Process for treating industrial sewage

A technology for industrial sewage and treatment methods, which is applied in water/sewage treatment, water/sludge/sewage treatment, separation methods, etc., can solve the problem of insufficient utilization of industrial wastewater, high industrial wastewater treatment costs, and high sewage treatment costs. problems, to achieve the effect of optimizing economic benefits, reducing preparation costs, and increasing combustion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

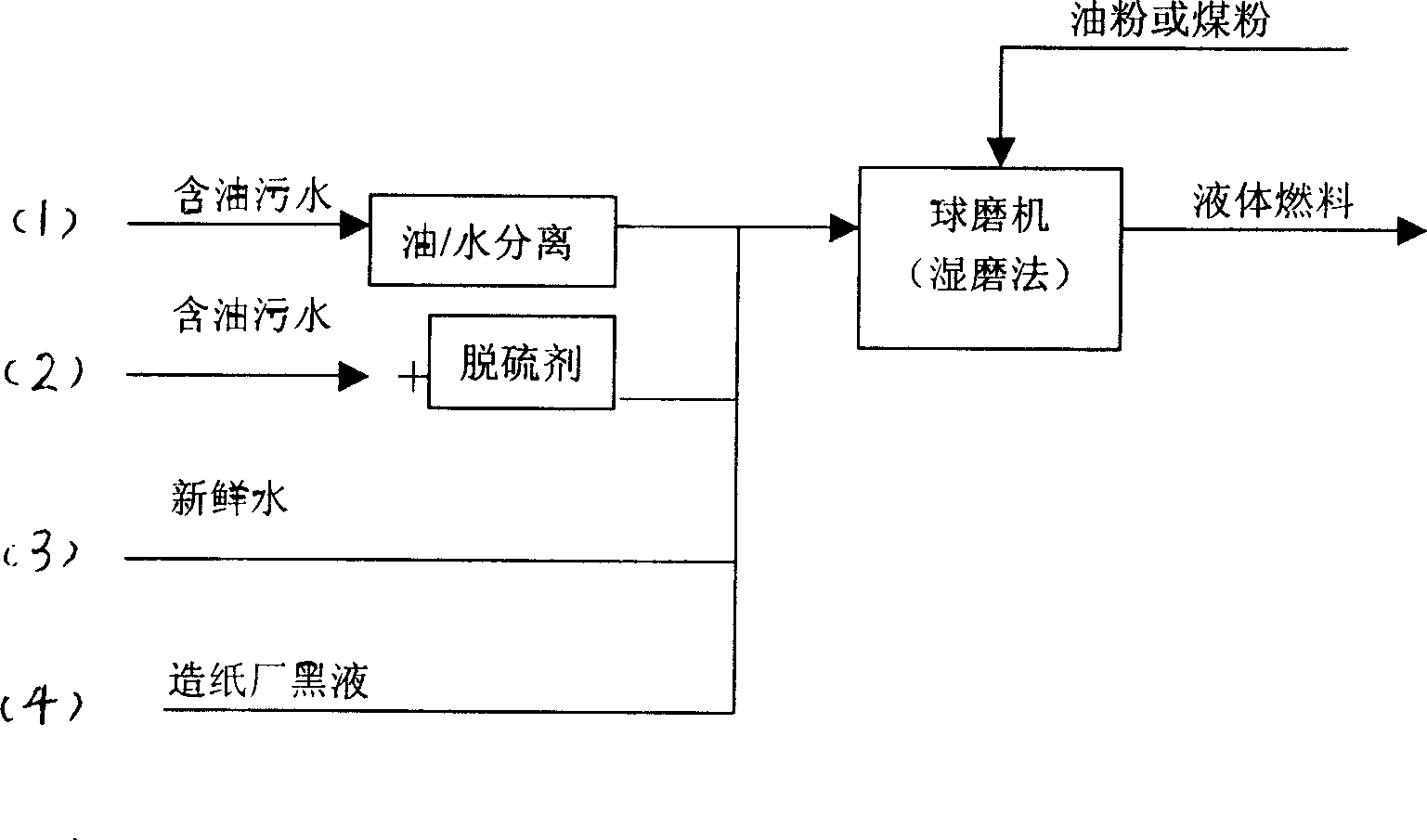

[0020] figure 1 The sources of water for four kinds of liquid fuels (water coke slurry or coal water slurry) are indicated in . Wherein mode (3) is prior art mode.

[0021] Method (1) is oily sewage, which first undergoes oil-water separation to control the oil content in the sewage below 500ppm, and then replaces fresh water as the preparation of liquid fuel.

[0022] Method (2) is the preparation of sulfur-containing sewage, adding calcium-based desulfurizer, and then replacing fresh water as liquid fuel.

[0023] Mode (4) is the preparation of paper mill black liquor, which directly replaces fresh water as liquid fuel.

[0024] The above-mentioned industrial sewage replaces fresh water, which can be completely replaced or partially replaced. When all of them are replaced, the dosage is equivalent to that of fresh water, and only needs to meet the viscosity requirement of liquid fuel. The preparation method of liquid fuel remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com