Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Eliminate heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

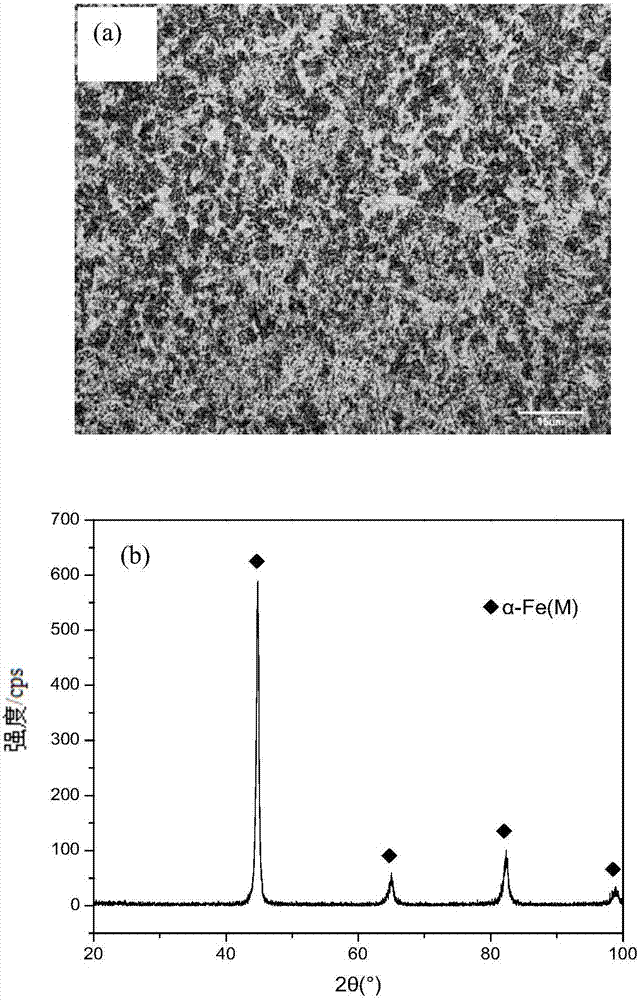

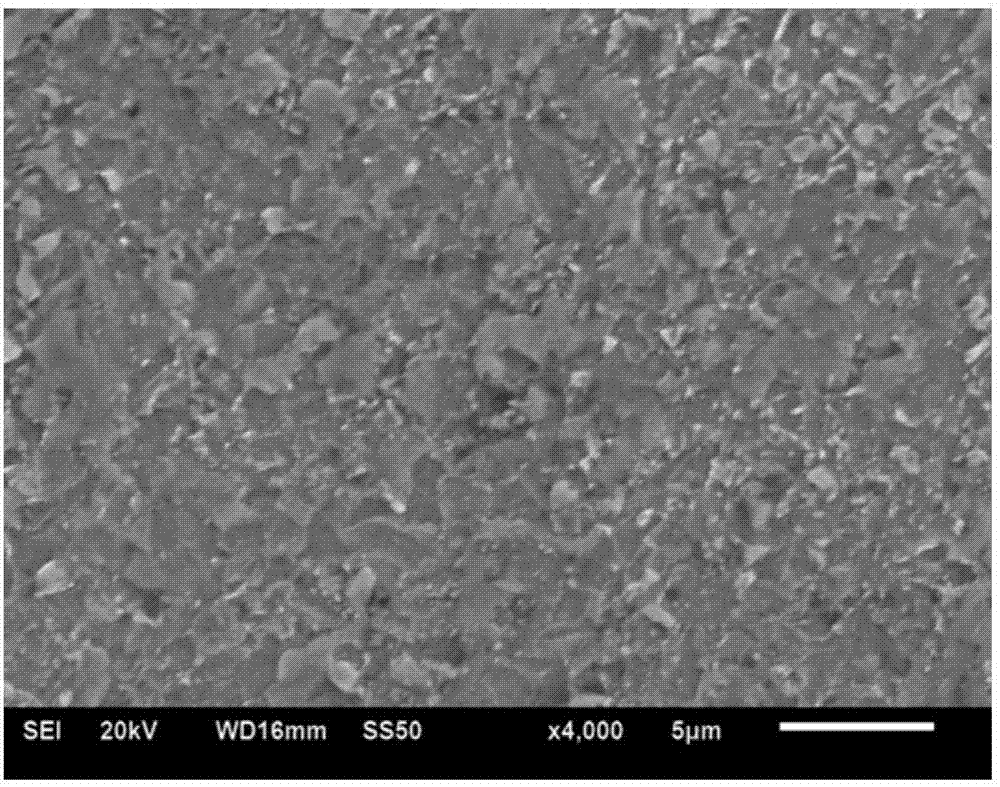

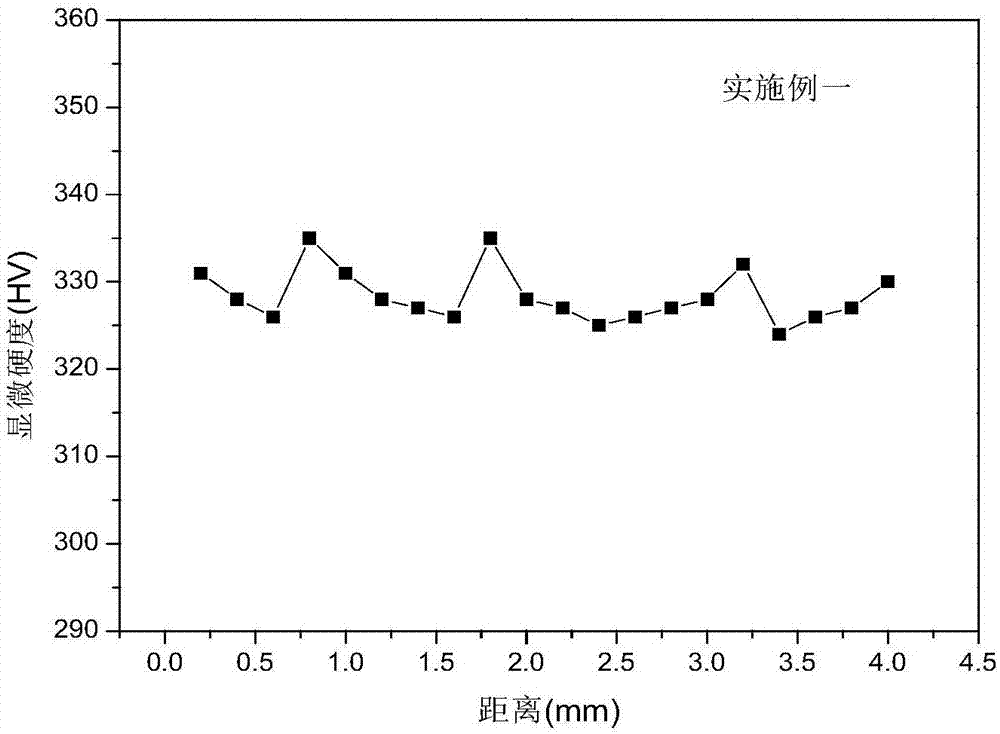

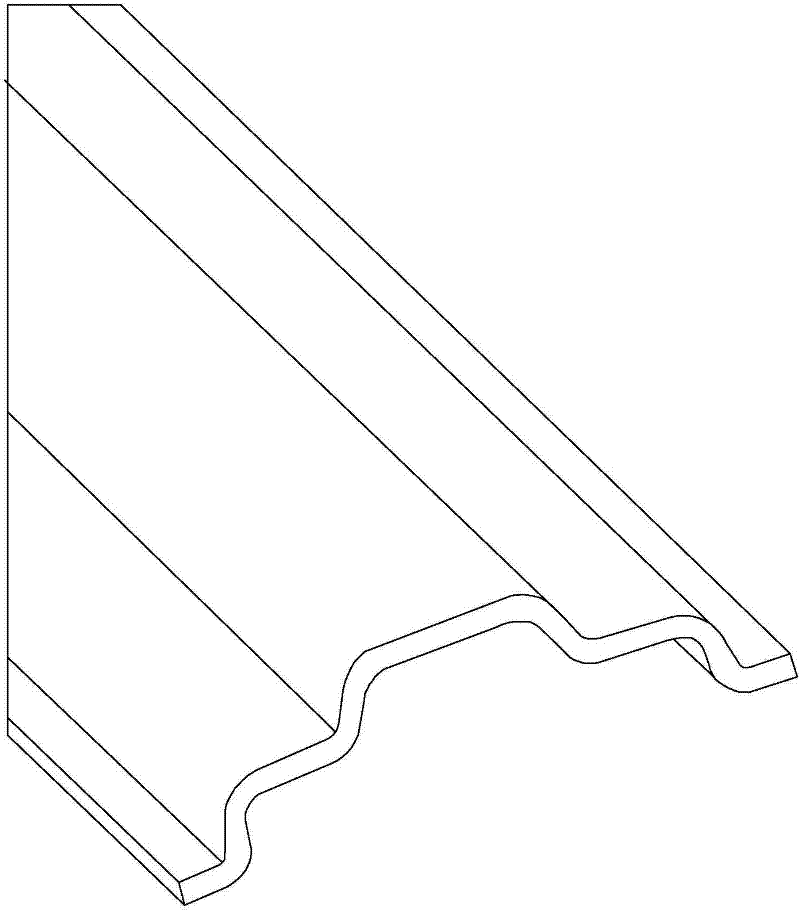

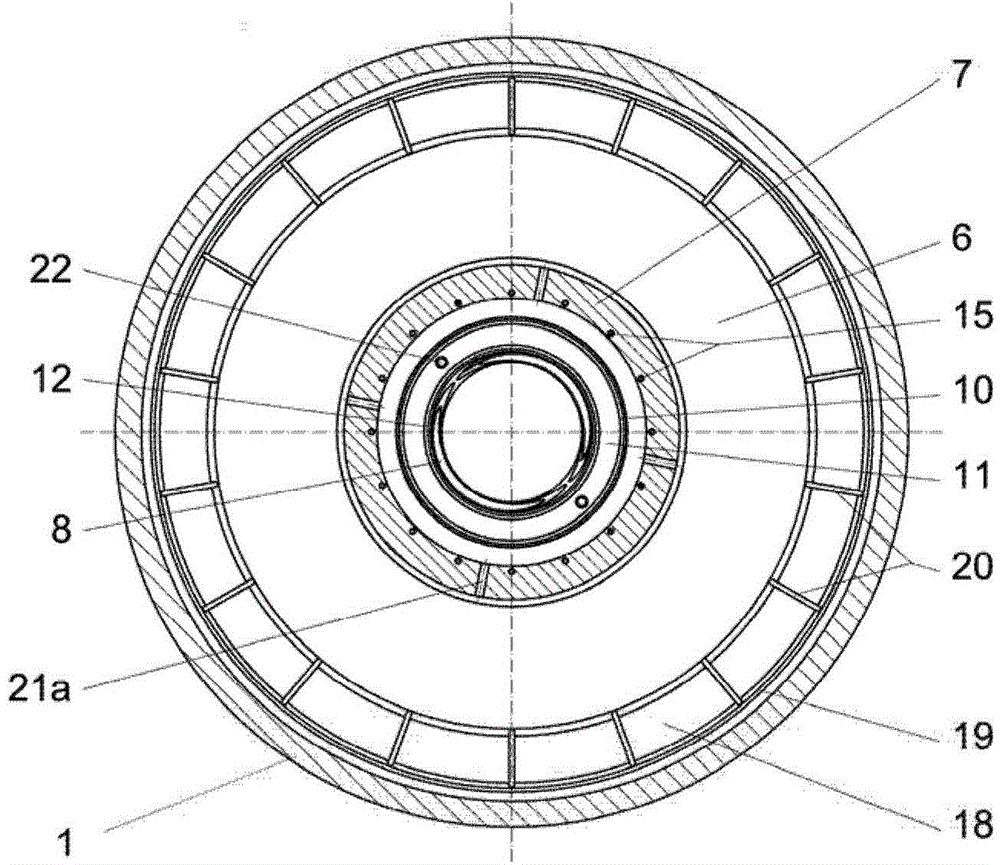

Method for preparing 24CrNiMo bainite alloy steel by using selective laser melting technology

ActiveCN107214336ARemarkable effect of fine grain strengtheningImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHardness

The invention provides a method for preparing 24CrNiMo bainite alloy steel by using a selective laser melting technology. The method includes the steps that a laser device is used for conducting scanning on 24CrNiMo alloy steel power which is spread out on a base plate according to a preset selective laser melt scanning route till the power melts. According to the method, by optimizing technology parameters, taking use of the effects of alloy elements such as C, Cr, Ni, Mo, the bainite alloy steel which is uniform in microstructure is obtained at a high selective laser melting cooling speed, the average micro-hardness of the obtained bainite microstructure reaches 330-346 HV, the tensile strength is 962-978 Mpa, the elongation ratio is 16.4-17.6%, the product of tensile strength and elongation reaches 16.1-16.9 Gpa%, and the microstructure has excellent matched strength and toughness. The method and the technology are mainly applied to selective laser melting manufacture of 24CrNiMo alloy steel high speed rail brake discs.

Owner:NORTHEASTERN UNIV

Manufacturing method of light-load automobile aluminum alloy wheel hub

The invention discloses a method for manufacturing an aluminum alloy wheel hub of a light-loaded automobile. The steps are as follows: A. Making the rim: according to requirements, select profiles of different cross-sections extruded from aluminum alloy materials, and then roll the profiles into a circle Cylinder, welding the butt joint, then rounding, and finally flanging the wheel lip; B. Spoke production: the circular aluminum plate is stretched or spun to make the aluminum plate reach the designed shape of the spoke, and then the spoke Stamping and processing various through holes; C. Manufacturing of the wheel hub: assembling the spokes in the inner circle of the rim; D. Completing the manufacturing: machining the lip parts of the wheel to complete the final manufacturing of the hub. The wheel rim in the present invention adopts the wheel rim profile that can be produced in large quantities to make the wheel rim. A large number of processing steps are reduced, manufacturing costs are saved, mass production is easier, and it can be directly entered into the ranks of low-end cars, making the promotion range of aluminum alloy wheels wider.

Owner:苏竞

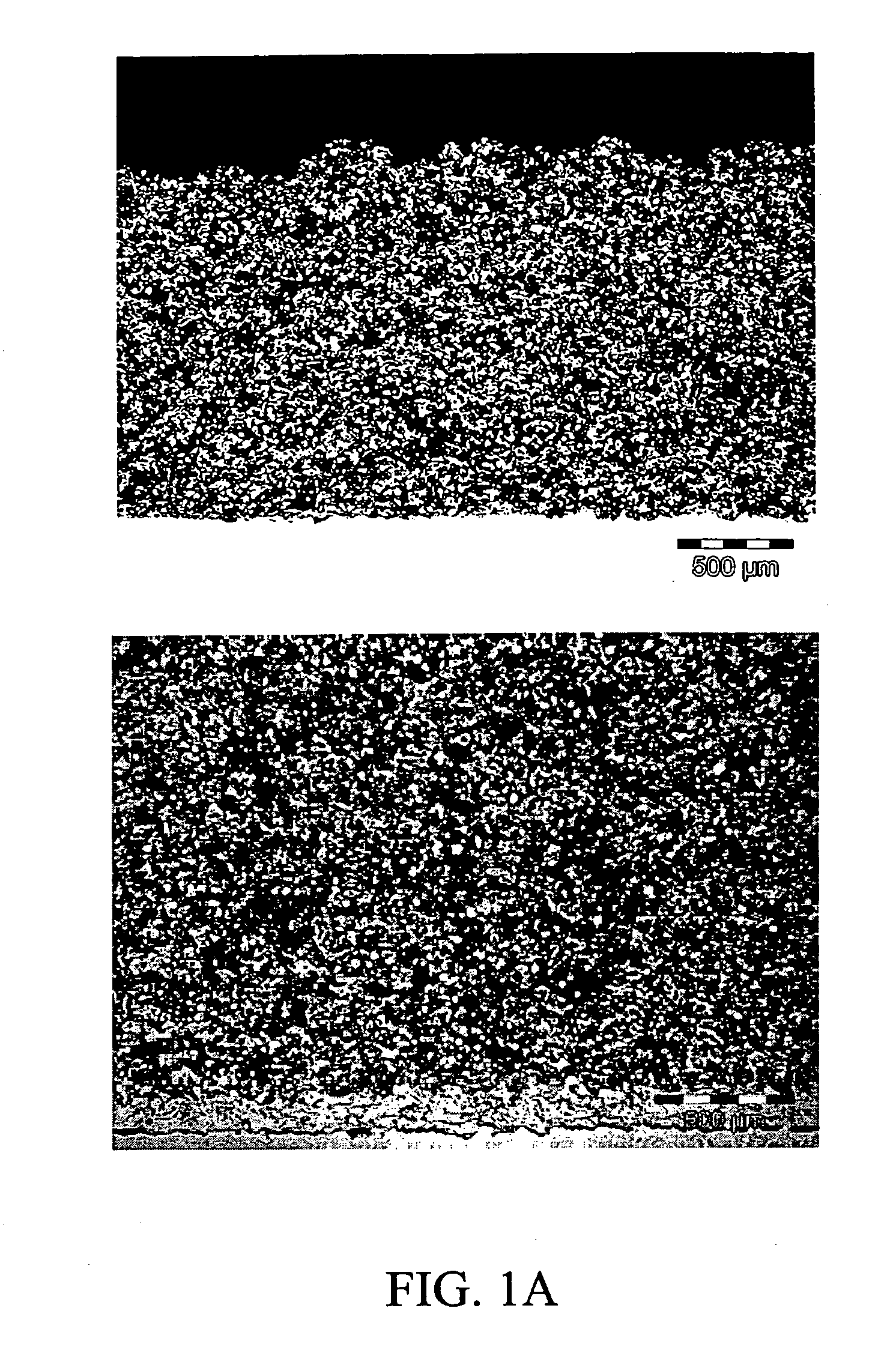

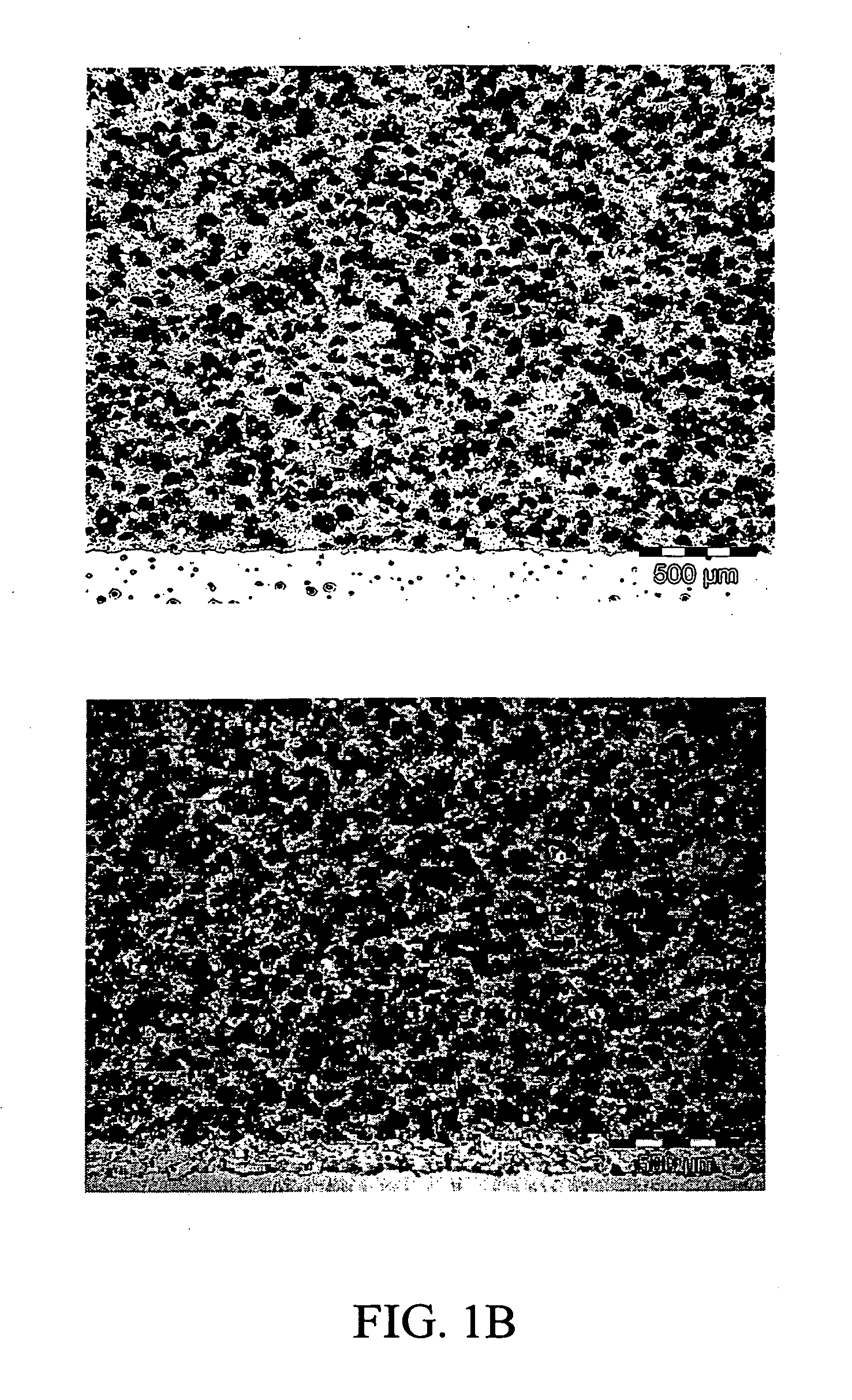

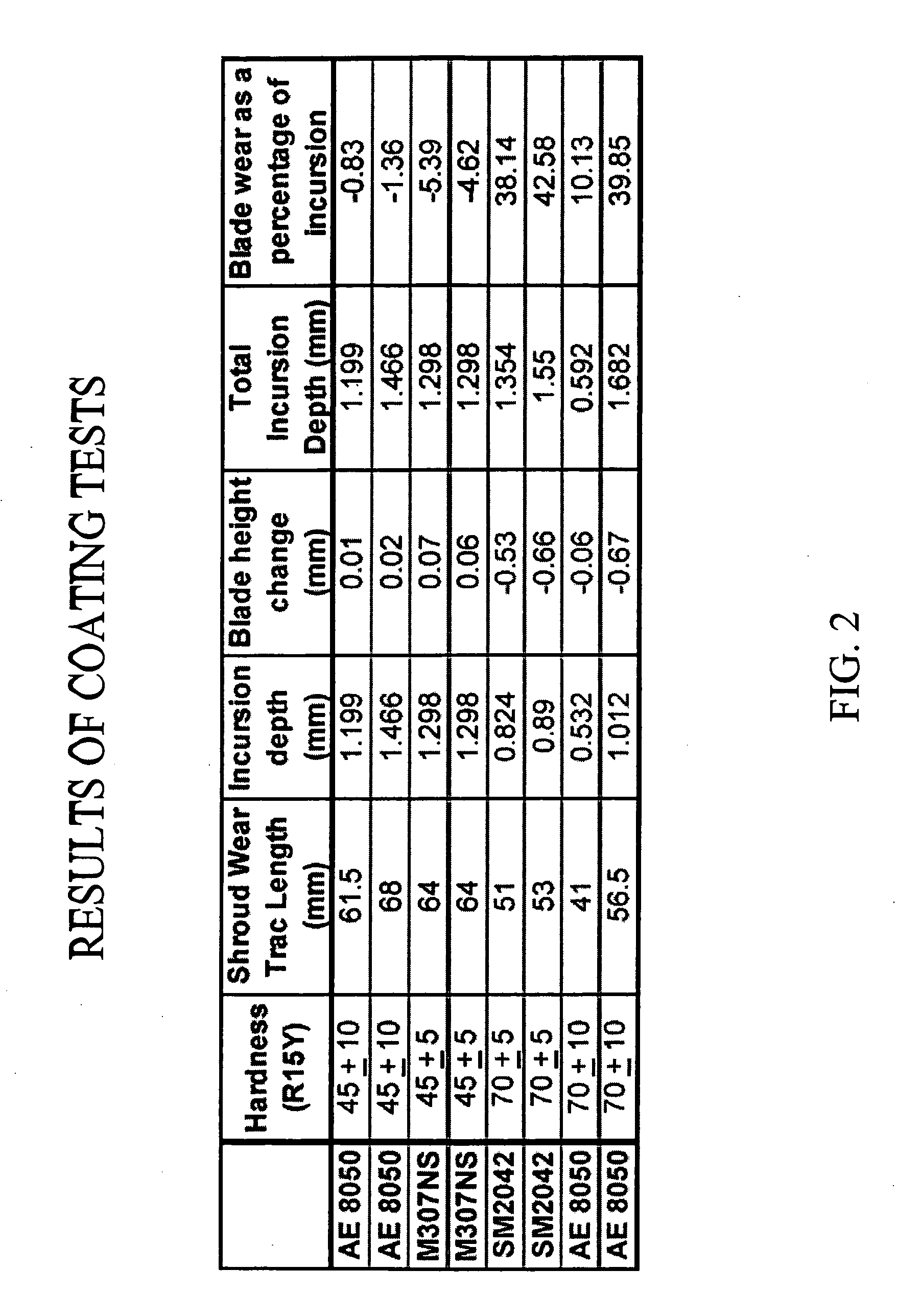

High temperature spray dried composite abradable powder for combustion spraying and abradable barrier coating produced using same

InactiveUS20060193993A1Lower coating densityImproved coating behaviorLiquid surface applicatorsMolten spray coatingPolyesterPore distribution

An improved method of forming an abradable thermal barrier coating comprises providing a spray-dried powder of M-CrAlY and a solid lubricant, such as CoNiCrAlY—BN. Unlike powders provided for use with plasma spray guns, the powder is essentially free of polyester or other organic fugitive additives provided to increase porosity. The powder is applied using a combustion spray process and results in a M-CrAlY abradable coating that has an average porosity comparable to that of a plasma-applied coating but with smaller and more uniform pore distribution, and without requiring post-application heat treatments to remove fugitive materials. Deposition efficiency is also increased.

