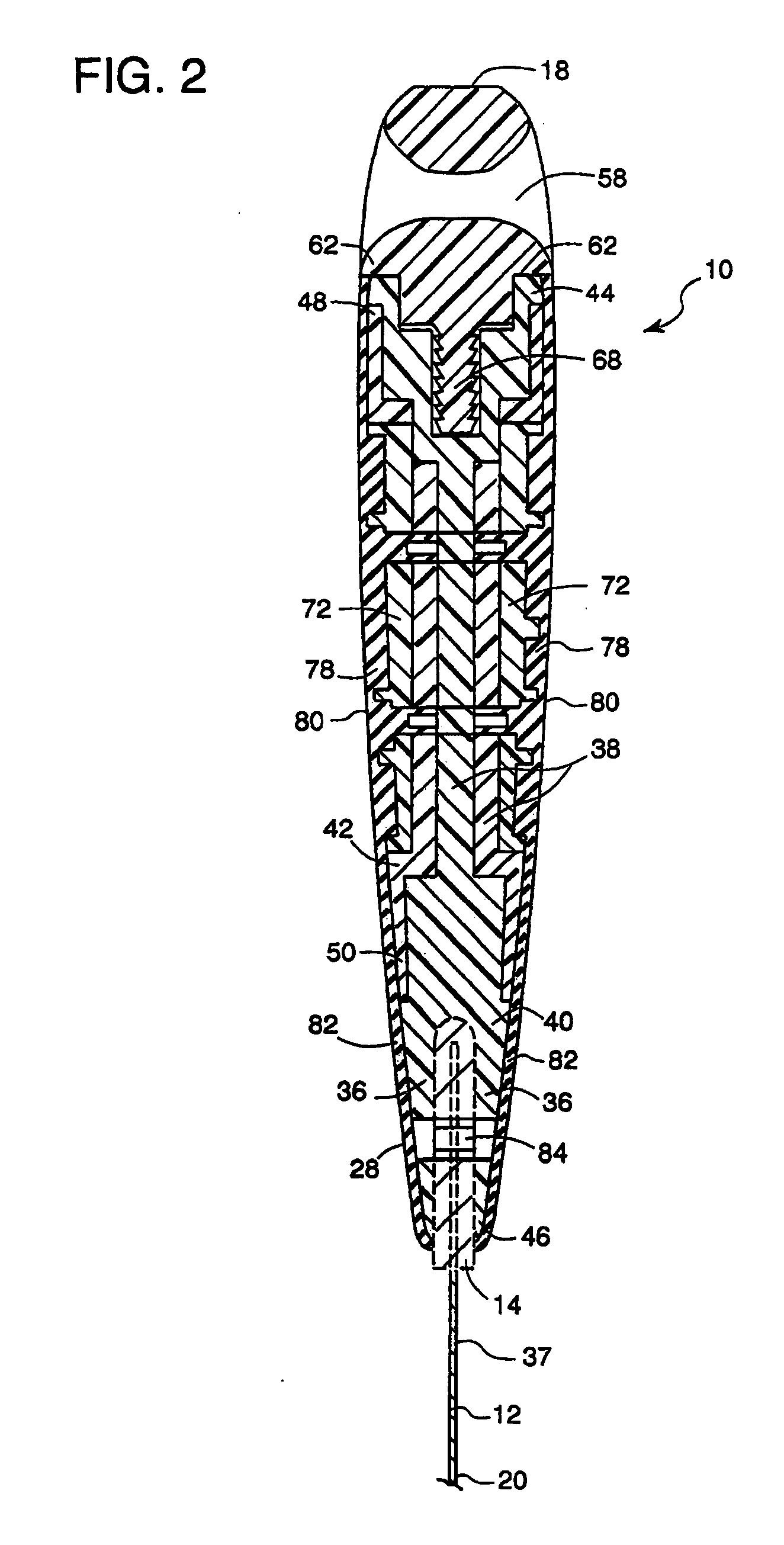

Torque-limiting device

A torque-limiting driver has a handle, a body, a torque-limiting assembly and a work-piece engaging tip. The torque-limiting assembly includes an upper and lower shank that have a plurality of teeth circumferentially spaced. The teeth have a vertical face, and inclined face and a flat peak. The inclined face is defined by a radius of curvature that transitions to the flat peak. There is a spring for applying pressure across the upper and lower shank. The teeth engage for relative rotation when the handle is turned and disengage when a predetermined value of torque is exceeded.

Owner:ECA MEDICAL INSTR

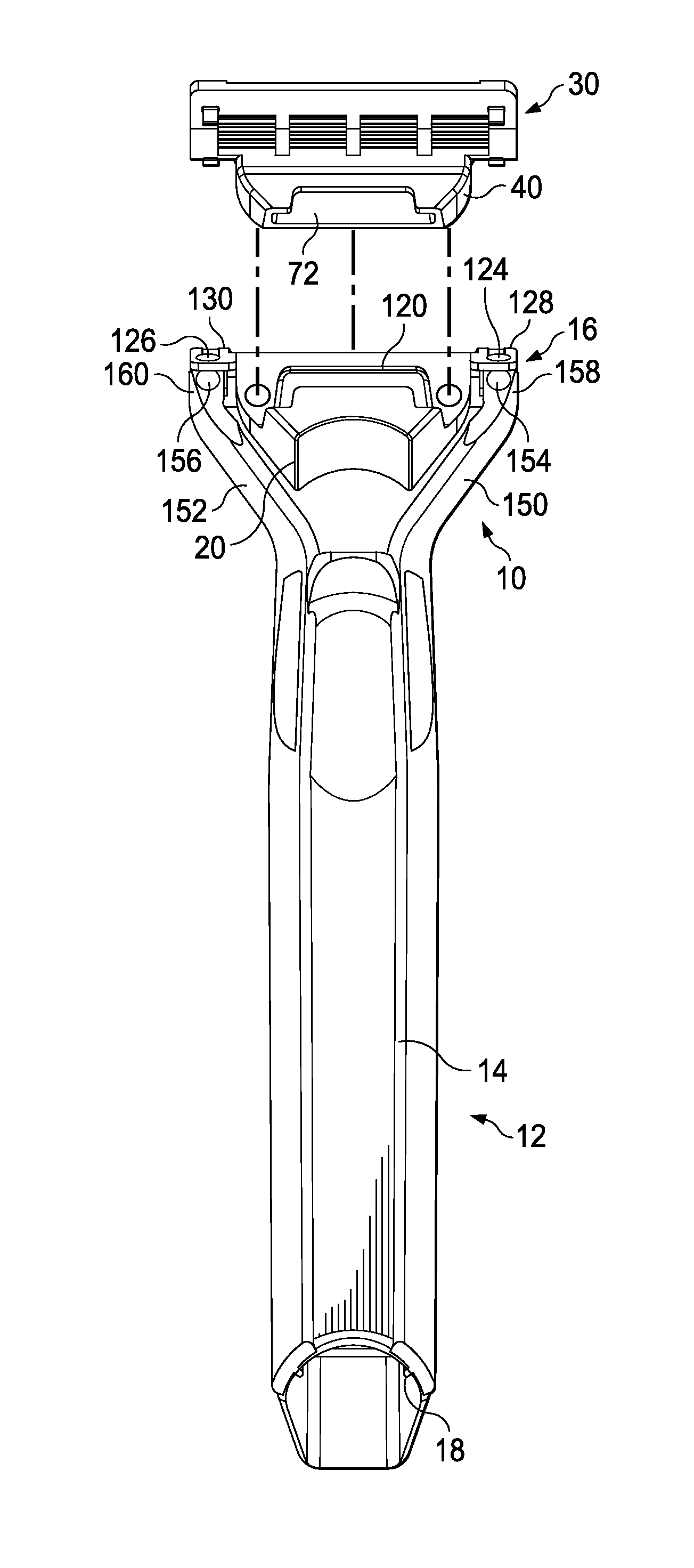

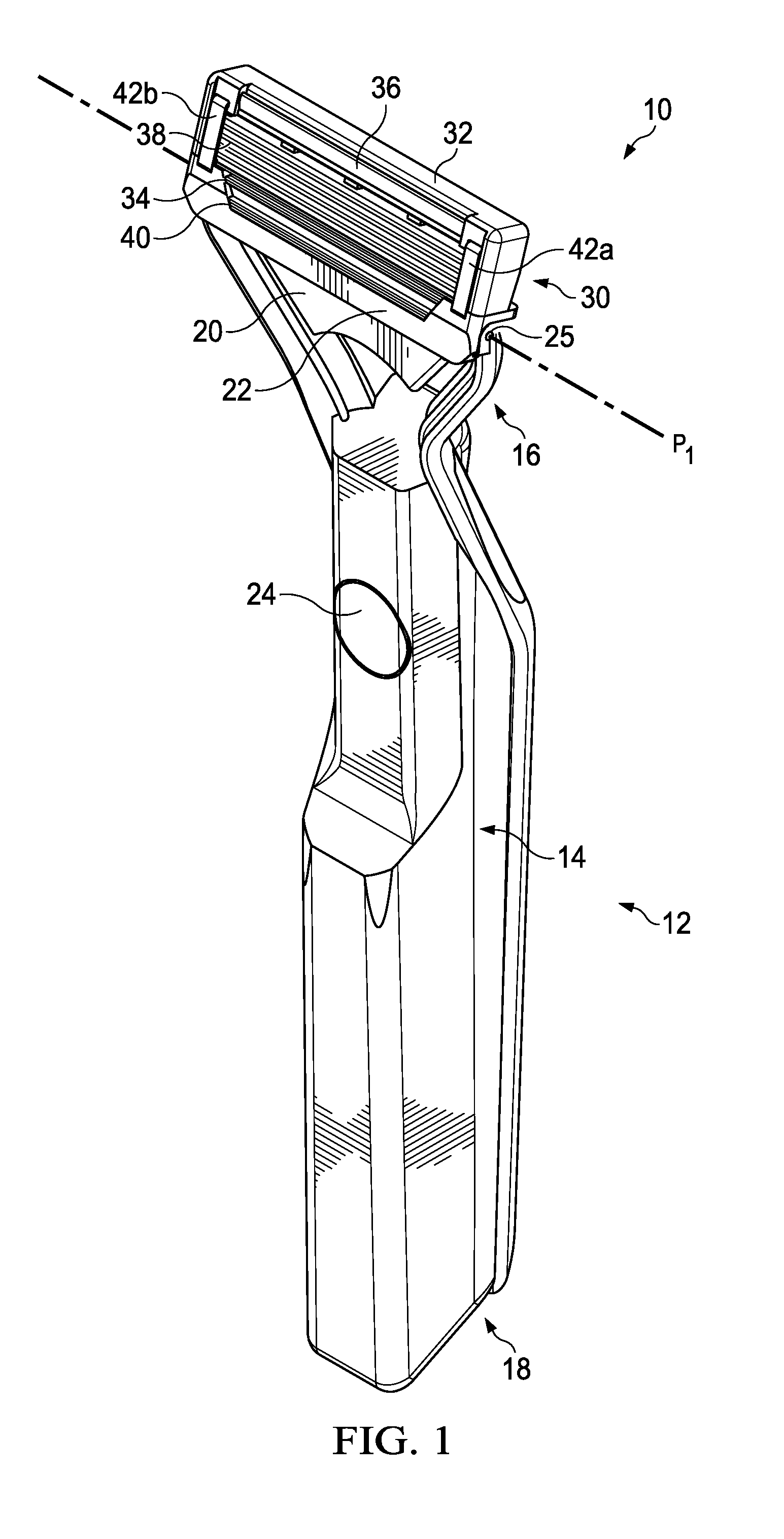

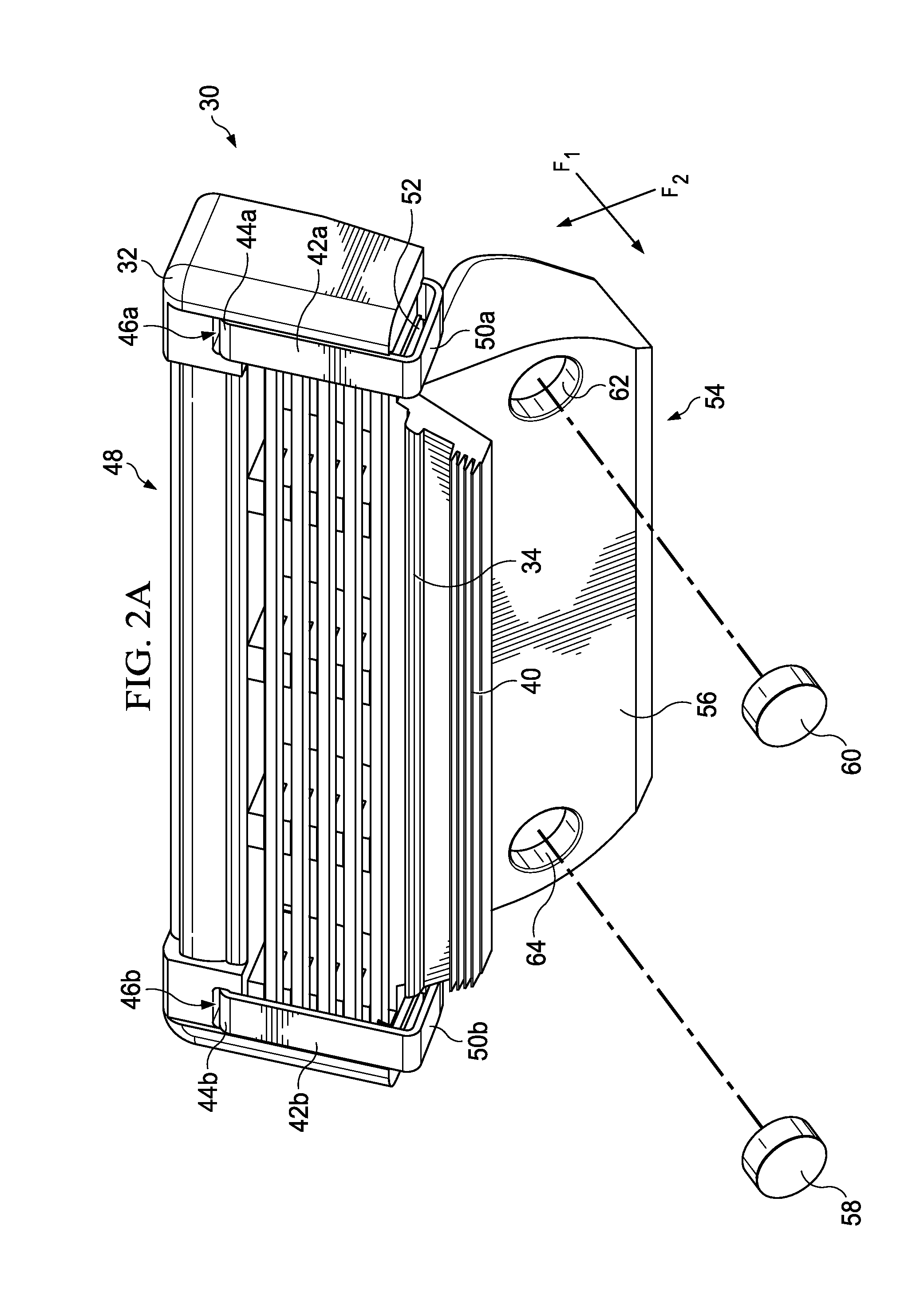

Heated shaving razor handle

A shaving razor system with a handle having an elongated gripping portion with a proximal end portion and a distal end portion. A connection base is mounted to the proximal end portion of the handle. A heater bar is operably connected to a power source positioned within the handle. The heater bar is joined to the connection base. A removable razor cartridge having a housing with a guard, a cap and at least one blade mounted to the housing between the guard and the cap. An interconnect member fixed to the housing and having a handle mounting surface releasably engaged with a corresponding surface on the connection base.

Owner:THE GILLETTE CO

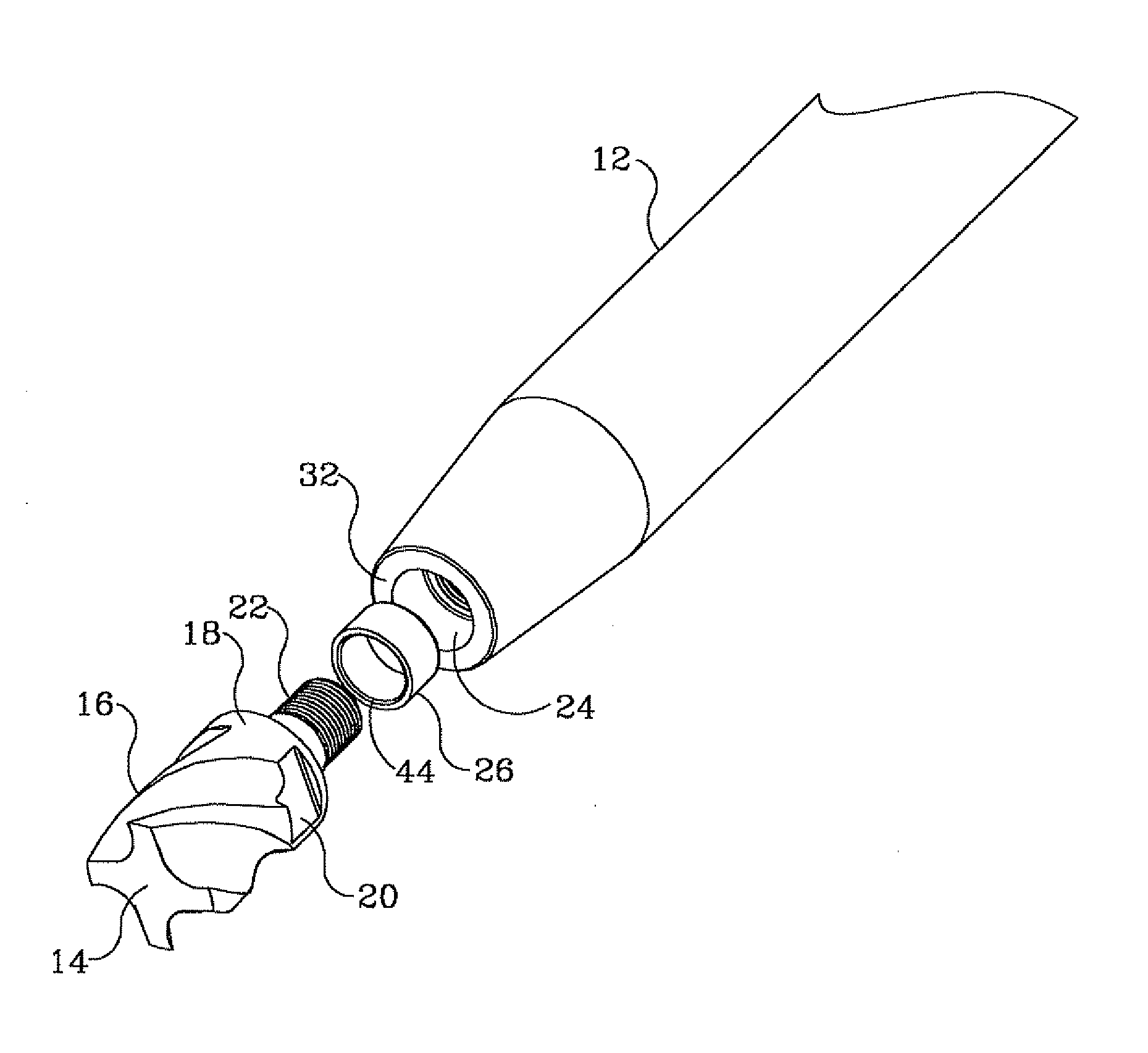

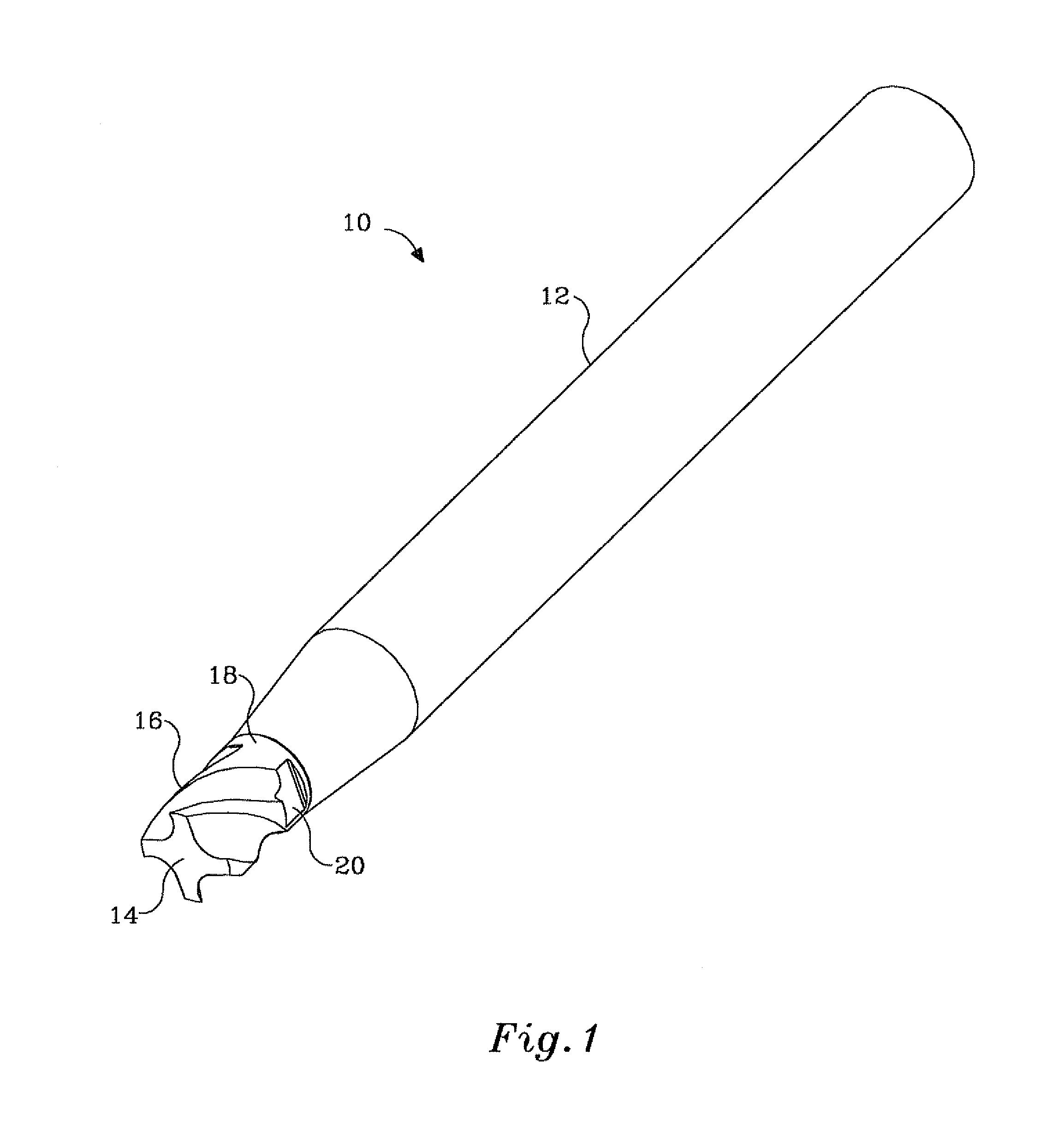

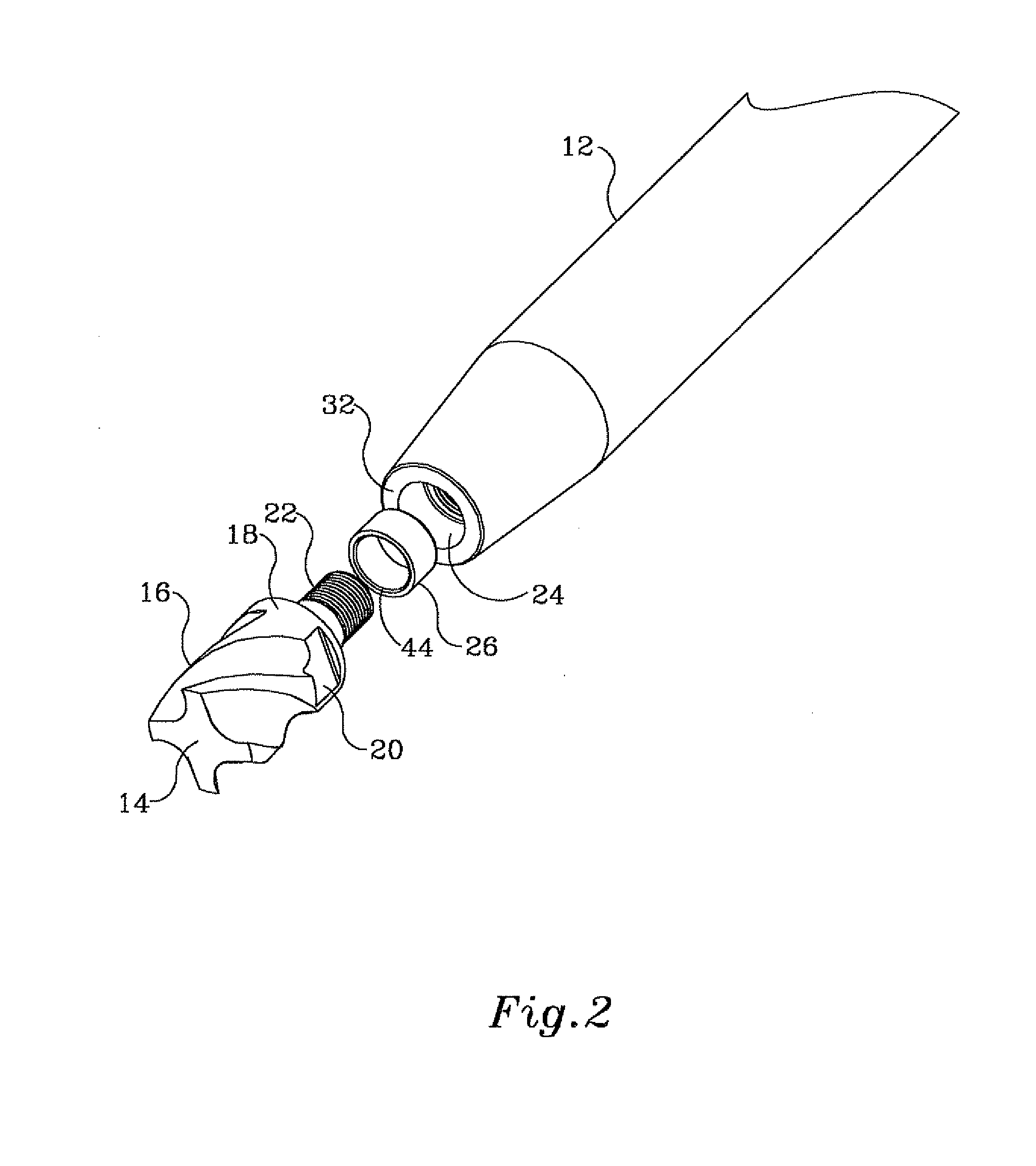

Milling Tool Assembly Having a Replaceable Cutter

A milling tool assembly has a replaceable cutter and a reusable shank connected to the cutter with a detachable joint. The joint may be, for example, a threaded connection. An intermediate alignment sleeve made of an elastic or semi-elastic material, is positioned between the cutter and the shank about the axis of rotation of the shank.

