Manufacturing method of pollution-free coal with high combustion value by household garbage

A domestic garbage and manufacturing method technology, applied in the field of coal manufacturing, can solve the problems of high processing technology requirements, little economic return, and high operating costs, and achieve the effects of advanced and reasonable process routes, low waste classification requirements, and economical operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

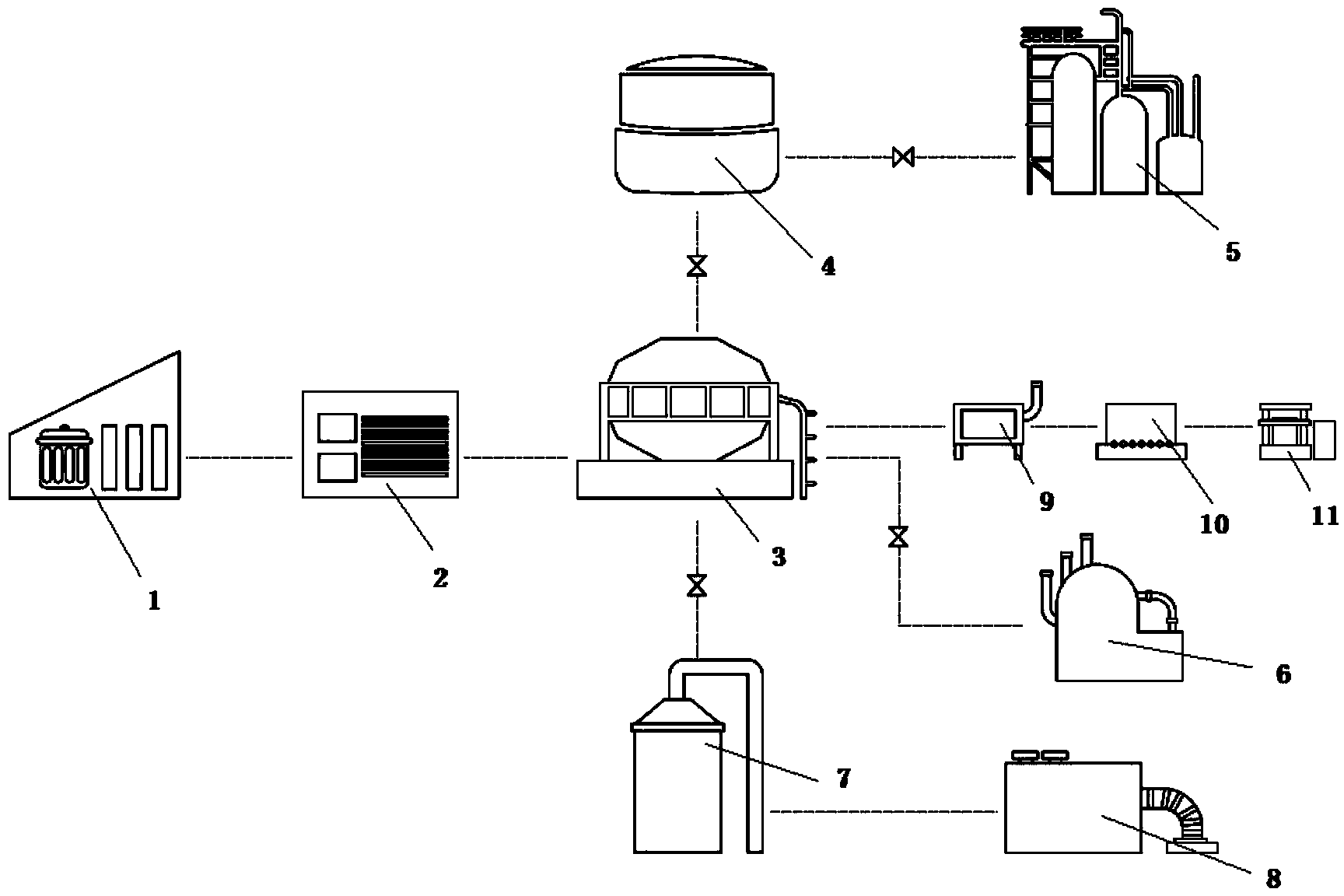

[0069] Such as figure 1 As shown, the present embodiment provides a method of utilizing domestic waste to produce high combustion value and pollution-free coal, such as figure 2 Shown is the equipment system required to realize the manufacturing method.

[0070] The manufacturing method of the present embodiment, specific steps include:

[0071] Step 1: Collect and store garbage, specifically: transport the garbage from each scattered point to the garbage storage warehouse or garbage storage pit 1;

[0072] Step 2: Put the garbage into the reaction box 2, and push the reaction box into the reactor 3: Transport the garbage from the garbage storage or garbage storage pit 1 to the reaction box 2 by automatic or manual means, and then pass the reaction box 2 through the track Push into the reactor 3, and completely seal the reactor 3;

[0073] Step 3: importing steam, and automatically controlling the reactor to react: the steam generator 6 generates steam, and introduces stea...

Embodiment 2

[0095] The overall preparation method of the present embodiment is the same as that of Example 1, and the different parameters involved are defined as follows:

[0096] In this embodiment, as described in step 3, the temperature and pressure dynamic control over time is carried out on the garbage, the overall reaction time is 7 hours, and the dynamic control by time period is as follows:

[0097] During the first 1 / 3 of the overall reaction, the temperature is 250°C and the pressure is 25bar;

[0098] During the middle 1 / 3 of the overall reaction, the temperature is 500°C and the pressure is 35bar;

[0099] In 1 / 3 of the time period after the overall reaction, the temperature is 300° C. and the pressure is 25 bar.

[0100] In this embodiment, in step 3, a catalyst is added to the garbage while dynamically controlling the temperature and pressure in the reaction vessel. The catalyst uses one or a combination of the following materials: marble powder, cryolite powder, talcum po...

Embodiment 3

[0106] The overall preparation method of the present embodiment is the same as that of Example 1, and the different parameters involved are defined as follows:

[0107] In this embodiment, as described in step 3, the temperature and pressure dynamic control over time is carried out on the garbage, the overall reaction time is 5 hours, and the dynamic control by time period is as follows:

[0108] During the 1 / 4 period before the overall reaction, the temperature is 180°C and the pressure is 20bar;

[0109] In the middle 2 / 4 of the overall reaction period, the temperature is 300°C and the pressure is 30bar;

[0110] During the 1 / 4 period of time after the overall reaction, the temperature is 200° C. and the pressure is 23 bar.

[0111] In this embodiment, in step 3, a catalyst is added to the garbage while dynamically controlling the temperature and pressure in the reaction vessel. The catalyst uses one or a combination of the following materials: quartz powder, diatomaceous e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com