Owner:DORFMAN MITCHELL R +2

Cold spraying device and method for preparing 316L stainless steel coating

InactiveCN103422088AImprove plastic deformation abilityTo accelerate the expansionPressure inorganic powder coatingMetallurgyGas heater

The invention discloses a cold spraying device and a method for preparing a 316L stainless steel coating, and belongs to the cold spraying technical field. The device mainly comprises a control system, a powder feeder, a gas heater, a laval nozzle and a powder heater. One end of the gas heater is connected with the laval nozzle, and the other end of the gas heater is connected with the powder feeder. One end of the powder feeder is connected with the control system, and the other end of the powder feeder is connected with one end of the powder heater. The other end of the powder heater is connected with the laval nozzle. In preparation of 316L stainless steel coating by utilization of the device, the technological parameters are as follows: the carrier gas preheating temperature is 200-600 DEG C, the spraying distance is 10-30 mm, the spraying pressure is 1.5-2.5 MPa, and the powder-feeding heating temperature is 200-500 DEG C. The modified cold spraying device heats the stainless steel powder from the powder feeder, and a compact stainless steel coating tightly combining with a matrix is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

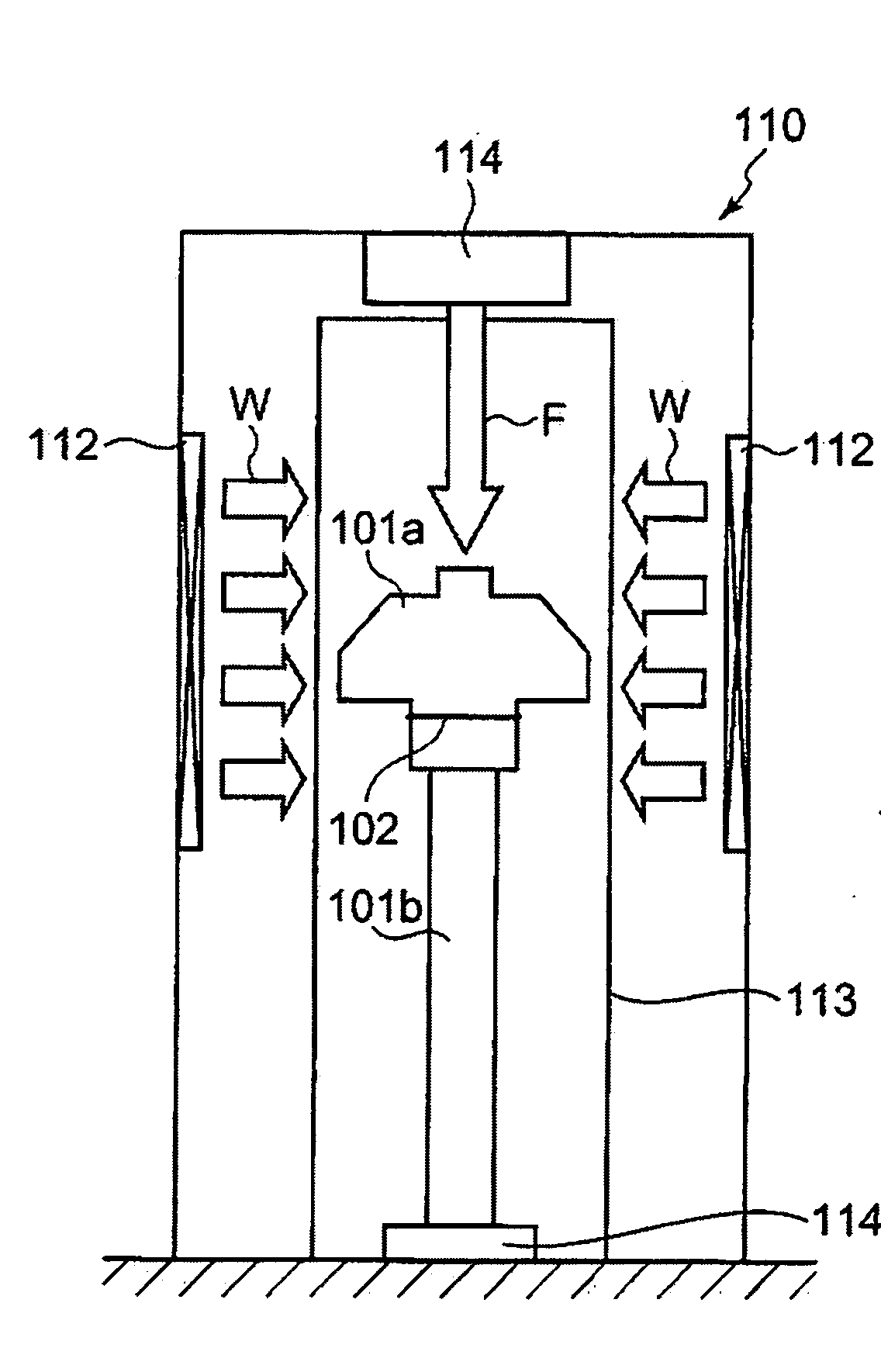

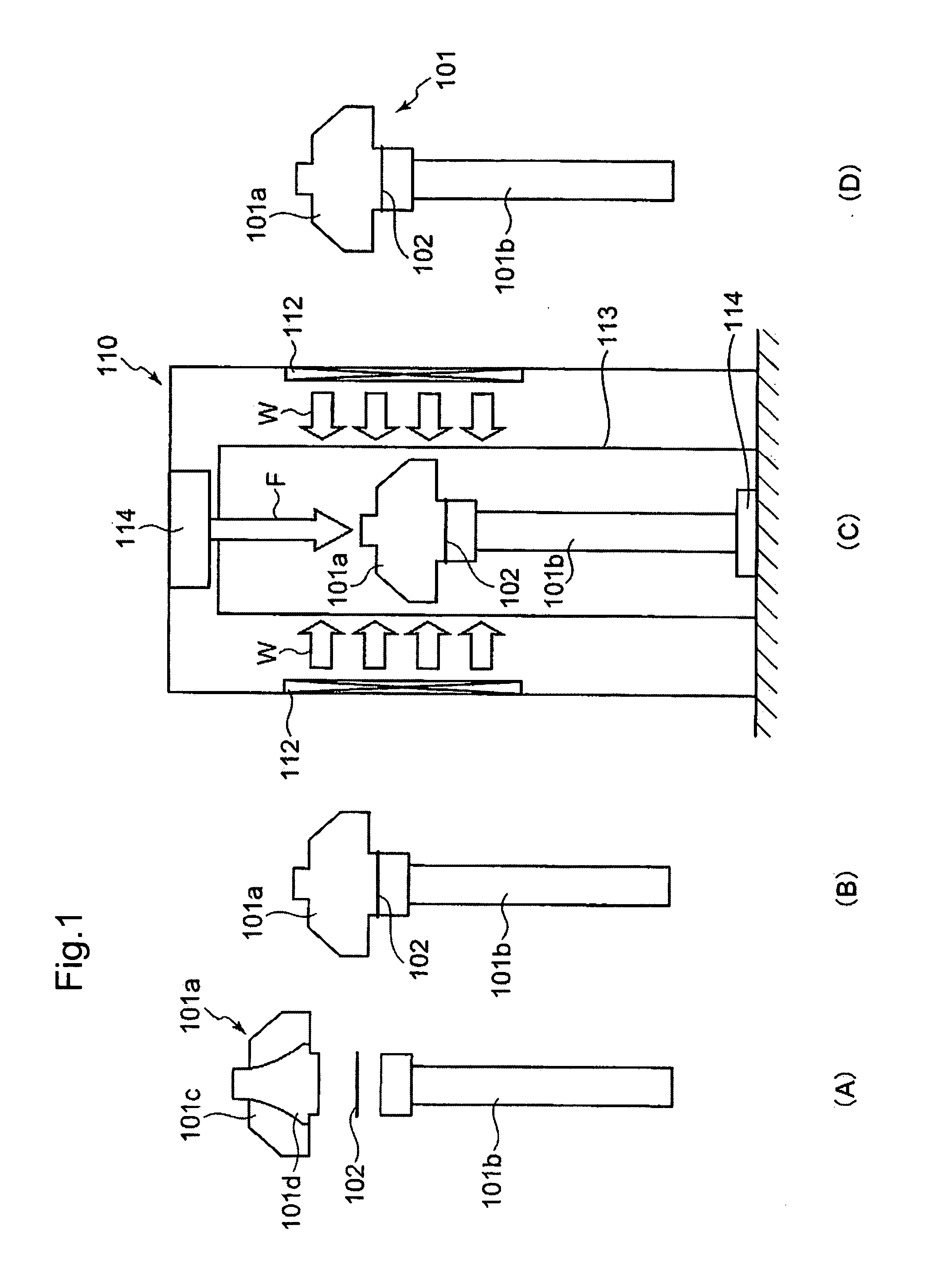

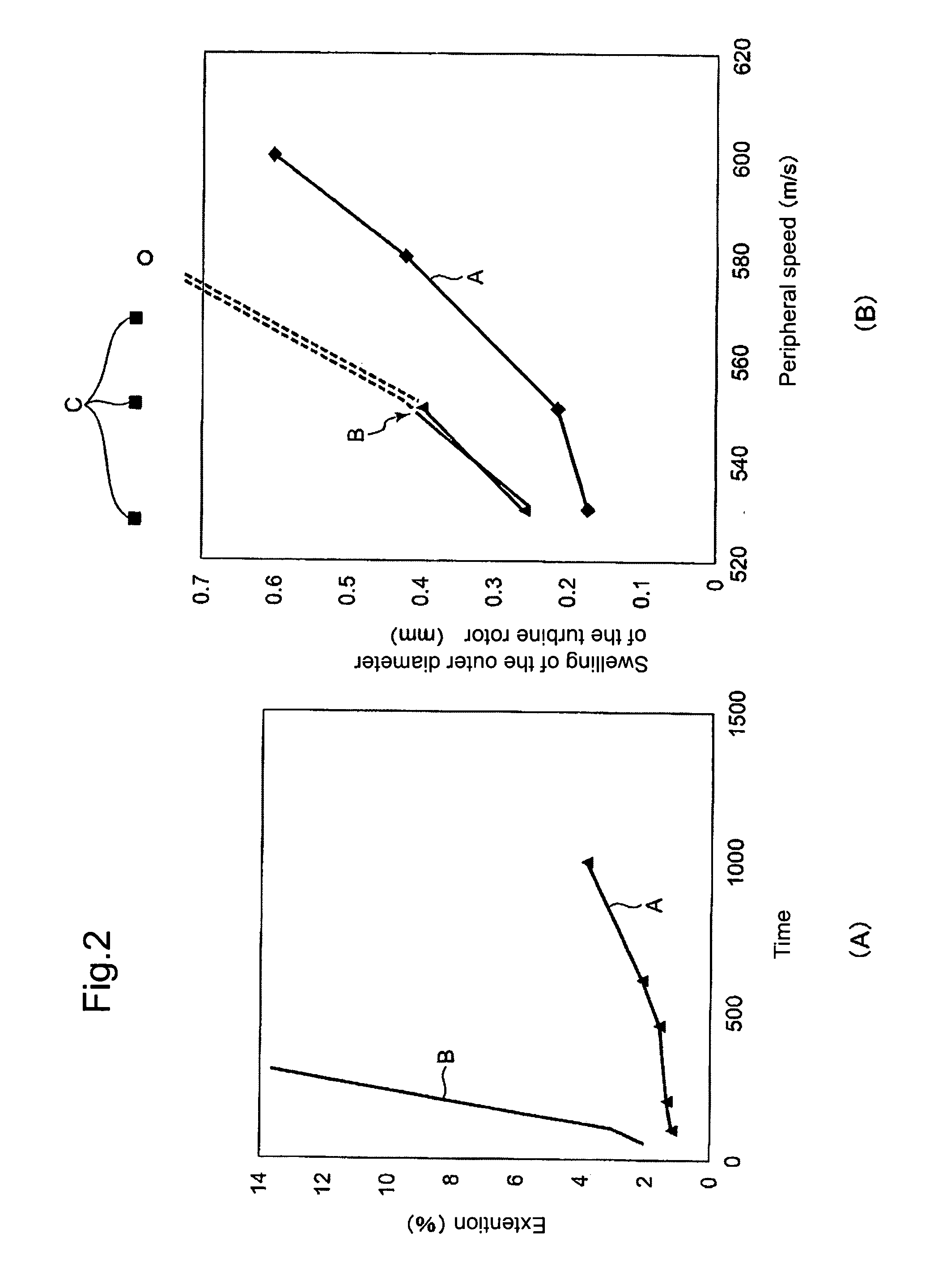

Method of manufacturing rotor and exhaust turbo-supercharge incorporating the rotor

InactiveUS20080199313A1High strengthInhibition strengthPropellersPump componentsCircular discTurbocharger

Provided are a method of manufacturing a brazed rotor composed of a wheel and a shaft joined to the former by brazing, having a durability and a reliability which can be enhanced without increasing the manufacturing man hours, and a turbine rotor for an exhaust turbo-supercharger. The wheel having a disc portion formed at its outer periphery with blades, and a rod-like shaft are arranged in a furnace, being opposed to each other at their surfaces to be joined with a brazing solder being interposed therebetween, and infrared radiation is irradiated onto a side part of the wheel so as to heat the surfaces to be joined up to a temperature in a range from 1,000 to 1,080 deg. C. in order to melt the brazing solder, thereby the wheel and the shaft are joined by brazing to each other at their surfaces to be joined.

Owner:MITSUBISHI HEAVY IND LTD

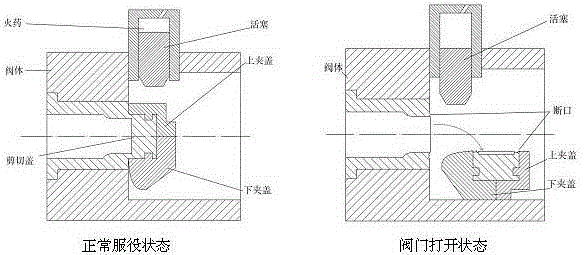

Crystalline grain control method for GH690 alloy shear cover of explosion valve

ActiveCN105170865AAddressing inhomogeneitySolve the problem of abnormal grain growthValve arrangementsMetal-working apparatusAlloyMaterials processing

The invention discloses a crystalline grain control method for a GH690 alloy shear cover of an explosion valve and belongs to the technical field of material machining. The method aims to solve the problems that the structure of a forge piece of the GH690 alloy material shear cover of the explosion valve is not even, and crystalline grains abnormally grow up. A heat treatment machining is organically combined with a forging machining, and the machining method that large deformation free forging is implemented at a high temperature (1020 DEG C to 1150 DEG C), small deformation foetal die forging is implemented at a medium temperature (710 DEG C to 850 DEG C), and the inhibition function of carbide second-phase particles on moving of a grain boundary is used for restraining the abnormal growth of the crystalline grains in forging machining of the shear cover in an auxiliary mode is provided. According to the crystalline grain control method for the GH690 alloy shear cover of the explosion valve, the forging piece forming and crystalline grain refinement are conducted synchronously, and the shear cover forge piece is obtained through heating twice; the machining limitation that a forging piece with the simple structure is subjected to high-temperature multiple-time hierarchical forging machining at present is overcome; the forging heating number is reduced; the follow-up heating treatment of the forging piece of the GH690 nickel-based alloy sheer cover is avoided. The structure with even carbides and refined crystalline grains of the GH690 alloy shear cover of the explosion valve forged through the method can be obtained.

Owner:DALIAN UNIV OF TECH +1

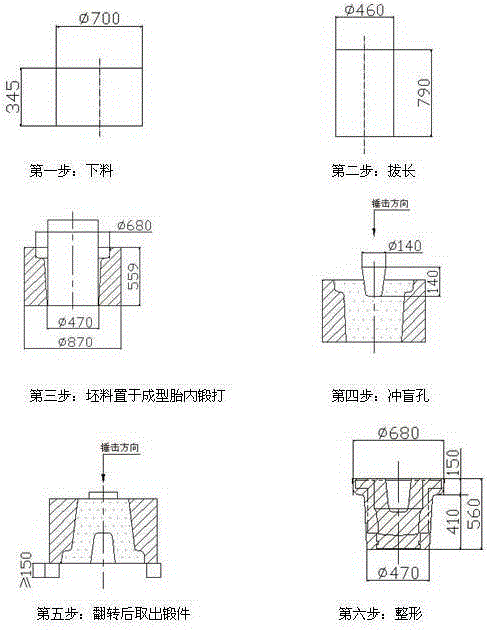

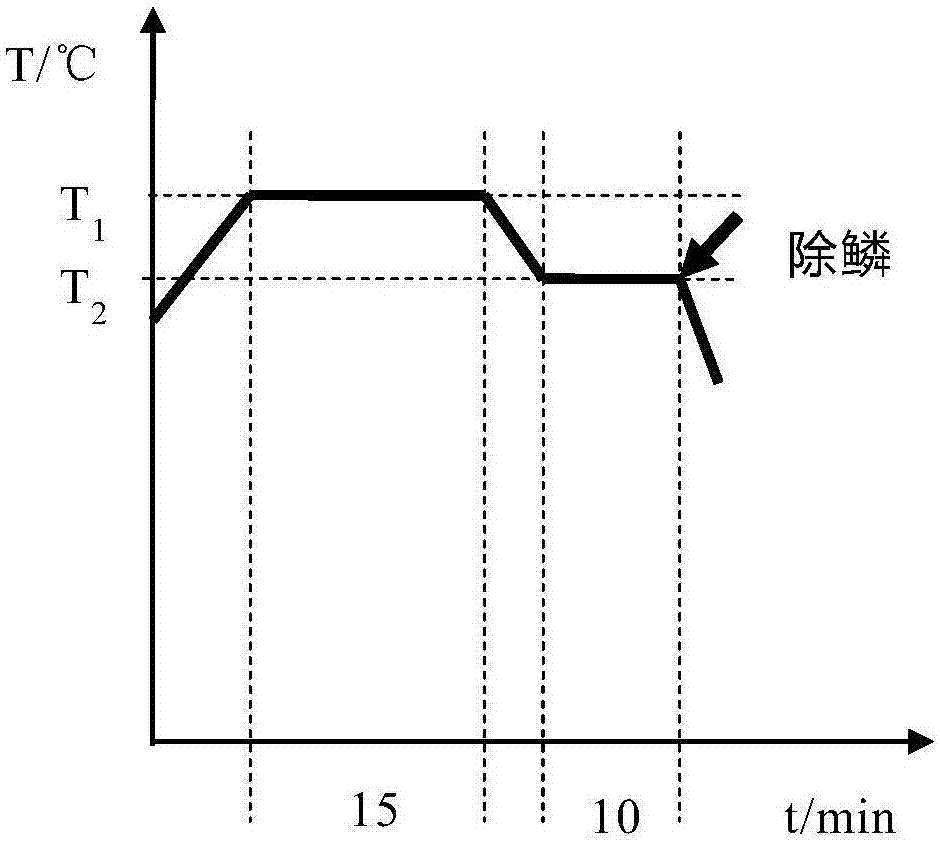

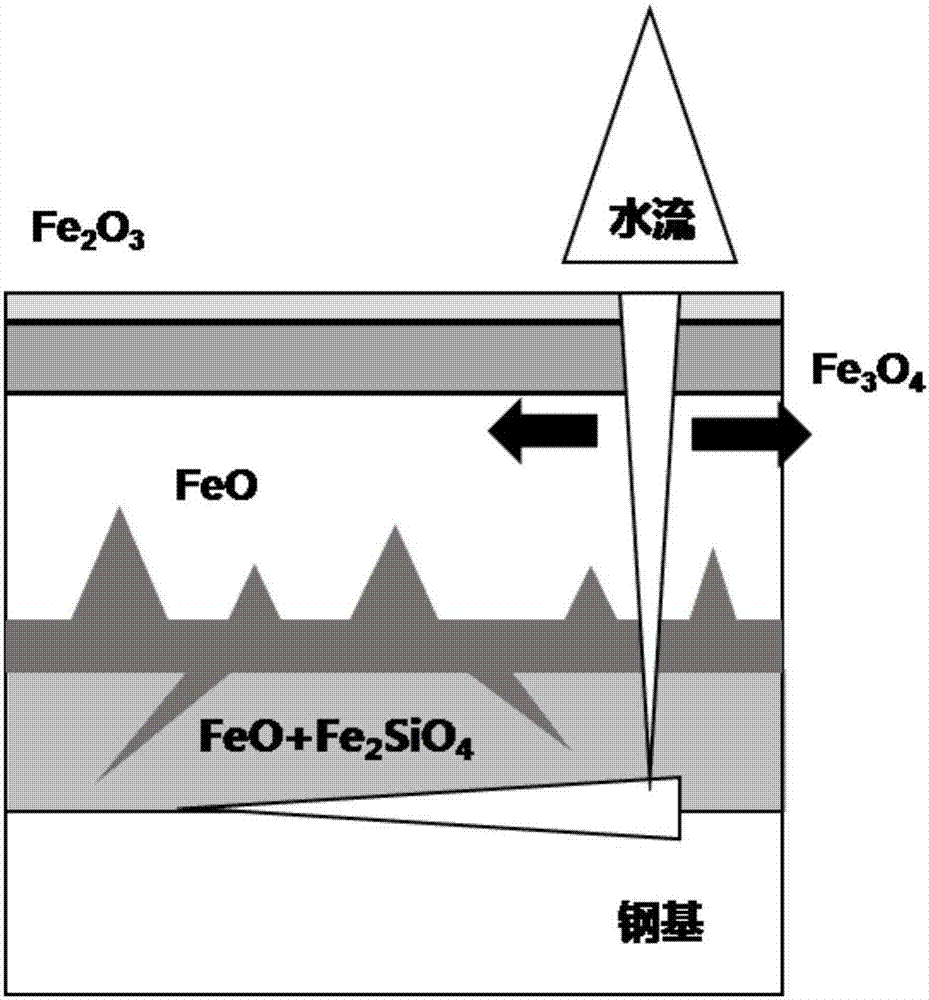

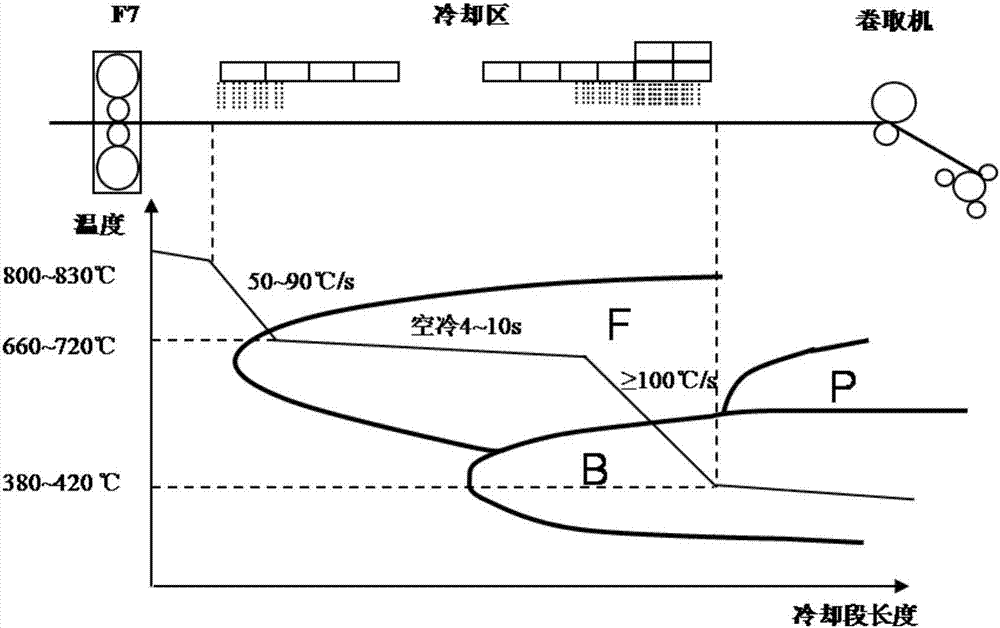

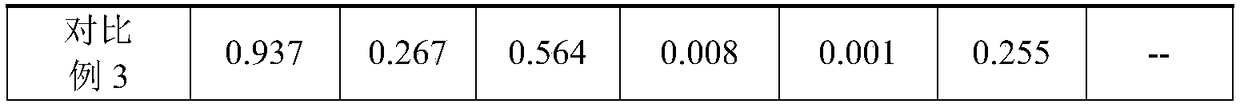

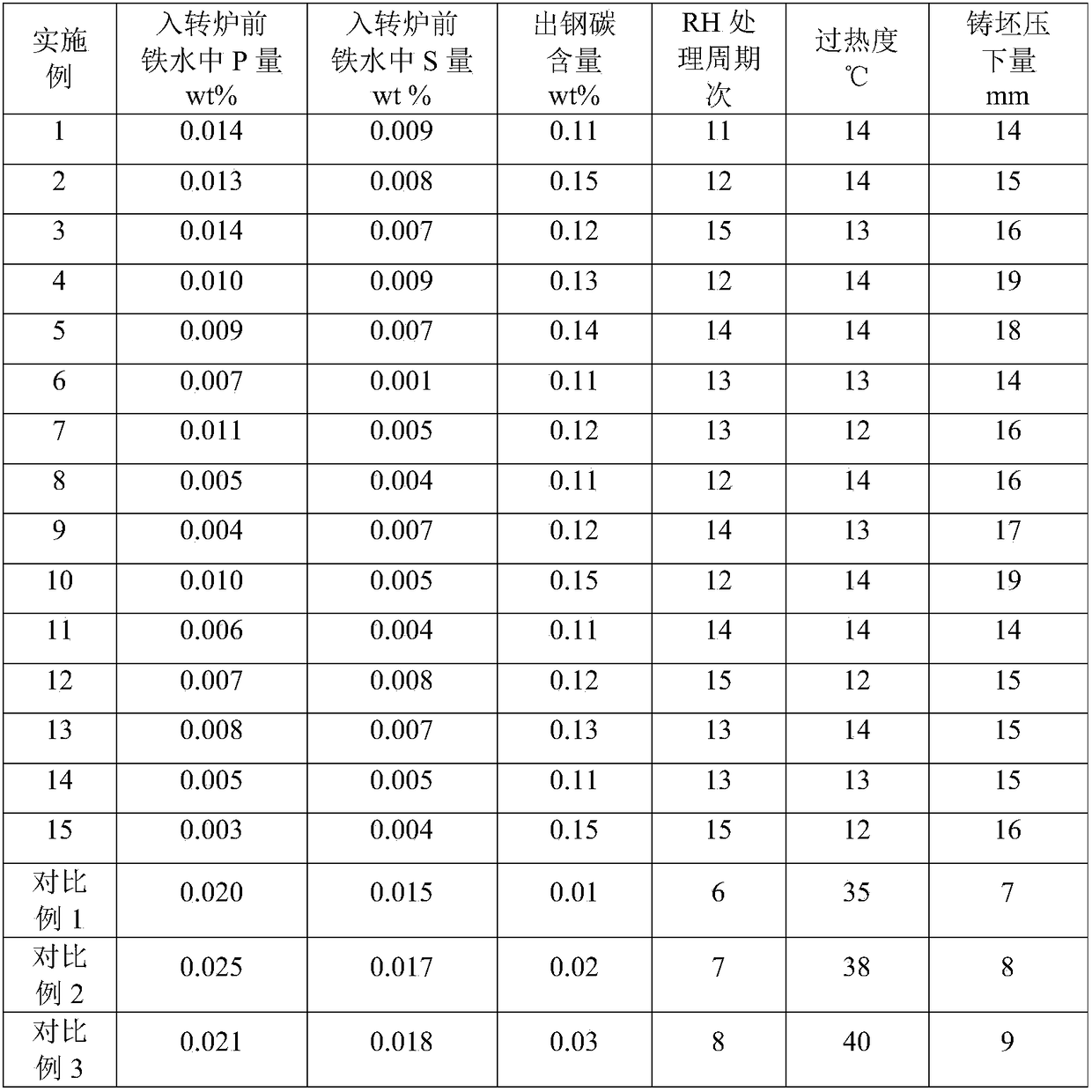

1,000 MPa level hot-rolled TRIP steel based on CSP process and manufacturing method