Owner:KENNAMETAL INC

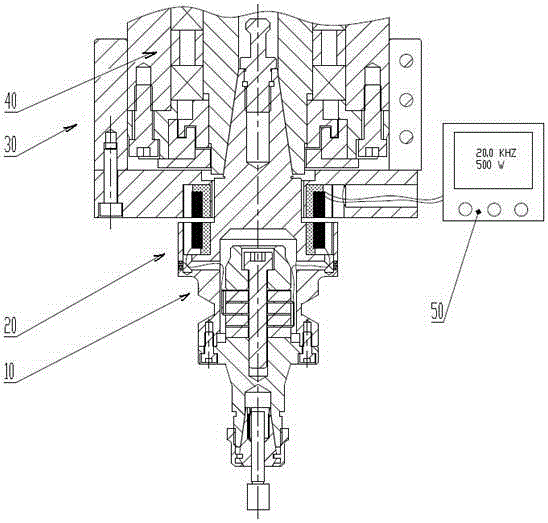

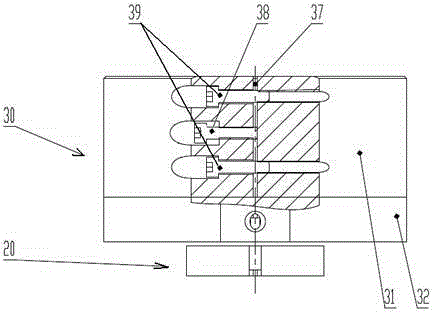

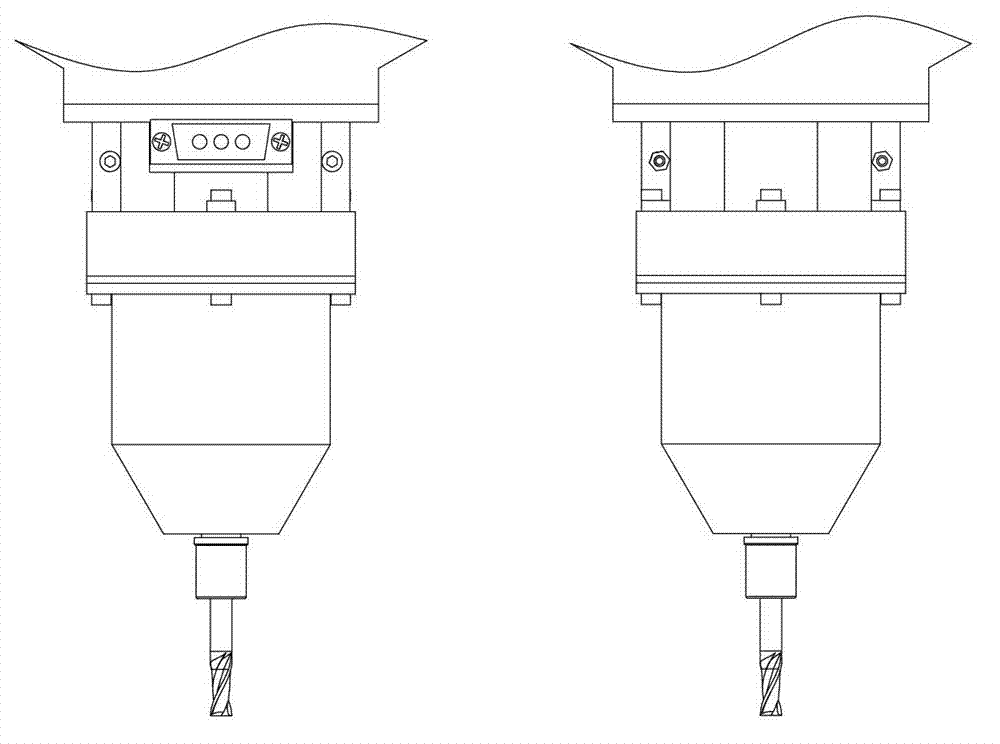

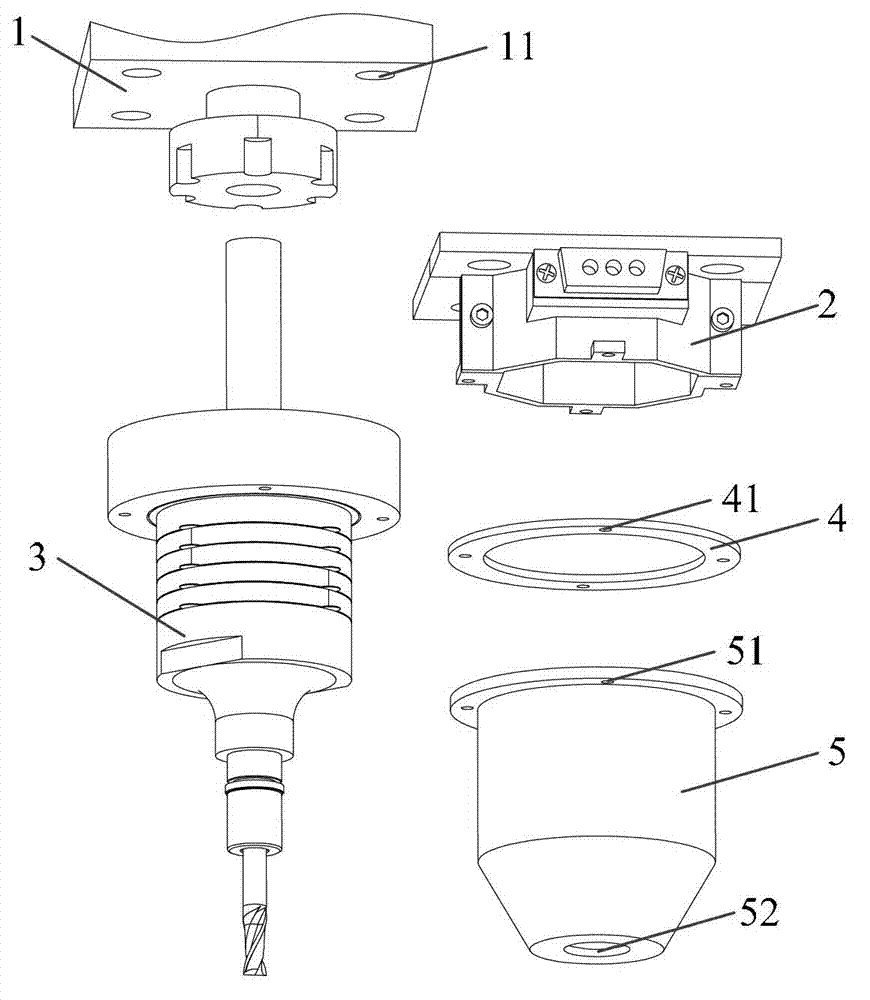

Rotary ultrasonic machining device based on non-contact energy transfer

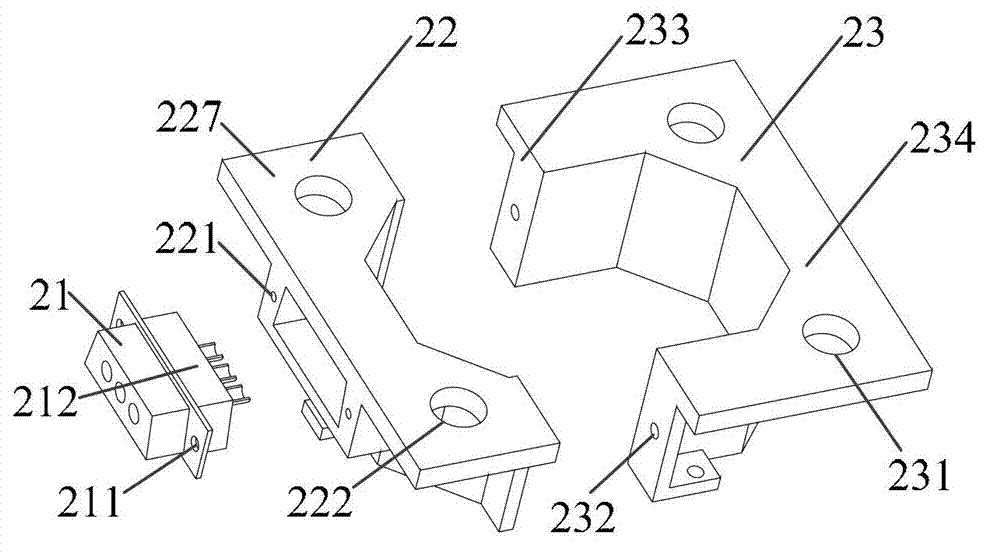

InactiveCN105171131AImprove processing efficiencyImprove machined surface qualityPositioning apparatusMetal-working holdersNumerical controlEnergy transfer

The invention discloses a rotary ultrasonic machining device based on non-contact energy transfer. The rotary ultrasonic machining device based on non-contact energy transfer comprises a high-speed electric spindle, a primary side assembly fixed to the lower end of the high-speed electric spindle, an ultrasonic knife handle assembly composed of an ultrasonic knife handle and a secondary side assembly arranged on the periphery of the ultrasonic knife handle, and an ultrasonic power supply generator. The ultrasonic knife handle assembly is arranged at the lower end of the high-speed electric spindle, so that the secondary side assembly corresponds to the primary side assembly up and down. The ultrasonic power supply generator is connected with the primary side assembly. According to the rotary ultrasonic machining device based on non-contact energy transfer, the ultrasonic machining technology can be directly combined with existing computer numerical control (CNC) machining centers such as CNC engraving and milling machines, engraving and milling machines, high-gloss CNC machines and drilling and tapping centers, and original spindles do not need to be modified; non-contact energy transfer of ultrasonic waves is achieved through the primary side assembly and the secondary side assembly, and the rotation speed reaches 10,000 turns / min; in addition, the automatic knife switching function can be achieved by using an exiting magazine.

Owner:YUHUAN CNC MACHINE TOOL

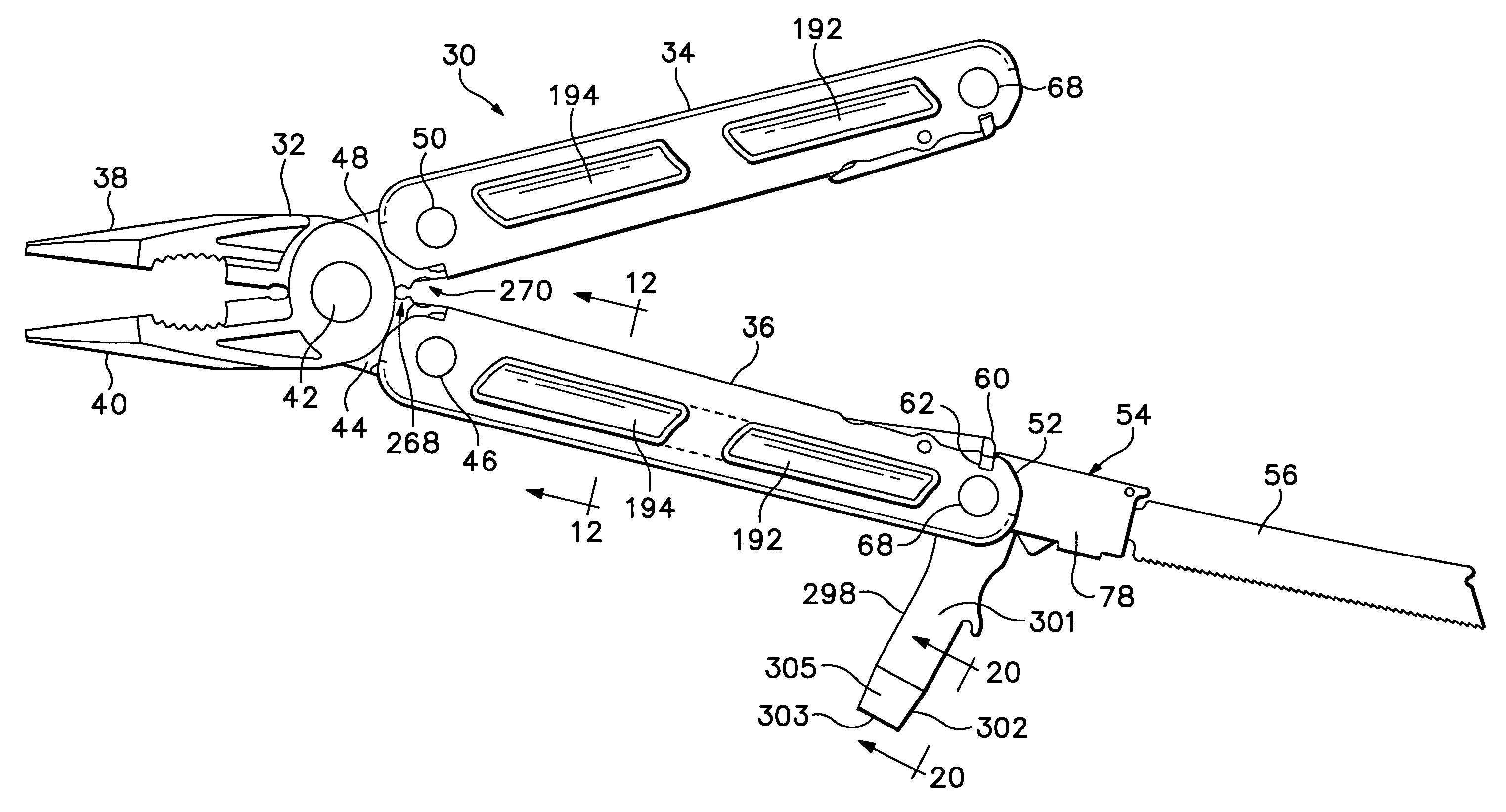

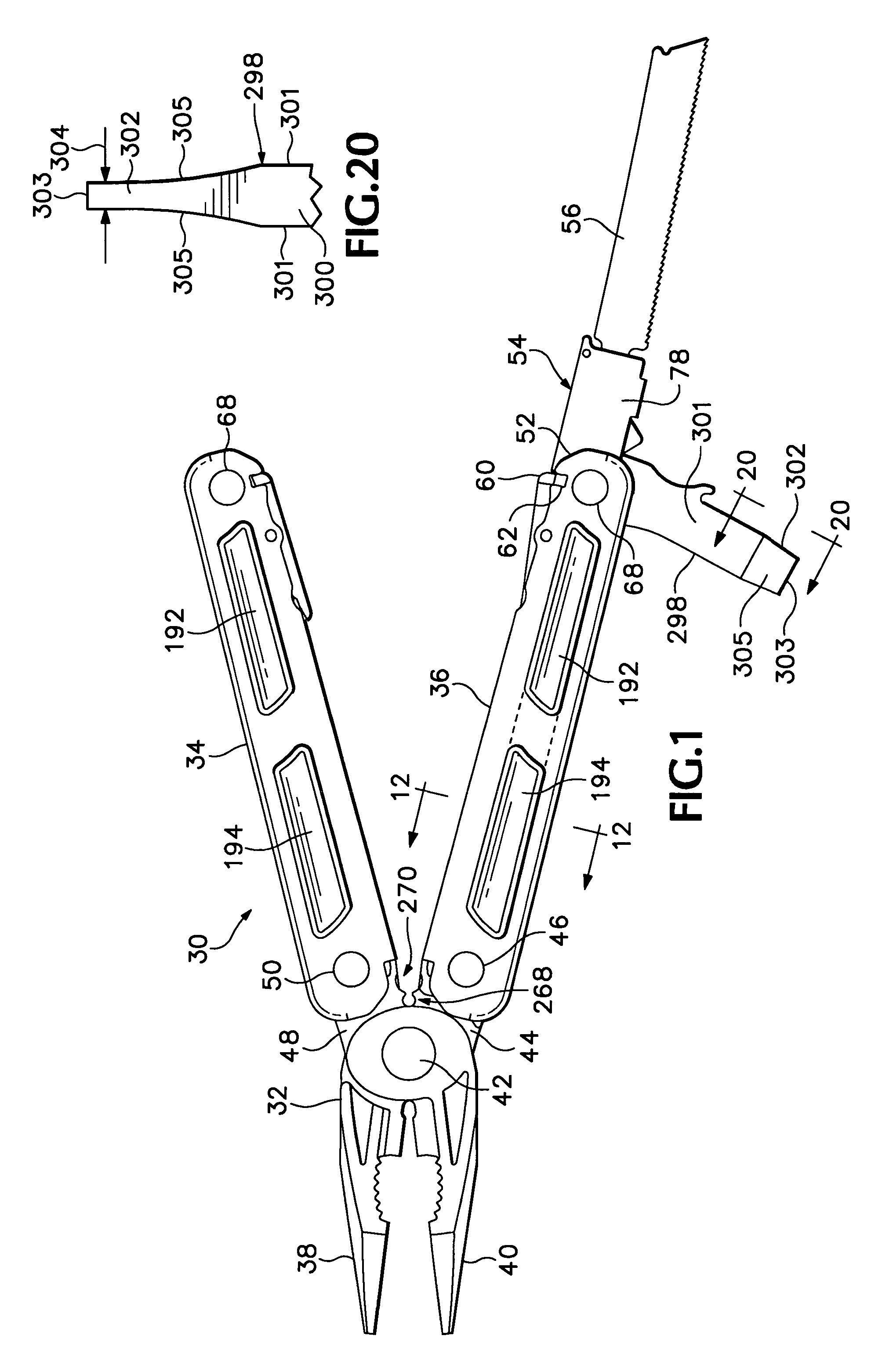

Multipurpose tool including holder for replaceable tool blades

A multipurpose folding hand tool including a tool holder permitting exchanges of blades. The tool may include a folding scissors including a spring that is moved into operative engagement with a scissors handle to open the scissors handles apart from each other only as the scissors approaches an extended, operative position with respect to the handle of the folding land tool, within which it may be stowed. A resilient grip member is incorporated in one of the handles of the folding multipurpose hand tool. A wire cutter and a crimping tool are located on pliers jaw tangs, between the pliers pivot and the foldable handles of the tool.

Owner:LEATHERMAN TOOL GROUP

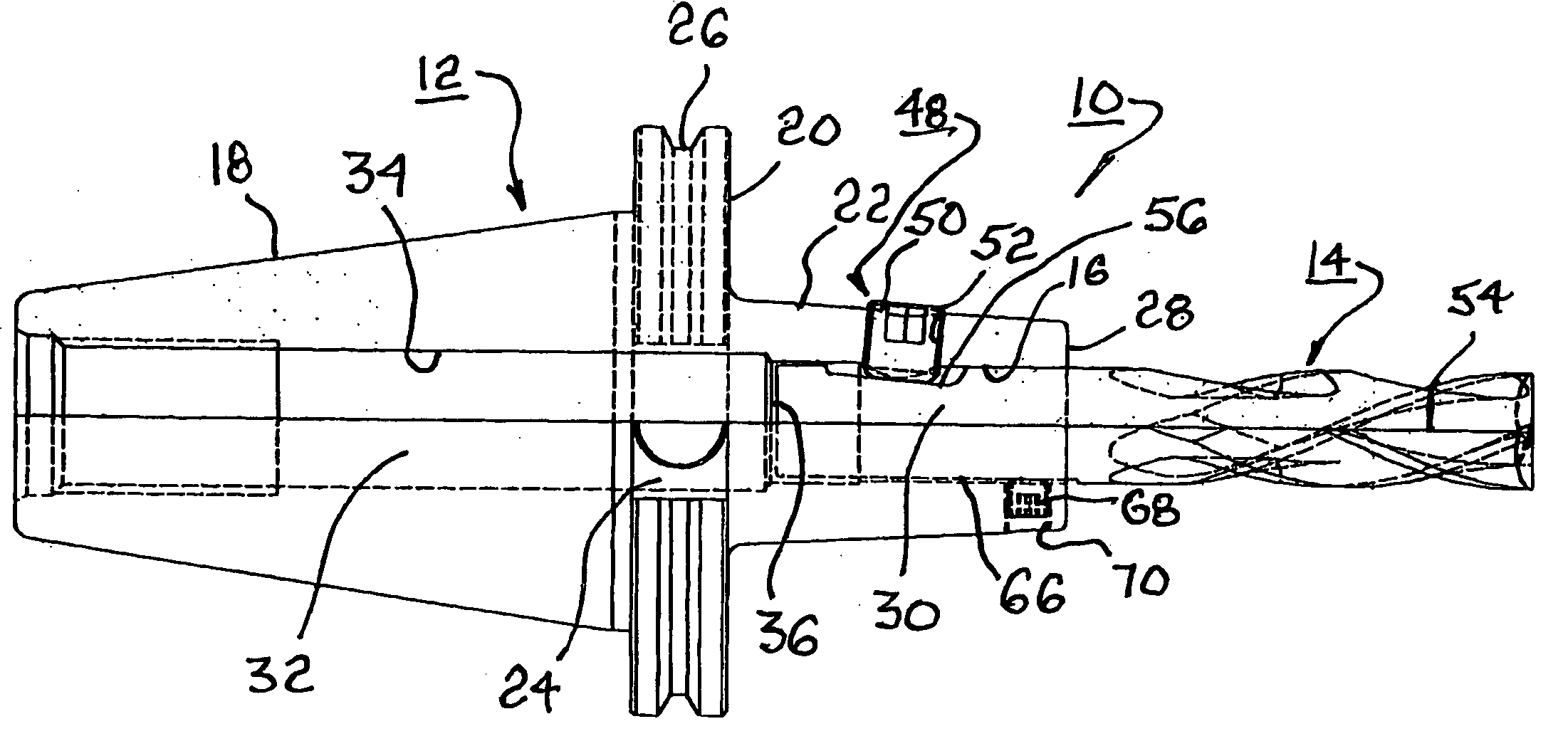

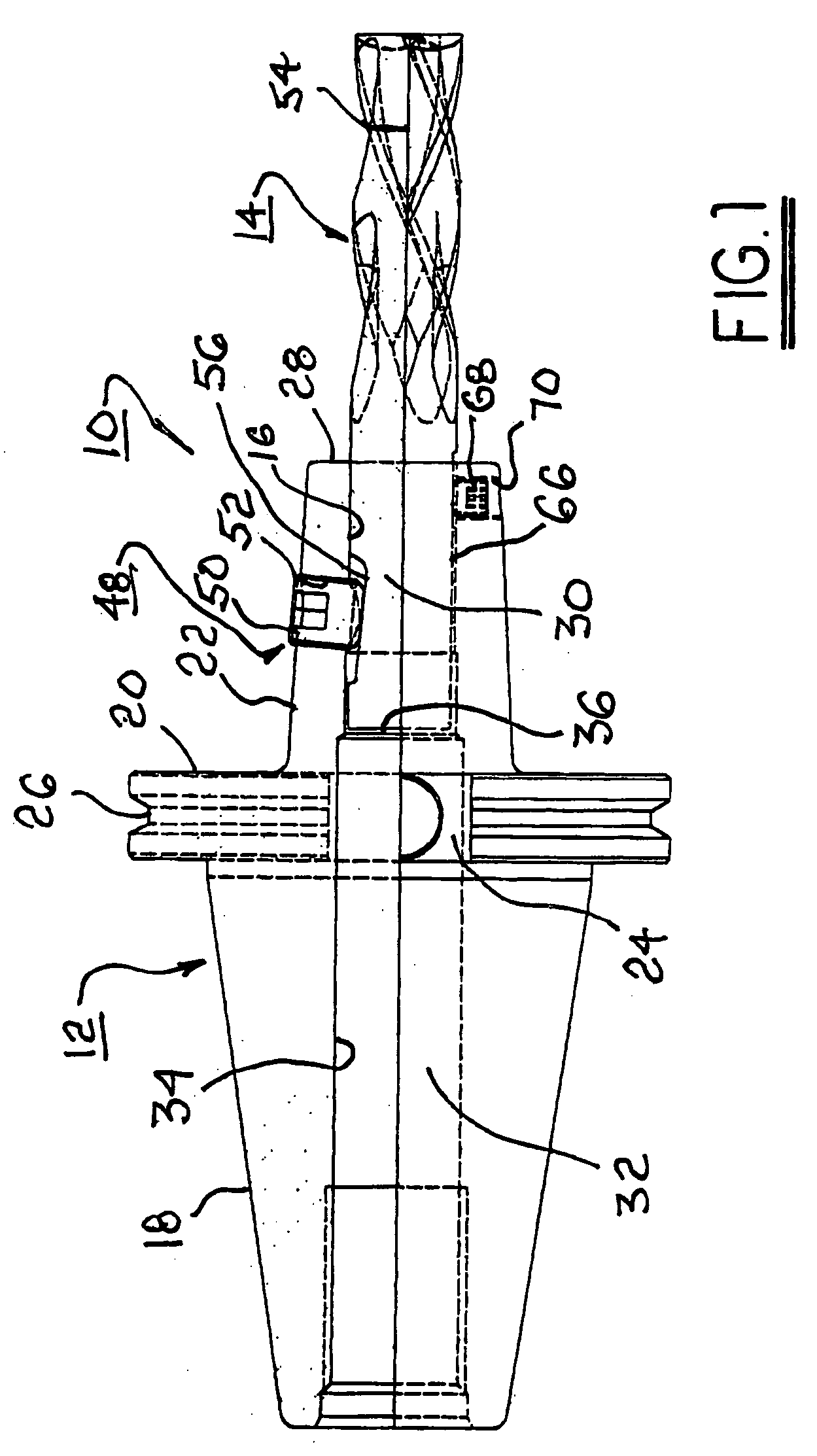

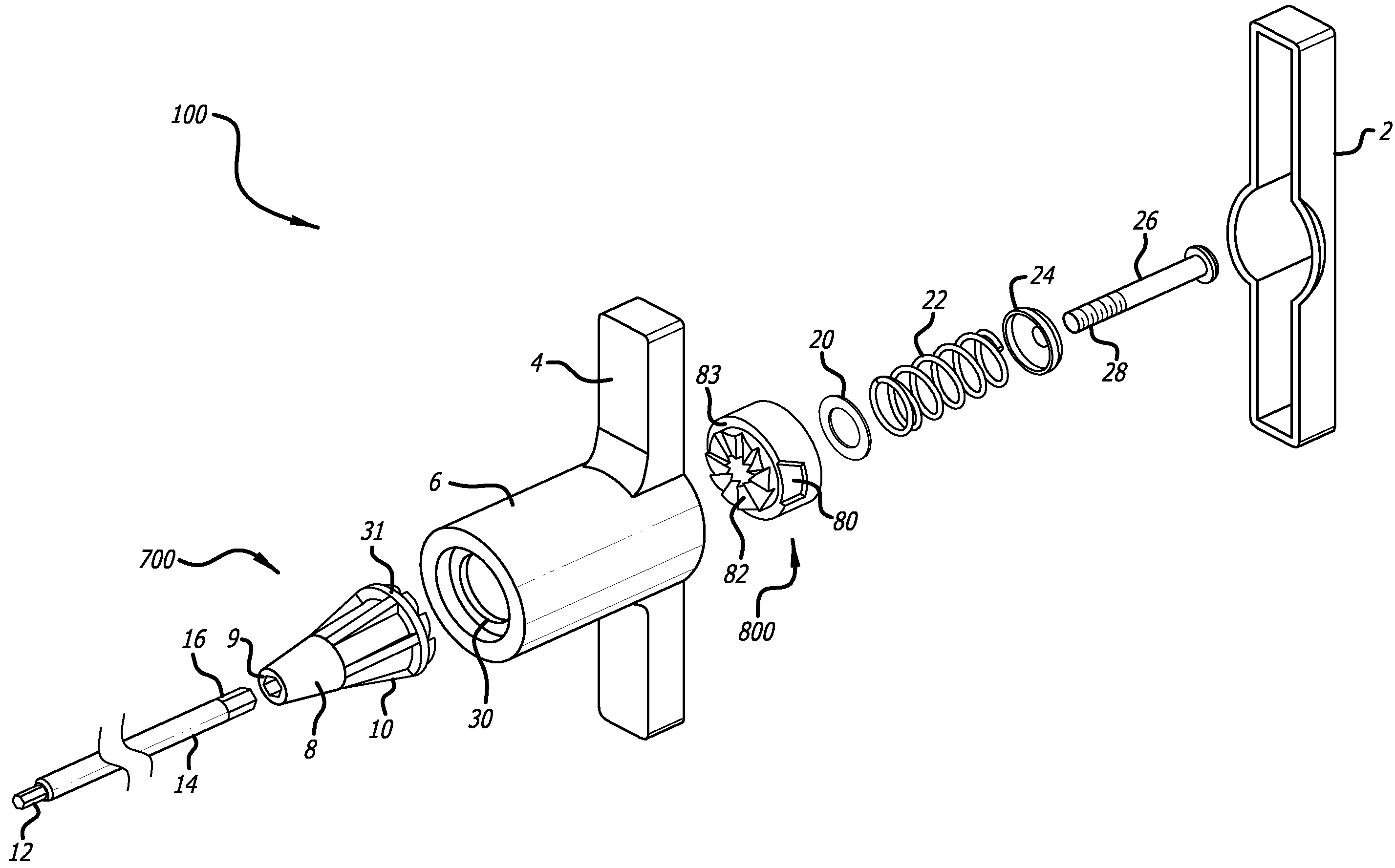

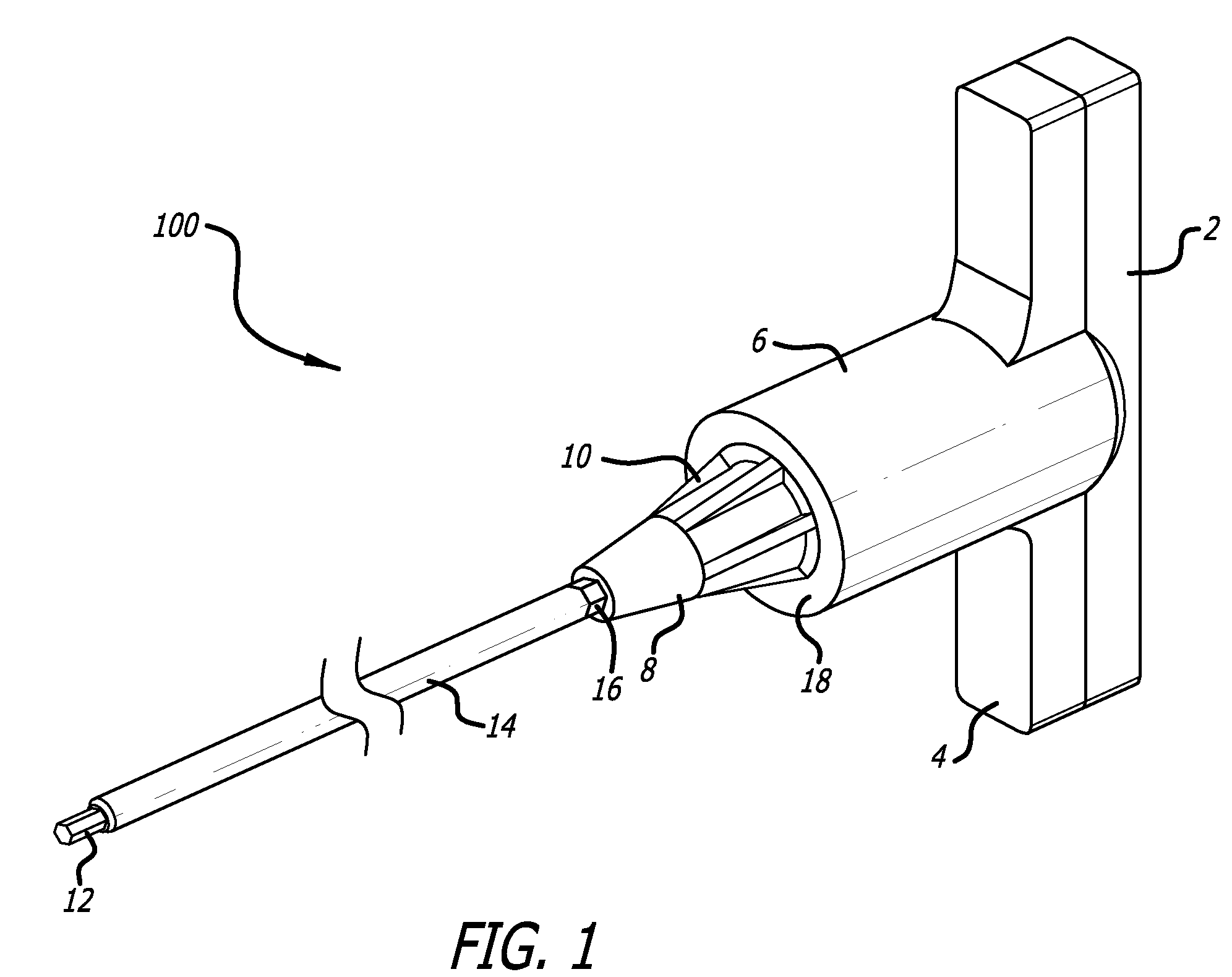

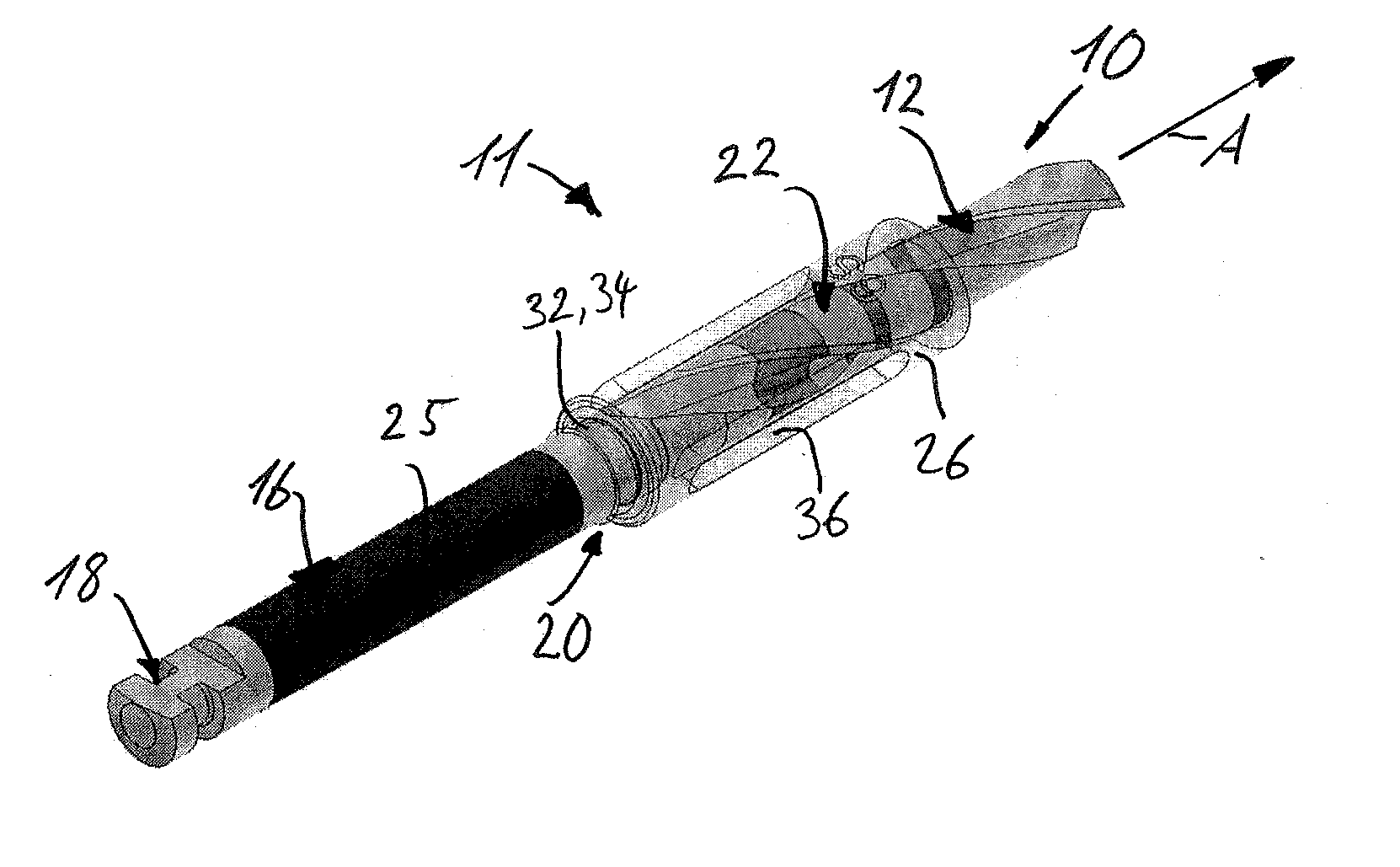

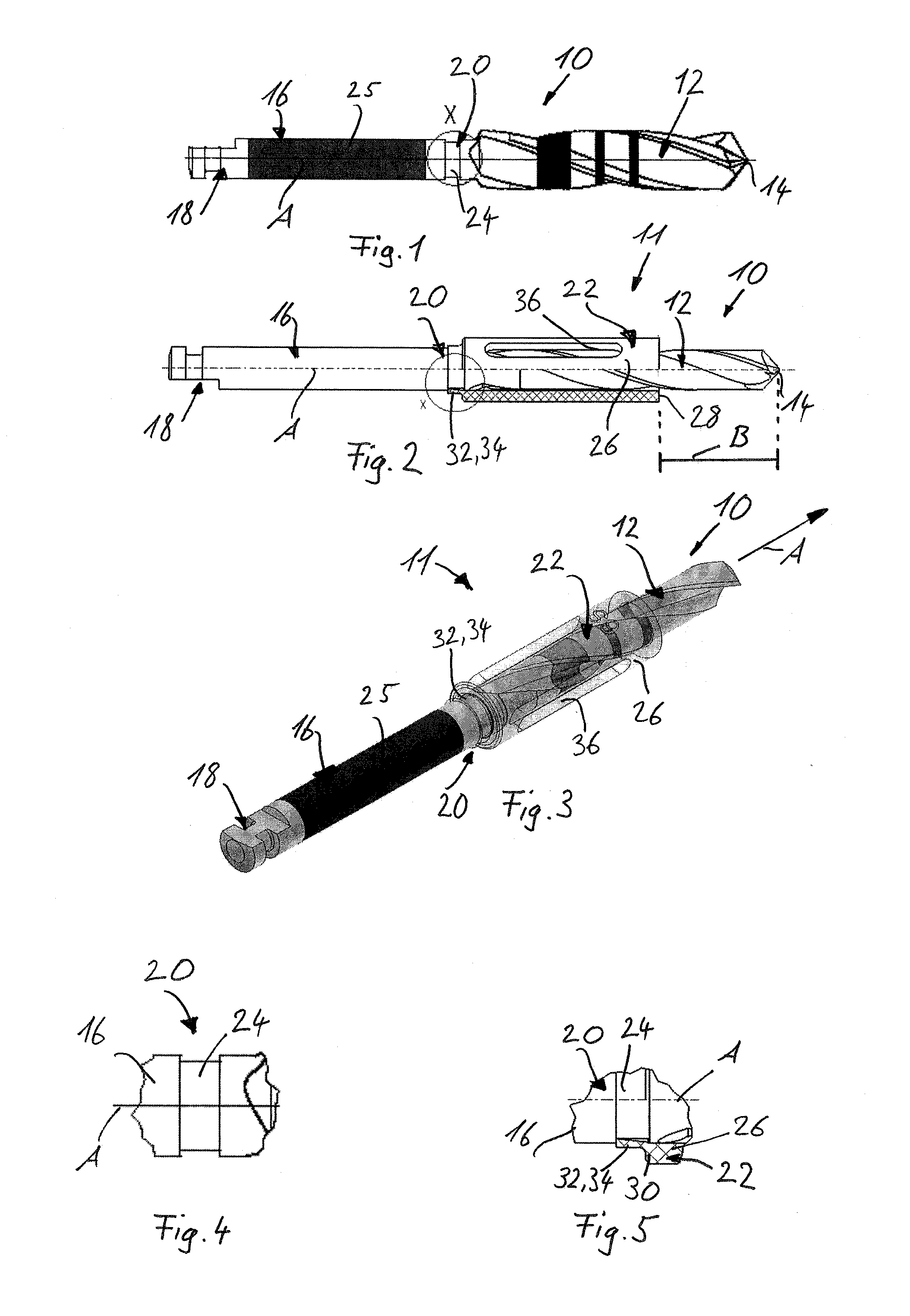

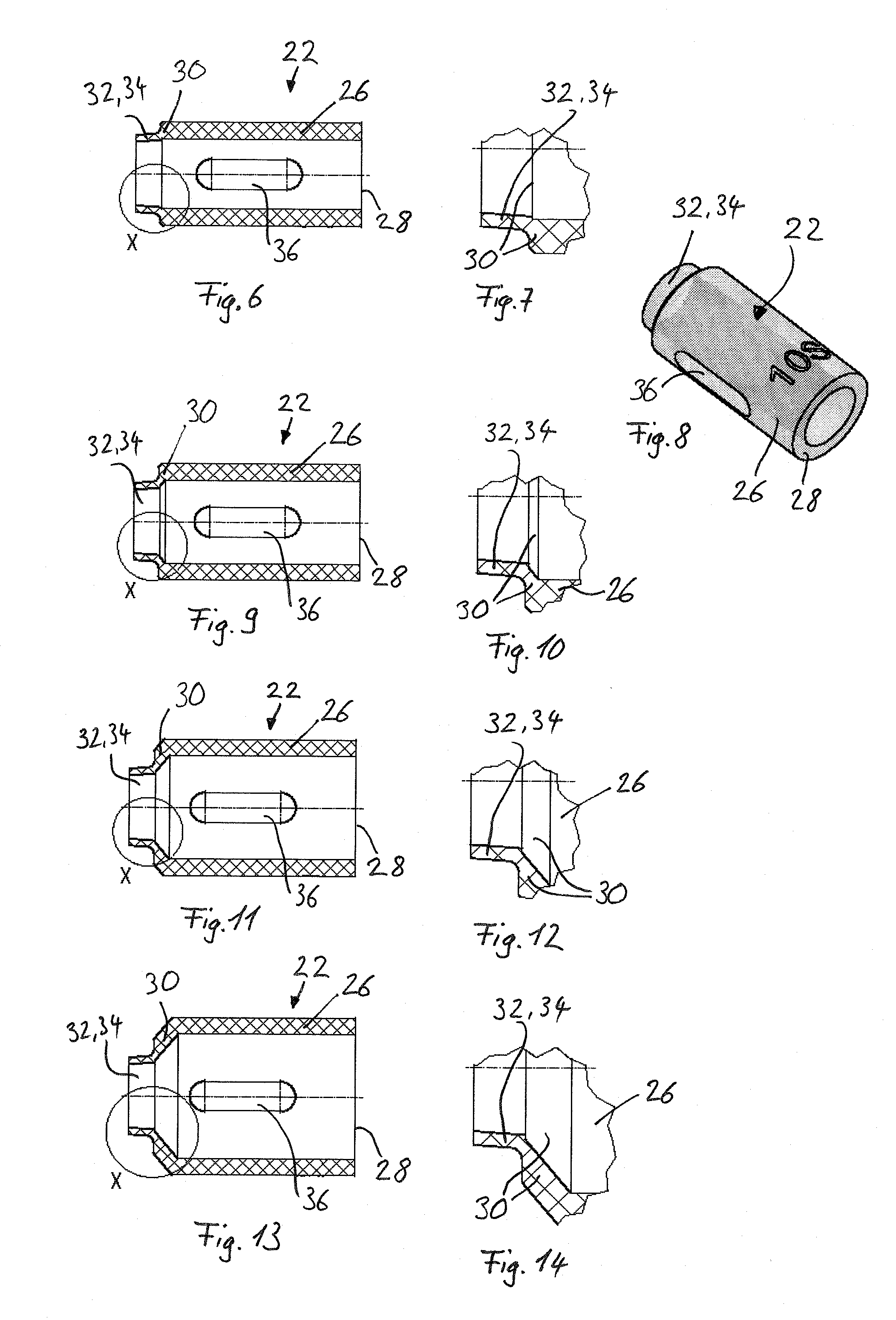

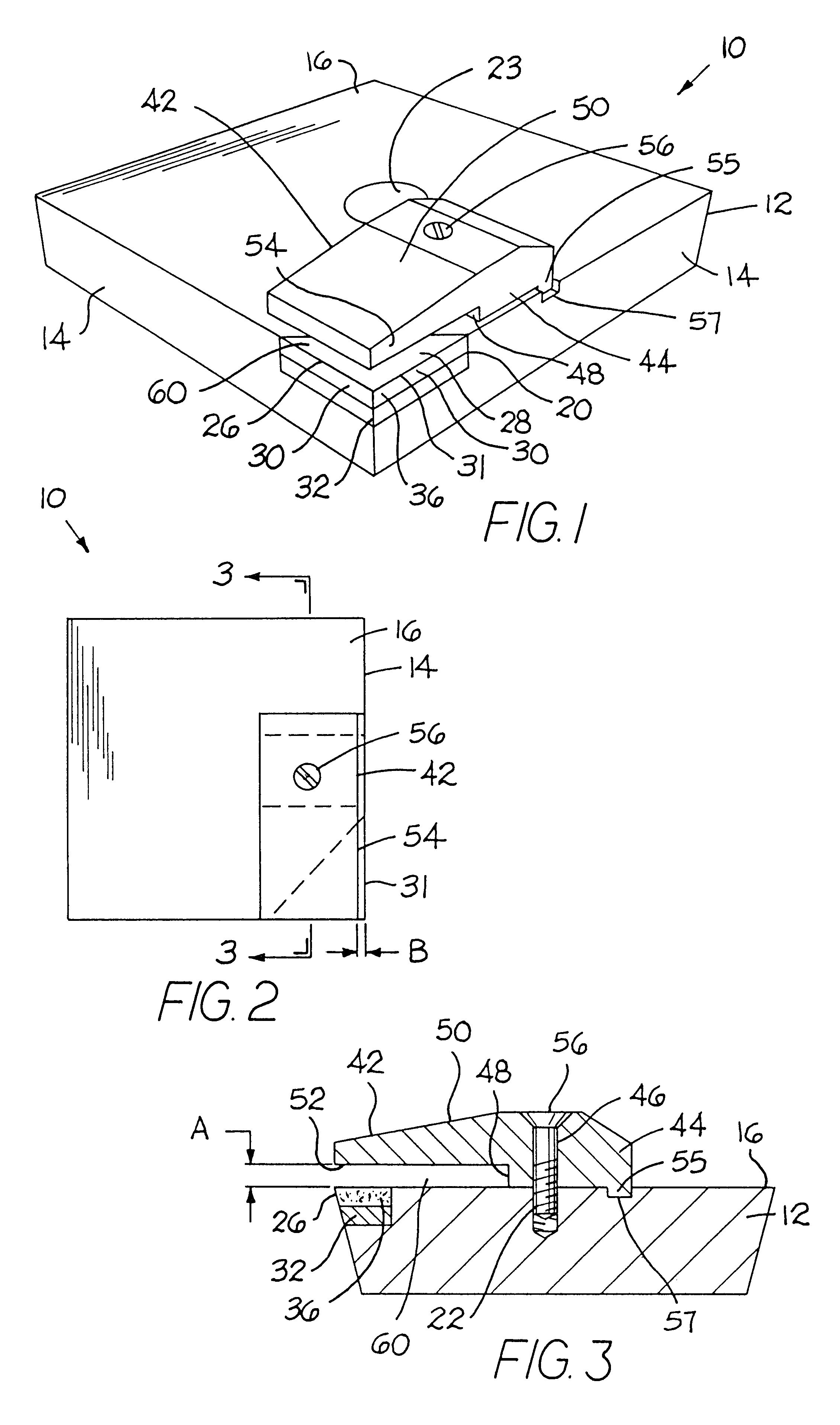

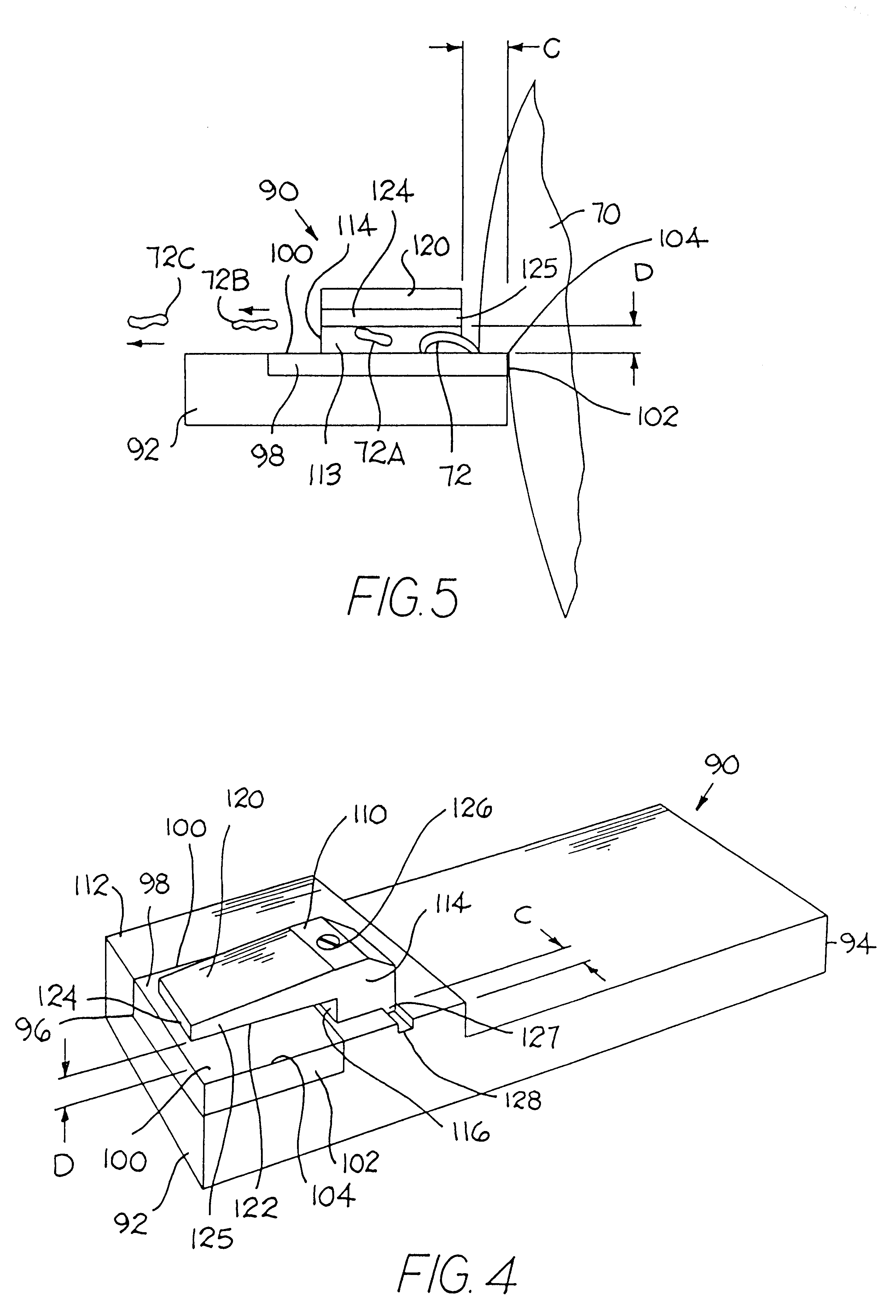

Holder for a surgical reamer and single use, flat reamer

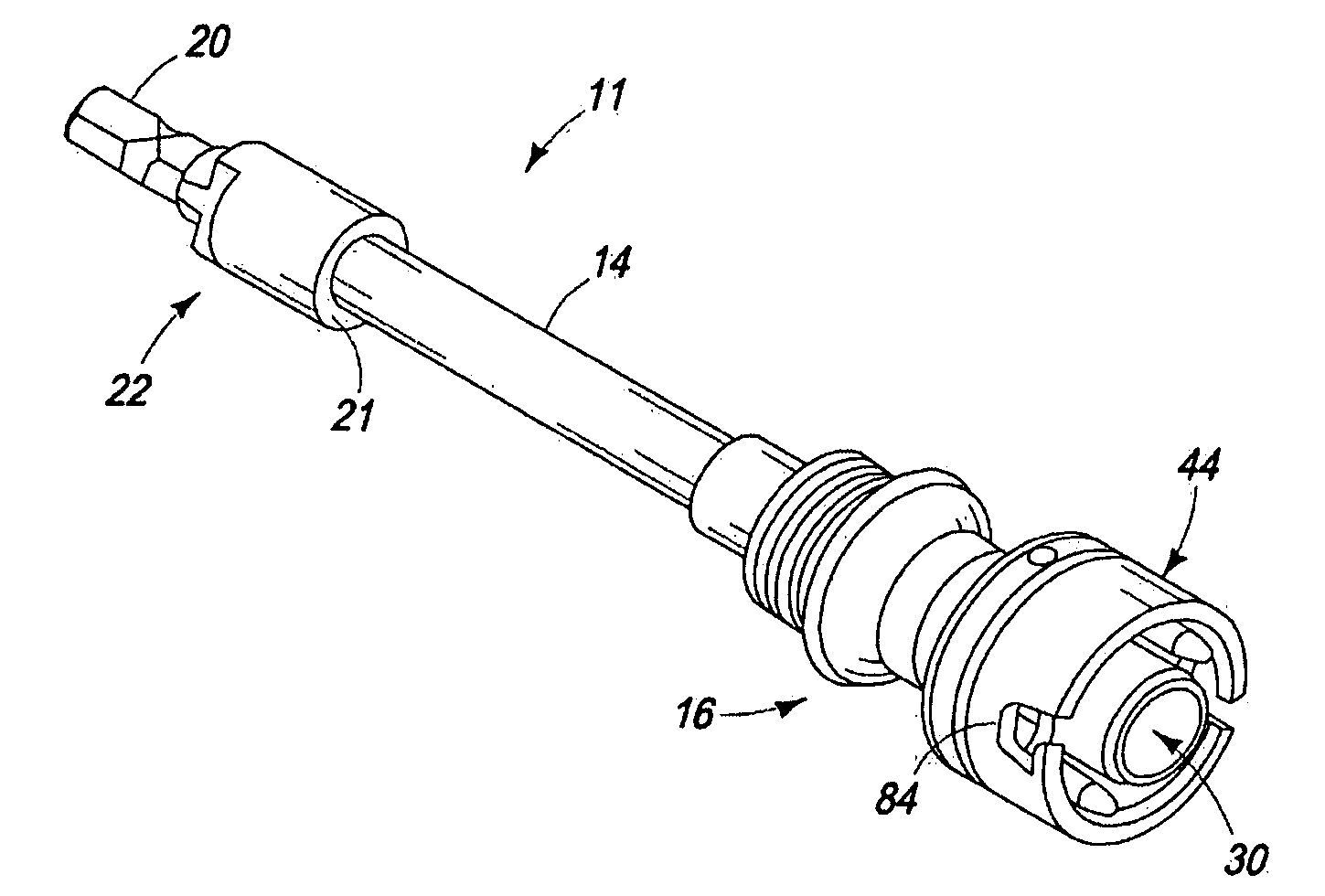

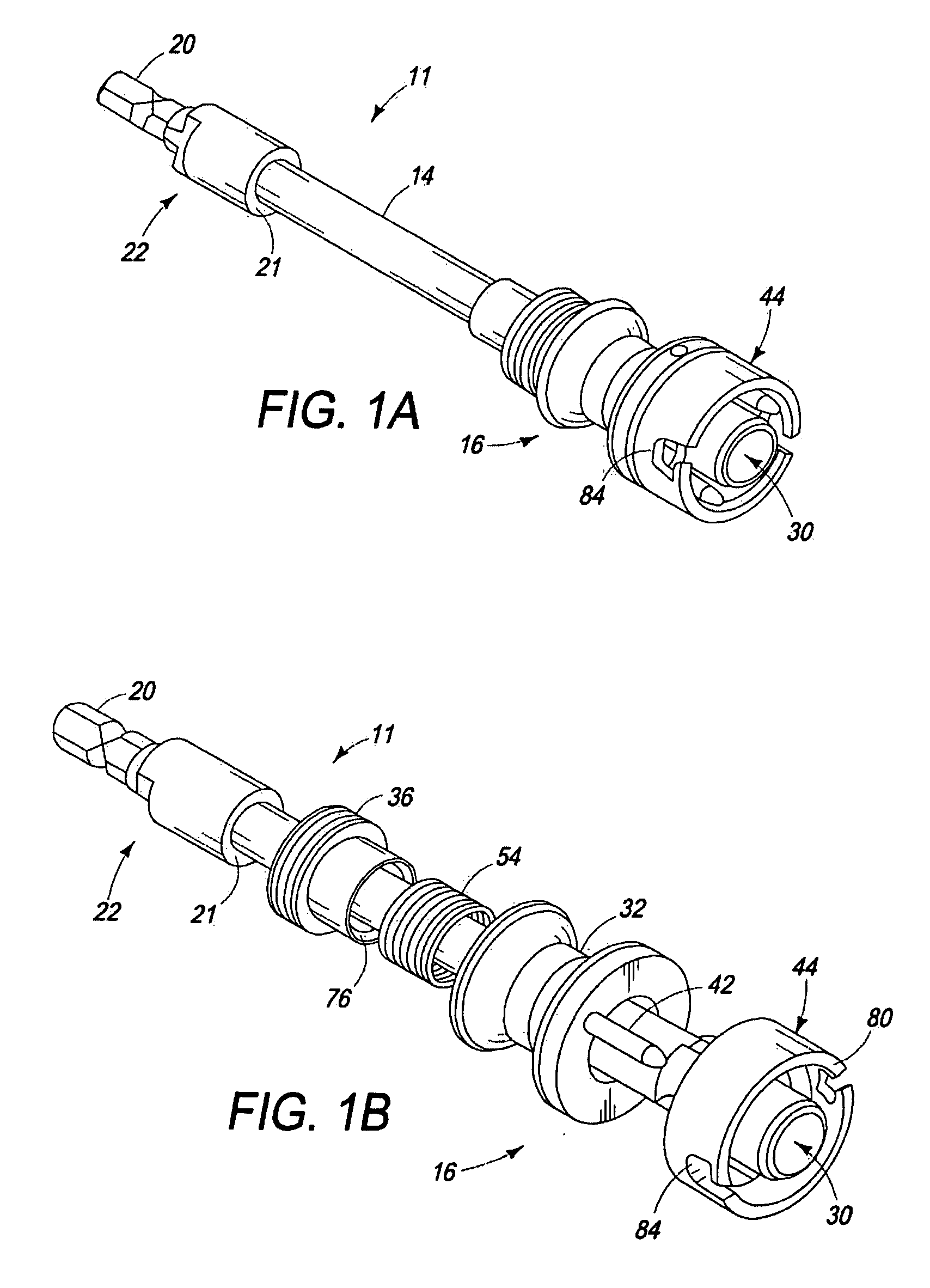

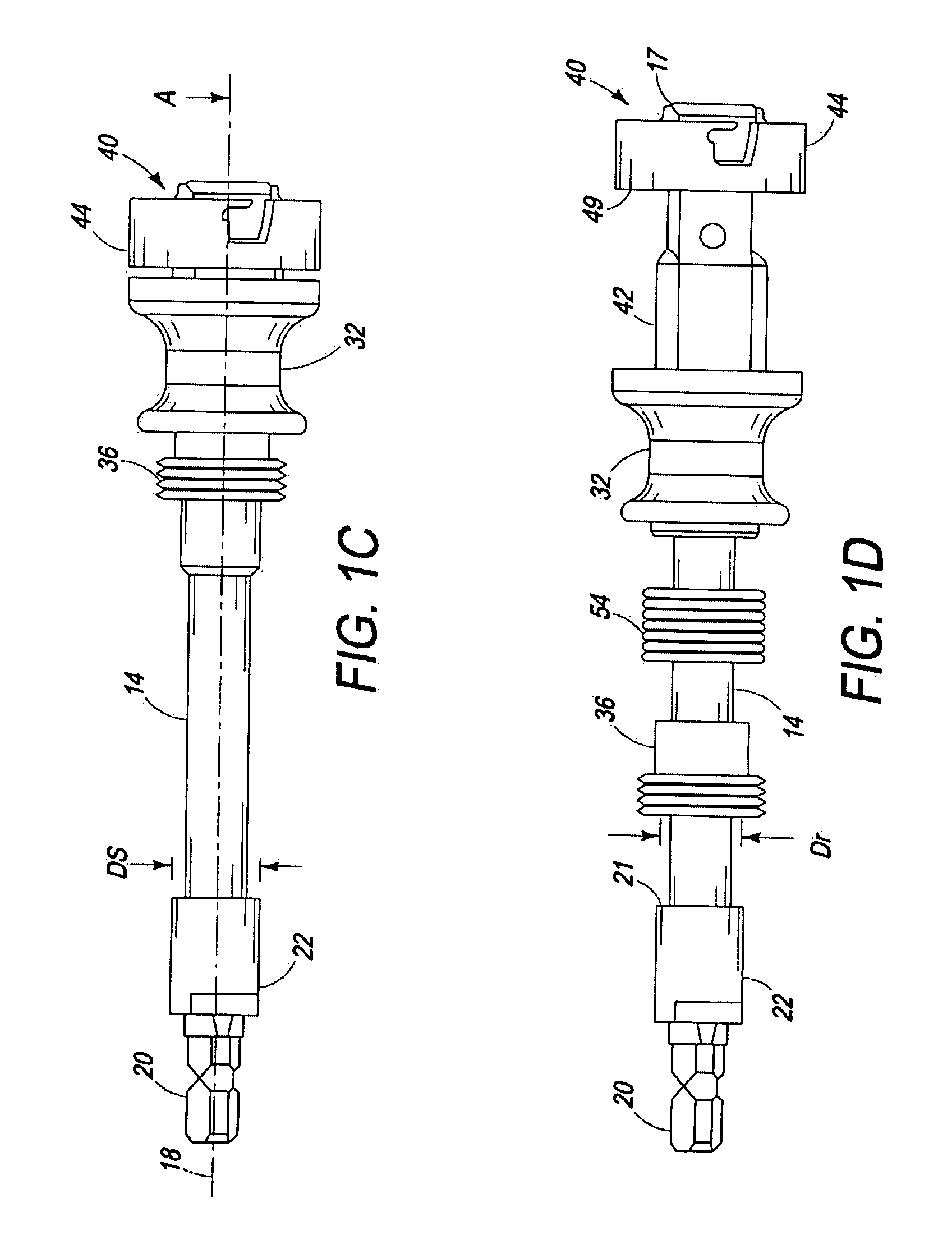

ActiveUS20080195101A1Easy to sterilizeQuick disassemblyDiagnosticsSurgical needlesCouplingLocking mechanism

Disclosed is a surgical tool holder 11 adapted to connect to a disposable cutting tool 12, and the surgical instrument 10 combination. The tool holder 11 has a shank 14 with a quick tool coupling 24 at one end 16 and a drive adaptor 20 at a second end 22. The coupling assembly 24 has a coupling interface 40 for holding the tool 12, and has a debris reservoir 44. A locking mechanism 26 is engageable with the shank 14 by a lock interface 95 that holds the coupling assembly in functional assembly, and when unlocked allows component parts of the coupling assembly to be separated for cleaning and sterilization. The surgical tool 12 has a flat base 104 and complementary fittings 114 adapted to be received by the holder's coupling interface. The combination of the flat base 104 with the reservoir 44 defines a relatively enclosed collection space 46 to receive cutting debris from the tool 12 while the holder 11 and tool 12 are coupled together.

Owner:VIANT AS&O HLDG LLC

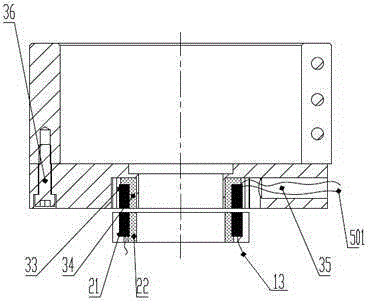

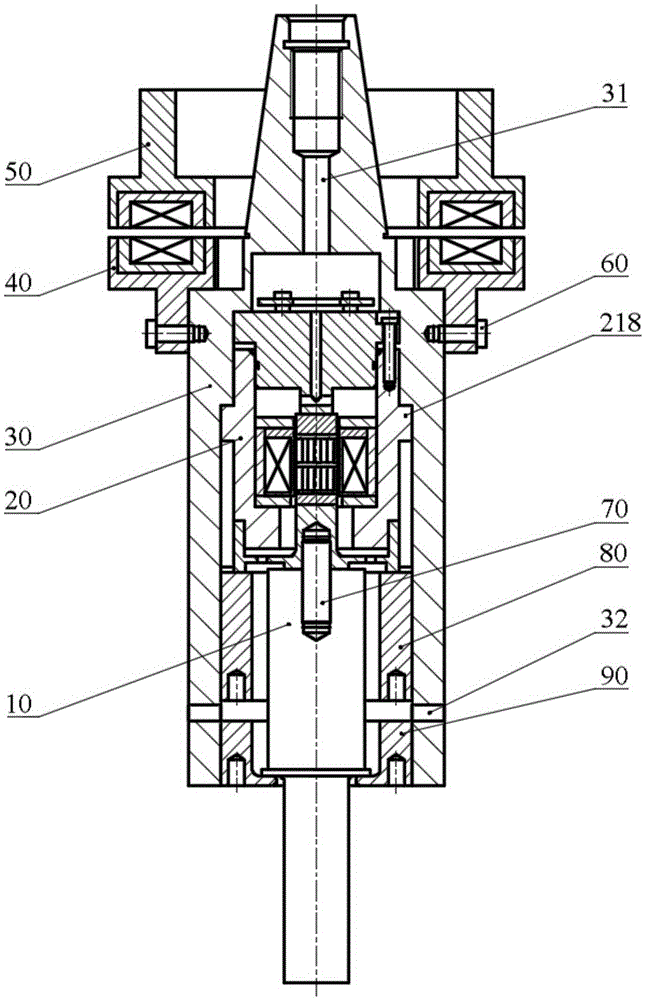

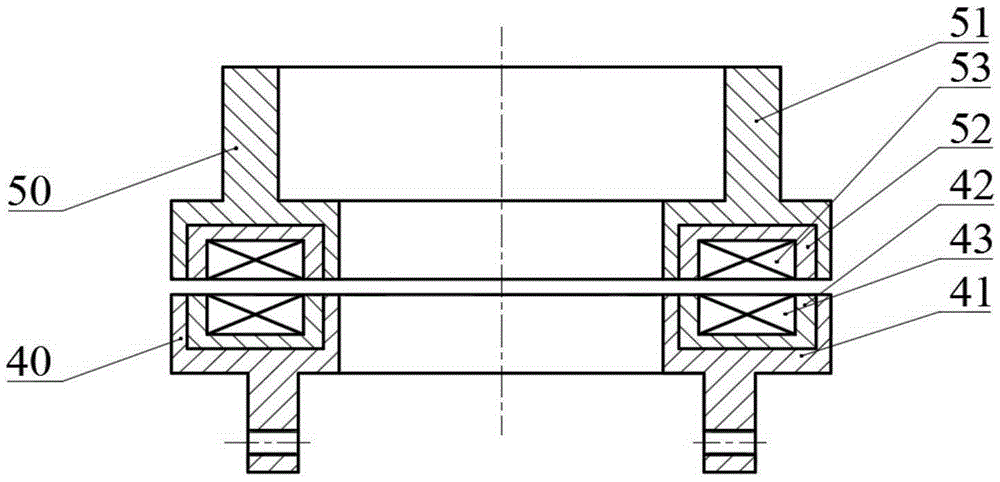

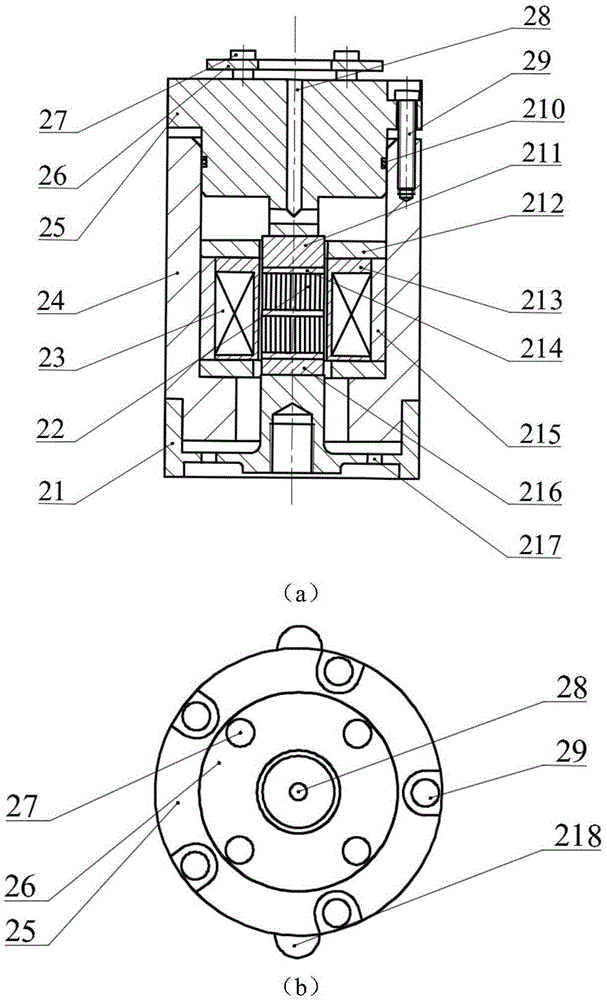

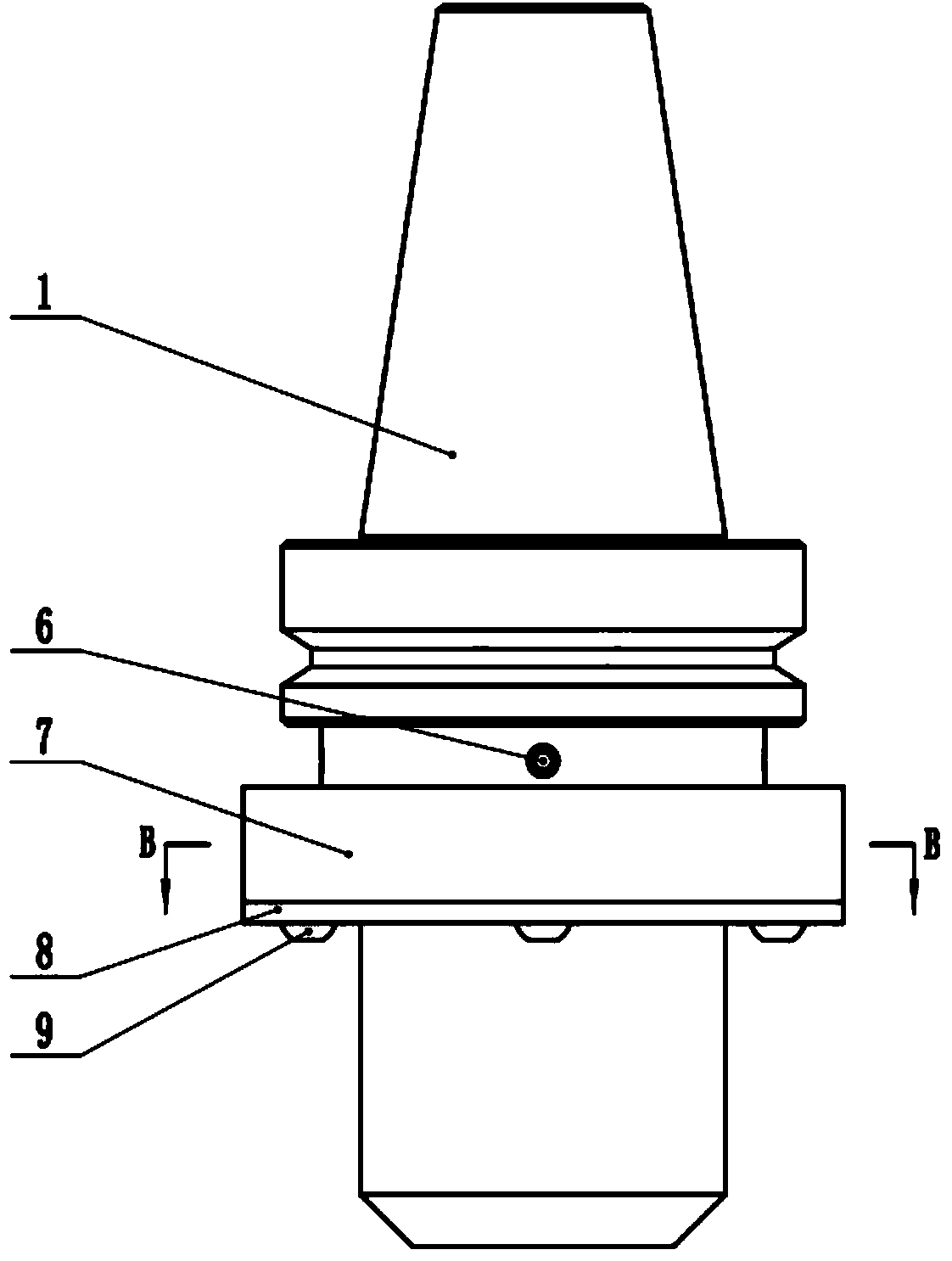

Giant magnetostrictive rotary ultrasonic vibration knife handle

ActiveCN105397920AHigh magnetostriction coefficientIncrease output powerMechanical vibrations separationStone-like material working toolsTransducerAir cooling system