ActiveCN107557692AGood strong plasticityGuaranteed stabilityHeat treatment process controlAluminiumTRIP steel

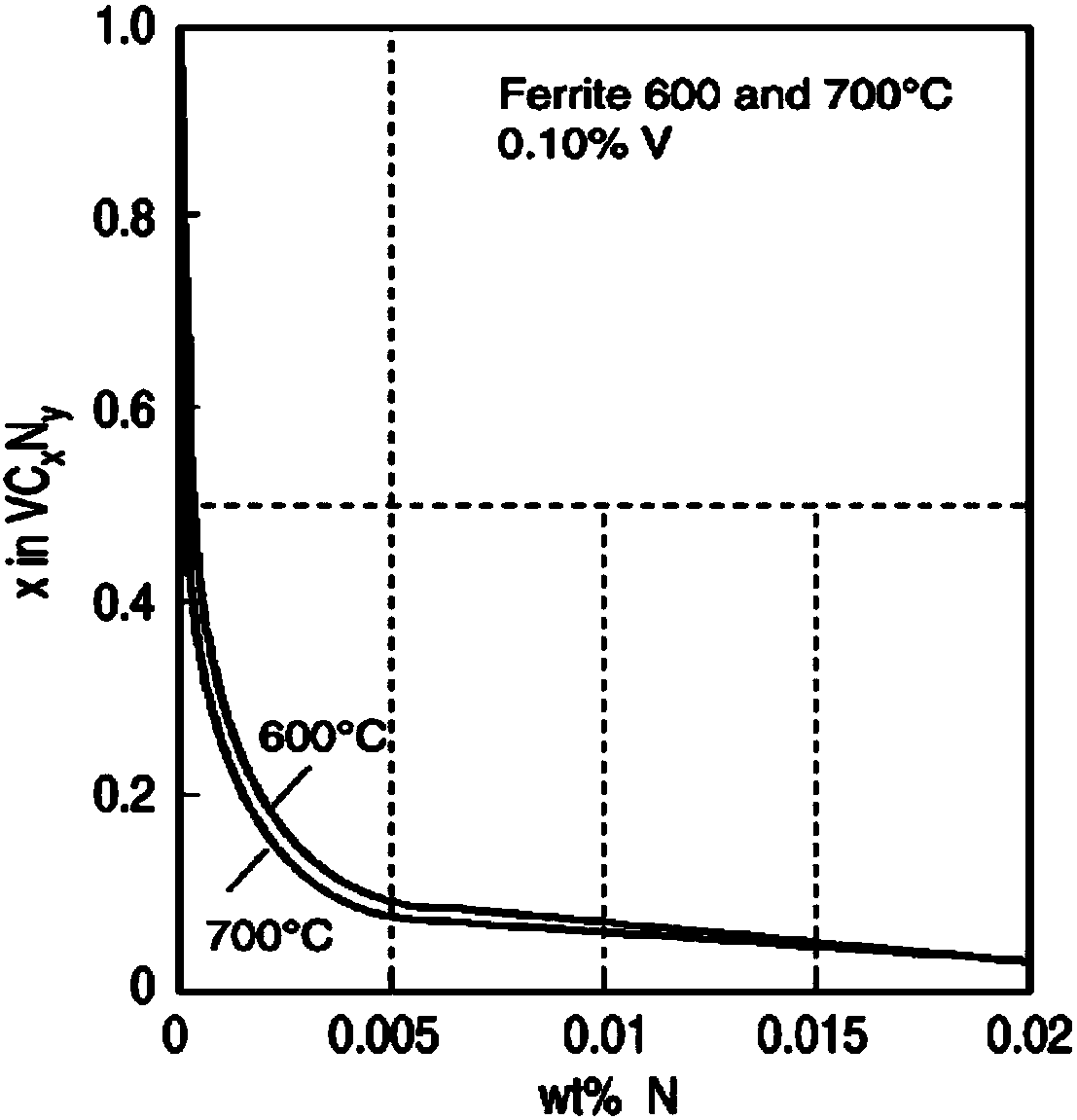

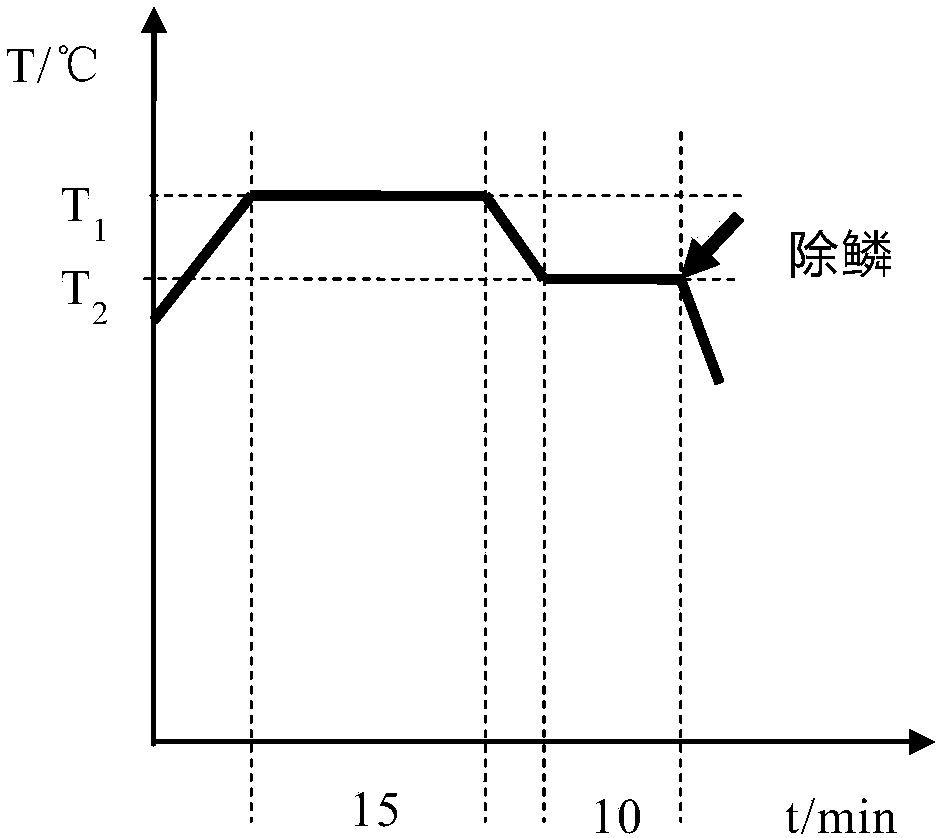

The invention discloses 1,000 MPa level hot-rolled TRIP steel based on the CSP process. The 1,000 MPa level hot-rolled TRIP steel comprises chemical elements and components including, by weight percent, 0.16%-0.20% of carbon, 1.60%-1.80% of silicon, 1.50%-1.60% of manganese, 0.20%-0.24% of vanadium, smaller than or equal to 0.008% of phosphorus, smaller than or equal to 0.005% of sulfur, 0.015%-0.060% of acid soluble aluminum, 0.015%-0.025% of nitrogen and the balance iron and inevitable impurities. The steel manufacturing method comprises converter smelting, refining, sheet billet continuouscasting, continuous casting blank uniform heating, high-pressure water descaling, controlled rolling, controlled cooling and coiling. Through the V-N adding microalloying component design, a ferrite phase and a bainite phase are strengthened, meanwhile, carbon concentration is not reduced, stability of retained austenite is maintained, and good strength and plasticity matching is achieved.

Owner:武汉钢铁有限公司

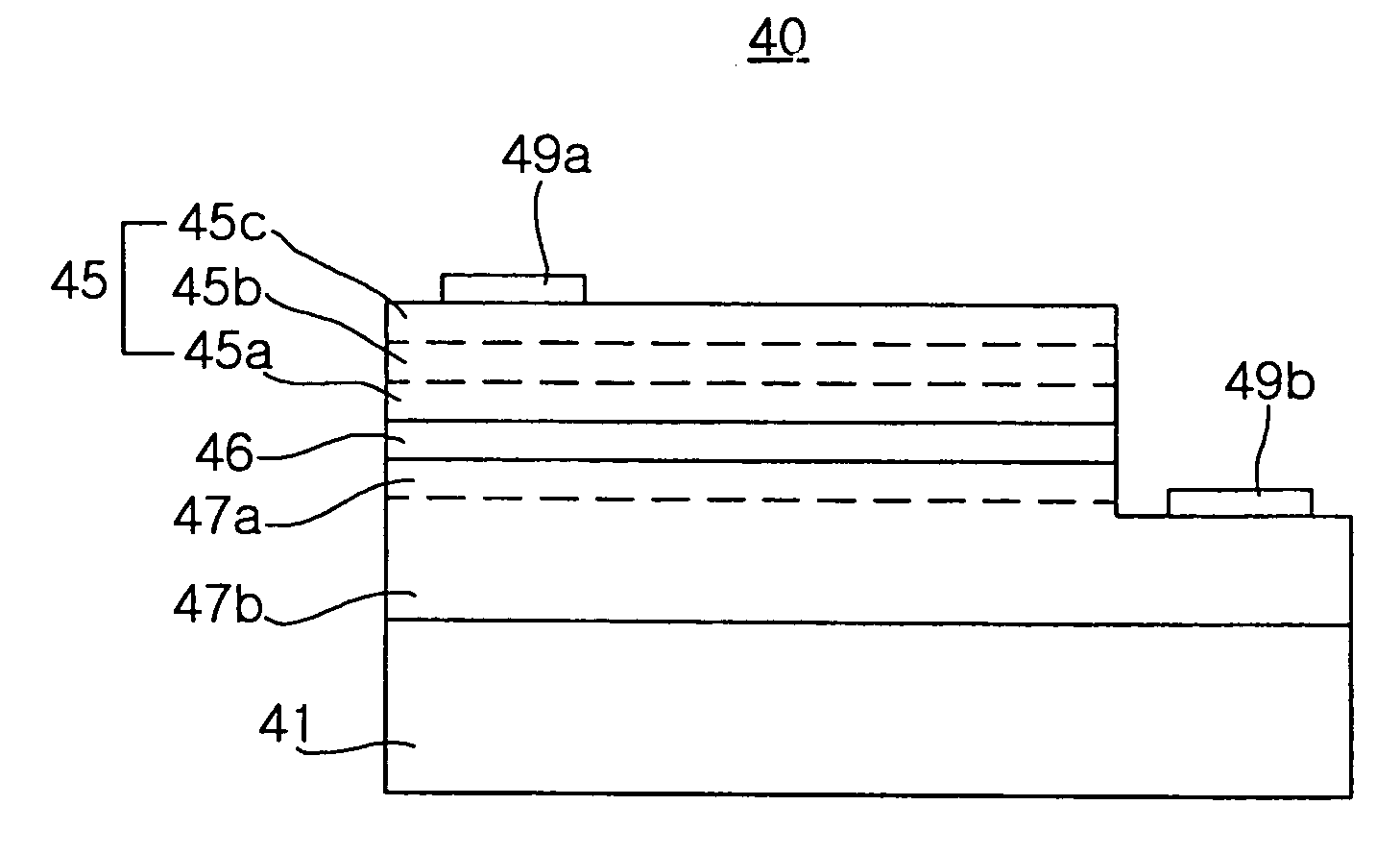

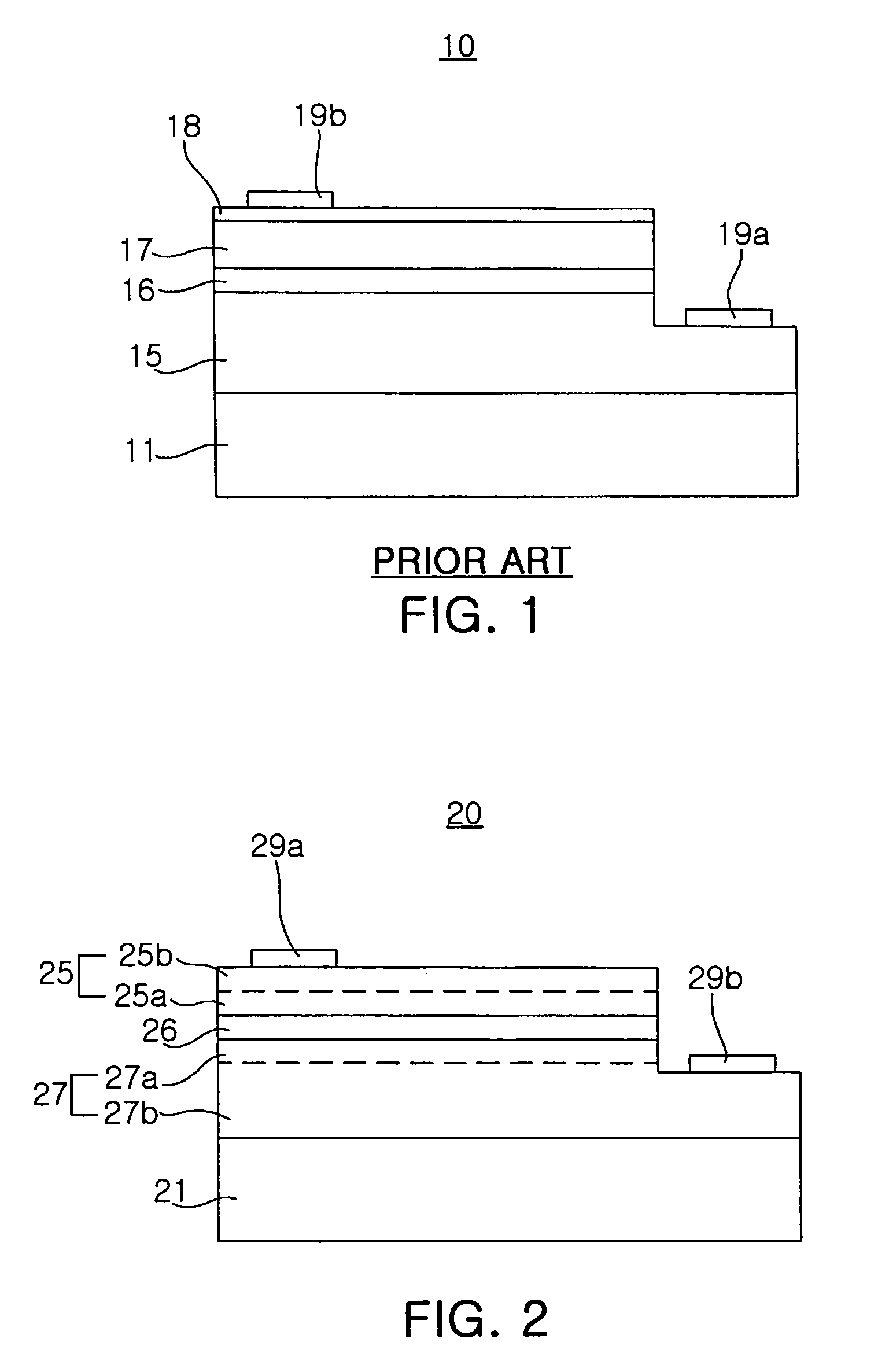

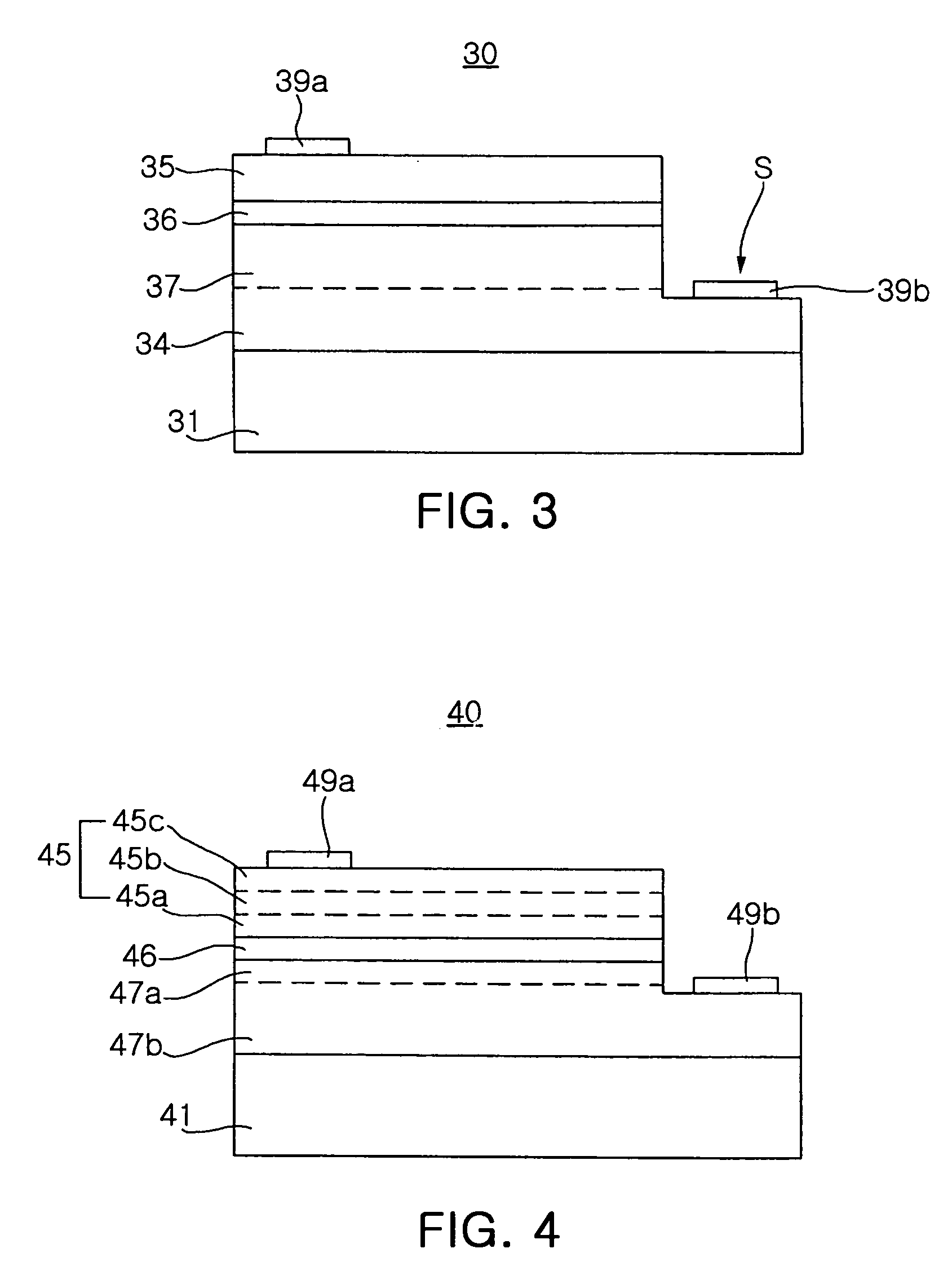

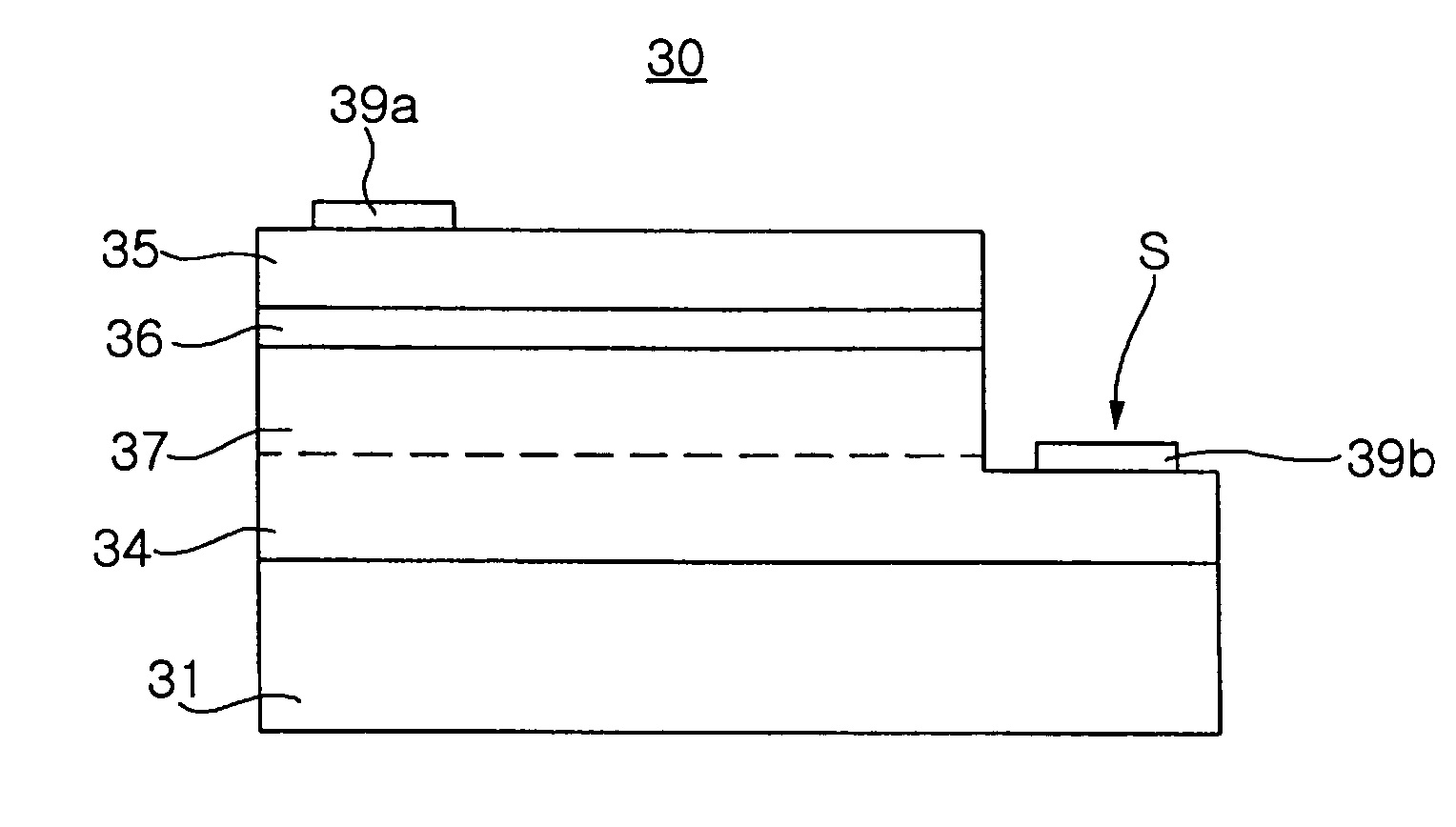

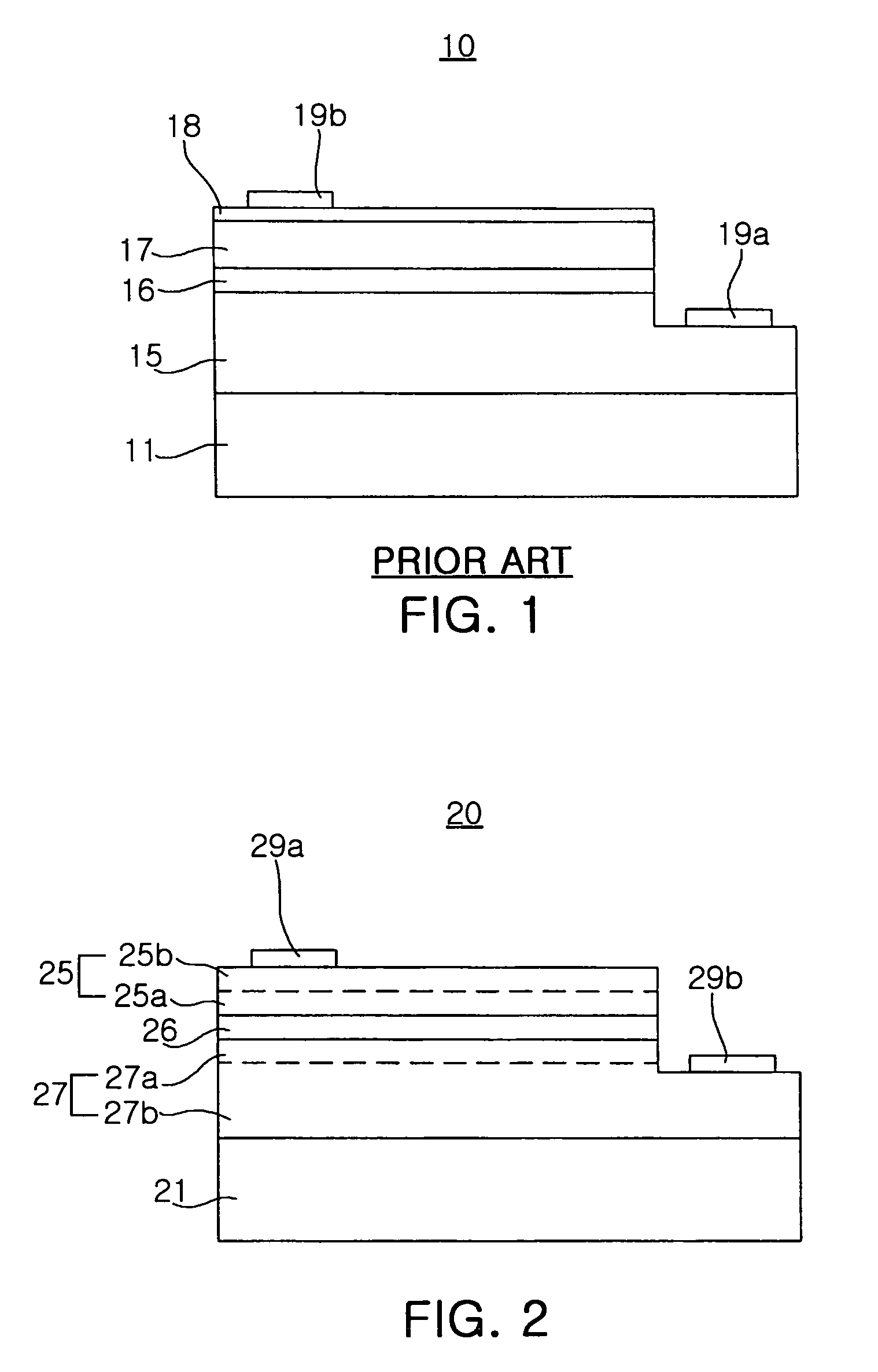

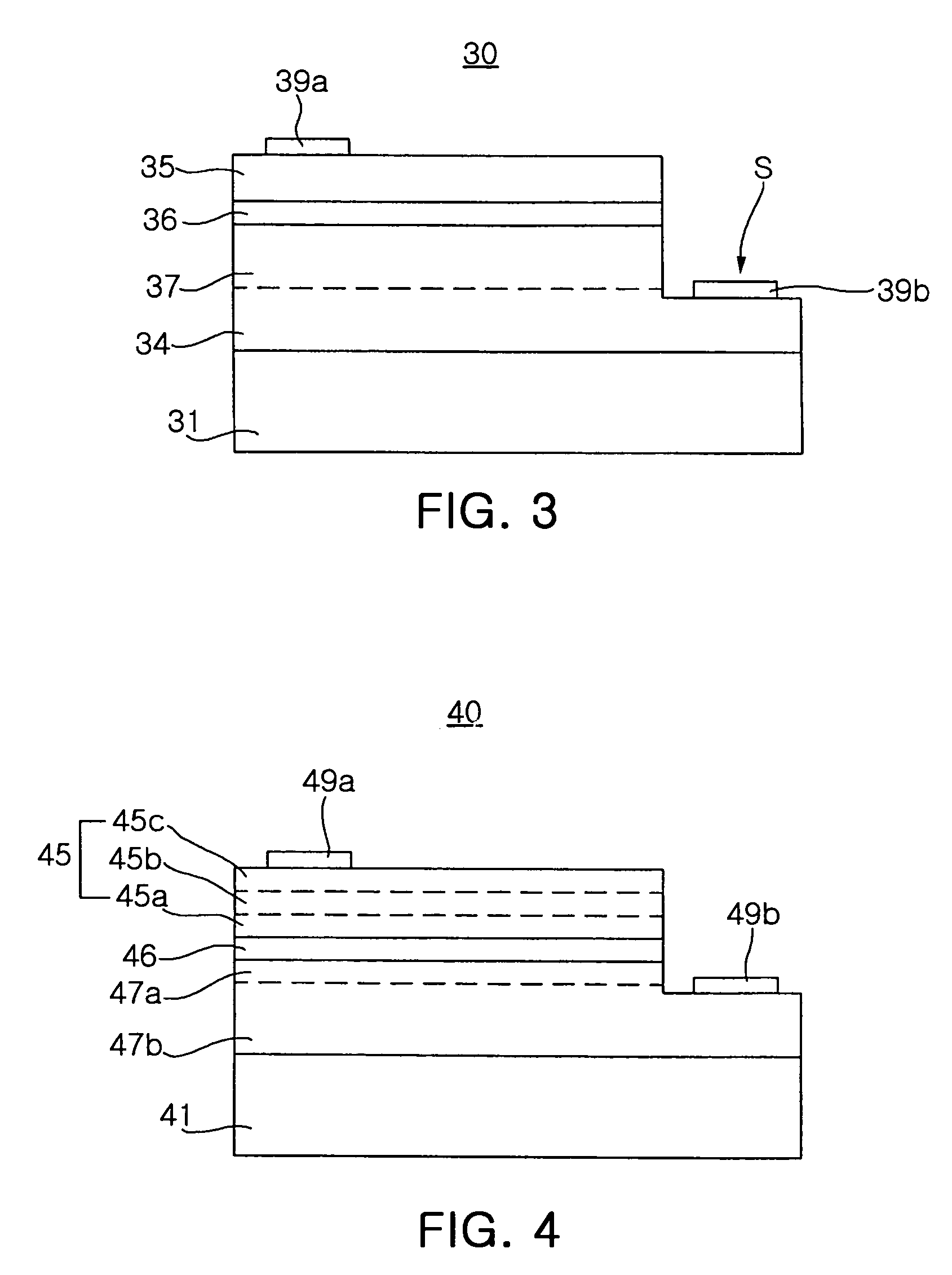

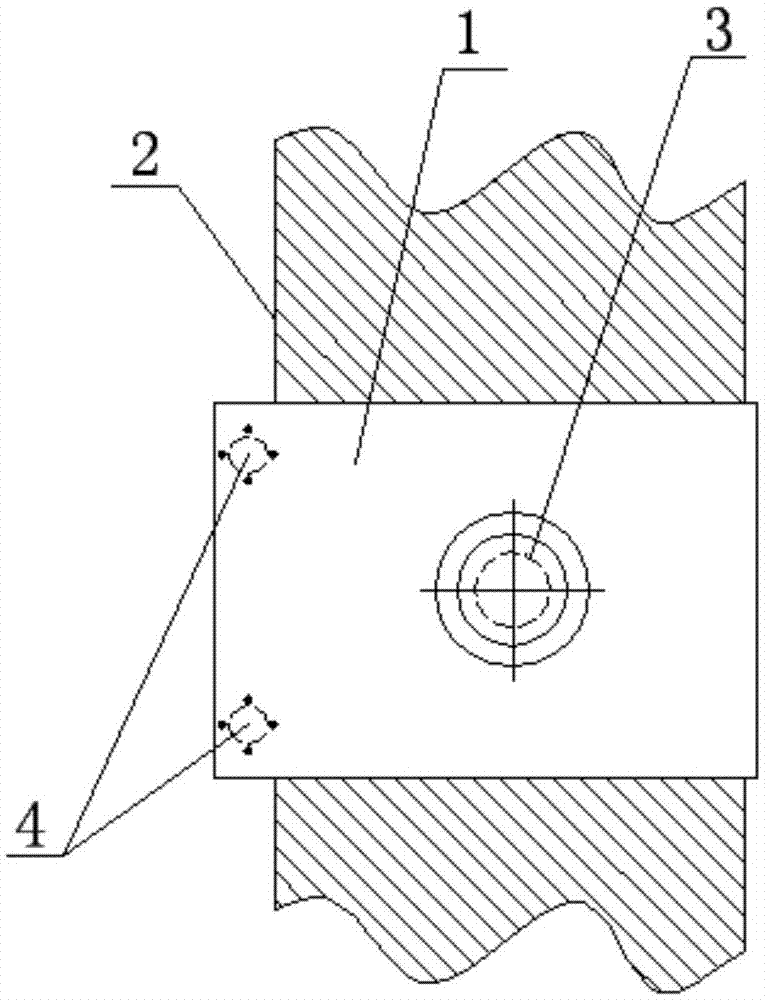

Process for producing nitride semiconductor light-emitting device

InactiveUS20050221526A1Eliminate heat treatmentIncrease resistanceSemiconductor/solid-state device manufacturingBulkheads/pilesElectrical connectionNitrogen

A process for producing a nitride semiconductor light-emitting device includes the steps of preparing a substrate, growing a p-type nitride semiconductor layer on the substrate by the MOCVD process using hydrazine-based gas as a nitrogen precursor and N2 gas as a carrier gas, forming an active layer on the p-type nitride semiconductor layer, forming an n-type conductive nitride semiconductor layer on the active layer, and forming p- and n-electrodes in electrical connection with the p- and n-type nitride semiconductors, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

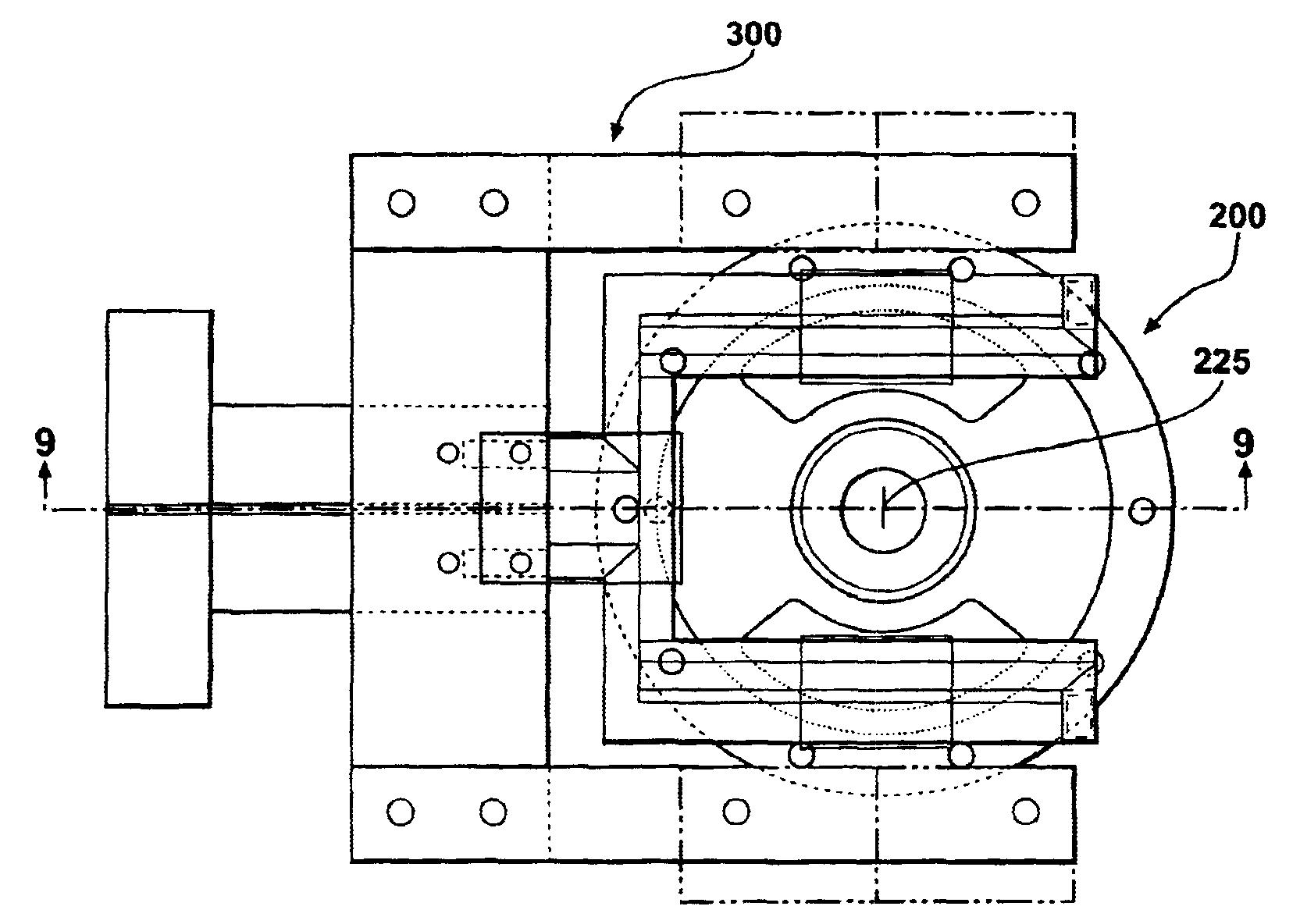

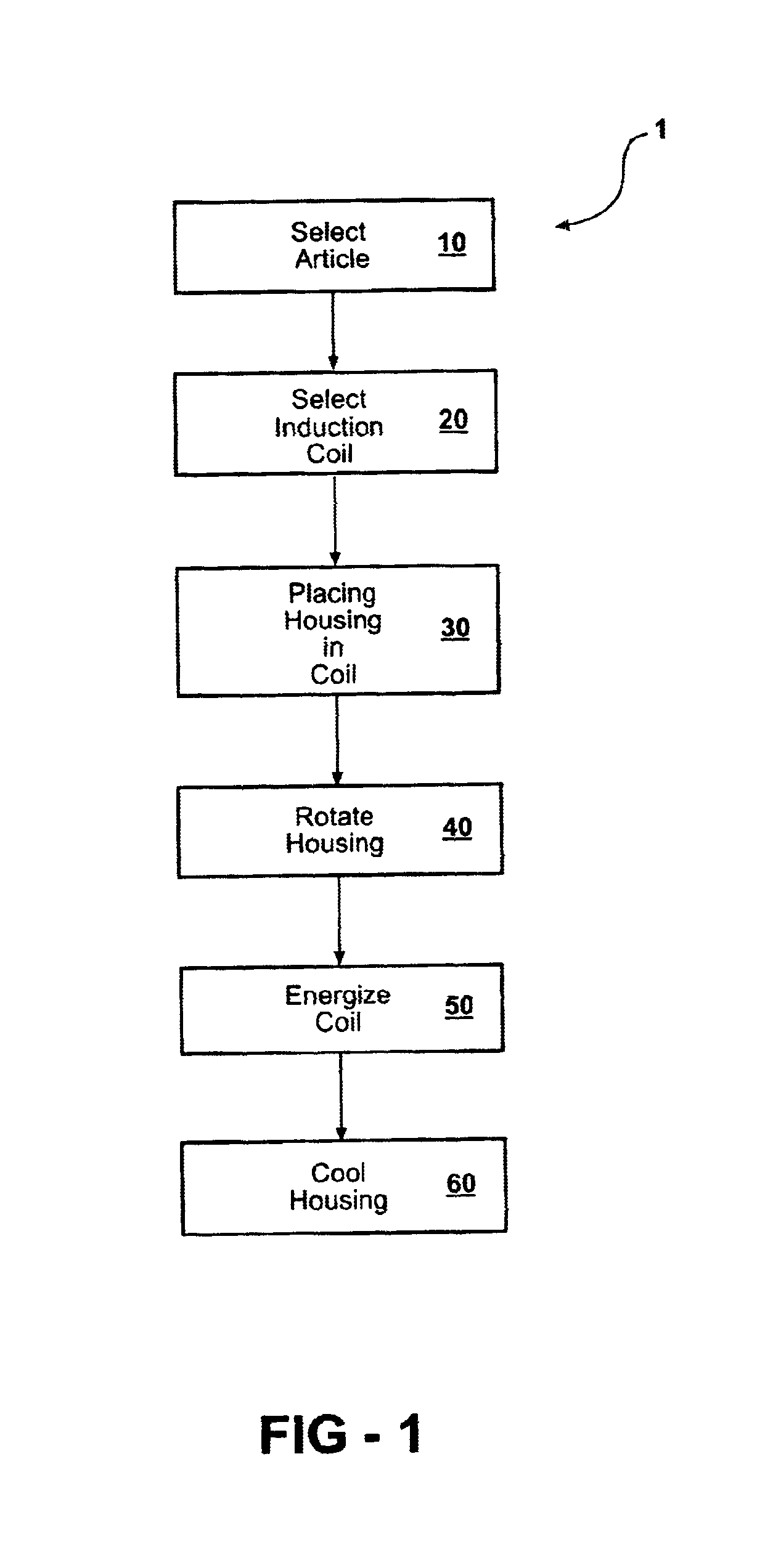

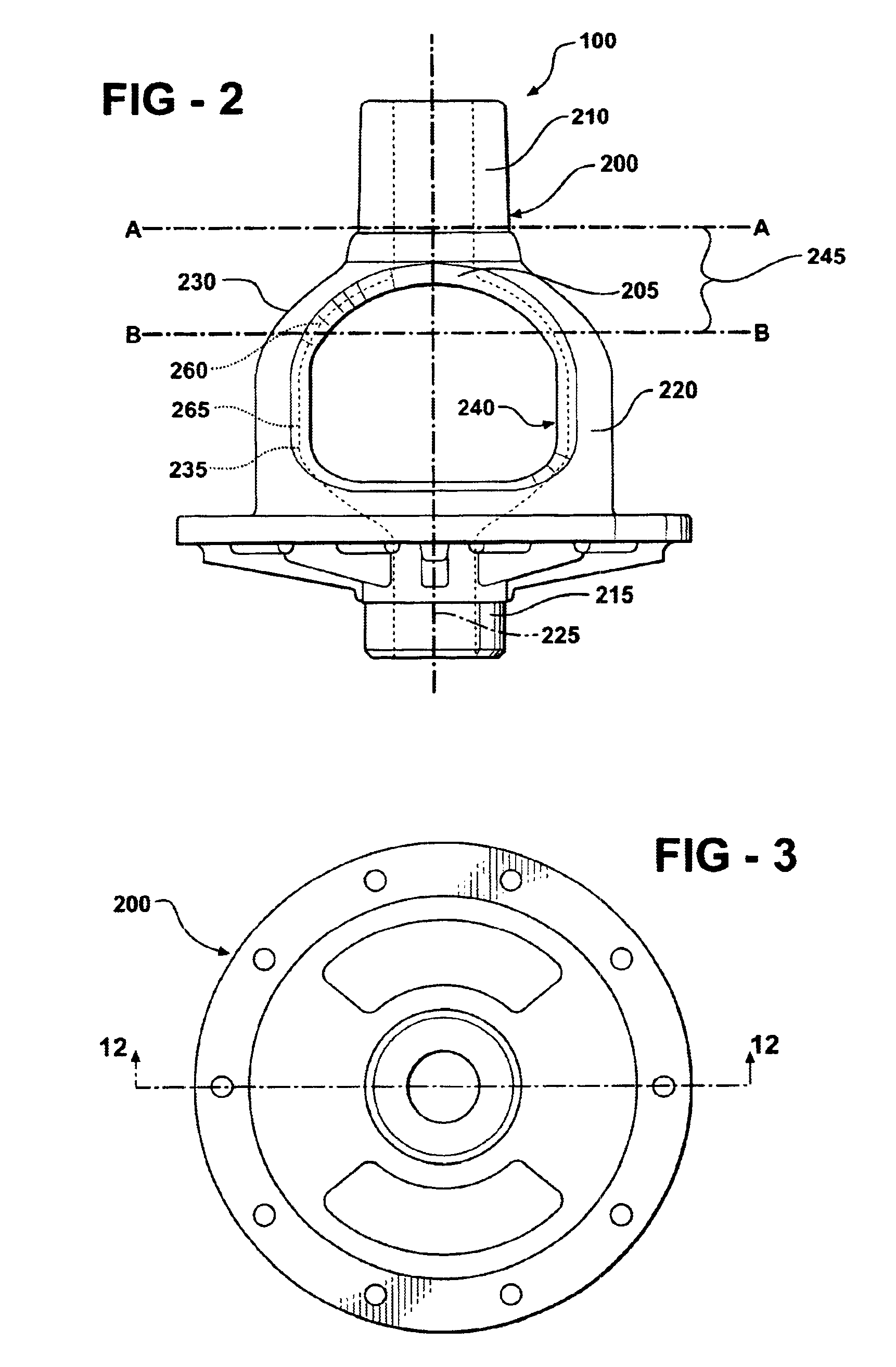

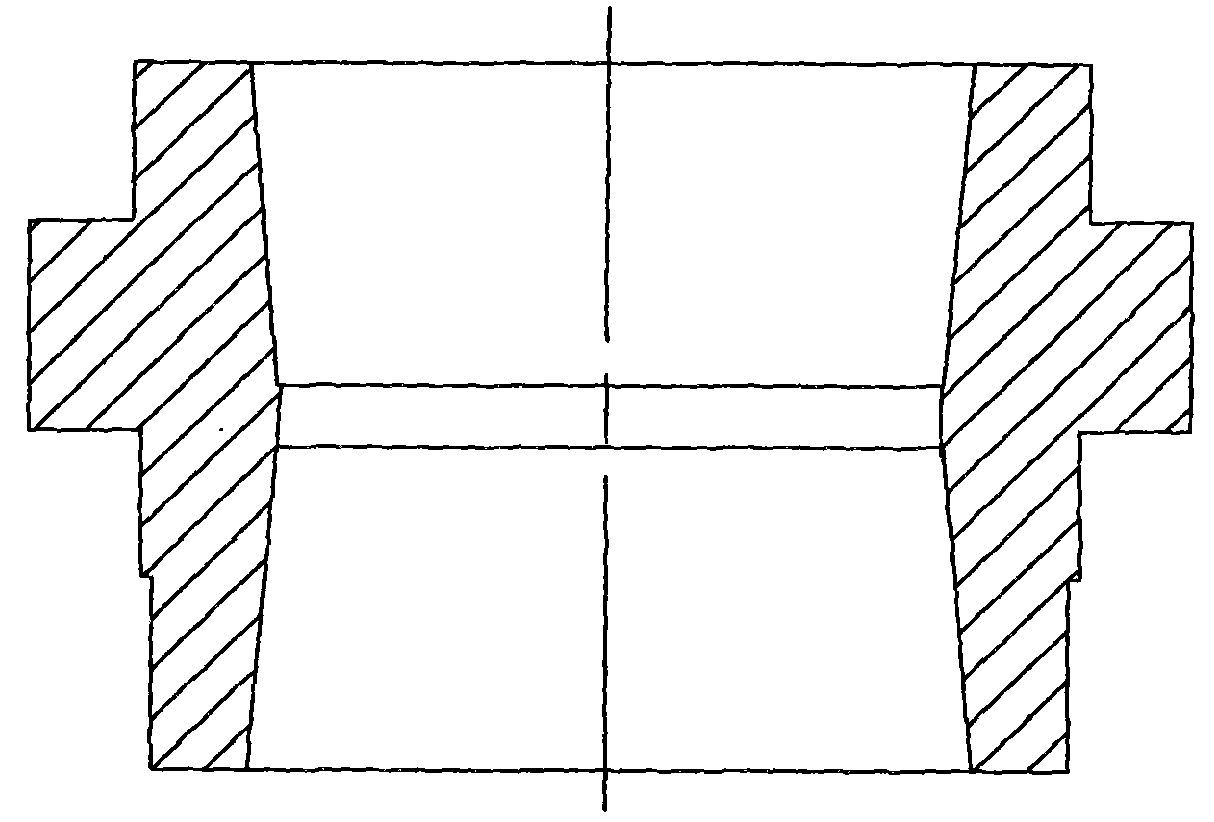

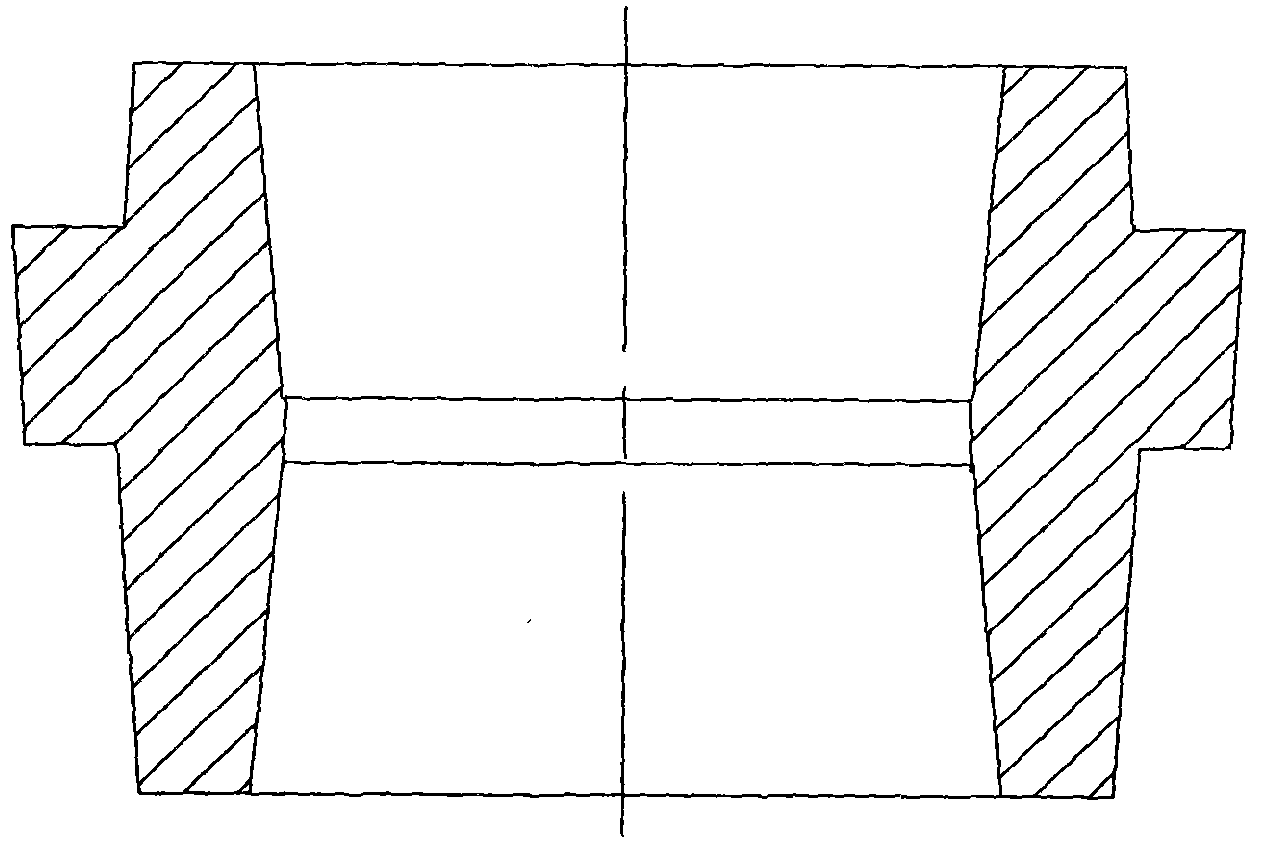

Induction heat treatment method and coil and article treated thereby

InactiveUS6940056B2High strengthMinimize distortionFurnaces without endless coreCoil arrangementsMartensite transformationEngineering

A method of induction heat treatment of articles having curved outer surfaces, such as differential housings. The method employs a semi-rectangular induction coil that is adapted to provide a plurality of lateral magnetic fields that are used to induce currents in, and thereby provide heat to, a portion of the curved section of the article. The method and induction coil are particularly adapted to provide an induction hardening heat treatment of a curved heat treatment portion of a differential housing. The differential housing was cast from nodular iron. The induction-hardening heat treatment comprised heating the heat treatment portion of the differential housing above the austenite transition temperature and quenching to below the martensite transformation temperature.