The invention relates to a giant magnetostrictive rotary ultrasonic vibration knife handle and belongs to the technical field of ultrasonic precise special machining. The knife handle comprises an amplitude-change pole, a giant magnetostrictive ultrasonic transducer, a hollow knife handle body, an auxiliary side component, a primary side component and a threaded pressing block, wherein the giant magnetostrictive ultrasonic transducer is connected with the amplitude-change pole through a threaded rod and installed in a cavity in the lower portion of the knife handle body; an ultrasonic vibrator formed by connecting the giant magnetostrictive ultrasonic transducer with the amplitude-change pole makes contact with the inner wall of the knife handle body, the lower end of the giant magnetostrictive ultrasonic transducer is tightly pressed onto the knife handle body through the threaded pressing block, and the threaded pressing block is connected with the knife handle body through threads; the lower end of the amplitude-change pole is tightly pressed through the threaded pressing block, and the threaded pressing block is connected with the knife handle body; the lower end of the auxiliary side component is fixed to the knife handle body through a screw, and the primary side component is fixed to the end face of a machine tool spindle. According to the giant magnetostrictive rotary ultrasonic vibration knife handle, the problem of heating of the transducer is effectively solved by means of a giant magnetostrictive material of a slice structure and an air cooling system. By the adoption of the knife handle, the machining efficiency can be improved. In addition, the knife handle can be suitable for any knife handle connection standards.

Owner:TSINGHUA UNIV

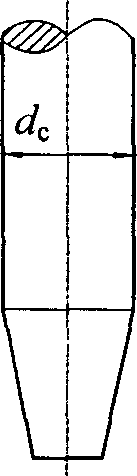

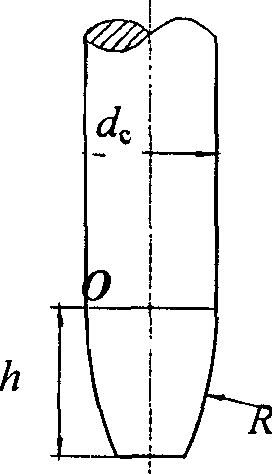

Drum taper tool and method for side milling complex cambered centrifugal impeller using drum taper tool

InactiveCN1413790AShort track lengthEasy to correct interferenceMilling cuttersMilling equipment detailsImpellerMachining time

A conic drum-shaped cutting tool and its feed pitch, feed step length and method for calculating the position of cutting tool are disclosed. Its cutting part is a rotary surface. Its generating line is an arc with radius R. Its advantages are high productivity, high rigidity and high rotation flexibility. A method for laternally milling a centrifugal blade wheel with complex curved surface with the said cutting tool is also disclosed, which features less number of tracings, short tracing and high productivity.