Owner:FORD GLOBAL TECH LLC

Process for producing nitride semiconductor light-emitting device

InactiveUS7063997B2Eliminate heat treatmentIncrease resistanceSemiconductor/solid-state device manufacturingBulkheads/pilesHydrazine compoundNitrogen

A process for producing a nitride semiconductor light-emitting device includes the steps of preparing a substrate, growing a p-type nitride semiconductor layer on the substrate by the MOCVD process using hydrazine-based gas as a nitrogen precursor and N2 gas as a carrier gas, forming an active layer on the p-type nitride semiconductor layer, forming an n-type conductive nitride semiconductor layer on the active layer, and forming p- and n-electrodes in electrical connection with the p- and n-type nitride semiconductors, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

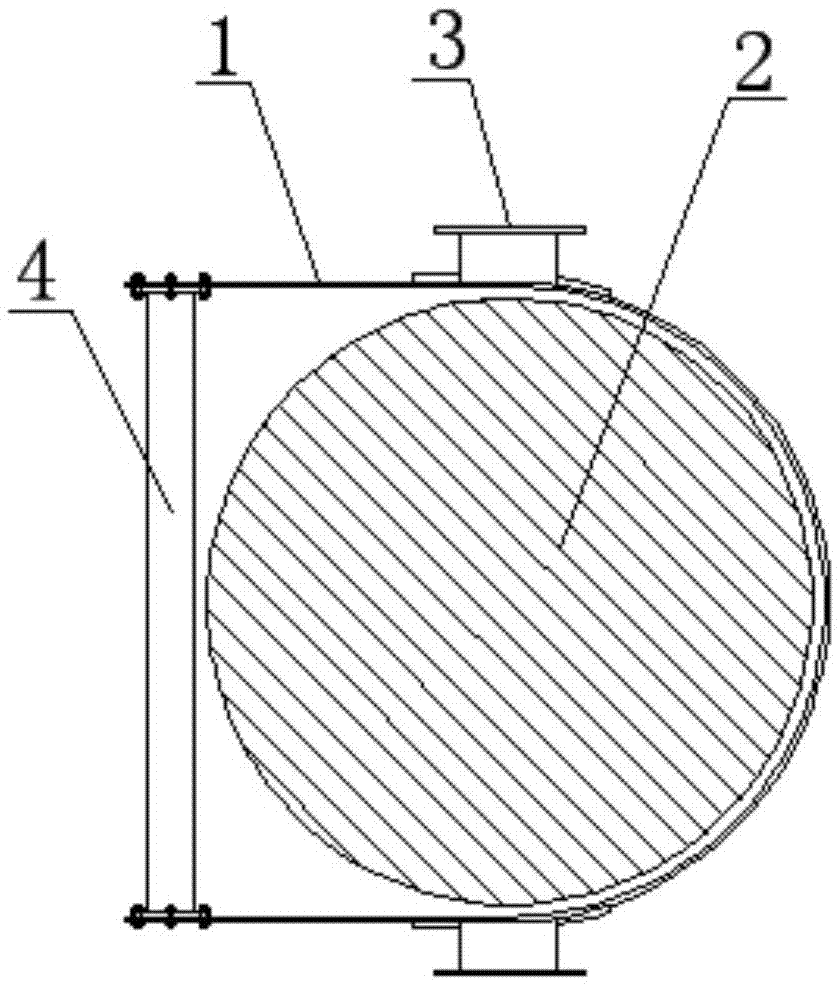

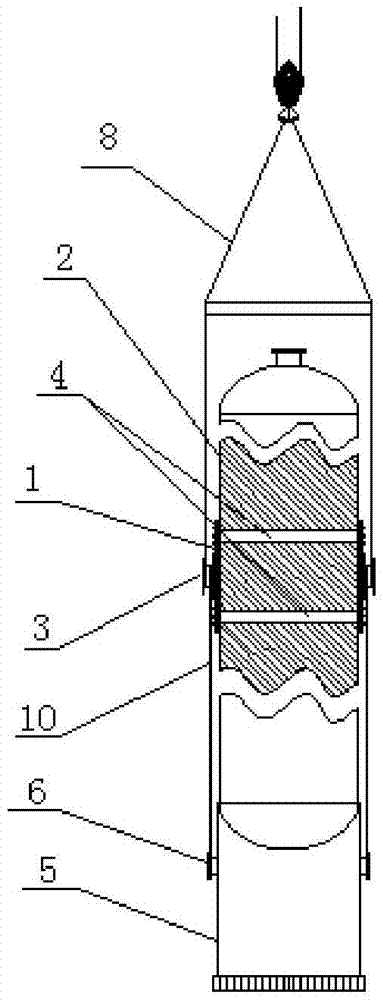

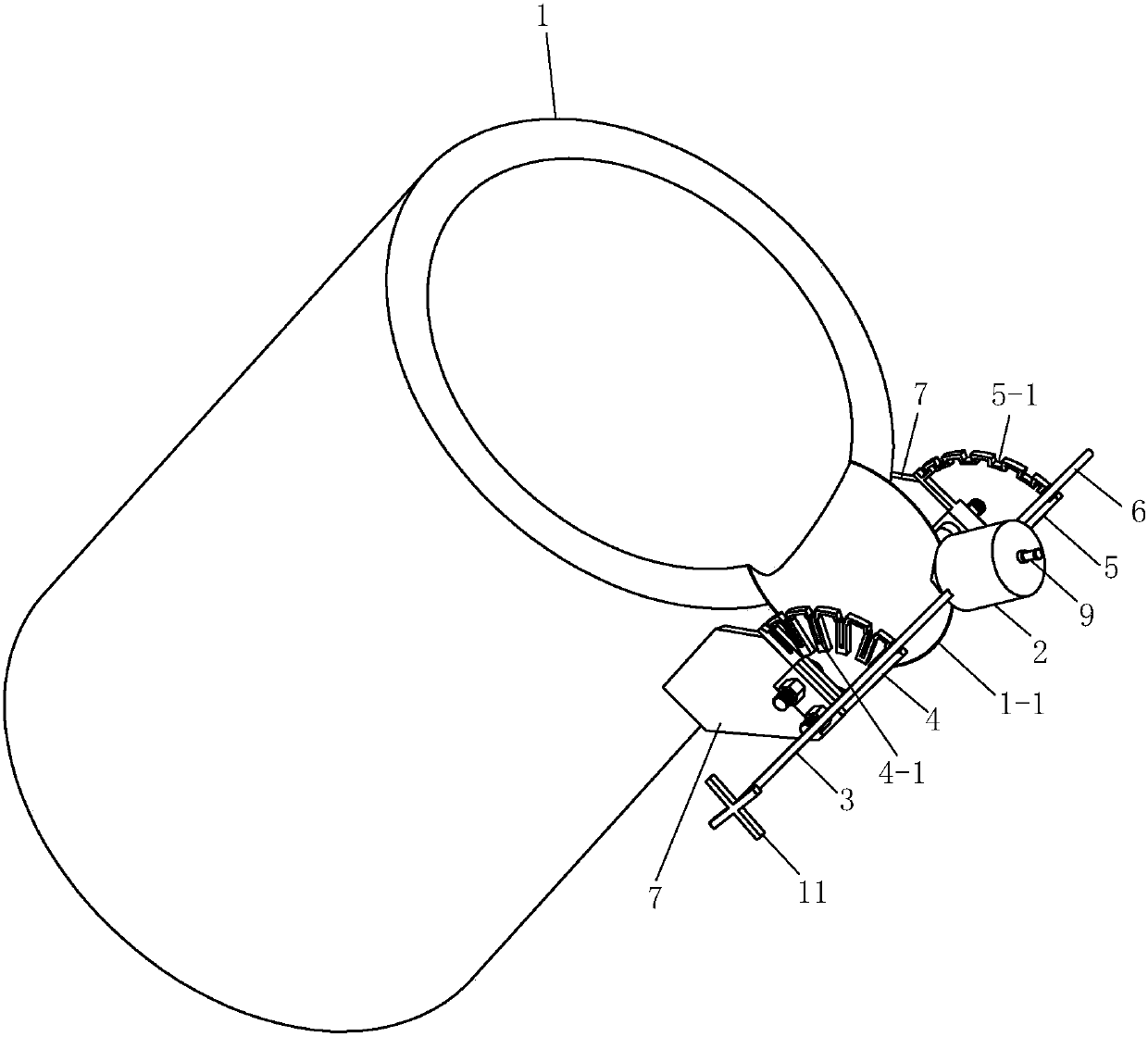

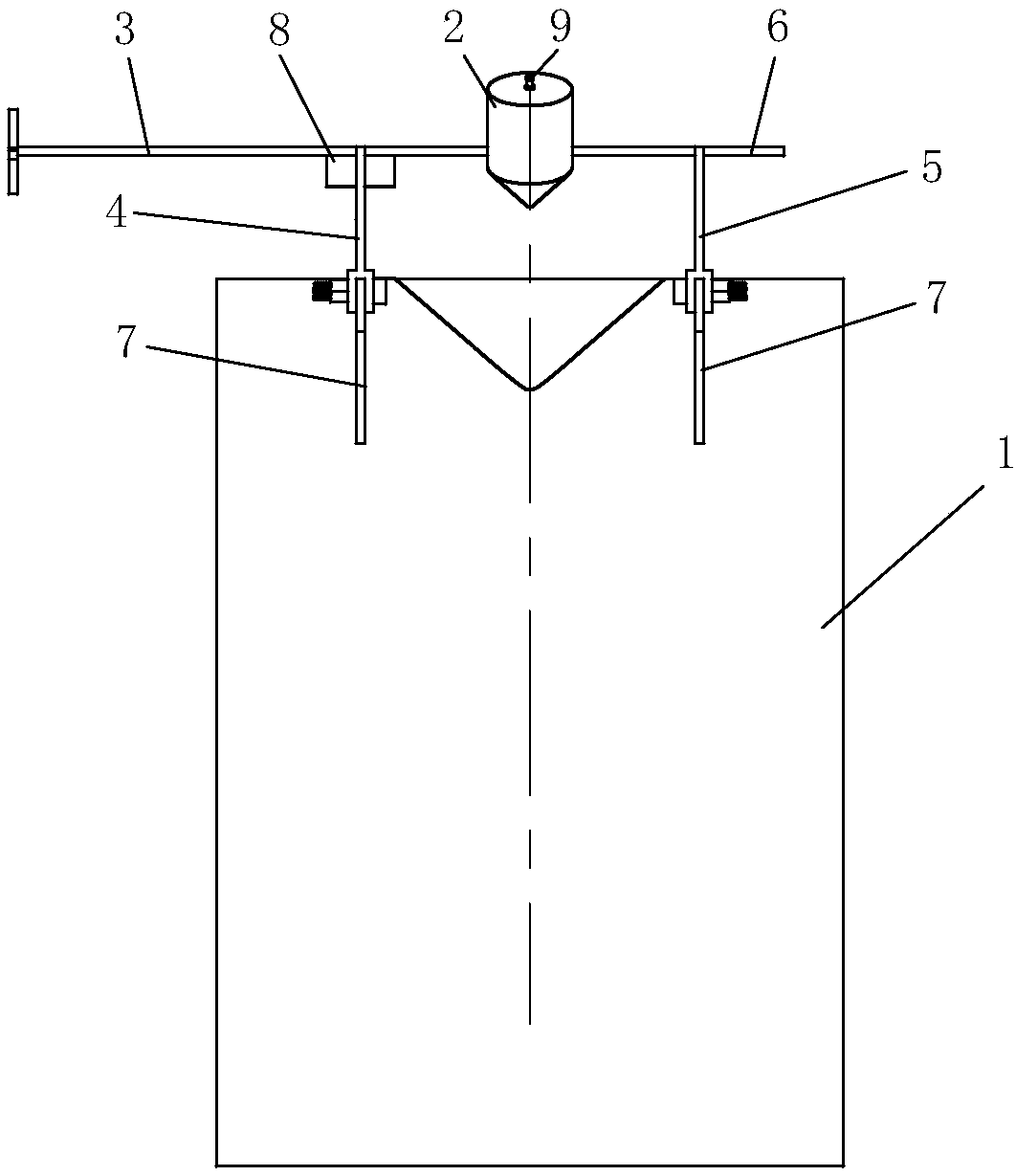

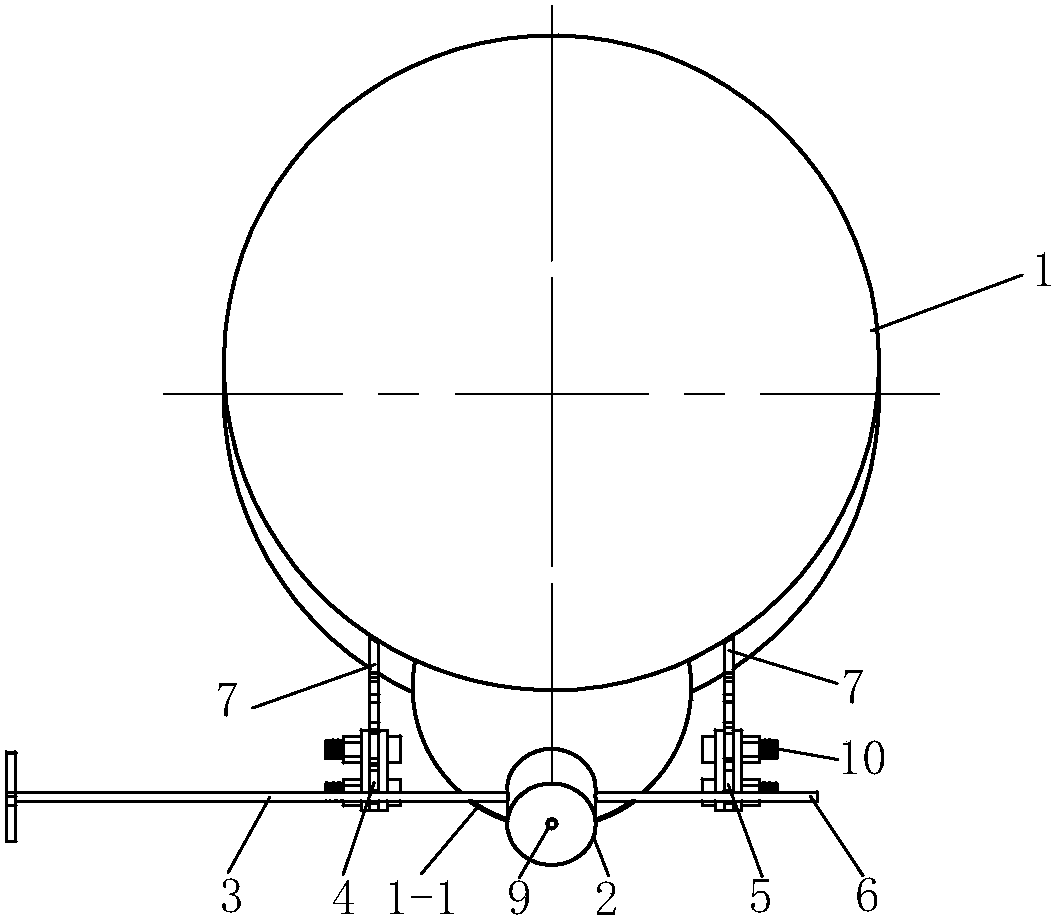

U-shaped movable hold hoop type lifting lug for hoisting tower facility and hoisting method thereof

ActiveCN105438960AAvoid WeldingEliminate heat treatmentLoad-engaging elementsTowerIndustrial engineering

The invention discloses a U-shaped movable hold hoop type lifting lug for hoisting a tower facility and a hoisting method thereof. The U-shaped movable hold hoop type lifting lug comprises a U-shaped hold hoop, wherein a hoop ring of the U-shaped hold hoop hoops the side wall of a tower body, a pair of pipe shaft type lifting lugs is symmetrically arranged on two sides of the U-shaped hold hoop, the circle center of the cross section of the side wall of the tower body is rightly located on the axis connection of the two pipe shaft type lifting lugs, connecting rods are connected between the open ends of the U-shaped hold hoop, the tower body is hooped through the U-shaped hold hoop, the pipe shaft type lifting lugs on the U-shaped hold hoop are hoisted through a sling of a main hoisting crane during hoisting, and the pipe shaft type lifting lugs are connected with auxiliary lifting lugs. Therefore, the lifting force of the sling is transferred to the auxiliary lifting lugs to avoid sliding of the U-shaped hold hoop, the sling of an auxiliary hoisting crane hoists a tail-lifting lifting lug, enables the tower body to be changed from a vertical state to a horizontal state under the cooperative effect with the main hoisting crane and enables the U-shaped hold hoop to bear the radial pressure of the tower body, and safety is ensured. The tower body is hoisted by using the U-shaped movable hold hoop type lifting lug and the hoisting method, welding operation required to be performed on the tower body is avoided, and the tower body is protected.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

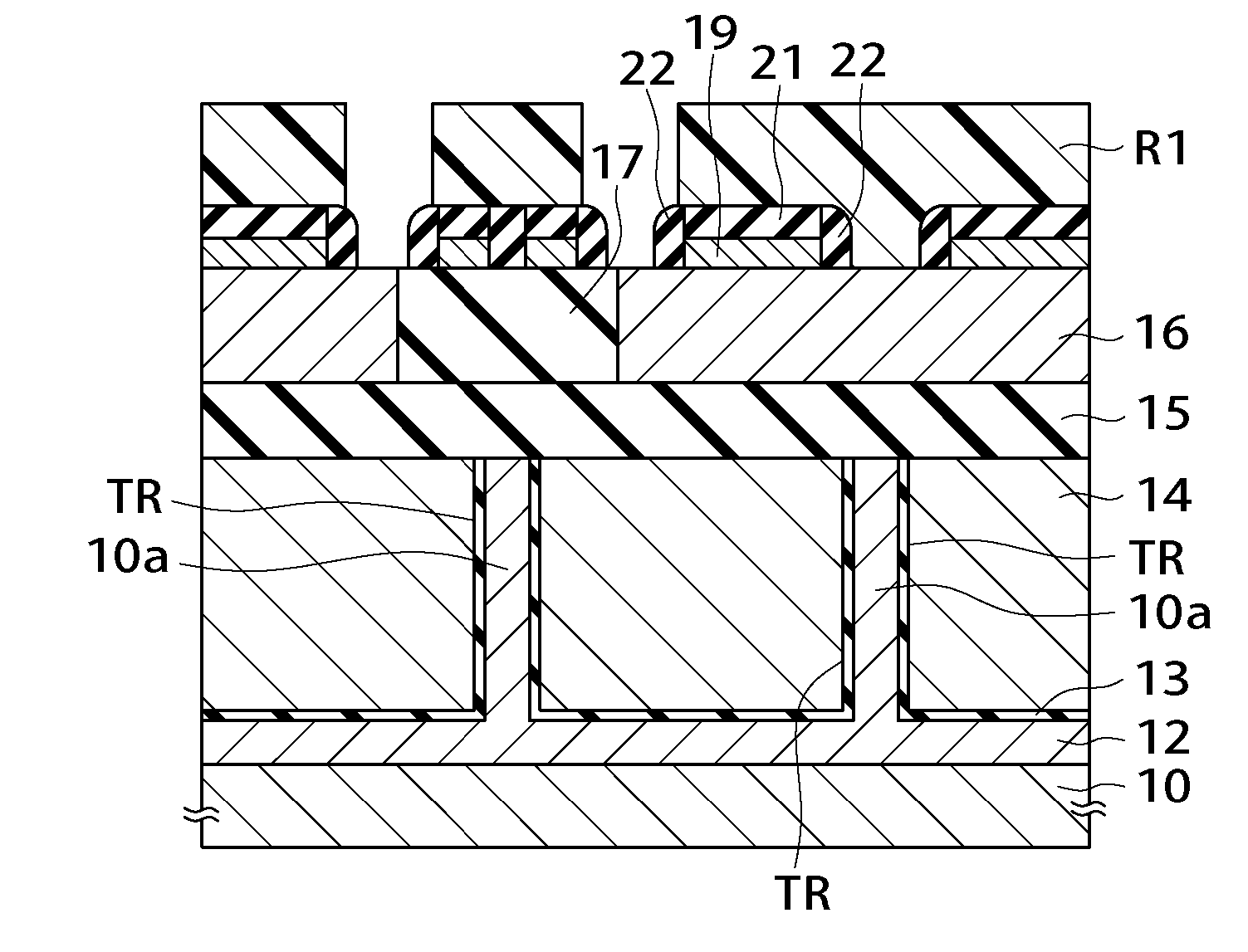

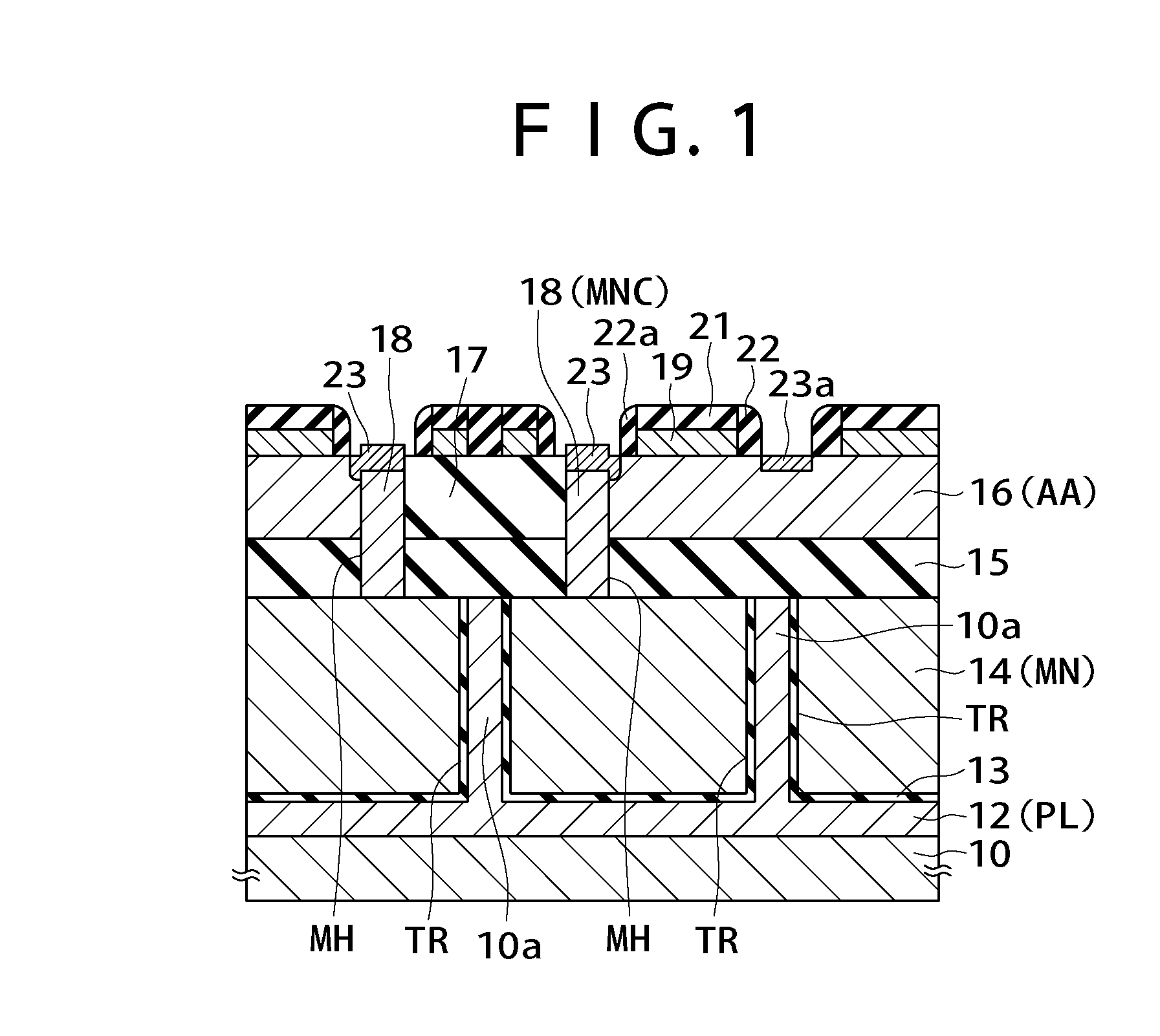

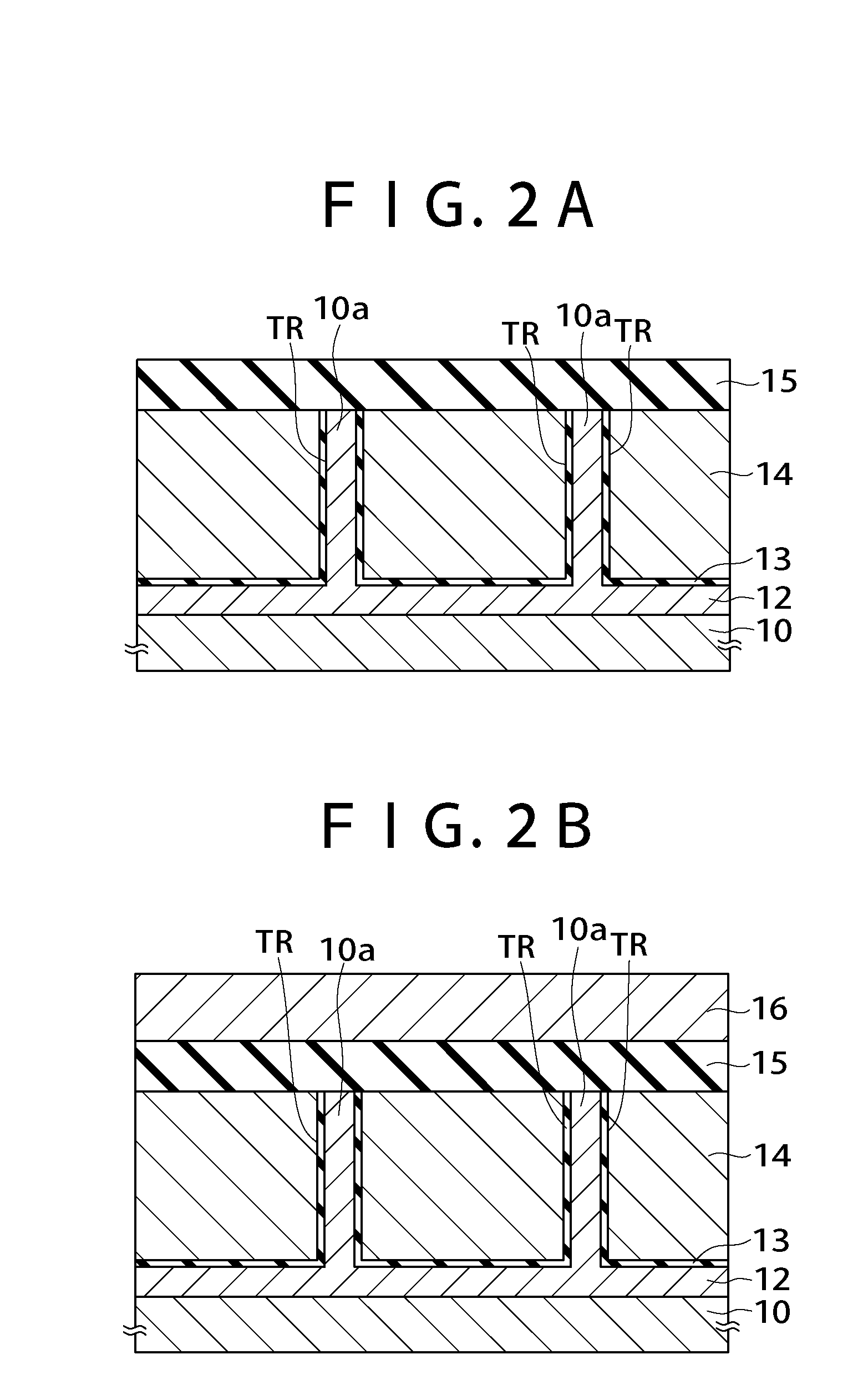

Semiconductor memory device, semiconductor device, and method for production thereof