Owner:XI AN JIAOTONG UNIV

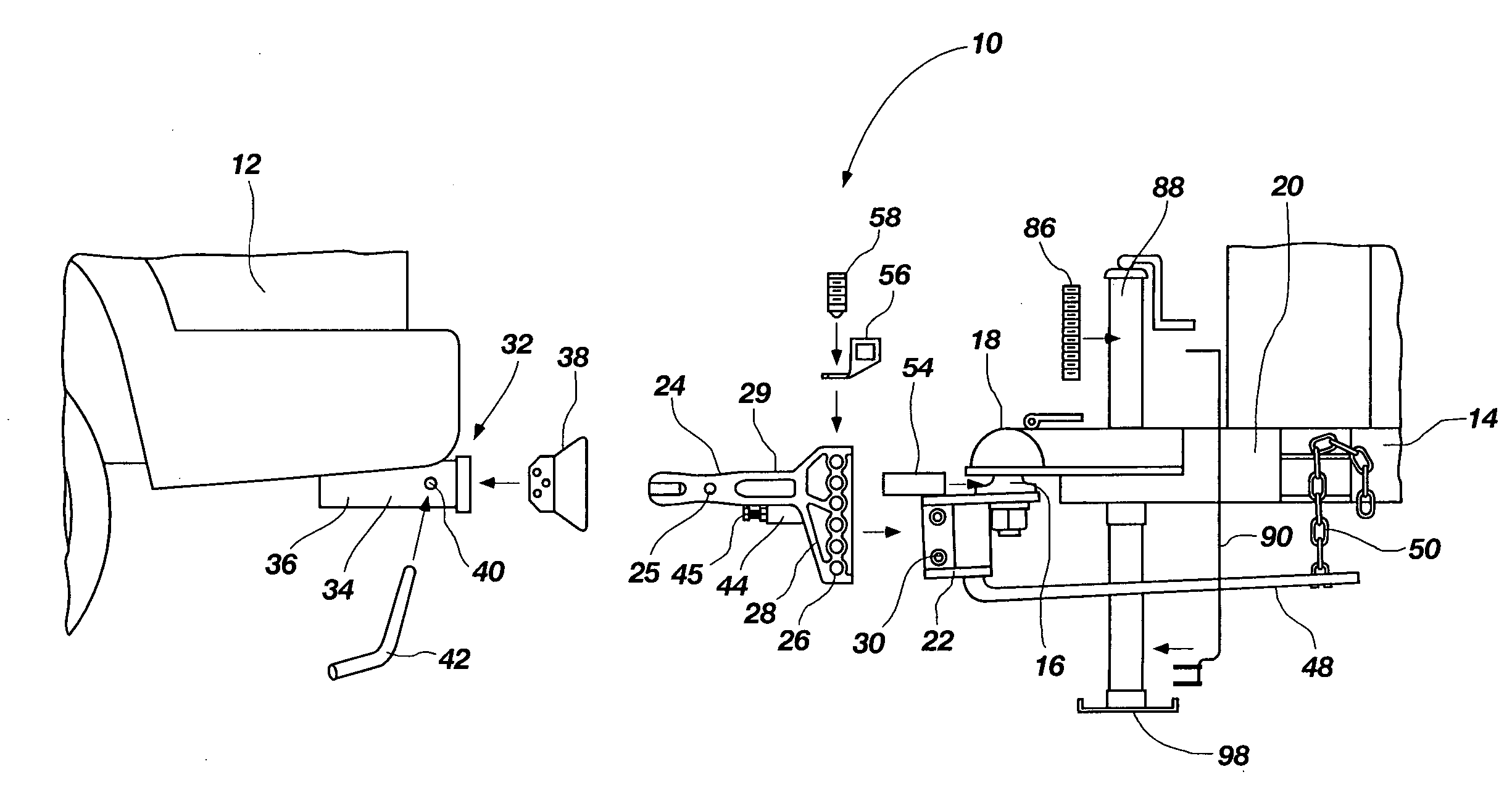

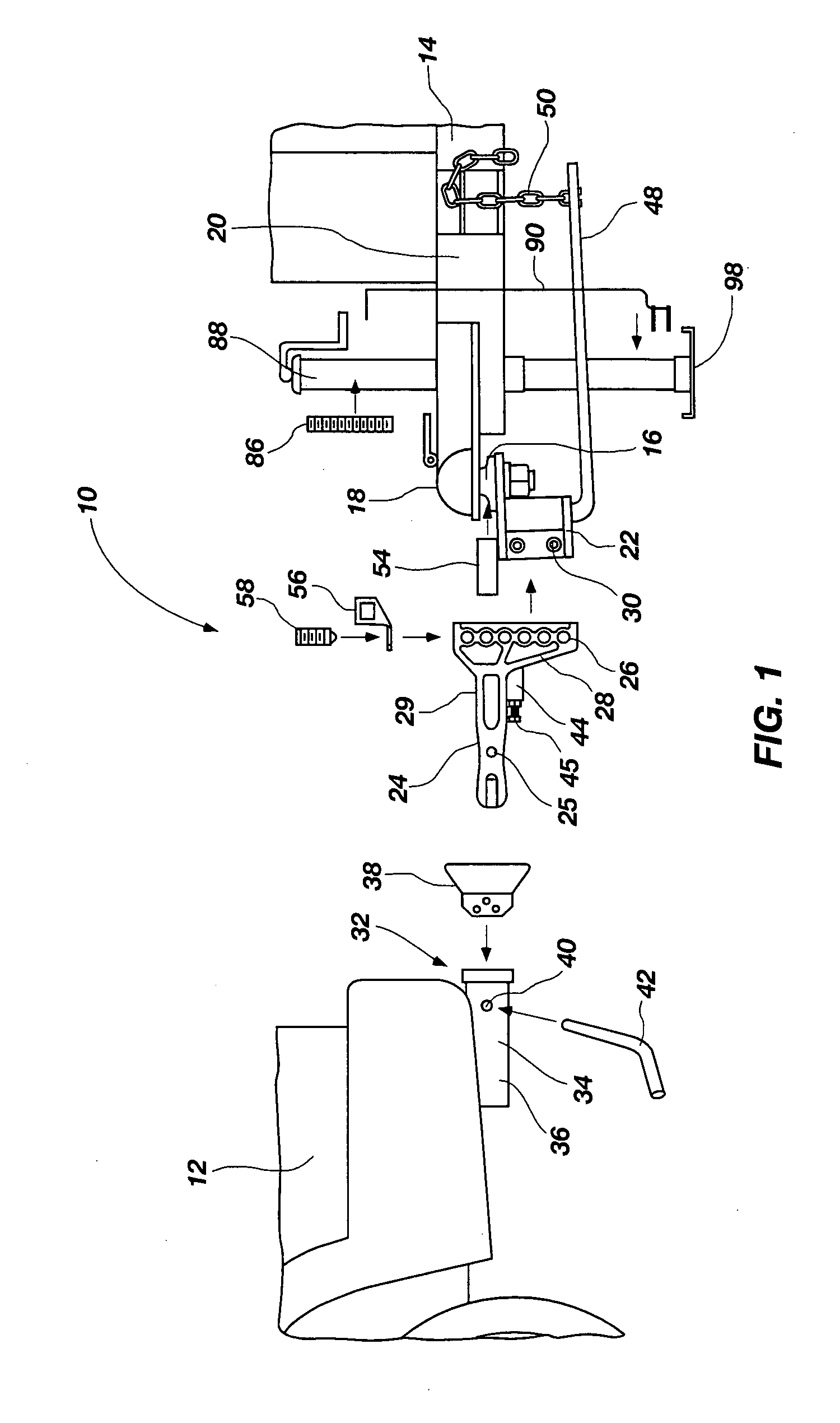

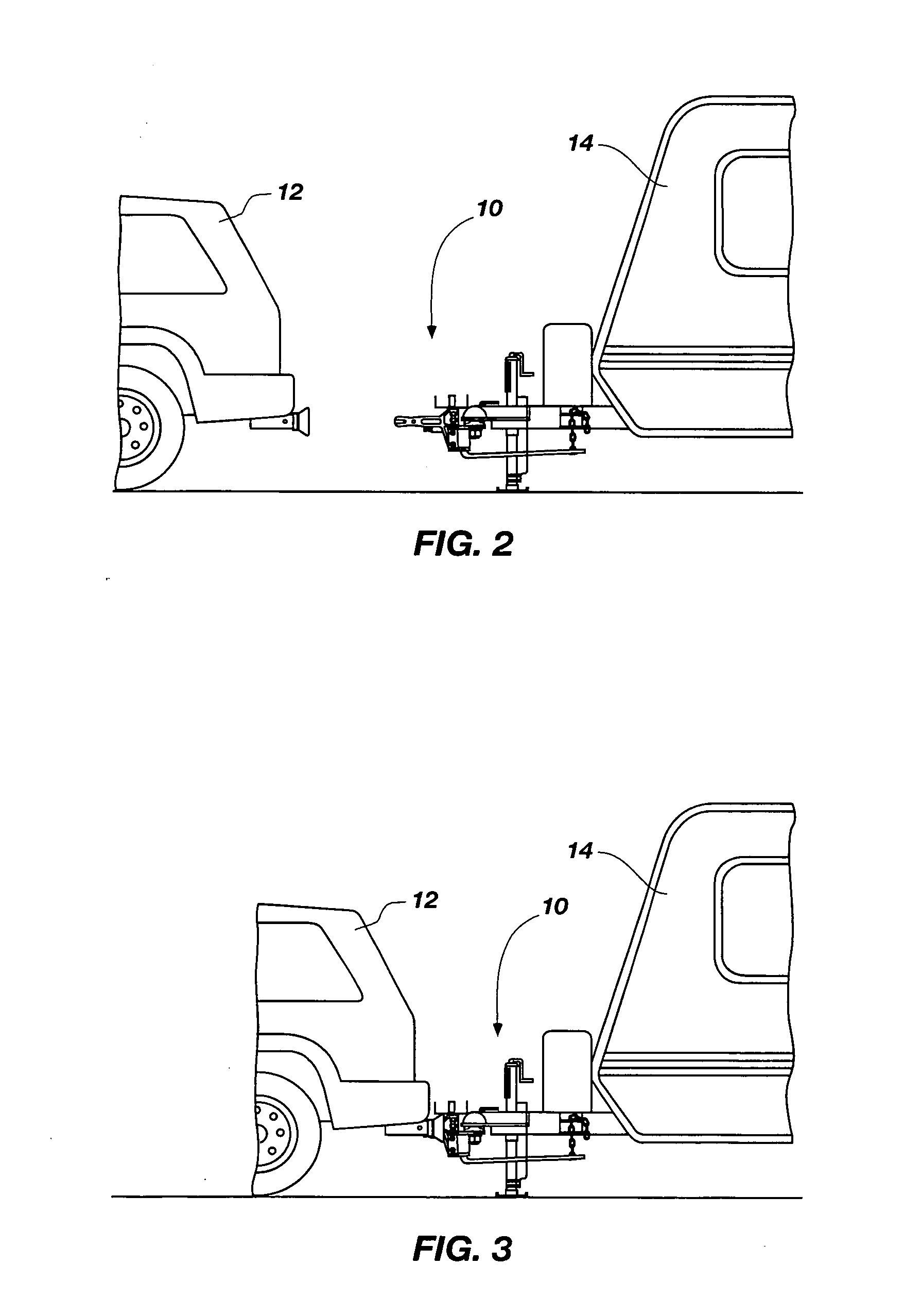

Trailer hitch system

A trailer hitch system for improving the speed and safety of attaching the trailer to a tow vehicle. The hitch may include a shank that may be attached to the trailer through a ball hitch. A receiver may be provided on the tow vehicle such that attachment of the trailer to the tow vehicle may be accomplished by introducing the shank into the receiver when the tow vehicle is backed to the trailer. A funnel shaped guide member may be provided to facilitate aligning the shank with the receiver. Also, friction reducing rollers may be used with the shank or the receiver. Moreover, a height adjustment and visual guidance system may be included to facilitate connecting the trailer to the tow vehicle.

Owner:PROGRESS MFG LLC

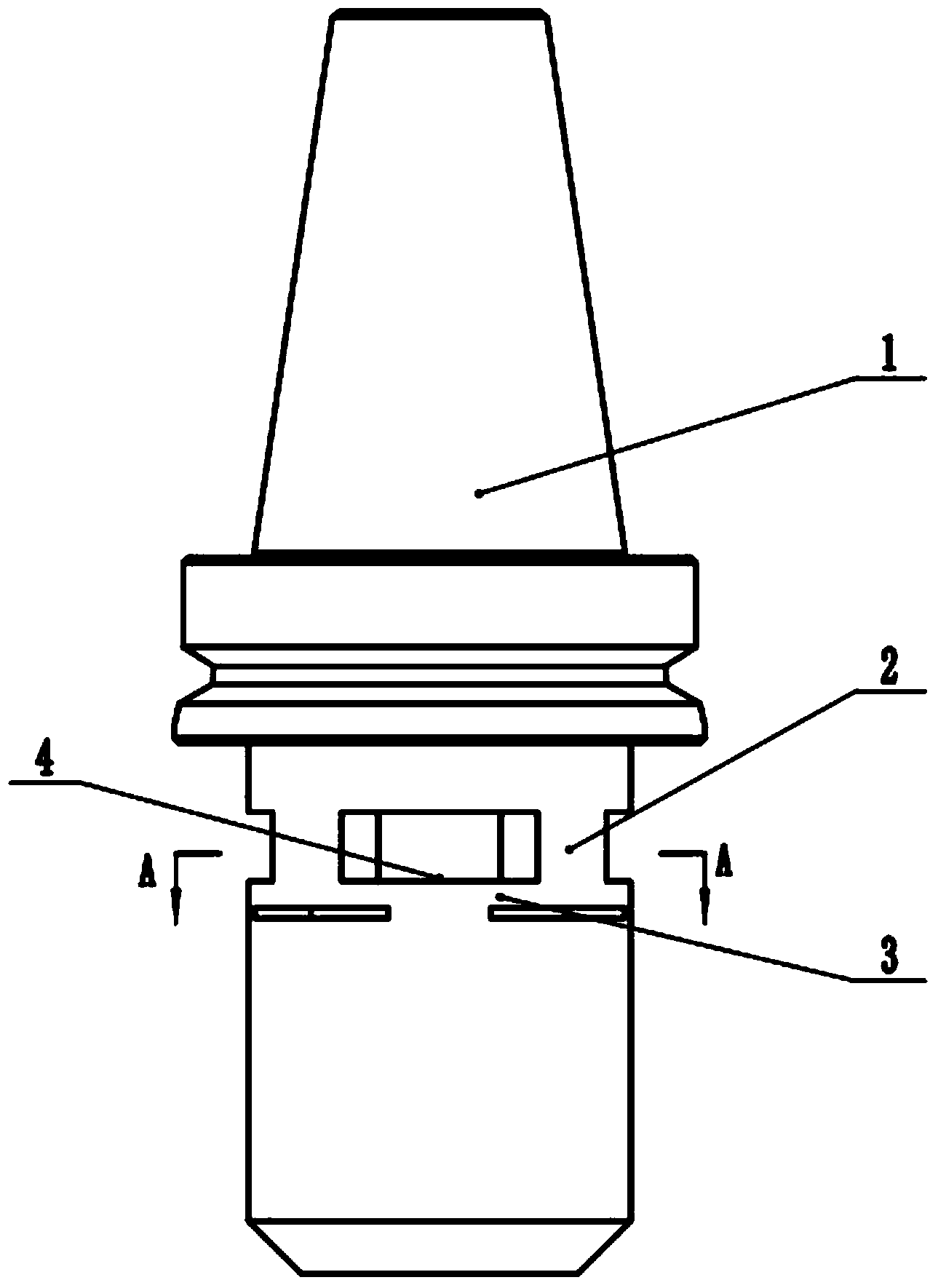

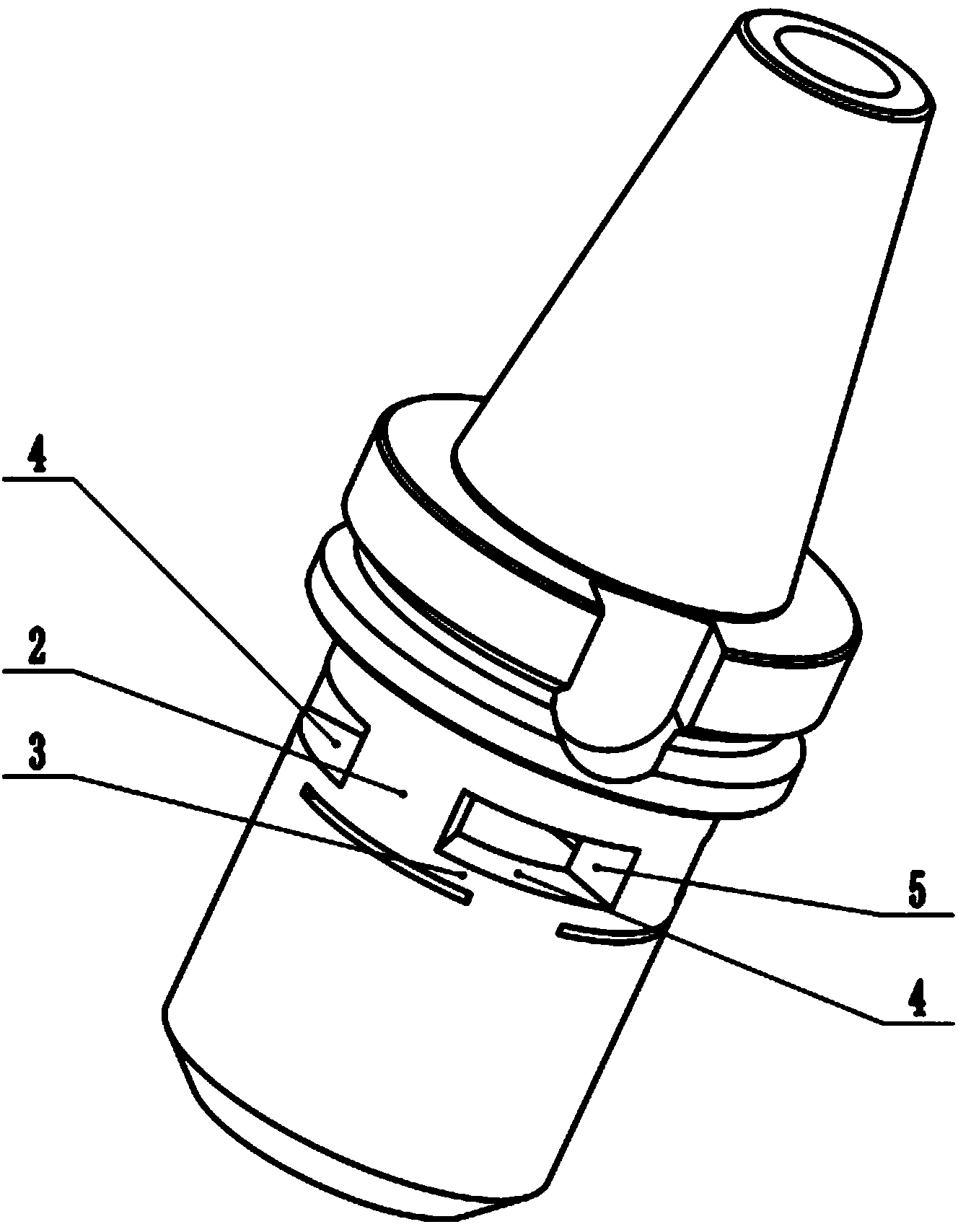

Capacitive intelligent knife handle system for detection of four-dimensional cutting force

ActiveCN104139322ADoes not affect installationDoes not affect normal useMeasurement/indication equipmentsMetal working apparatusRobot handComputer module

The invention discloses a capacitive intelligent knife handle system for detection of a four-dimensional cutting force. The capacitive intelligent knife handle system mainly comprises a standard knife handle, a capacitive displacement sensor, a lithium battery, a capacitive sensor detection circuit, a signal preprocessing and collecting unit, a signal wireless transmitting module, an outer packaging ring, a sealing cover and a fixing block, wherein a deformation rib structure is formed through grooving at a cylinder part of the lower end of the standard knife handle, the four-dimensional cutting force is computed by utilizing the deformation of a deformation rib, and the deformation is measured by the capacitive displacement sensor. The capacitive intelligent knife handle system for the detection of the four-dimensional cutting force, disclosed by the invention, has the advantages that the structure change of an original knife handle is smaller, the installation and the use of a knife and the catching of a mechanical hand are not influenced, the capacitive intelligent knife handle system has the advantages that the structure is simple, the applicability is strong and the like, the accuracy of detecting the deformation of the deformation rib by utilizing a high-accuracy capacitive micro displacement sensor is higher than the accuracy of detecting the deformation of the deformation rib by utilizing a strain type dynamometer, and the dynamic performance is better.

Owner:HARBIN INST OF TECH

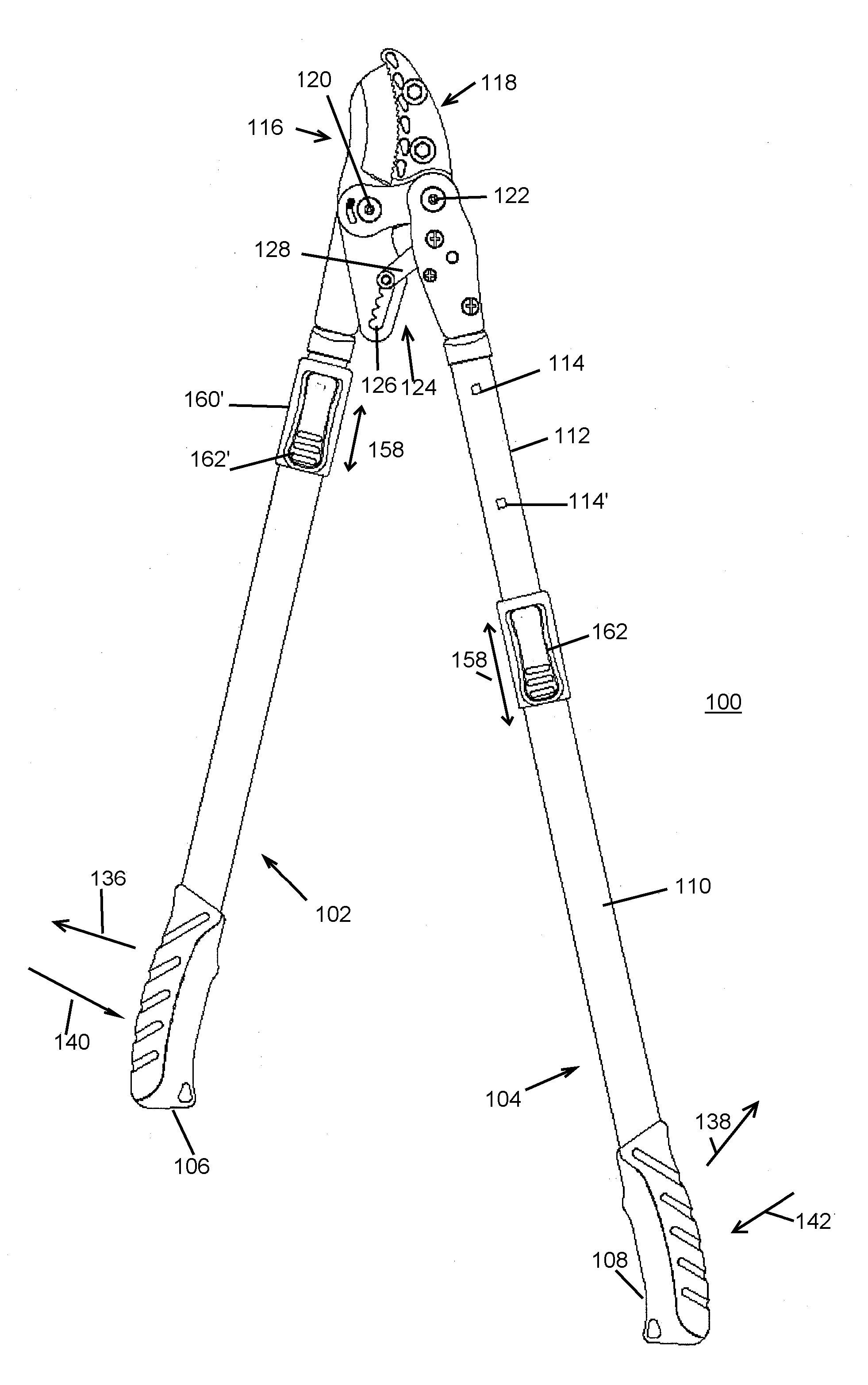

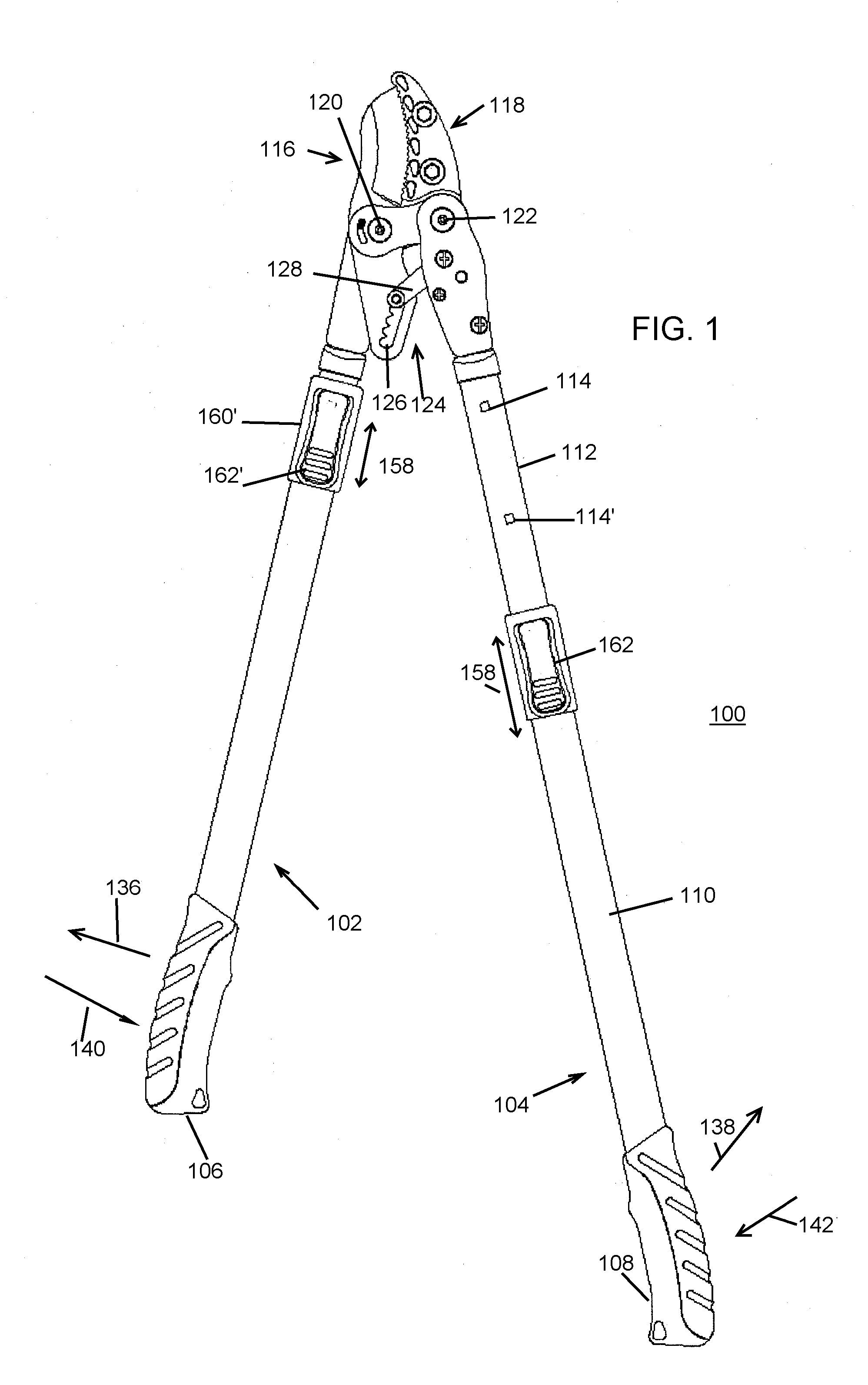

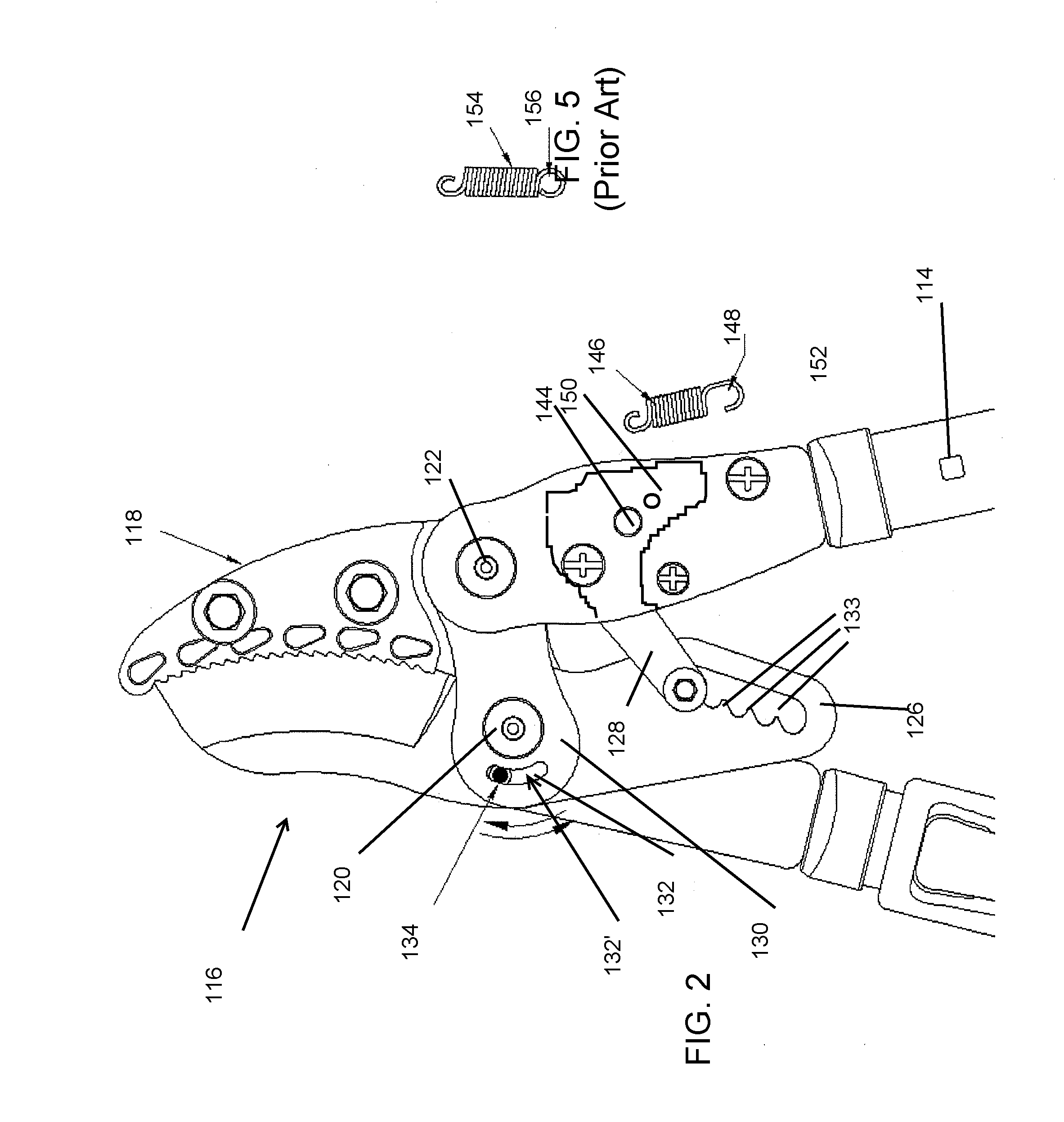

Ratchet pruner with dual pivot lubrication bolts

InactiveUS20070079512A1Reduce frictionEffectively lubricate the pivoting membersCuttersCutting implementsScrew threadKnife blades

A pruner employs dual lubricating fasteners as pivots. Each pivot has a head, and a shank which is provided with a lubricant cell and plural channels. The lubricant cell is in communication with the exterior of the shank area, the channels enabling the lubricant contained in the lubricant cell to lubricant the two blades. The lubricant cell includes a depressed oiling region for containing oil therein during re-lubrication. The shank has outer threads to mesh with inner threads of the nut. An anvil portion is provided in a material less likely to dull the blade portion. Extensible handles are providing, having lock member with square or rectangular lock iron for improved operation. A ratchet spring configuration provides ease of replacement of the spring.

Owner:BARNEL INT

Taping knife handle with identification insert

InactiveUS20070074401A1Easy to identifyPortable power-driven toolsBuilding constructionsEngineeringKnife blades

A handle for a taping knife having a blade with a working edge and an attachment edge opposite the working edge, the handle including a handle core with distal and proximal ends, the proximal end associated with the attachment edge, the core defining a recess, and at least one identification insert insertable into the handle core recess.