InactiveUS20060275982A1Reduce areaSmall sizeTransistorSolid-state devicesLithographic artistEngineering

Disclosed are a semiconductor memory device, a semiconductor device, and a method for production thereof. The semiconductor memory device and semiconductor device do not need for a distance for alignment of lithography to make the contact hole with lithography to form the gate electrode. Hence the resulting devices have a reduced area for the cell array. The semiconductor memory device is composed of a substrate having trenches formed side by side, a plate electrode which is formed to a prescribed depth from the surface of the inner wall of the trench, a capacitor insulating film which covers the surface of the inner wall of the trench, a memory node electrode MN which fills the trench, with the capacitor insulating film interposed between them, and a memory node contact plug which is buried in a contact hole which is so made as to reach the memory node electrode from the surface of the semiconductor layer. A metallized region is integrally formed to connect at least part of the surface of the semiconductor layer and at least part of the surface of the contact plug to each other.

Owner:SONY CORP

CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel and fabrication method

ActiveCN107475627AGood strength and plasticity matchingReduce the chance of residuesMetal rolling arrangementsManganeseHigh pressure water

The invention discloses CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel. The CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel comprises the chemical element ingredients of, in percentage by weight, 0.14-0.16% of carbon, 0.90-1.20% of silicon, 1.20-1.40% of manganese, 0.07-0.10% of phosphorus, less than or equal to 0.005% of sulphur, 0.015-0.060% of acid soluble aluminium and the balance ferrum and inevitable impurities. The fabrication method of the CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel comprises the following steps of converter smelting, refined smelting, thin plate billet continuous casting, continuous-casting billet soaking, high-pressure water descaling, controlled rolling, controlled cooling and rolling up. The economic C-Si-Mn-P ingredient design is adopted, a metallographic structure is composed of 50-65% of ferrite, 25-40% of bainite and 5-20% of residual austenite; the yield strength is 390-450 MPa, the strength of extension is 600-680 MPa, and the elongation A80 is 28-35%; and the CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel has good high-plasticity matching.

Owner:武汉钢铁有限公司

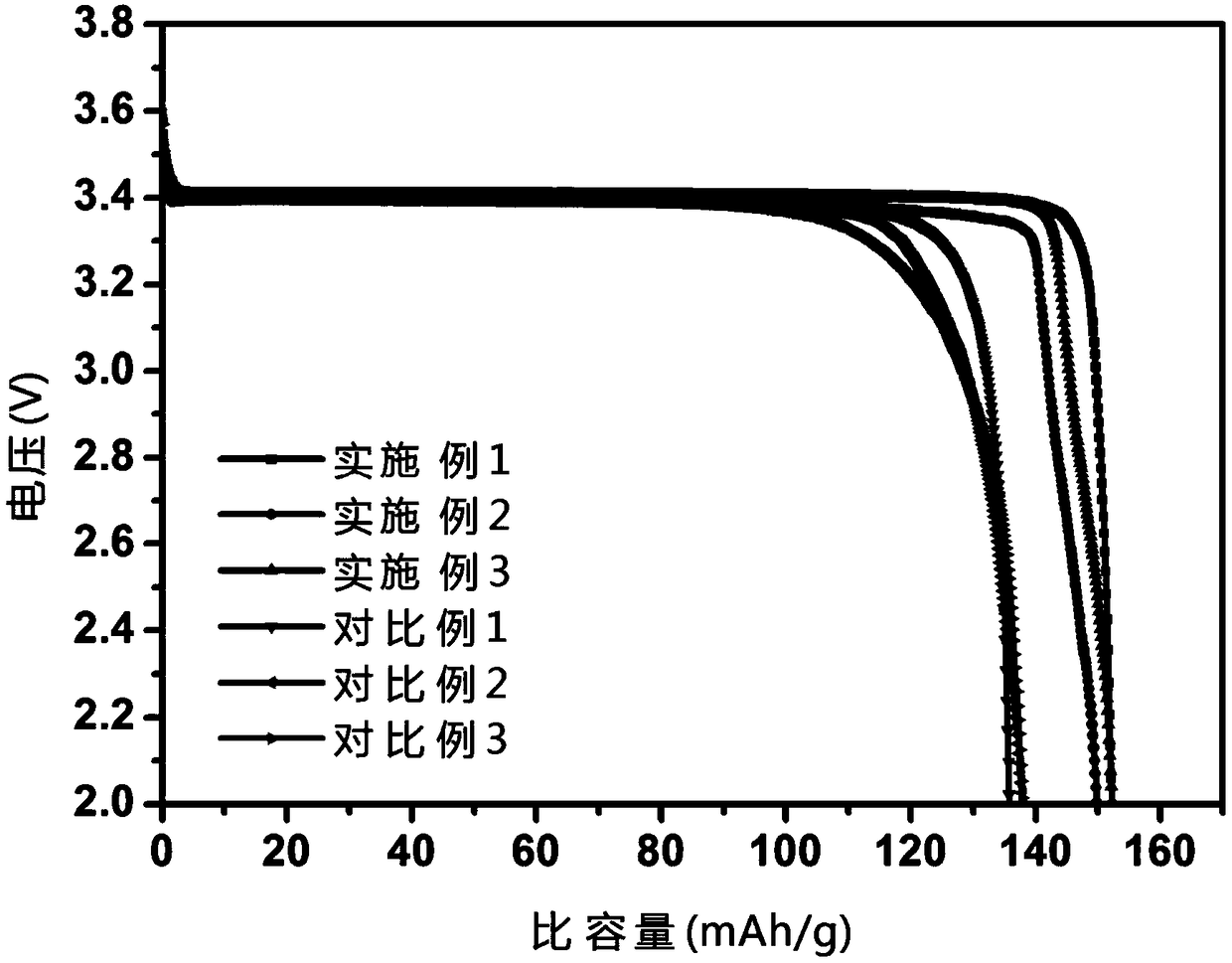

A preparation method of lithium iron phosphate

ActiveCN109192936AImprove processing performanceReduce overall energy consumptionCell electrodesSecondary cellsSolventChemistry

The invention provides a preparation method of a lithium iron phosphate positive electrode active material, comprising: (1) firstly mixing a lithium source, an iron source and a doped element source,then sequentially adding a phosphorus source and a carbon source, uniformly mixing to obtain a mixed material; the mixture is placed in a double-cone dryer under solvent-free conditions, and the mixture is dried in a temperature range of 150 DEG C to 400 DEG C, and that heat preservation is performed for 8-12h to obtain dry material, crushing and refine that dry material by adopting a jet mill toobtain powder particles having a primary particle size of 100-200 nm; 2, sintering that powder particle to obtain a primary sintering material under a protective atmosphere, and crushing and refine the primary sintering material by a gas flow crusher to obtain a lithium iron phosphate positive electrode active material. The preparation method comprises the following steps of: adding raw materialsrequired for synthesizing lithium iron phosphate in a certain order without using a solvent; and sintering the raw materials in one step to obtain an end product with uniform size and excellent performance. The preparation method has the advantages of simple process, low energy consumption and environment friendliness.

Owner:SHENZHEN DYNANONIC

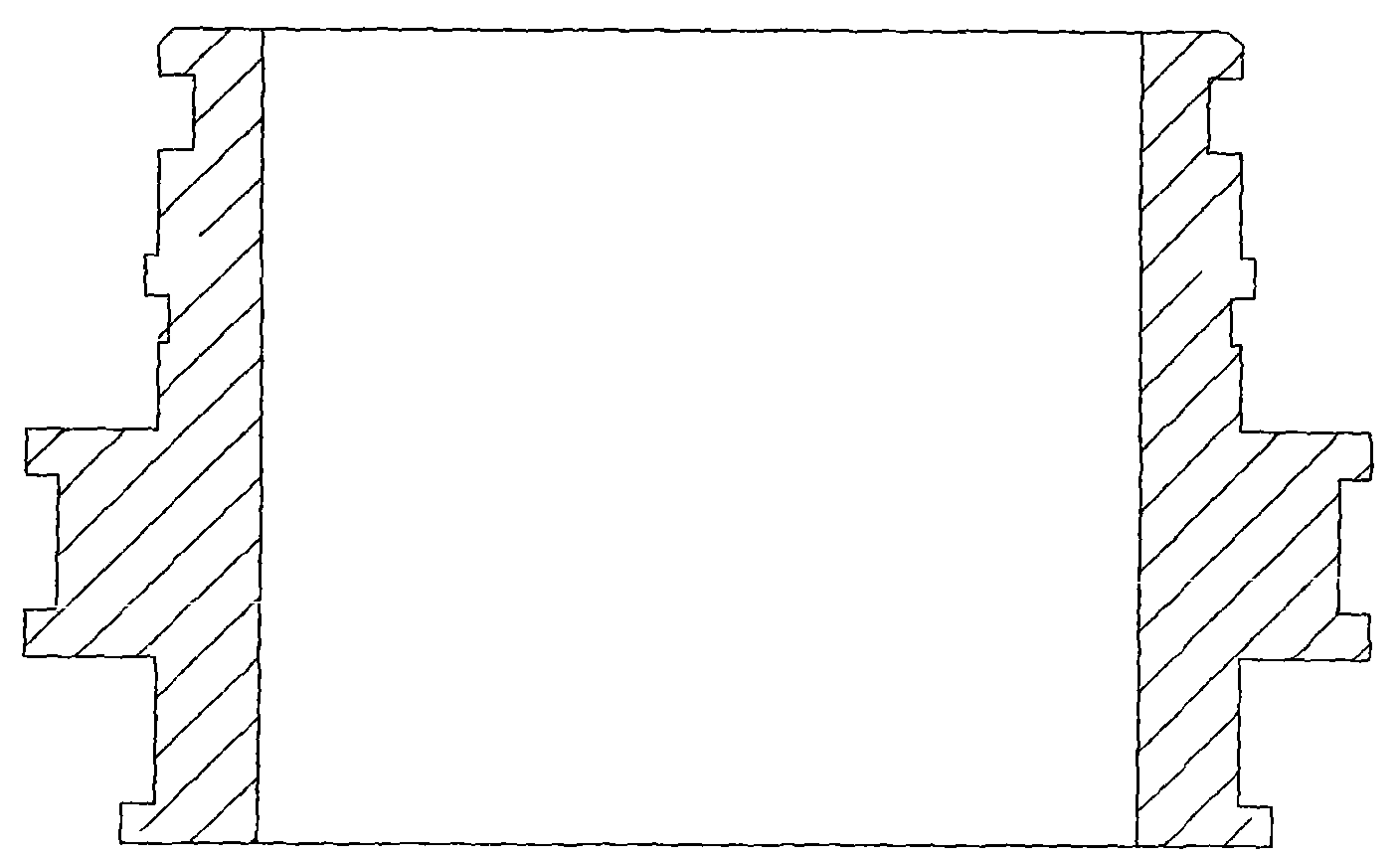

Thick-walled seamless steel tube short process casting and squeezing continuous formation method

InactiveCN103056183AIncrease profitEasy to processFoundry mouldsFoundry coresMedium frequencyThick wall

The invention relates to a thick-walled seamless steel tube short process casting and squeezing continuous formation method, and belongs to a short process casting and squeezing continuous formation method for producing large-caliber thick-walled seamless steel tubes, aiming at solving the technical field of severe material and energy source waste of the existing method for producing heavy-caliber thick-walled seamless steel tubes. The technical scheme provided by the invention is that the thick-walled seamless steel tube short process casting and squeezing continuous formation method comprises the steps of alloy melting, steel liquid refining, dead head loop blank pouring, hot extrusion, heat treatment and refine shaping step; a medium-frequency induction electric furnace is adopted for liquid steel refining, and the metallurgy temperature is 1650 DEG C-1700 DEG C; the step of dead head loop blank pouring is realized in a way that refined liquid steel is subjected to thin neck dead head pouring at 1590 DEG C-1610 DEG C, and molds are extruded out at 1280 DEG C-1330 DEG C after pouring; and the step of hot extrusion is realized in a way that the cast hollow loop blanks are placed on a steel tube extruding machine and are directly extruded and formed at the initial extrusion temperature of 1200 DEG C-1250 DEG C by utilizing residual heat of cast blanks, and the extrusion ratio is 10-12.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