Owner:UNITED STATES GYPSUM CO

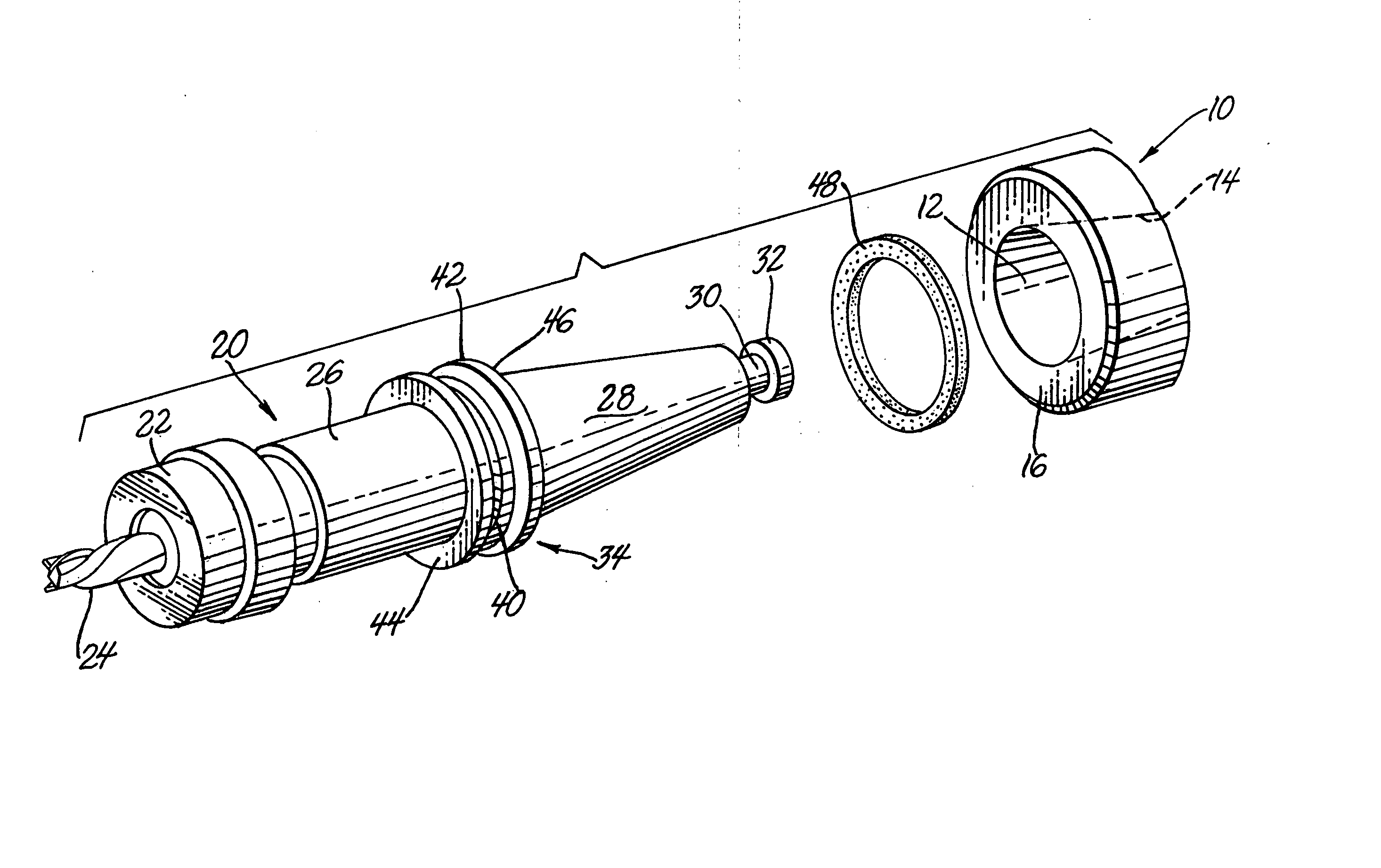

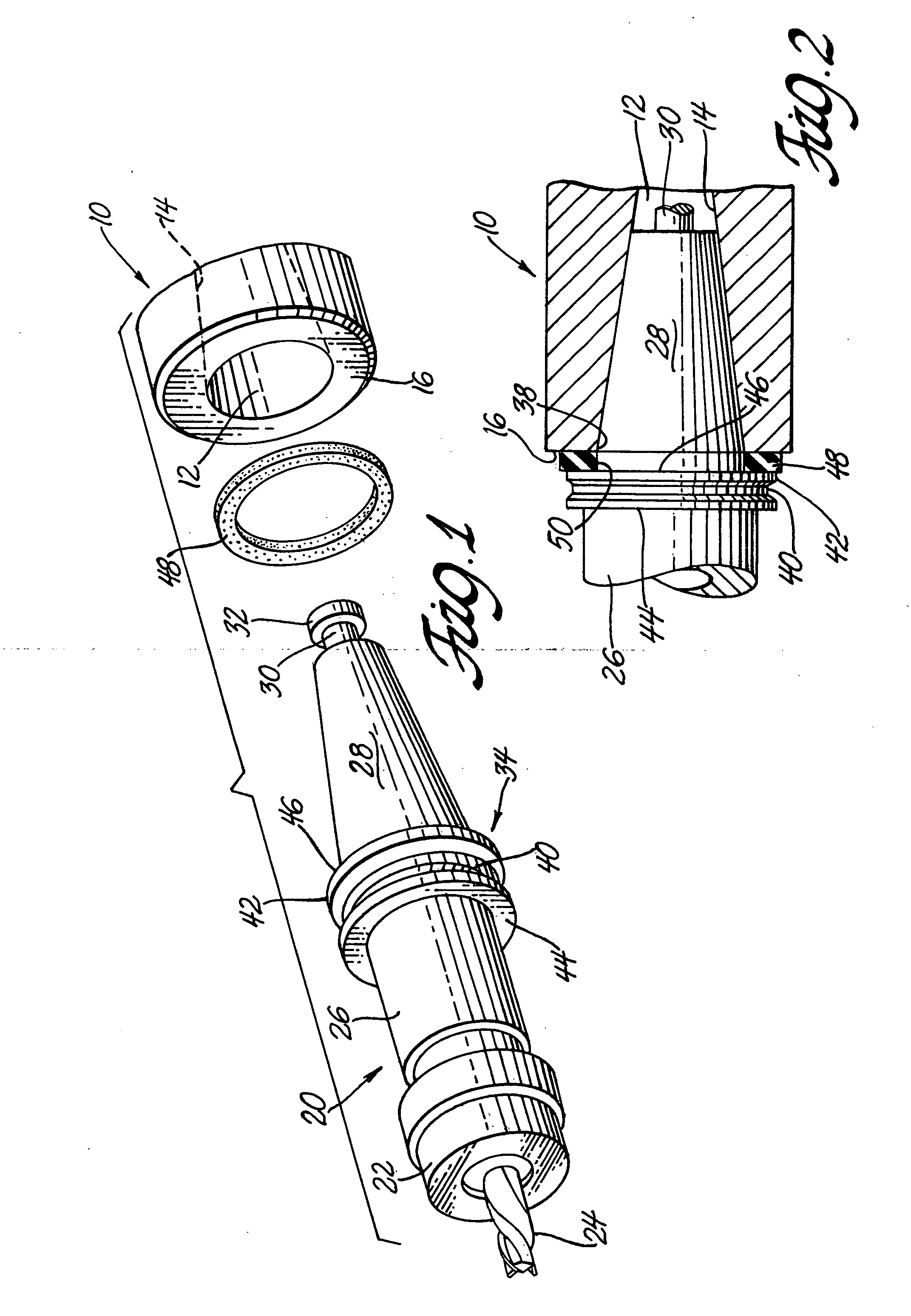

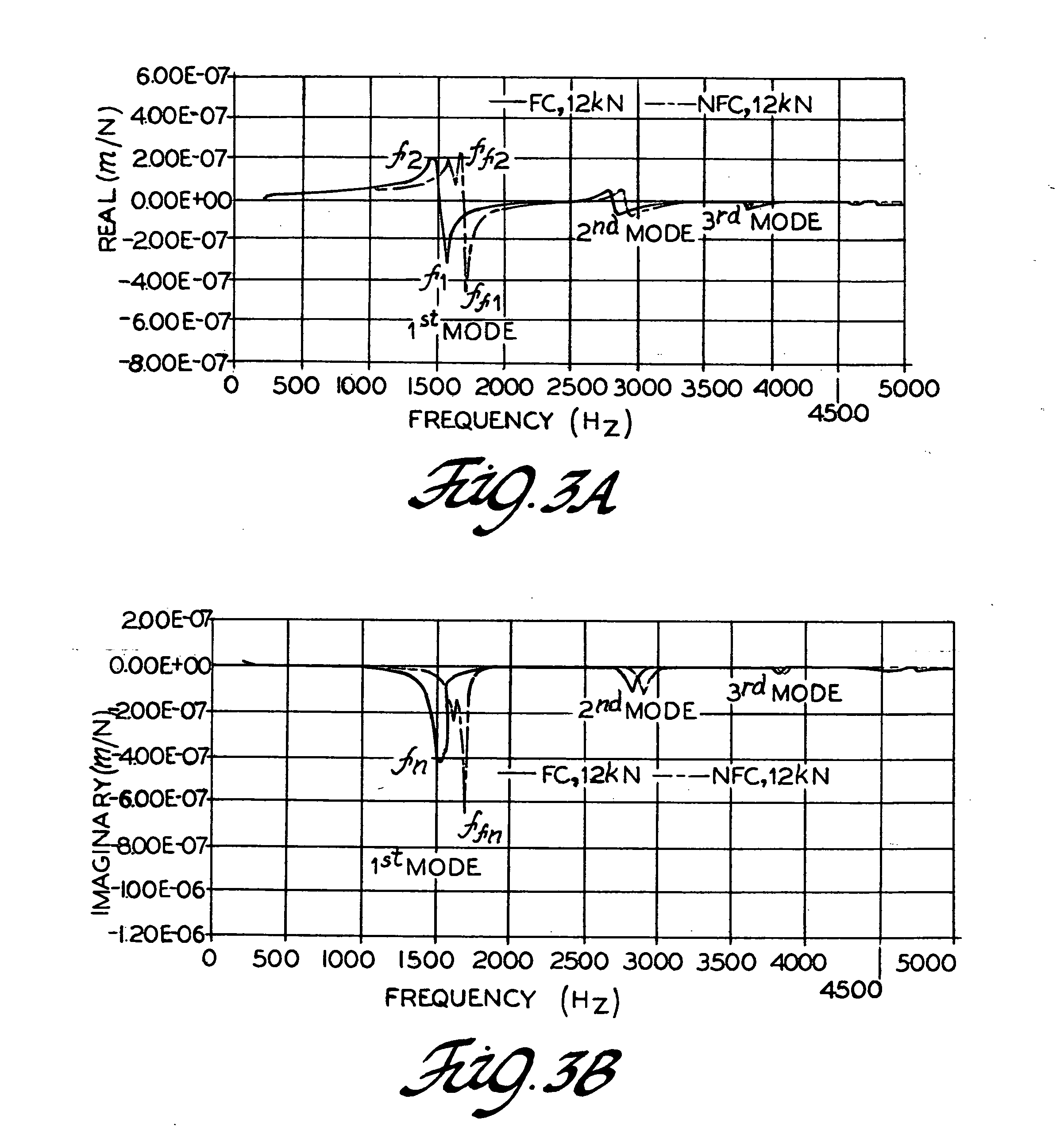

Spacer adapter for toolholders

InactiveUS20050214087A1Reduce vibrationSuitable flexibilityWorkpiecesMilling machinesEngineeringShaft collar

A toolholder for a cutting tool is disclosed for use with a machine tool having a main shaft or spindle with a flared or tapered end socket. The toolholder has a tool-holding end for a cutting tool and a tapered shank end for placement in the tapered socket of the machine tool spindle. The toolholder also has an annular flange near its tapered shank, the flange or collar generally being used for location and gripping by a tool exchange mechanism. An elastic spacer ring is used and compressed between said flange and the face of said machine tool shaft in machining operations for dampening vibrations and flexing of the toolholder and cutting tool.

Owner:GENERAL MOTORS COMPANY

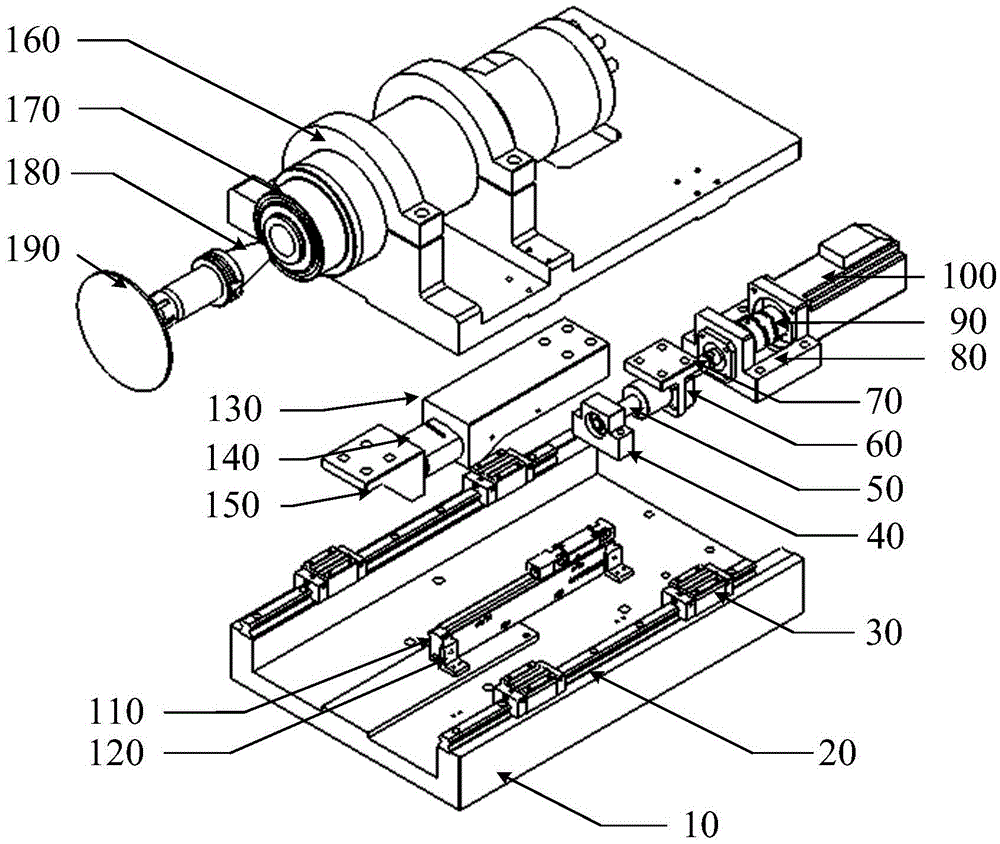

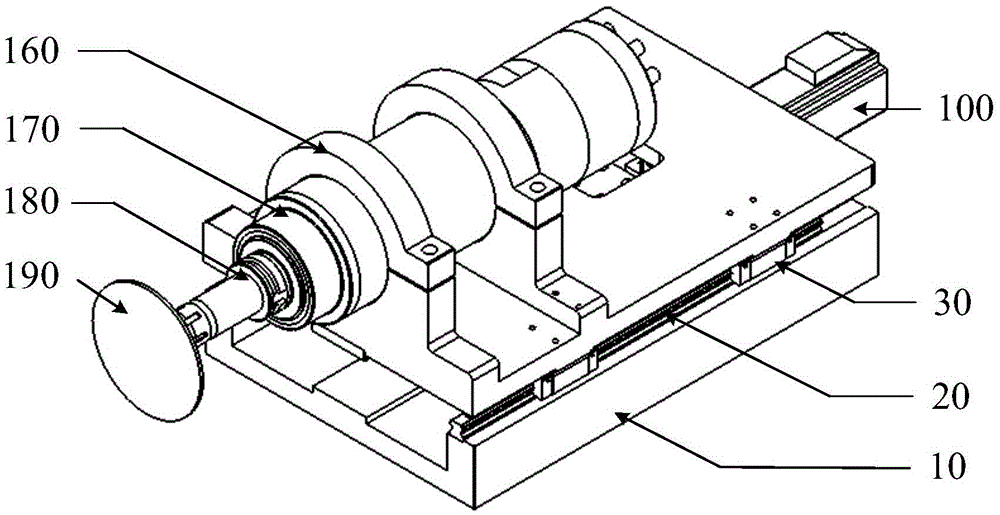

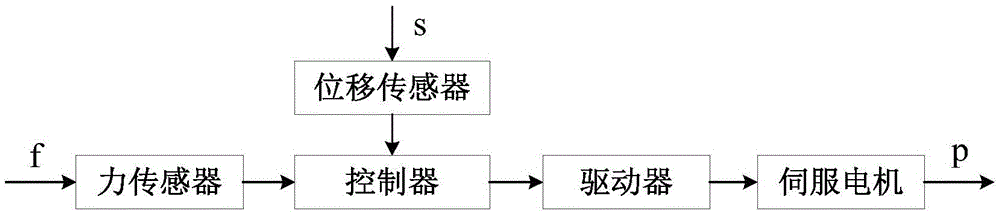

Active compliance end effector for controllable-pitch propeller robot grindingand control method of active compliance end effector

ActiveCN105563309AWith automatic replacementHigh control precisionAutomatic grinding controlGrinding headsEngineeringAlternating current

The invention discloses an active compliance end effector for controllable-pitch propeller robotgrinding and a control method. The active compliance end effector comprises a grinding tool, a BT30 knife handle, a grinding electric spindle, brackets for fixing the grinding electric spindle, a force sensor for detecting a normal grinding force, a support for mounting the force sensor, a displacement sensor for detecting deviation of an end position, a support for fixing the displacement sensor, a ball screw for providing axial movement degree of freedom and transmitting torque, a bearing block for supporting and fixing the ball screw, a ball screw nut, a ball screw nut support, an alternating-current servo motor, a flange support, a coupler, linear guide tracks, sliders, a bottom supporting plate and a control system, wherein the servo motor is connected with the ball screw through the flange support and the coupler; and the control system is used for driving the servo motor. The active compliance end effector has the advantages of simple structure, convenience in assembly, high control precision and high response speed; and meanwhile, the grinding tool can be changed automatically.

Owner:HUAZHONG UNIV OF SCI & TECH

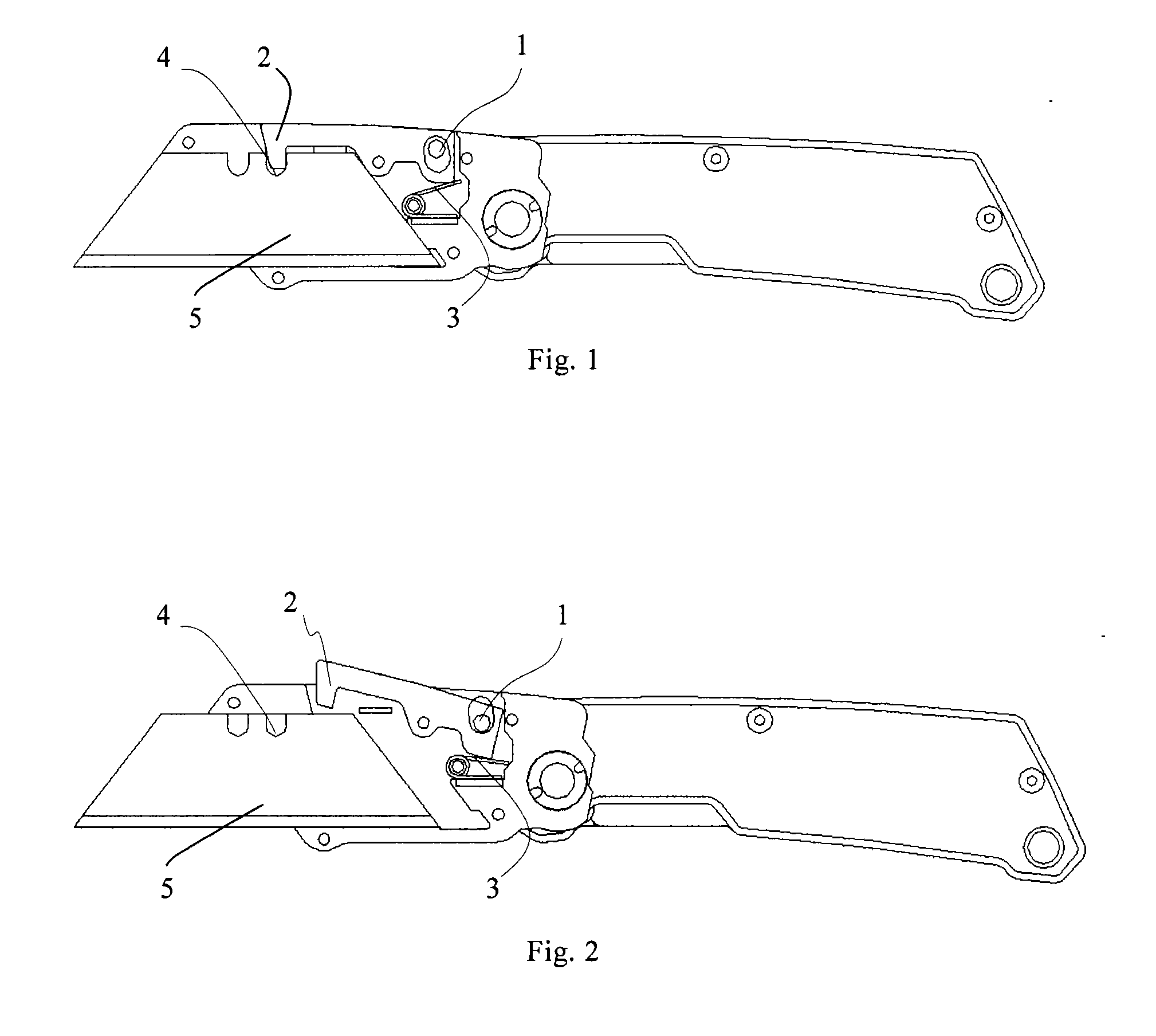

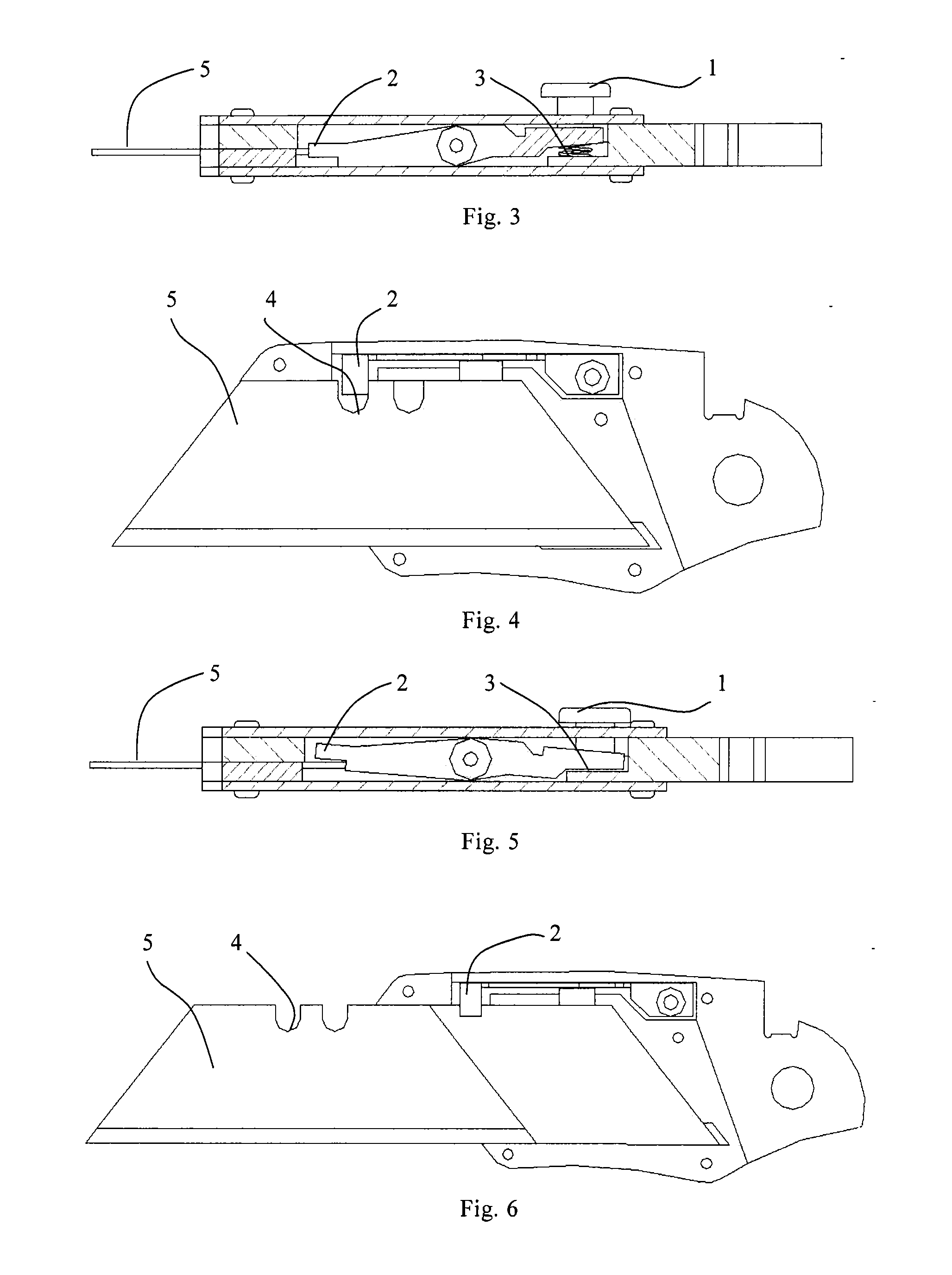

Utility knife with replaceable blade

InactiveUS20130255087A1Prevent disengagementEliminate potential safety hazardsThrusting weaponsWeapon componentsBlade plateKnife blades

The present invention first provides a utility knife with a replaceable blade, comprising a knife handle, a blade holder, a blade and a locking device that locks the blade in the blade holder. The blade holder and the blade are enabled to switch between a first position and a second position. When the blade holder and the blade are in the first position, the blade is used for cutting operation, and when the blade holder and the blade are in the second position, both the blade holder and the blade are received in the knife handle. The utility knife further includes a restriction means which is thus arranged as, when the blade holder is in the second position and the locking device is in unlocked state, the restriction means is used for preventing the detachment of the blade from the blade holder by confining the movement of the blade relative to the blade holder. The present invention also provides a folding utility knife with a replaceable blade and a retractable utility knife with a replaceable blade, and a utility knife with multiple tools and replaceable blades.

Owner:HANGZHOU GREAT STAR TOOLS +1

Ultrasound ellipse vibration milling knife handle device

ActiveCN103157593AAvoid rotation errorEasy tool changeMilling cuttersMechanical vibrations separationEllipseTitanium alloy

An ultrasound ellipse vibration milling knife handle device comprises a power supply box, an ultrasound ellipse vibration milling knife handle, a sealing ring and a protective cover. The upper end surface of the power supply box is connected with the lower plane of a cutter disk of a tool through bolts, a small circular shaft of the ultrasound ellipse vibration milling knife handle is connected with the cutting disk through a spring collet, the upper end surface of a large cylinder is connected with the lower end surface of the power supply box in a screw mode, the sealing ring is arranged on the lower end surface of the large cylinder, and the sealing ring is connected with the protective cover through bolts. The ultrasound ellipse vibration milling knife handle device can be flexibly connected with a traditional processing center in a butted mode, high frequency ultrasound ellipse vibration milling is achieved, and the effects of titanium alloy and composite material milling with high accuracy and high efficiency are achieved. The ultrasound ellipse vibration milling knife handle device has a wide application prospect in the technical field of ultrasound vibration processing devices.

Owner:BEIHANG UNIV

Nicked cutting rule

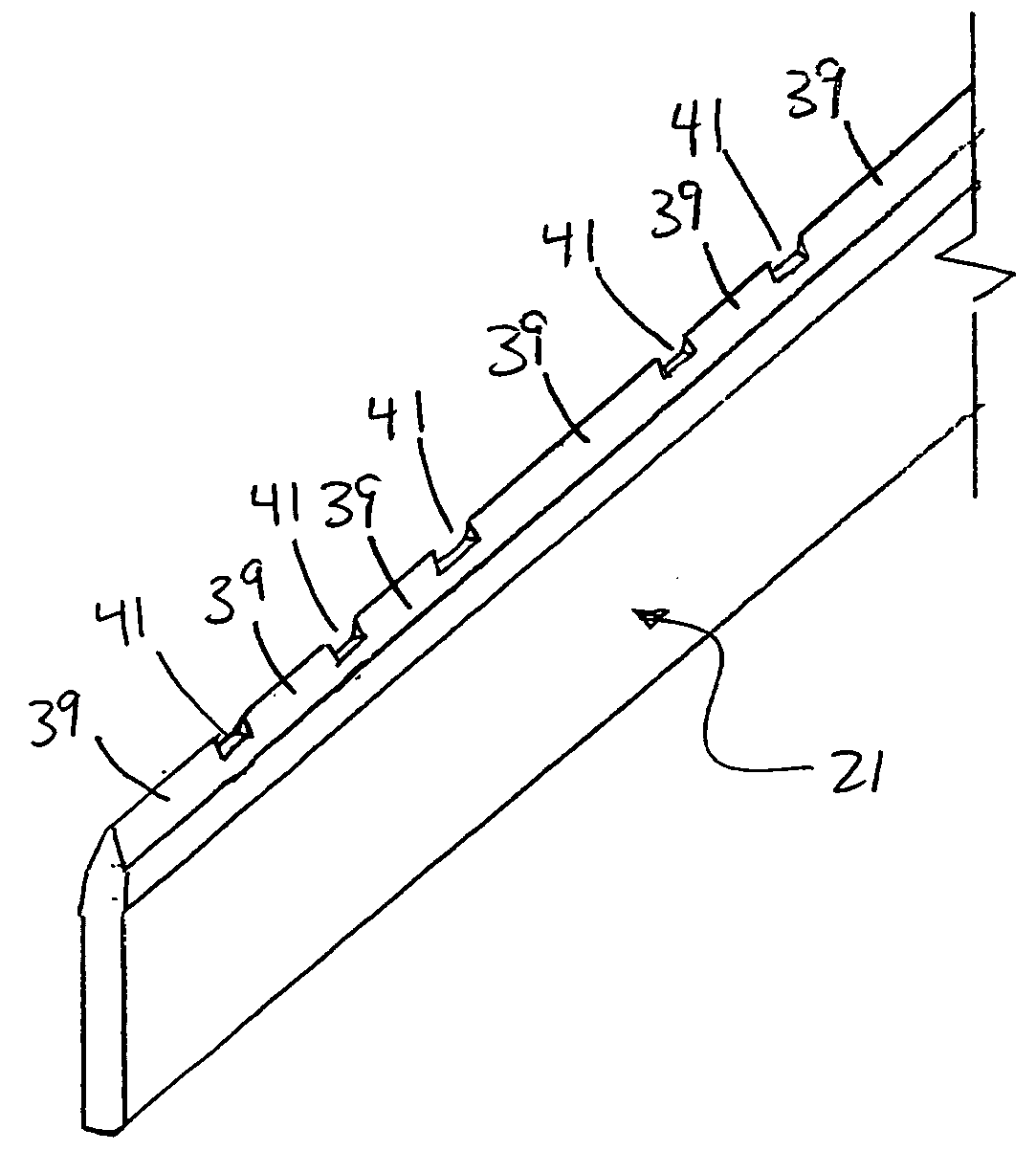

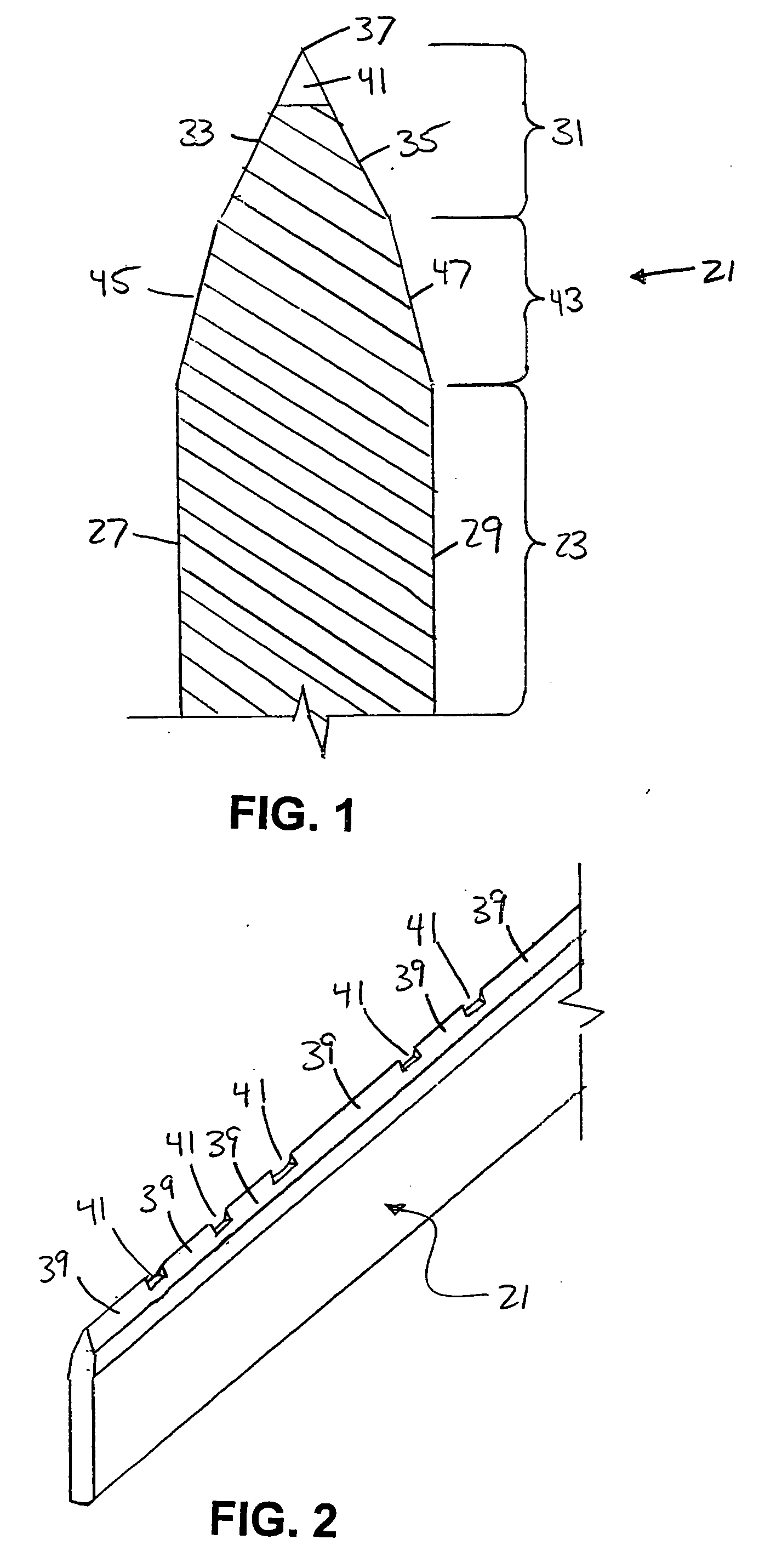

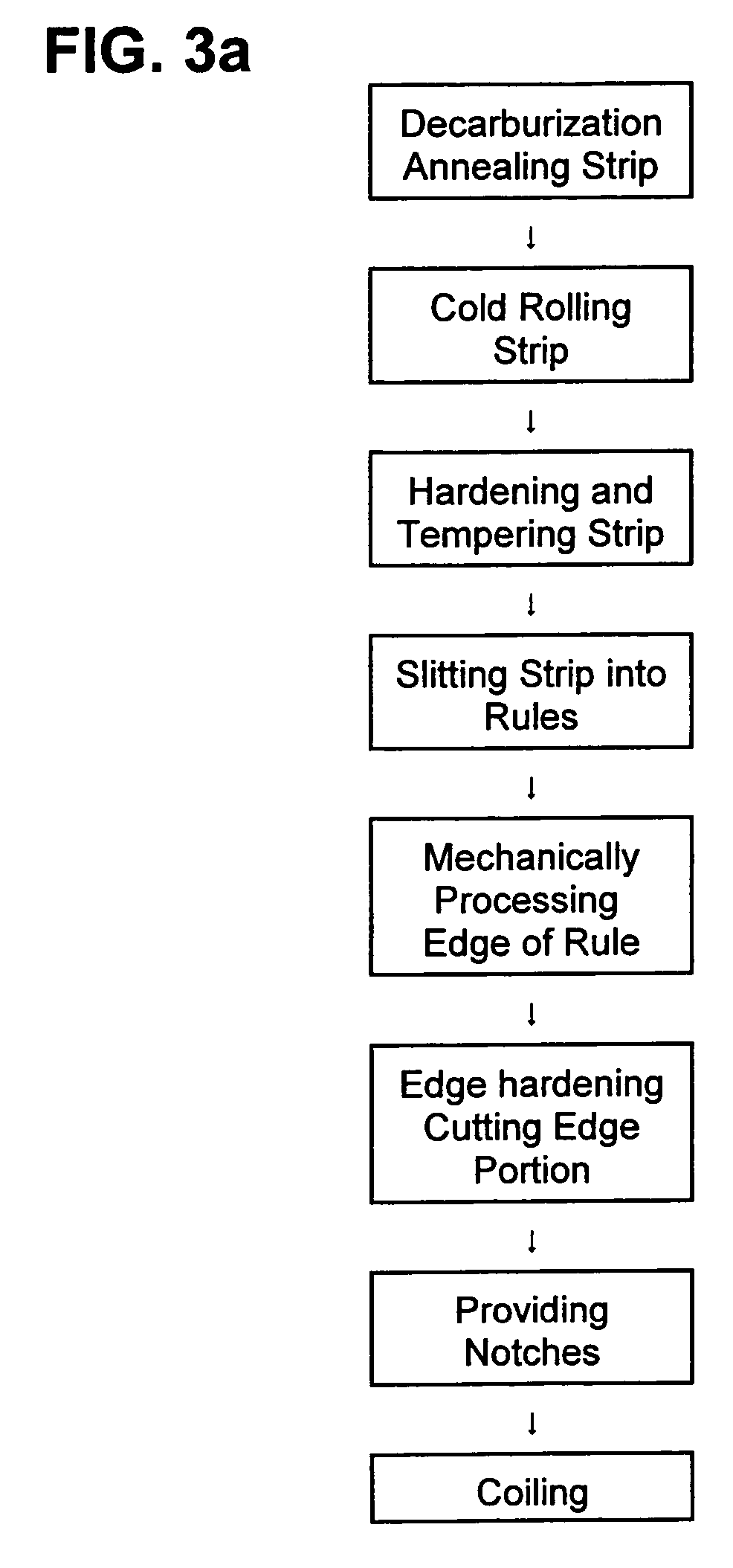

InactiveUS20050155478A1Increased durabilityLess capable of bendingCutting toolsMetal working apparatusHardnessKnife handles

A nicked cutting rule includes a shank portion having two substantially parallel shank side surfaces extending in a direction of length of the rule separated by a thickness of the shank portion. The nicked cutting rule further includes a V-shaped cutting edge portion defined by two cutting edge portion surfaces that intersect at ends remote from the shank portion to define a cutting edge, the cutting edge portion having portions separated in the direction of length of the rule by a plurality of notches extending inwardly from the cutting edge toward the shank portion. The nicked cutting rule also includes an intermediate portion between and integral with the shank portion and the cutting edge portion, the intermediate portion being thinner than the thickness of the shank portion and including two intermediate portion surfaces extending between the two shank side surfaces and the two cutting edge portion surfaces. A hardness of the shank portion, a hardness of the cutting edge portion, the thickness of the shank portion, and the thicknesses of the intermediate portion and the cutting edge portion are selected such that the nicked cutting rule is bendable.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

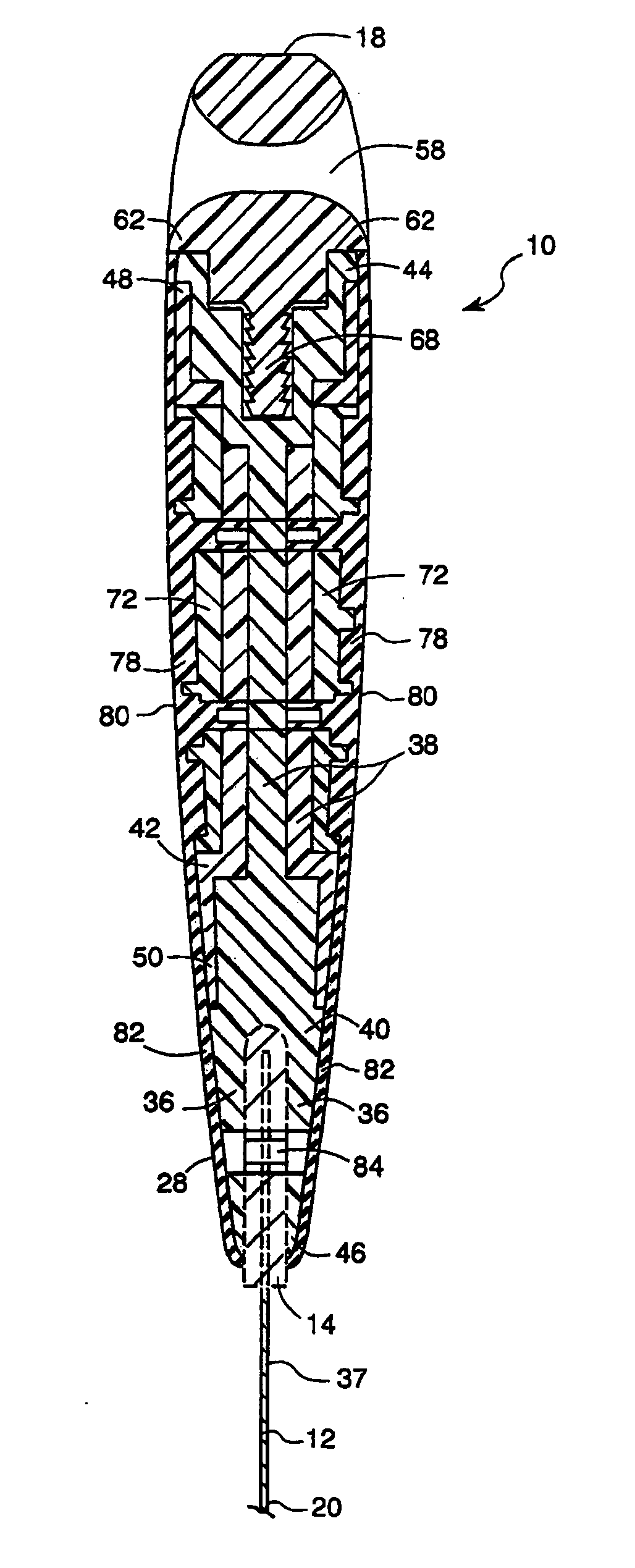

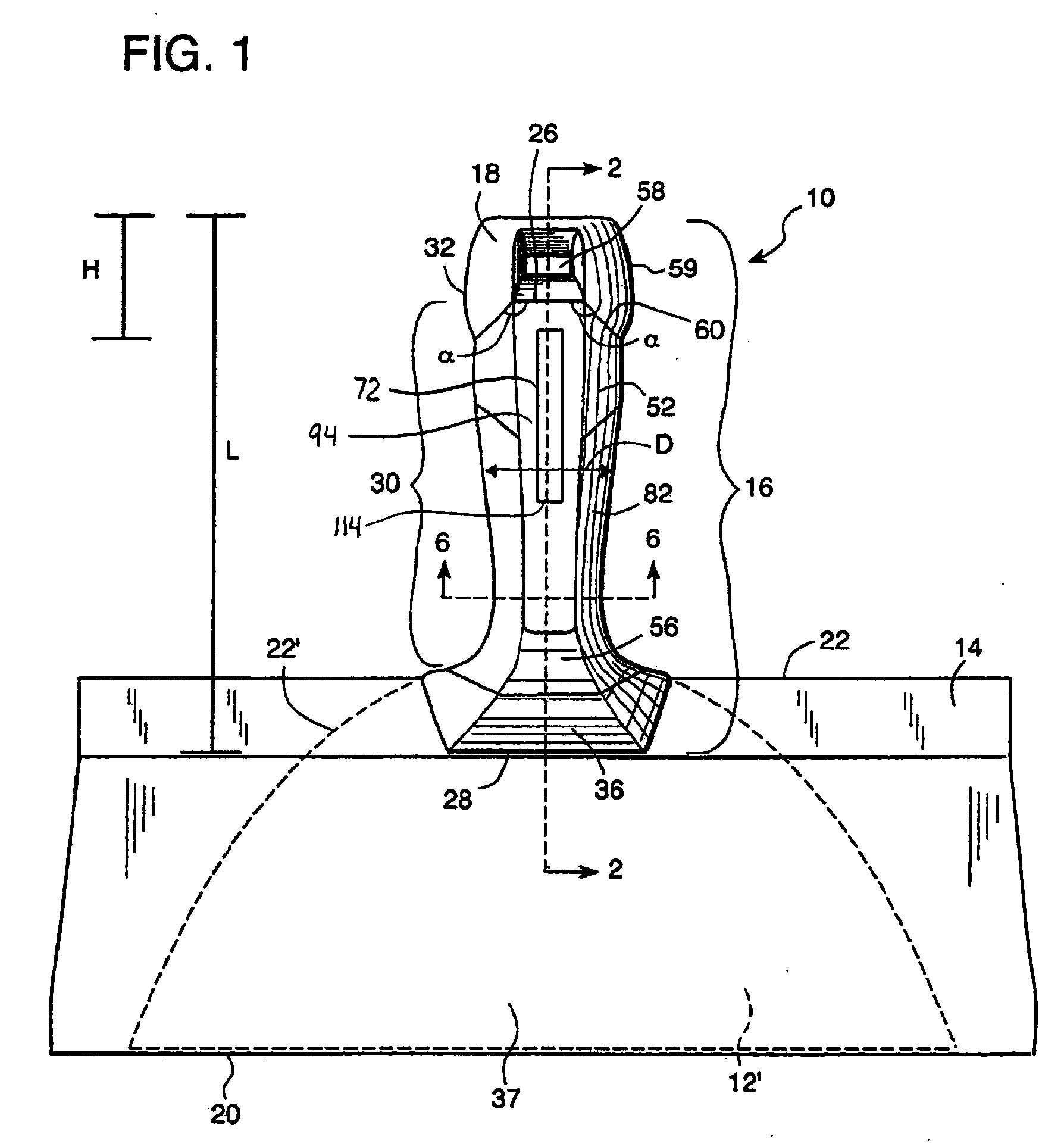

Drill stop sleeve for a dental drill, dental drill device with a drill stop sleeve, and set containing several drill stop sleeves

InactiveUS20070298375A1Improve viewing effectGuaranteed cooling effectThread cutting toolsDrilling/boring measurement devicesEngineeringBlisters

A dental drill (10) defining a bore diameter and a drill stop sleeve (22) which is transparent or translucent, thereby improving the view of the drilled hole formed by the drilling during the operation. The drill stop sleeve (22) comprises an uninterrupted circumferential lip (34), which interacts with a groove (24) formed in the shank part (16) of the dental drill (10) and thus fixes the drill stop sleeve (22) on the dental drill (10). The drill stop sleeves (22) of equal length are held in a blister of a set, the blister having, for each drill stop sleeve (22), a specific receiving recess that is closed in a sterile manner. Each blister comprises several drill stop sleeves with sleeve diameters corresponding to the bore diameters.

Owner:STRAUMANN HLDG AG

Toolholder and toolholder assembly with elongated seating pads

A toolholder assembly has a pocket adapted to receive a double-sided on-edge cutting insert with wiper facets. A pocket has at least two sides and supports pads extending from each of the at least two sides, wherein the support pads contact the wiper facets of the cutting insert when the cutting insert is mounted within the pocket.