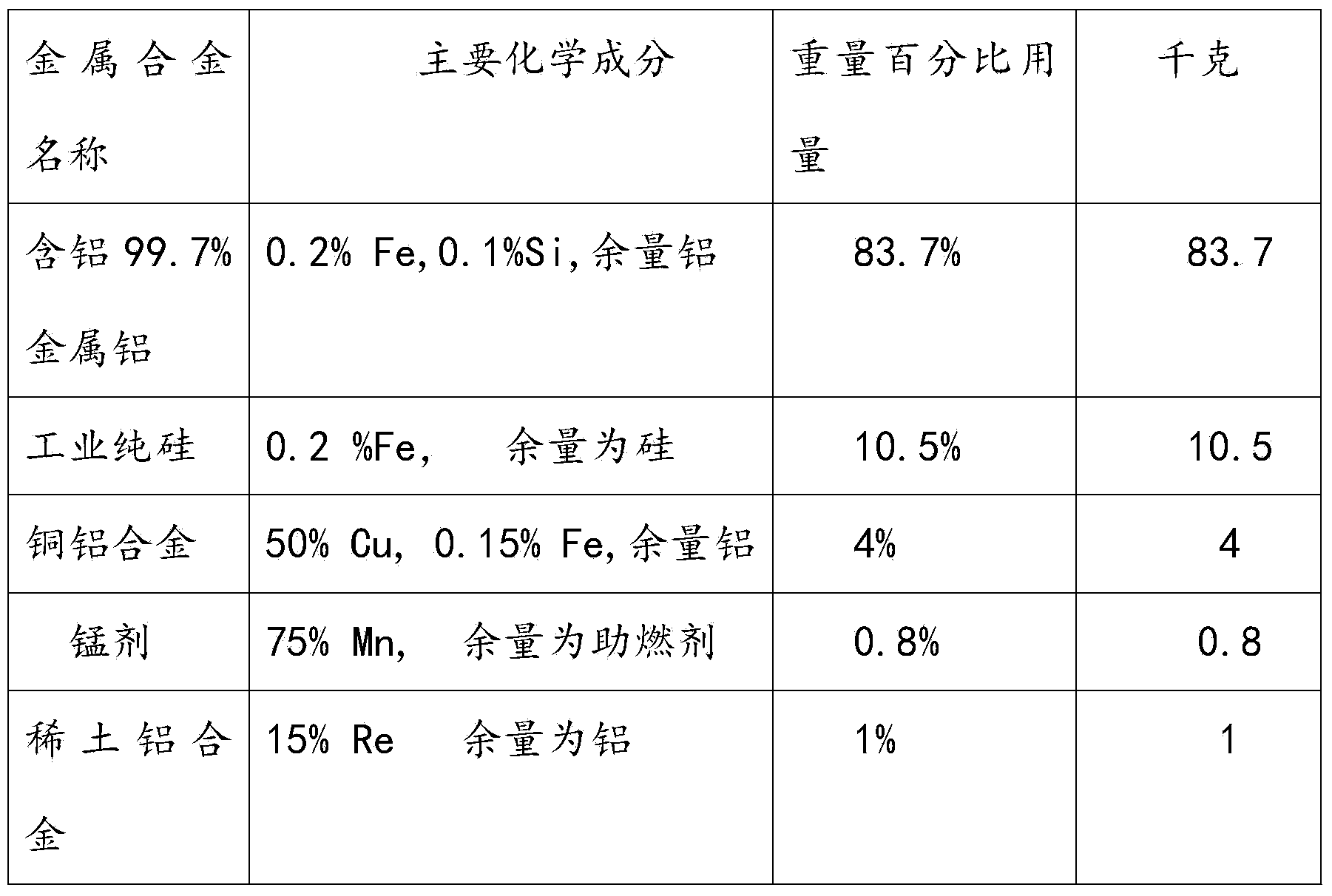

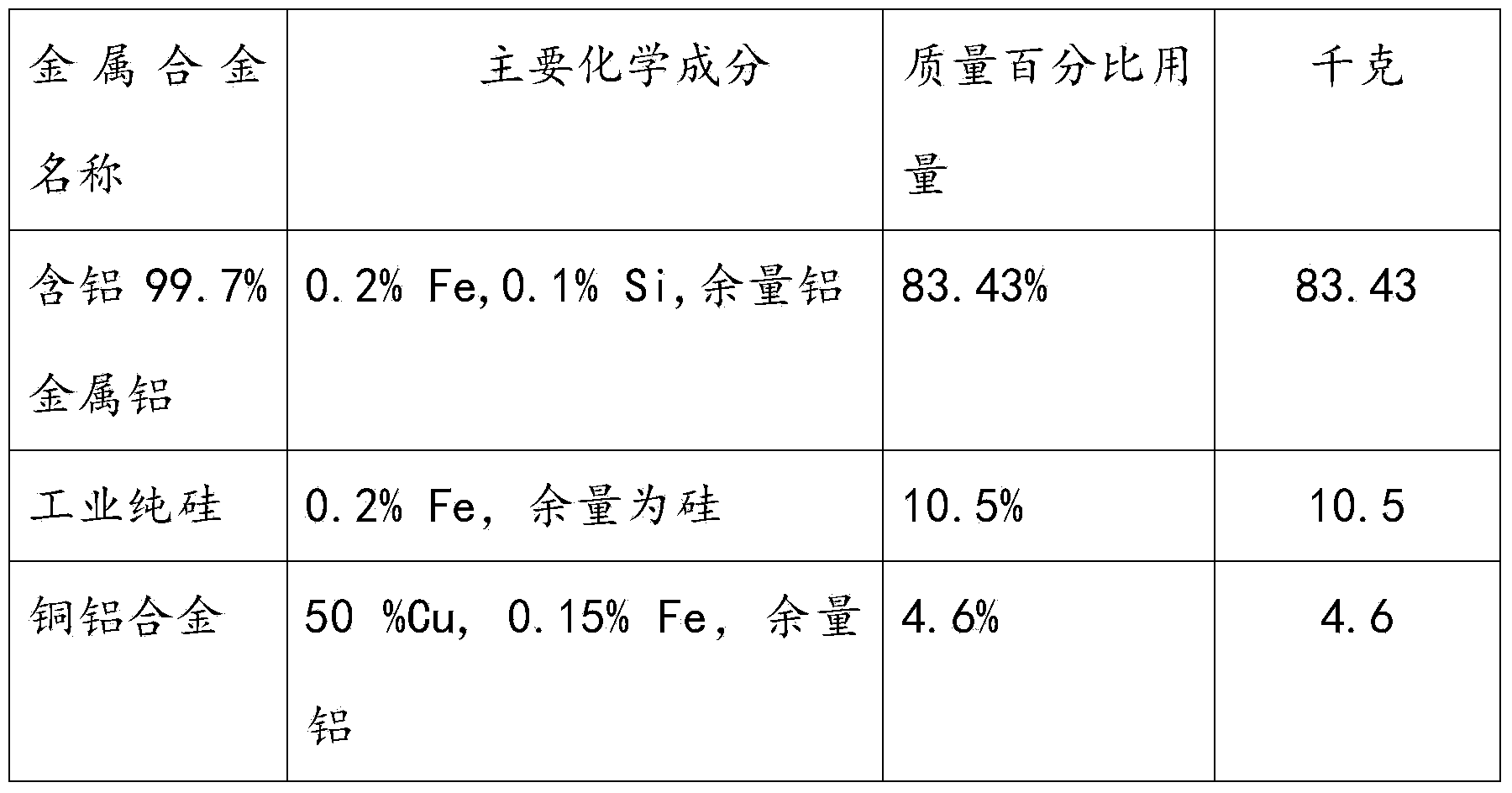

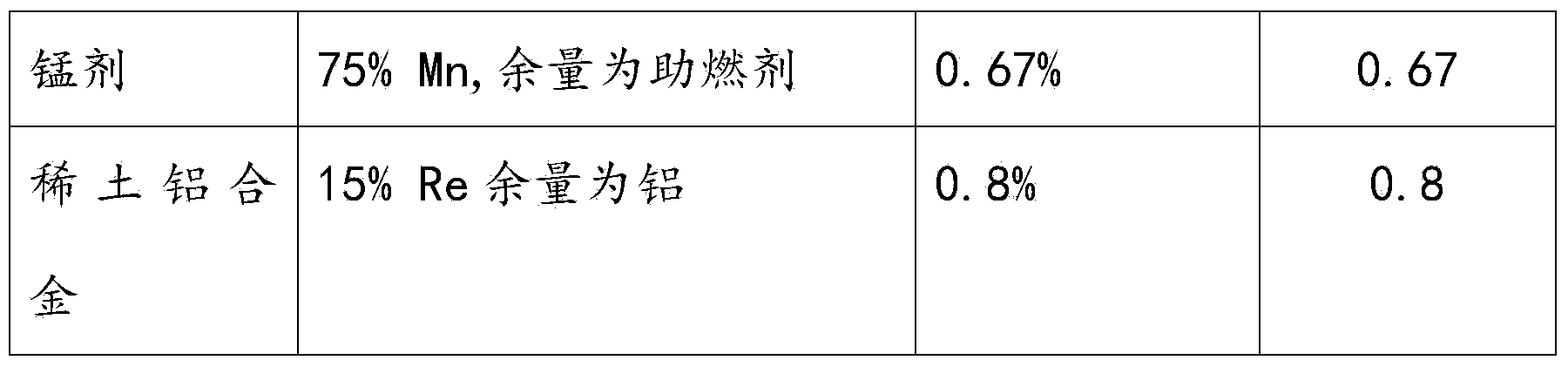

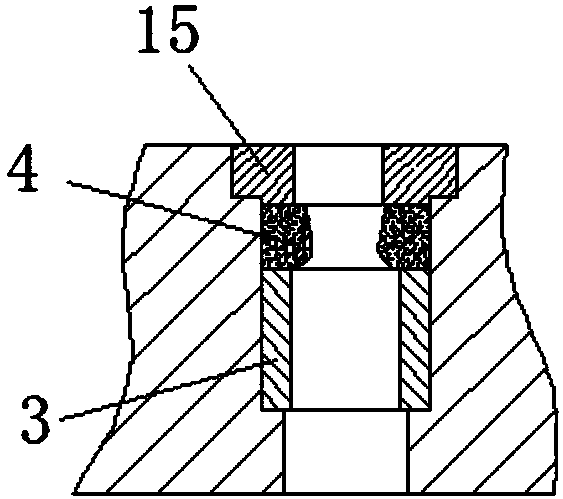

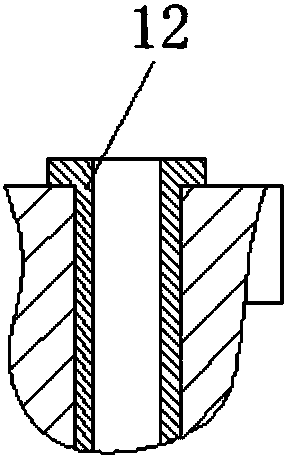

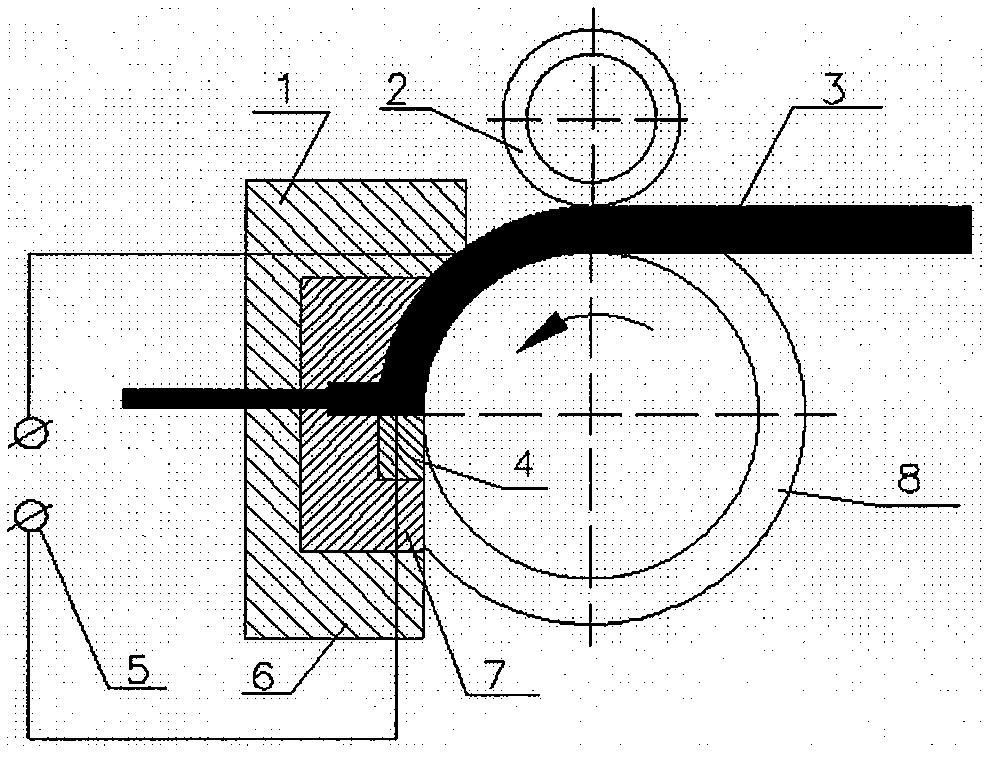

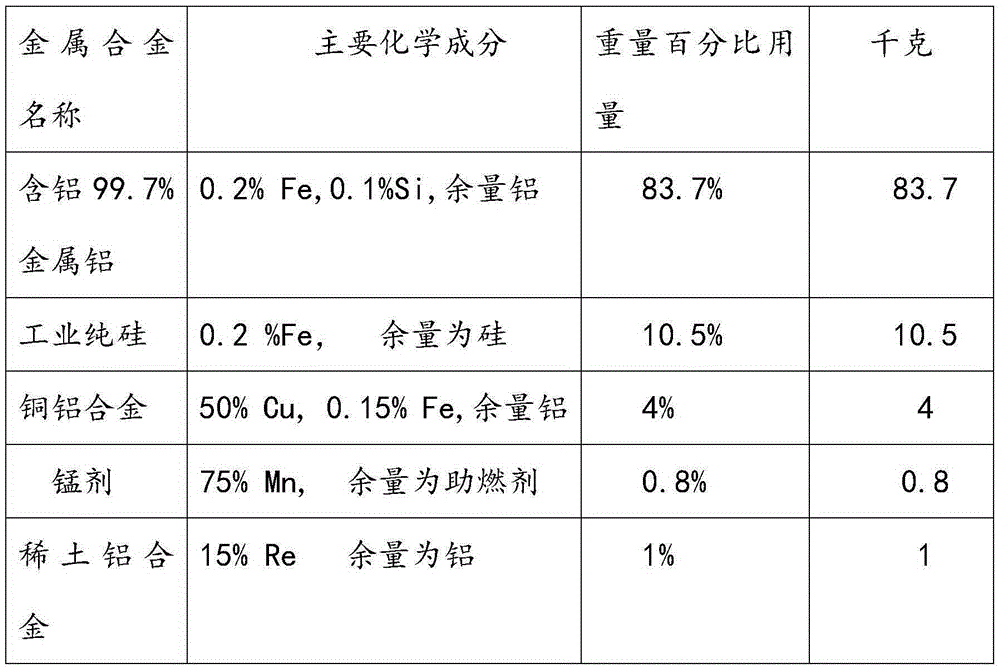

Aluminum, silicon, copper and rare earth alloy material for metal mold casting and preparation method and application thereof

The invention discloses an aluminum, silicon, copper and rare earth alloy material for casting a dual-balance shaft shell of an automobile and a preparation method of the material. The aluminum, silicon, copper and rare earth alloy material comprises the following components (in percent by weight): 10-12 percent of silicon, 1.5-2.5 percent of copper, 0.3-0.9 percent of manganese, 0.1-0.3 percent of rare earth element, 0.18-0.2 percent of impurity element iron and the balance of aluminum. The dual-balance shaft shell of an automobile is made of the aluminum, silicon, copper and rare earth material. The aluminum, silicon, copper and rare earth alloy material has the beneficial effects that the dual-balance shaft shell of the automobile, which is made of the aluminum, silicon, copper and rare earth alloy material, is capable of lightening 2 / 3 of the weight of an existing dual-balance shaft of the automobile, the corrosion resistance is good, the hardness is high, the hardness (HBM (Brinell Hardness)) of the dual-balance shaft shell of the automobile reaches 80-85, and the tensile strength (theta b) reaches 230-240MPa; the casting yield of the dual-balance shaft shell of the automobile is increased to 90 percent from 80 percent, the thermal treatment procedure is saved, and the production cost is lowered to 5000RMB / ton.

Owner:济南润祥新材料科技有限公司

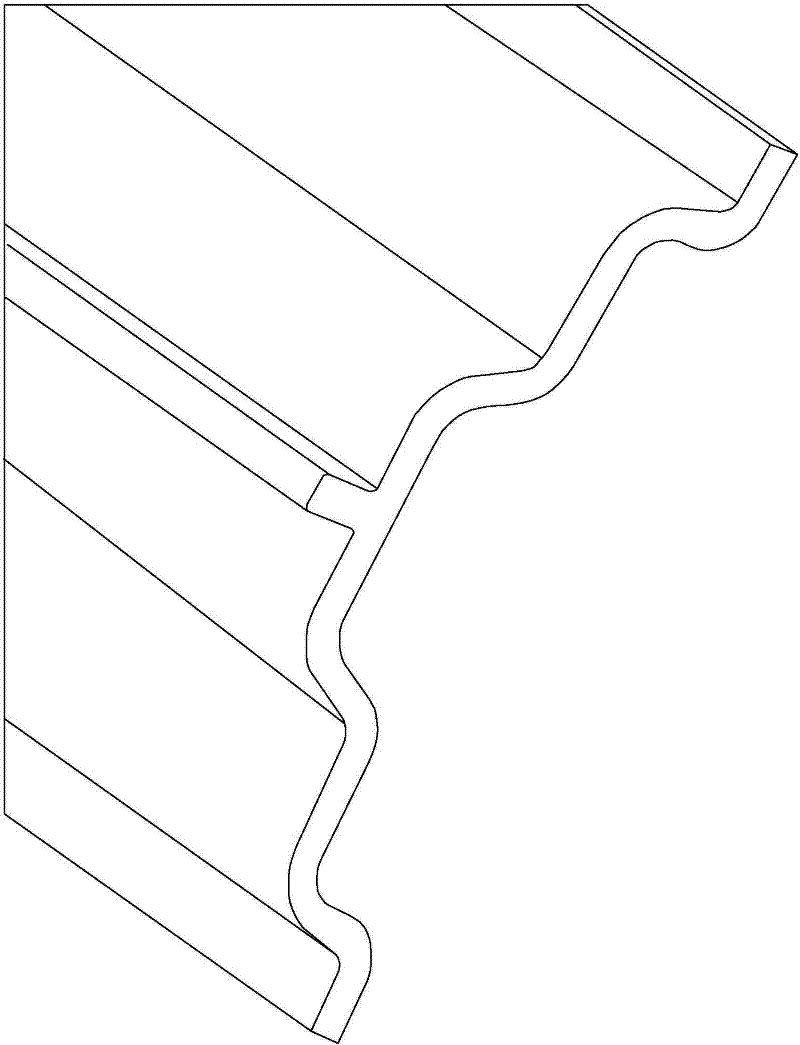

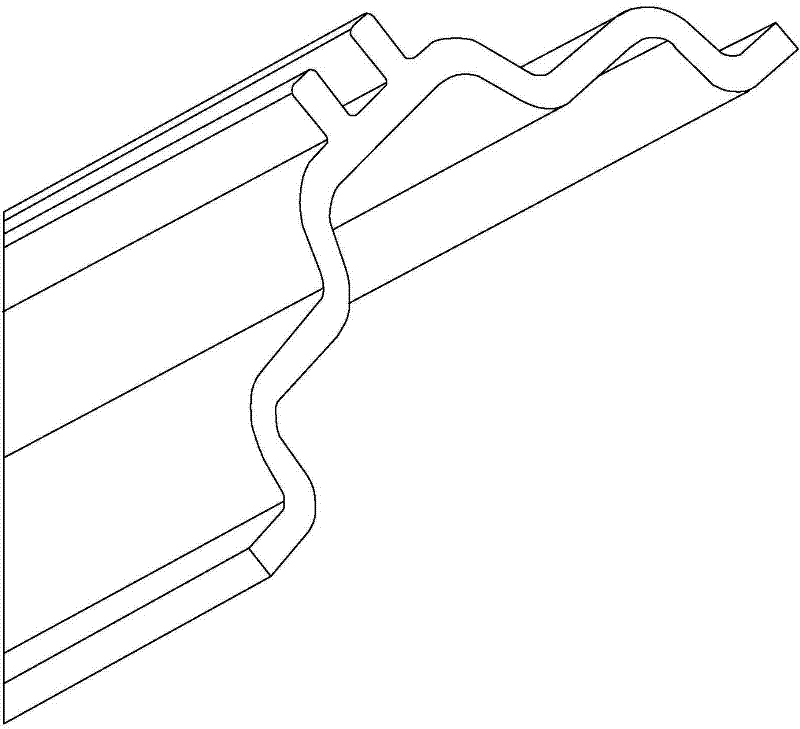

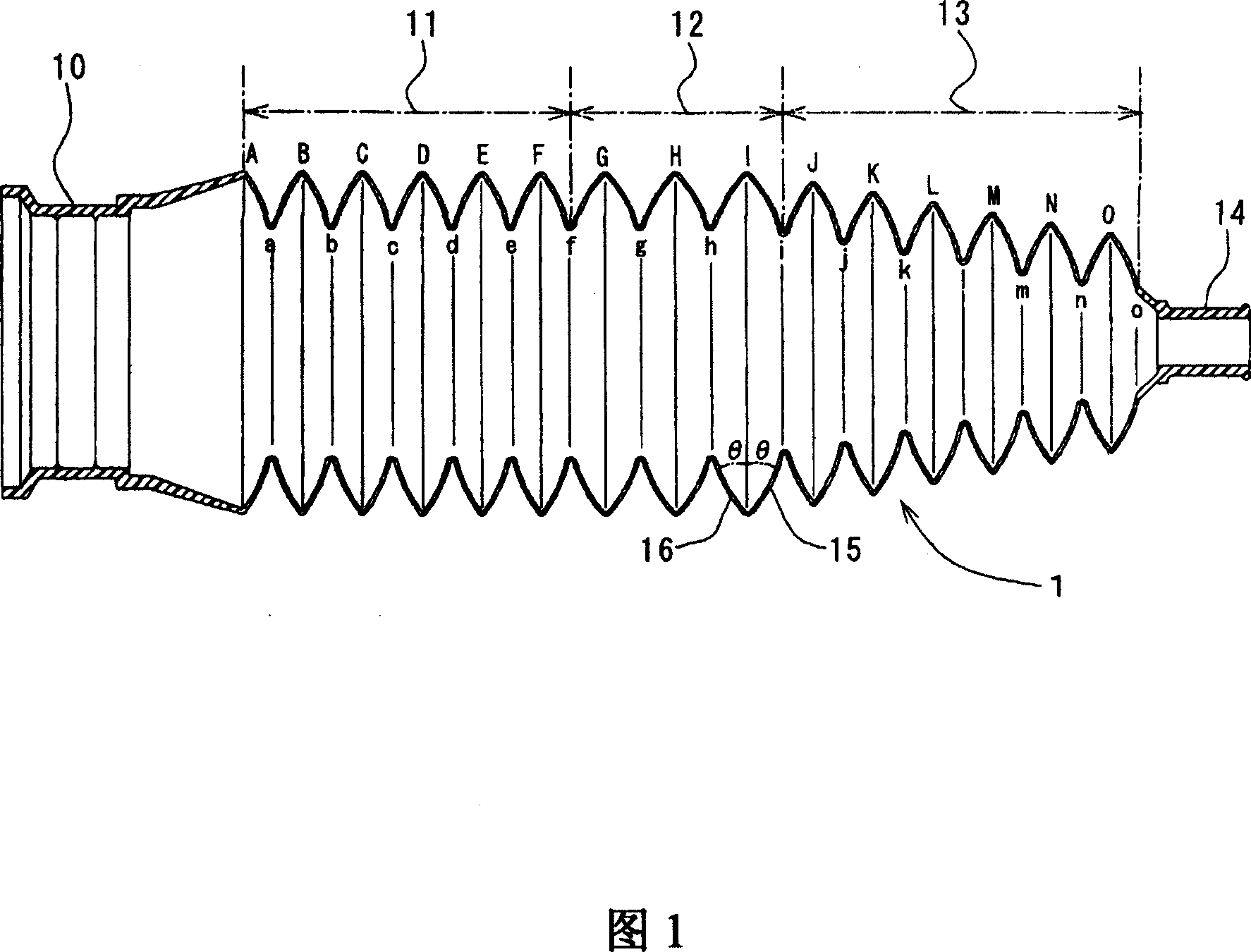

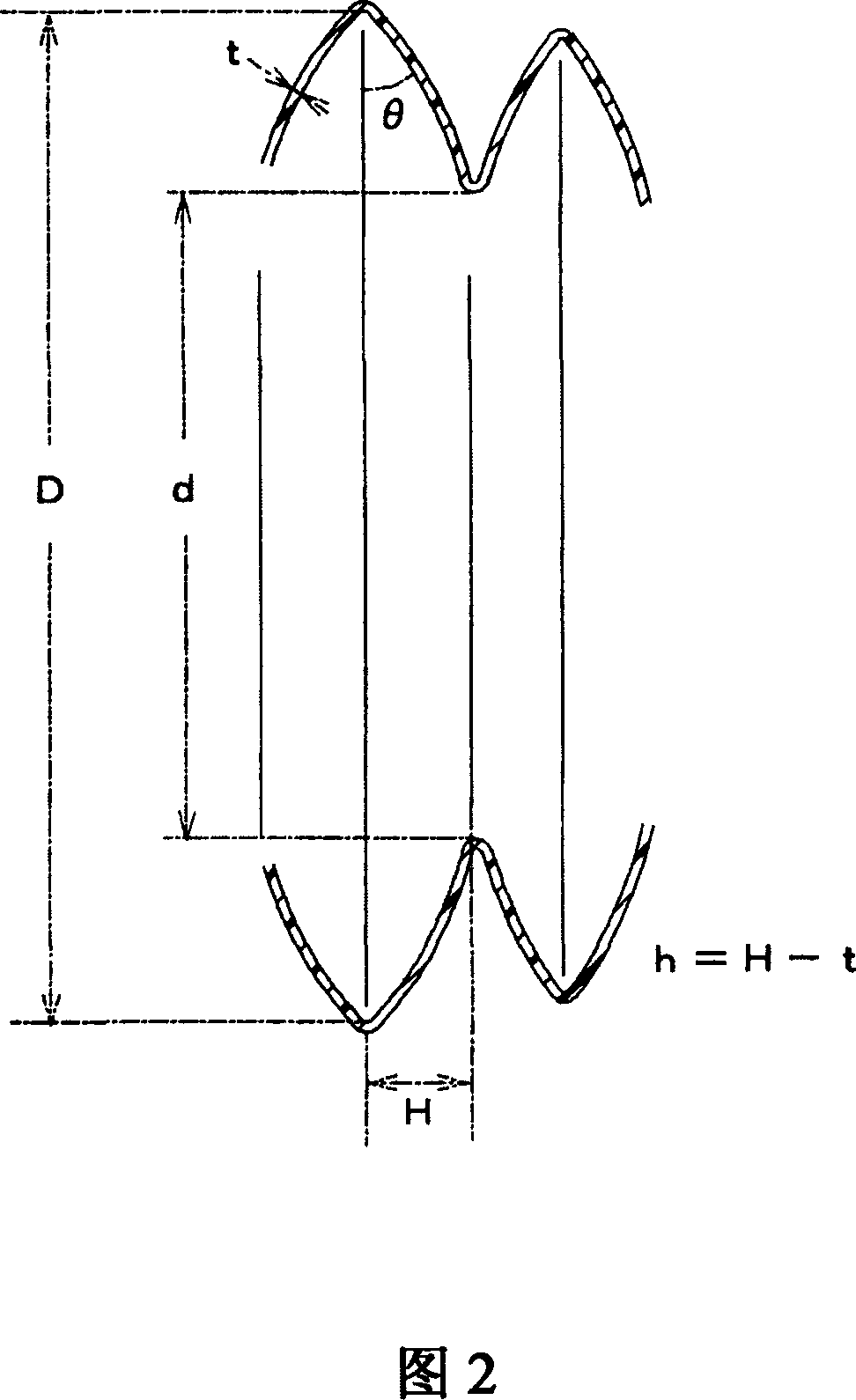

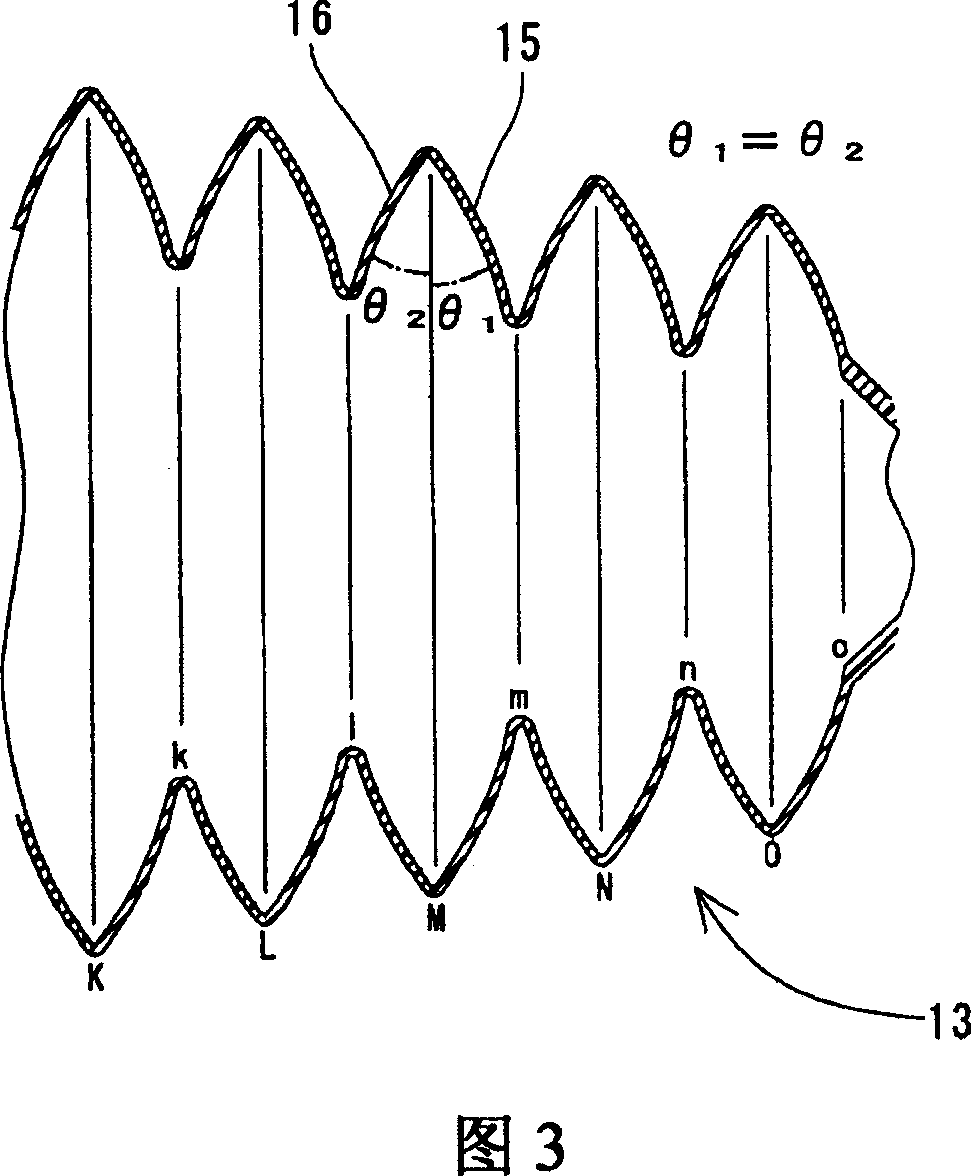

Boot

ActiveCN101033802AReduce processing timePrevent undulating deformationEngine sealsBellowsEngineeringFastener

A boot includes a major-diameter fastener, a first bellows, a second bellows, a minor-diameter-side bellows, and a minor-diameter fastener. The major-diameter fastener is to be fastened to a mating major-diameter member. The first bellows is disposed continuously from the major-diameter fastener. The second bellows is disposed continuously from the first bellows. The minor-diameter-side bellows is disposed continuously from the second bellows. The minor-diameter fastener is disposed continuously from the minor-diameter-side bellows, and is to be fastened to a mating minor-diameter member. The first bellows exhibits an averaged first axial rigidity. The second bellows exhibits an averaged second axial rigidity. The minor-diameter-side bellows exhibits an averaged third axial rigidity. The averaged first axial rigidity and the averaged third axial rigidity are lower than the averaged second axial rigidity.