Owner:KENNAMETAL INC

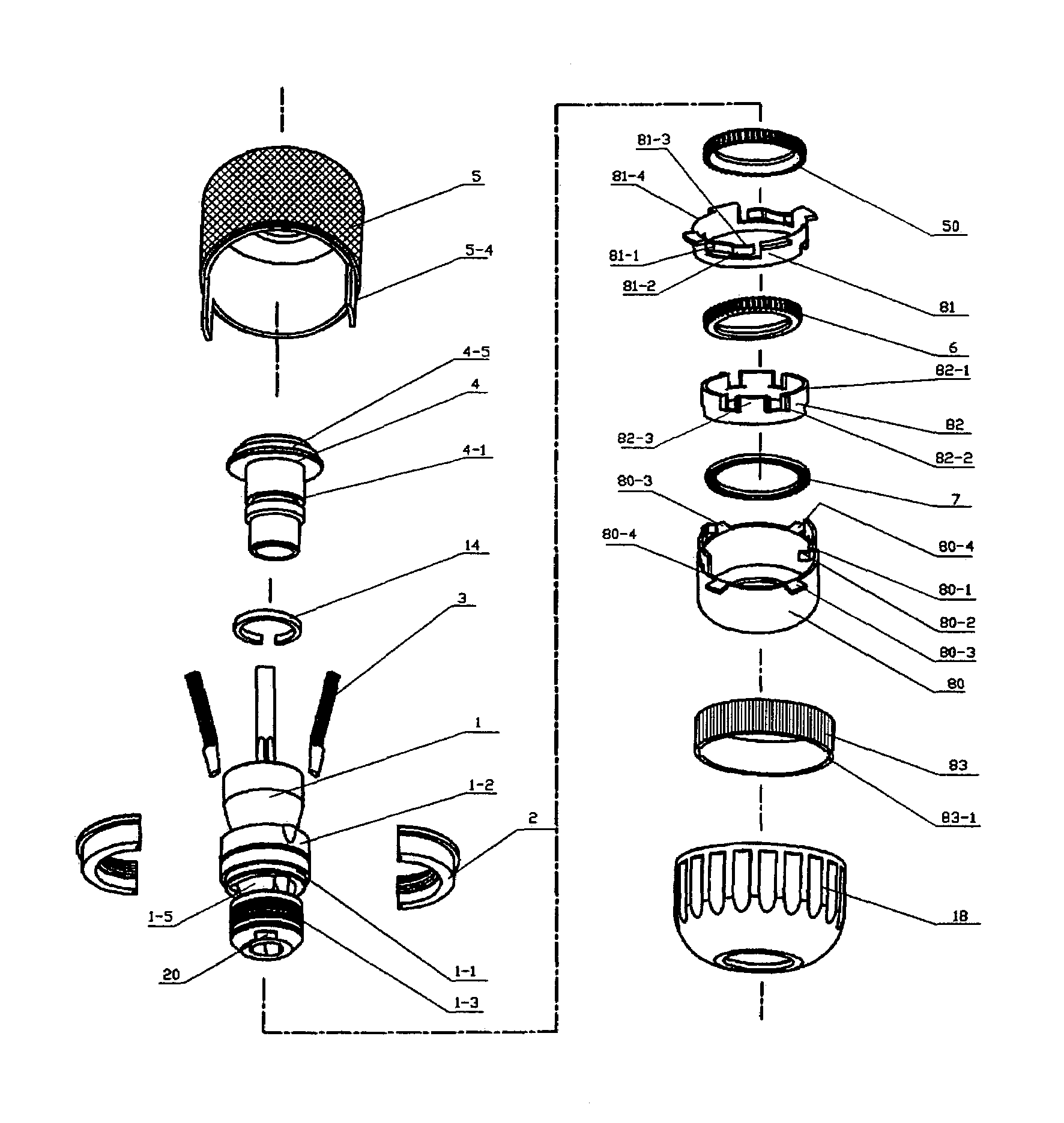

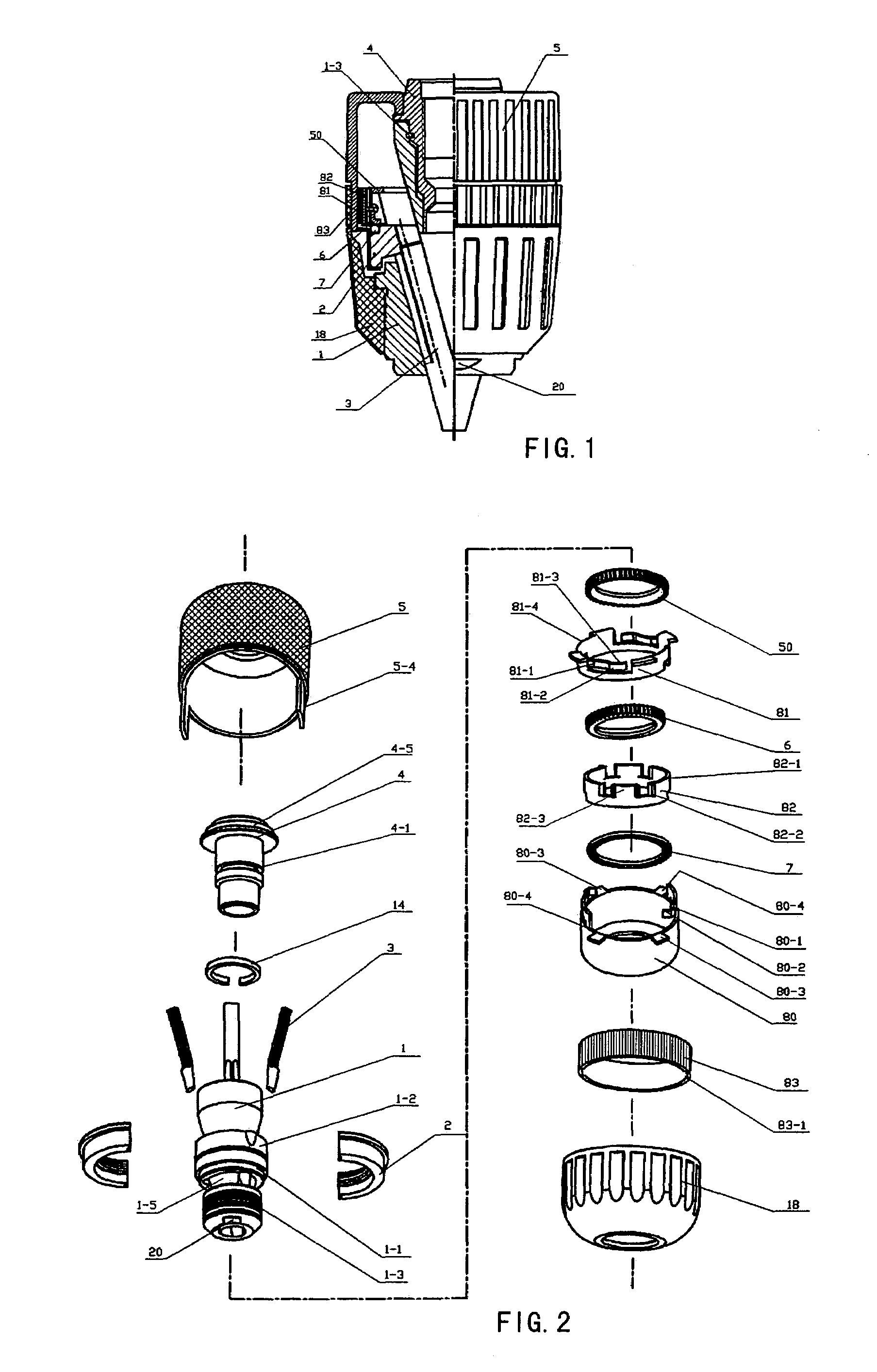

Chuck

Owner:SHANDONG WEIDA MASCH CO LTD

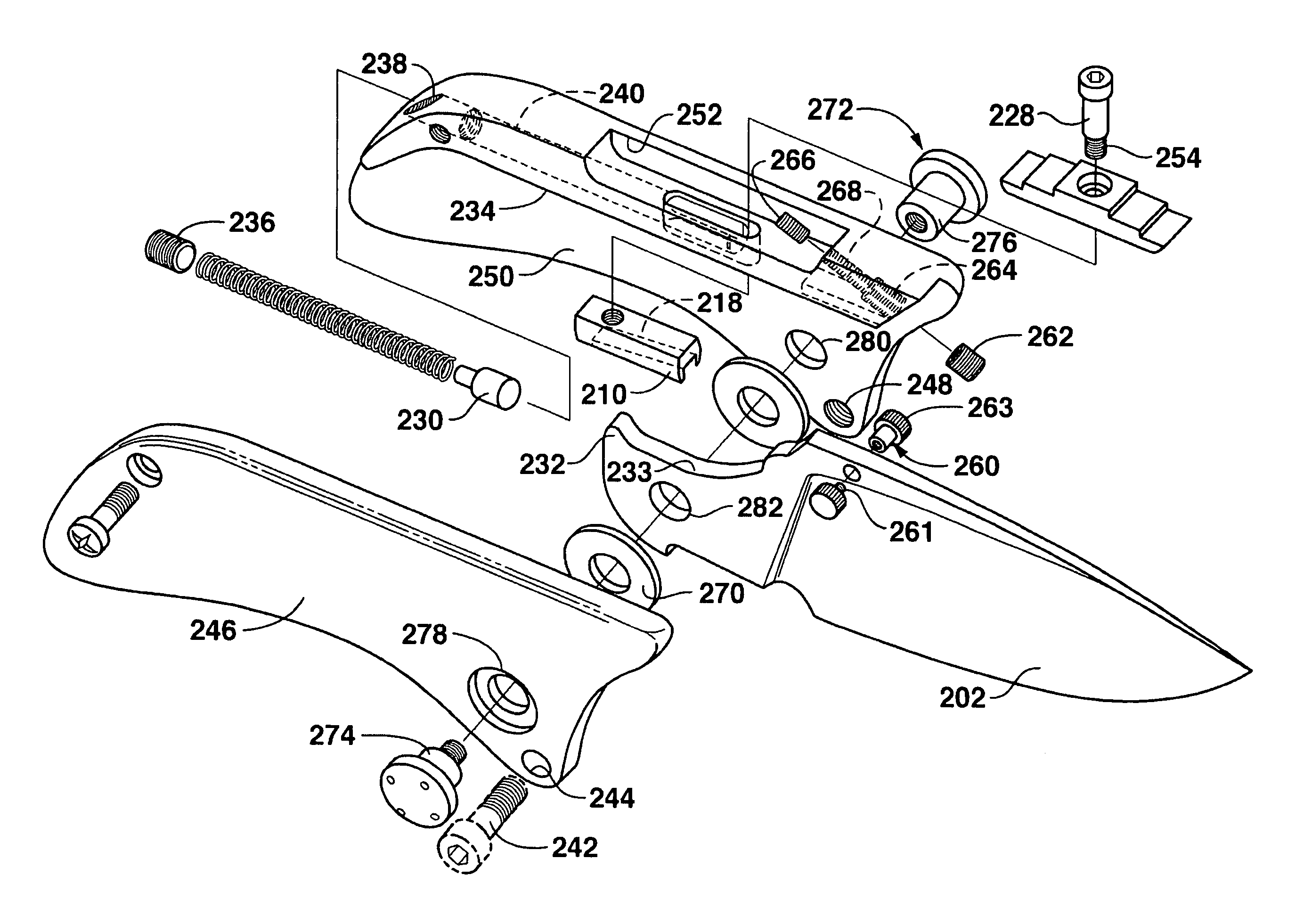

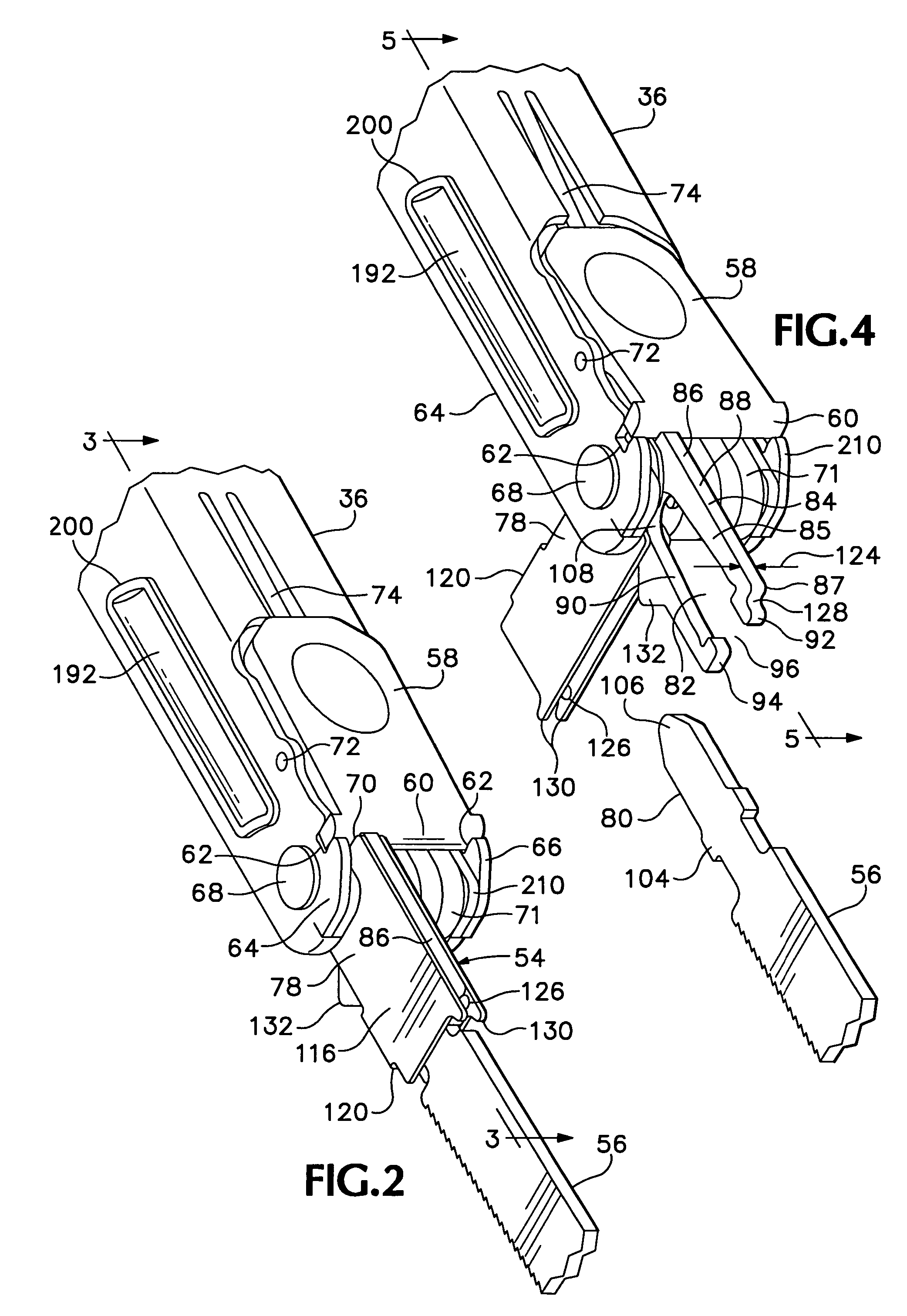

Folding knife with locking blade

InactiveUS7340837B1Improved blade locking mechanismEasy to solveThrusting weaponsWeapon componentsEngineeringKnife blades

A folding knife having a blade locking member carried for sliding movement within a channel defined in the handle, the locking member being movable to a blade locking position when the blade is in an extended position. A spring, or other biasing means, such as an opposing magnet arrangement, provide a spring-like biasing of the locking member towards a blade locking. In one embodiment, the locking member extends substantially the full width of the handle and is accessible from either side of the knife handle. The locking member includes a ramp on the underside thereof for contacting a projection, or bump, on the rearward portion of the blade tang. An adjustable bushing is provided which allows for adjustment of the blade within the handle to provide for both ease of pivoting of the blade, while reducing any lateral play in the blade within the handle.

Owner:BUSSE JERRY P

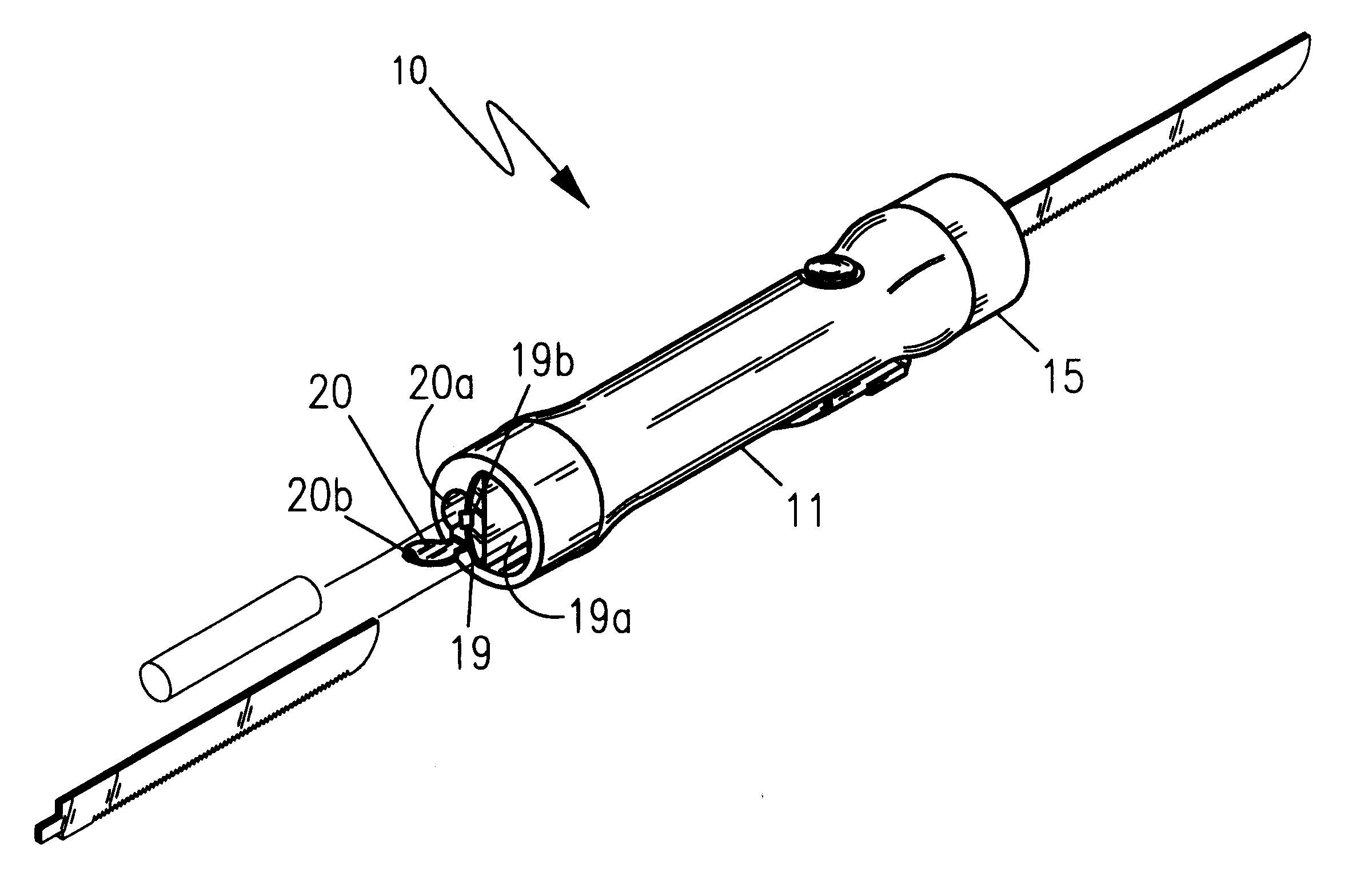

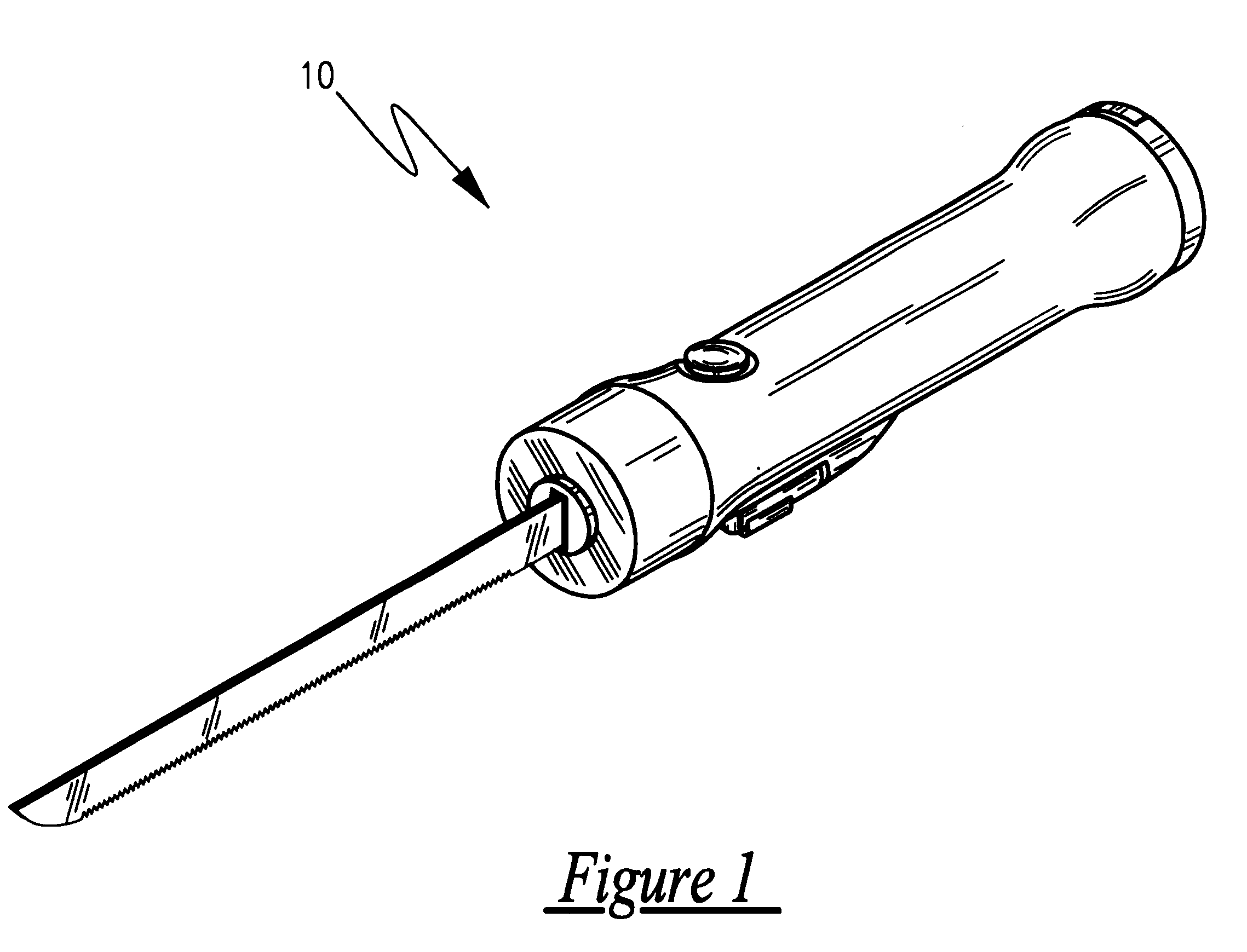

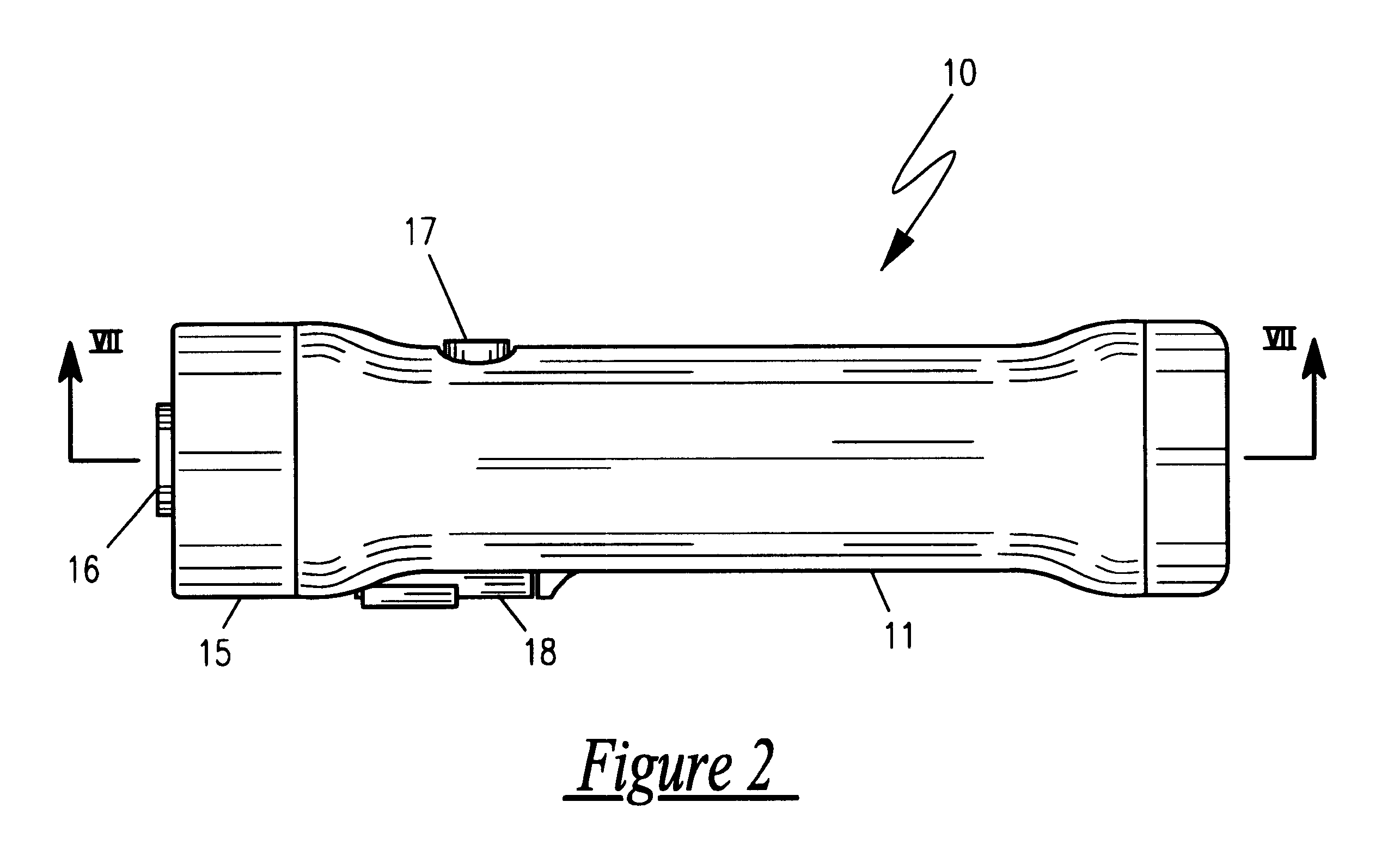

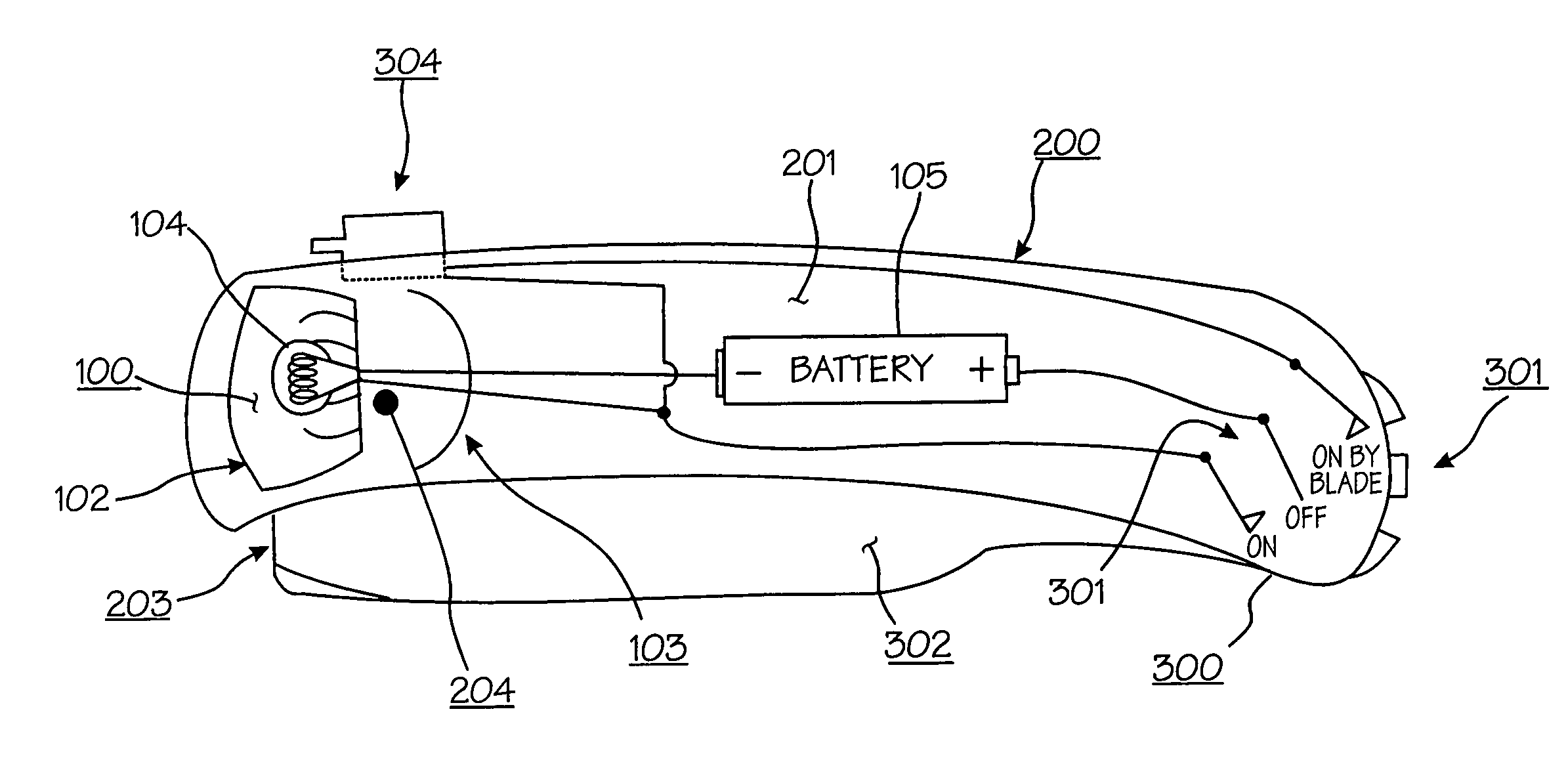

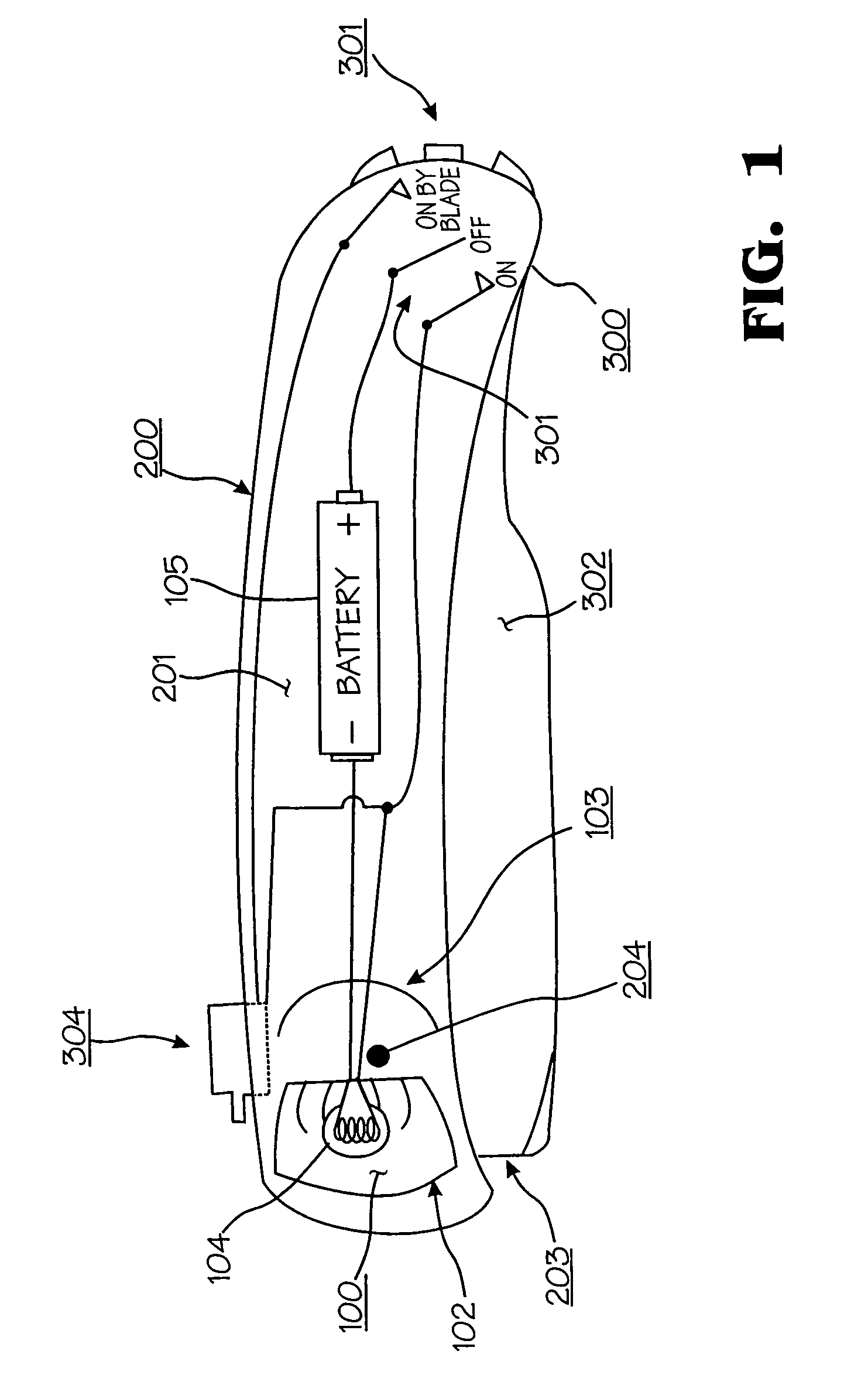

Interchangeable blade cordless electric knife

InactiveUS6434836B1Improve securityAvoid disadvantagesPortable power-driven toolsMetal working apparatusHeavy dutyKnife blades

The invention is an electric knife that runs on a battery or by use of a corded power converter. The handle housing has an electric reciprocating motor activated by a power button located on the handle of the knife. Different sizes and shapes of knife blades, dependent on the task, can be inserted into a locking slot in the front of the motorized head, and only released by a heavy-duty lock knife release button. The motorized head is powered directly by an electric motor located directly behind it in the handle.

Owner:OLIVARES HECTOR

Folding knife light tool

A folding knife light tool with an ergonometric handle in which an illuminating means whether an LED or light bulb or a laser light is incorporated into the handle housing in the spaces existing between the blade, the locking mechanism, and the handle. A knife handle is provided having a body contoured for the hand. The housing is made from one molded piece with a slit in the middle. The handle includes a pivot point for supporting a blade between the longitudinal sides or scales of the blades. A conventional locking or non-locking system is utilized for keeping the blade open once it is unfolded. When the blade is folded, a portion of the blade extends above the sides of the knife handle for digital engagement in the opening operation.

Owner:ZIRK JASON E +1

Detachable chipbreaker for a cutting insert

A cutting insert which includes a holder that contains a pocket and a hard insert that has a rake surface. The hard insert is contained within the pocket so as to present a cutting edge. The cutting insert also includes a chipbreaker which comprises a plate with a bottom surface. The chipbreaker is attached to the cutting insert (or optionally to the holder) so that the plate is spaced above the rake surface of the hard insert a first distance forming a conduit for passage of the chips away from the cutting insert. The conduit is defined at least in part by the rake surface of the cutting insert and the bottom surface of the chipbreaker plate.

Owner:KENNAMETAL PC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com