Owner:TOYODA GOSEI CO LTD

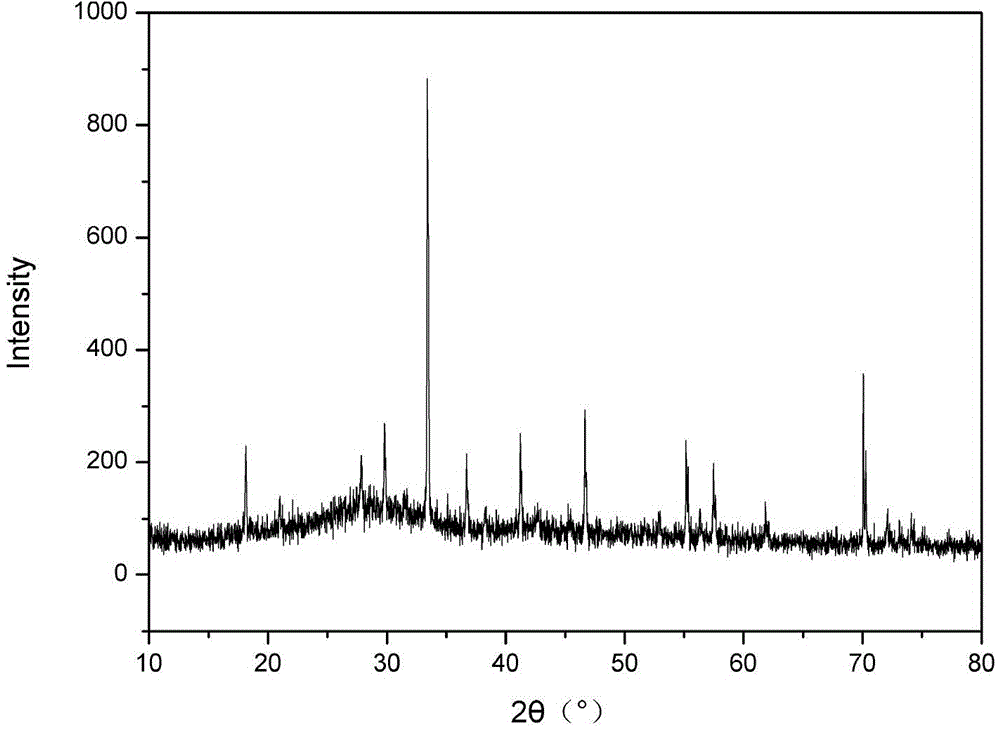

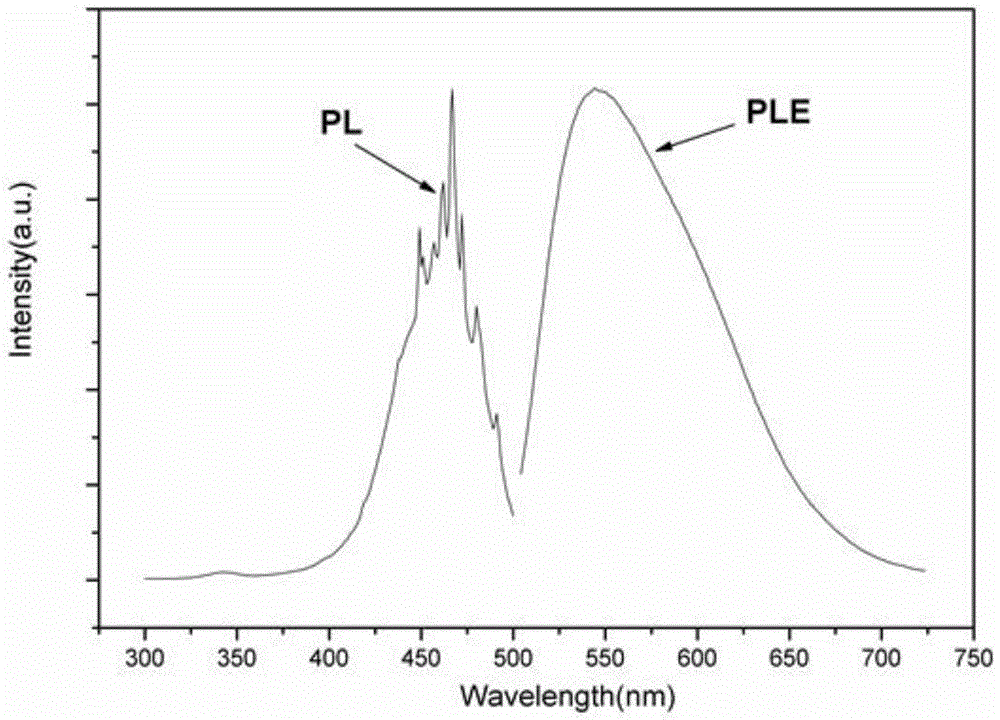

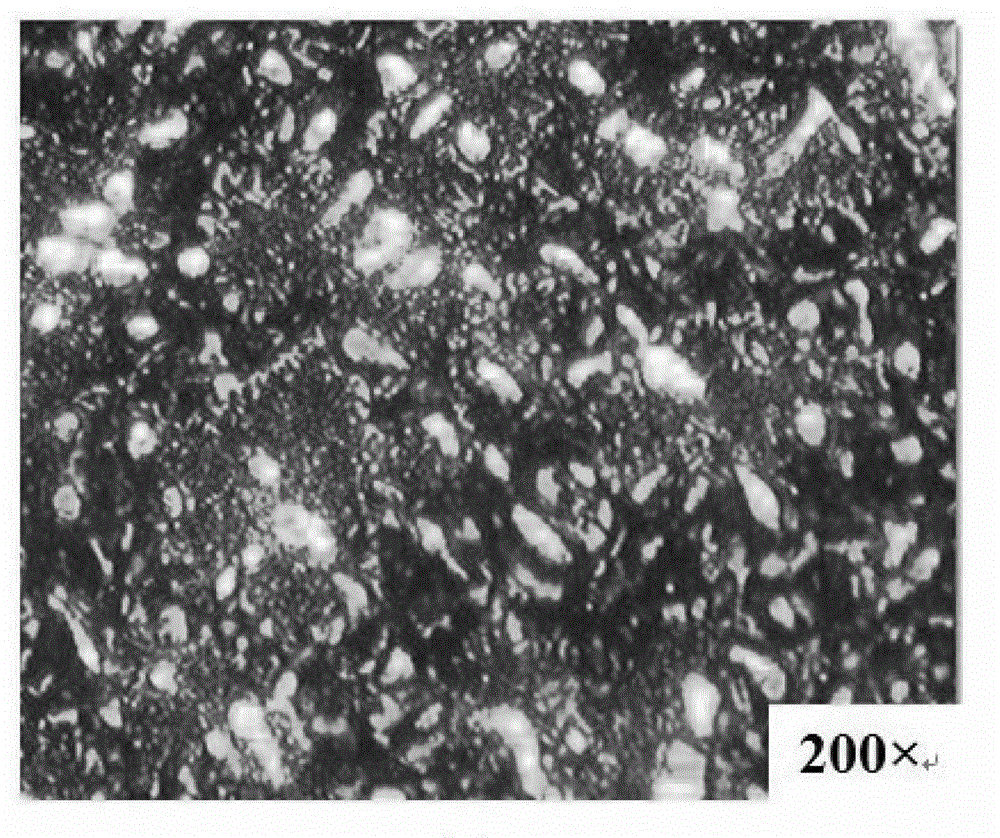

Transparent Ce:YAG microcrystalline glass and application of transparent Ce:YAG microcrystalline glass in white LED

The invention discloses transparent Ce:YAG microcrystalline glass and application of the transparent Ce:YAG microcrystalline glass in a white LED. The microcrystalline glass is self-crystallized, and is prepared from the following active materials in percentage by mole: 19-30mol% of SiO2, 15-30mol% of Al2O3, 5-20mol% of Y2O3, 40-60mol% of PbO, 0.5-5mol% of CeF3 and 2-10mol% of B2O3, wherein the sum of the mole percentage of the components is 100 percent. The Ce:YAG microcrystalline glass disclosed by the invention meets the requirements that the glass melting temperature is low, a preparation method is simple, the raw materials are readily available, the production cycle is short, the batch production is easily realized, and the glass is stable in physicochemical properties, high in uniformity, long in service life and high in heat conductivity; and moreover, the Ce:YAG microcrystalline glass emits bright yellow light under blue light excitation of 465nm, the yellow light and blue light are combined to generate strong white light, and the microcrystalline glass can be used for preparing the white LED.

Owner:WENZHOU UNIVERSITY

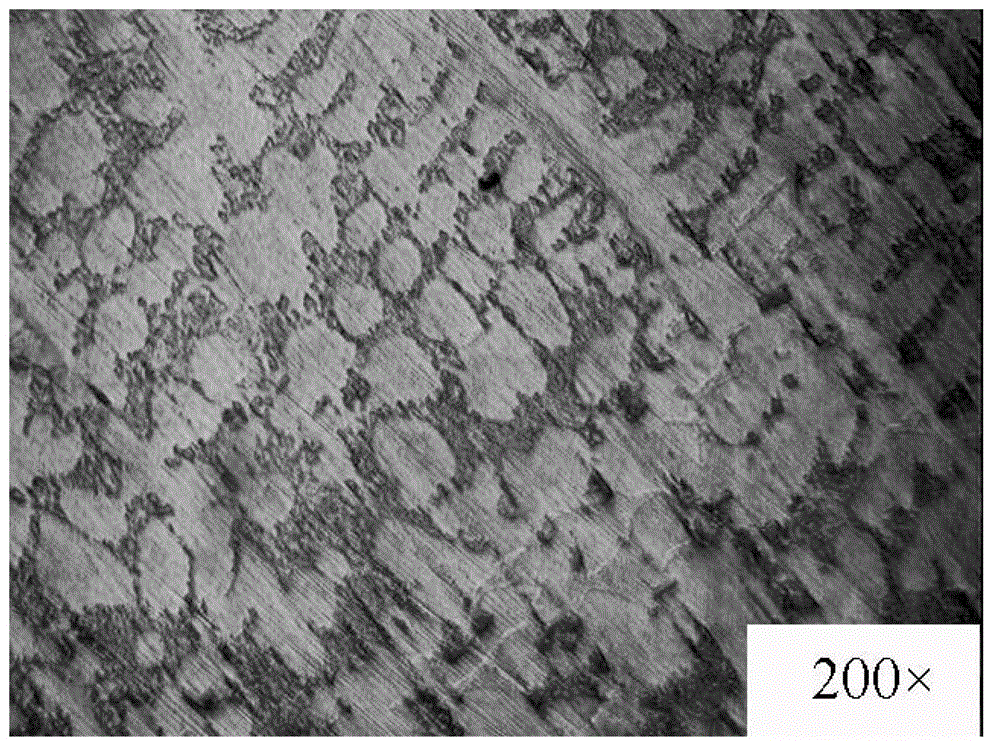

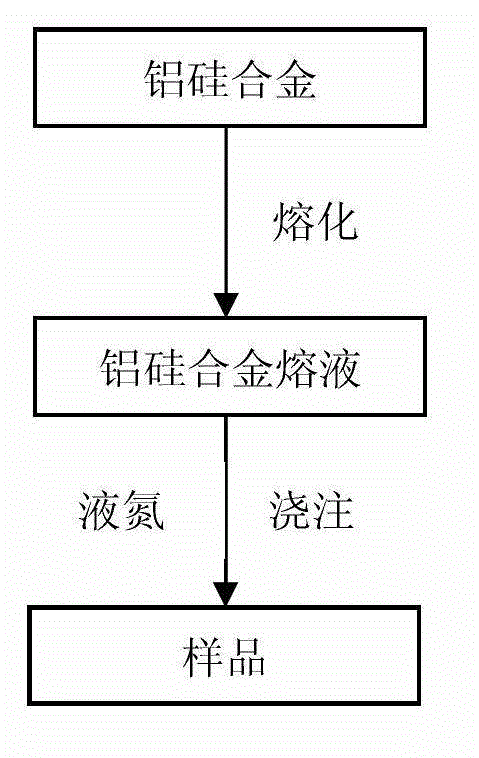

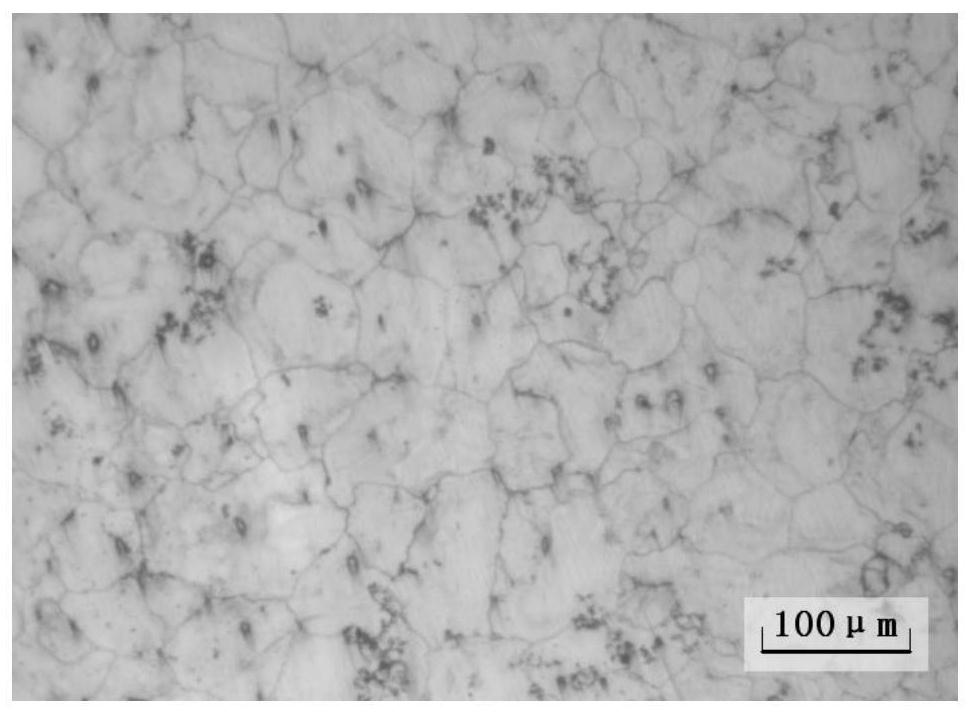

Method for refining hypo eutectic aluminum-silicon alloy structure

The invention discloses a method for refining a hypo eutectic aluminum-silicon alloy structure. The method comprises the steps of: firstly melting down an aluminum-silicon alloy; then casting rapidly, solidifying and shaping the melt aluminum-silicon alloy in a liquid nitrogen environment. The method for refining the hypo eutectic aluminum-silicon alloy structure has the advantages of being simple in operation, safe and environment-friendly, obvious in refining effects and fast to prepare. A relatively large number of eutectic structures which are distributed uniformly, have compact and fine organization and have low cutting function for a basal body can be obtained after the AC4B aluminum-silicon alloy is cooled by liquid nitrogen, so that the hardness of the aluminum alloy is up to 148 HBS. The AC4B aluminum-silicon alloy which is obtained by being cooled rapidly in the liquid nitrogen environment has a size of about 3 microns to 15 microns. The crystal particle structure is fine; and the edges and corners of the crystal particles are passivated and smooth.

Owner:ANHUI RUNXIN TAIDA INTELLIGENT SYST ENGCO

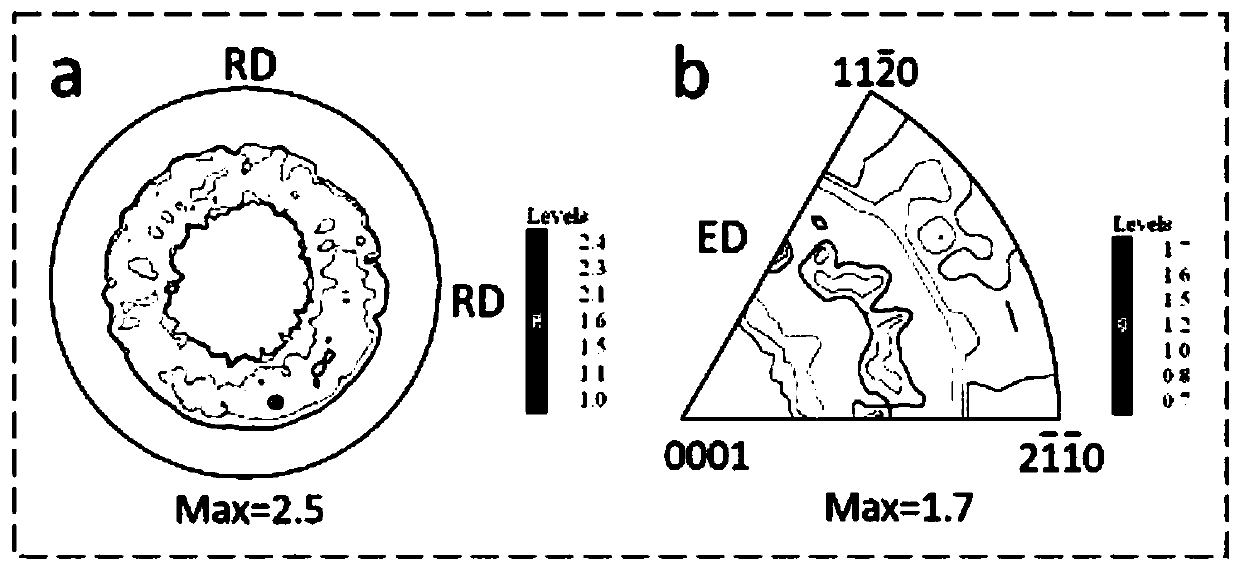

Ultrahigh-plasticity magnesium alloy and preparation method of deformation material of ultrahigh-plasticity magnesium alloy

The invention discloses an ultrahigh-plasticity magnesium alloy and a preparation method of a deformation material of the ultrahigh-plasticity magnesium alloy. The magnesium alloy comprises the following components of, by weight, 1.0%-3.0% of Gd, 0.3%-1.0% of Zr and the balance Mg. The preparation method of the deformation material of the magnesium alloy comprises the following steps that S1, alloy smelting is carried out, wherein a pure magnesium ingot, a Mg-Gd intermediate alloy and a Mg-Zr intermediate alloy are taken as raw materials, proportioning is carried out according to the magnesiumalloy components and the weight percentage, and alloy ingredients are smelted and then are cast into an alloy ingot; S2, machining is carried out, and specifically the alloy ingot prepared in the step S1 is machined into an extruded blank; and S3, extrusion forming is carried out, wherein the extruded blank prepared in the step S2 is preheated to an extrusion temperature, and primary extrusion forming is carried out by adopting a hot extrusion process so as to obtain the deformation material of the magnesium alloy. The ultrahigh-plasticity magnesium alloy shows ultrahigh room-temperature plasticity, can be conventionally and rapidly formed, is low in cost, is simple in process and can undergo large-strain forming and cold working.

Owner:CHONGQING UNIV

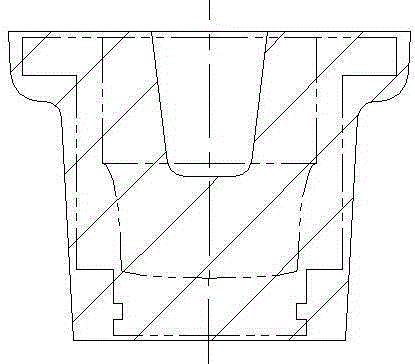

Manufacturing technology of individual hydraulic prop piston

InactiveCN101549459AReduce production efficiencySave raw materialsFurnace typesForging press detailsMetal formingManufacturing technology

The invention relates to a manufacturing technology of an individual hydraulic prop piston, which comprises the following steps of: a. blanking; b. heating a steel billet blanked to a temperature between 900 DEG C and 1,200 DEG C; c. completing billet manufacturing of the heated steel billet on mechanical billet manufacturing equipment; d. forging the billet manufactured on a friction press in a closed manner; e. heat-treating a piston forge piece forged by using surplus heat from forging; and f. one-step finishing the manufacturing of the piston forge piece heat-treated by processing on a rough and fine machine. The invention utilizes the closed type die forging of the friction press (or metal forming machineries of other types) to replace fitting piston blanks of coal mine individual hydraulic prop of laminated spring hammer blocker-type forging with high energy consumption, low production efficiency and poor technical equipment, thus being capable of saving raw materials, improving production efficiency and reducing production cost. The use of surplus heat from the forging of piston blanks for heat treatment not only satisfies the requirements on hardness, but also reduces production cost.

Owner:SHANDONG UNIV

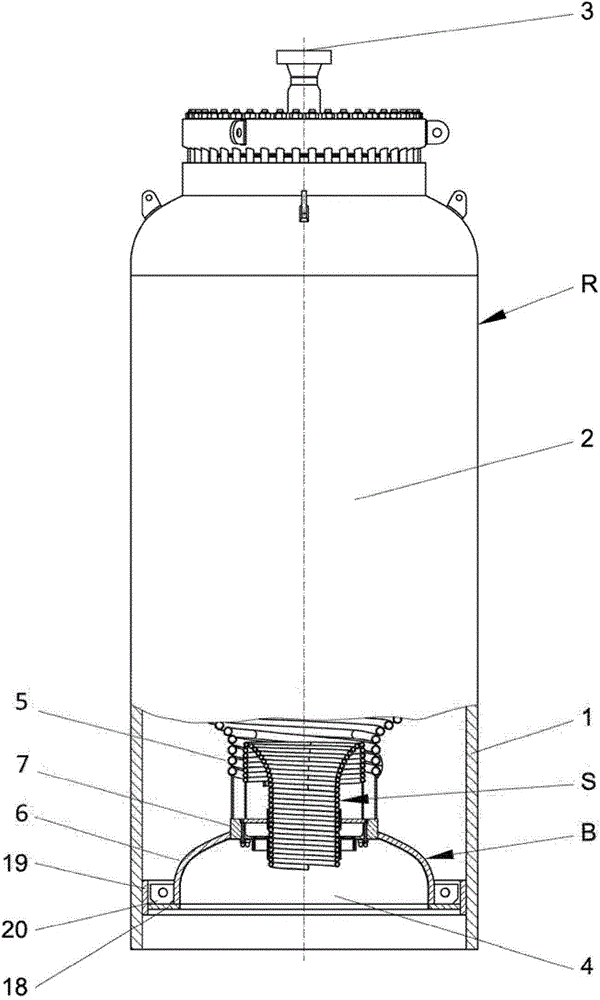

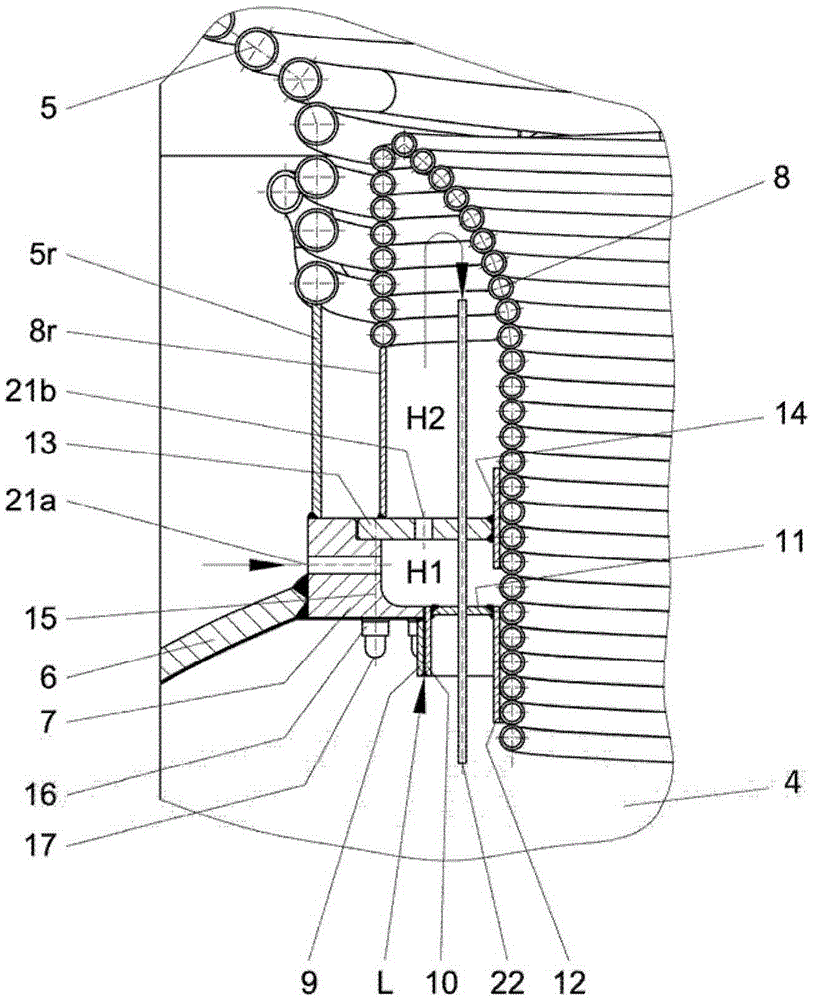

A reactor for being directed at carbon containing fuel carries out entrained flow gasifica tion

ActiveCN105985807AReduce corrosionExtended use timeGasifier mechanical detailsGasification processes detailsCooling chamberEngineering

The invention relates to a reactor for being directed at carbon containing fuel carries out entrained flow gasifica tion, it has a reacting chamber and one cooling chamber that borders on this reacting chamber within the reaction wall of pressure -bearing. The invention aims at providing a corrosivity wearing and tearing that the structure solution of bottom plate in the middle of is used for, this solution improves effective operating duration of entrained flow gasifica tion ware, and its mode does, reduces in middle bottom plate region to also reduce consumeing of dismantlement of sediment eduction gear and installation under repair. This purpose is following the realization, a plurality of components of this centre bottom plate each other continuously the unoccupied place and discharge to personally experience sth. Part of the body with this sediment and be connected as going to the fields for discharge at this sediment and form a gas space's air seal, limited this cooling chamber of this centre bottom plate downside between the body and this reaction wall, and the cavity between these components of this centre bottom plate through the pressure balance passageway each other, sweep the device and be connected with the gas space of this cooling chamber with an inert gas.

Owner:CHOREN INDTECHN

Hot-rolled wire rod for cord thread with tensile strength being 4000MPa and production method

The invention relates to a hot-rolled wire rod for a cord thread with tensile strength being the 4000MPa grade. The hot-rolled wire rod is prepared from the components in percentage by weight: 0.71 to0.75 percent of C, 0.36 to 0.40 percent of Si, 0.10 to 0.14 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.01 percent of S, 0.10 to 0.25 percent of Cr, and 0.0005 to0.0015 percent of B. A production method comprises the steps of smelting through a converter; carrying out RH vacuum treatment; continuously casting into small square ingots; slow cooling the ingot blanks; heating the ingot blanks; rolling at high speed; spinning; and air cooling for standby use. According to the hot-rolled wire rod for cord thread with tensile strength being the 4000MPa grade andthe production method provided by the invention, through reducing the content of carbon, improving the content of silicon, and adopting the matched process, on the premise of ensuring the tensile strength to be larger than 4000MPa, the diameter of a wire material reaches to 3.0 to 3.5mm, so that the fracture surface of the wire material is homogenized in structure and better in performance, gammacrystal particles are micronized, the aging during wire drawing processing is inhibited, and the fracturing of a cementite is inhibited; and the strength and the wire drawing limit of the wire material are improved, the times of stranding filament break does not exceed 2 times / ton steel, and secondary processing by a user can be omitted and simplified, so that the production cost is reduced, andthe production efficiency is improved.

Owner:武汉钢铁有限公司

Ultrahigh-plasticity aluminum alloy and preparing method thereof

PendingCN111979457ARefining as-cast grainObtain ultra-high plasticity at room temperatureMetallic materialsToughness

The invention relates to the technical field of metal materials and machining technology of the metal materials and discloses an ultrahigh-plasticity aluminum alloy and a preparing method thereof. Thealuminum alloy comprises, by weight percent, 0.8%-1.2% of Mg, 0.4%-0.8% of Si, 0.2%-0.4% of Fe, 0.2%-0.5% of Cu, and the balance Al. The preparing method of the aluminum alloy comprises several processes of burdening, smelting, casting, homogenizing treatment and extruding deformation treatment. When the aluminum alloy is prepared, the aluminum alloy composition components and the use amounts ofall the components are reasonably controlled, a wrought aluminum alloy microstructure with the structure still being of the single phase is obtained, and in addition, the structure is uniform; and dueto a solution strengthening effect of various elements, the phenomenon that elements are excessively added, a second phase is generated, and the subsequent extruding deformation treatment process ishindered is avoided, the problem of difficult aluminum alloy extruding is solved, grain growth in the extruding process is avoided, and the high-toughness aluminum alloy with the small and uniform alloy microstructure is obtained finally. The method is simple and easy to operate, low in requirement for equipment, low in cost and suitable for large-scale production.

Owner:YANTAI NANSHAN UNIV +1

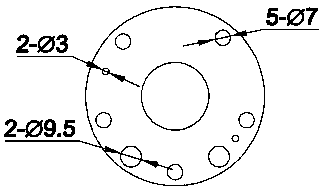

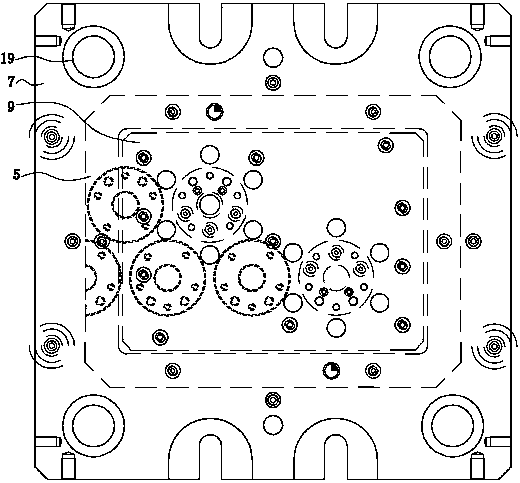

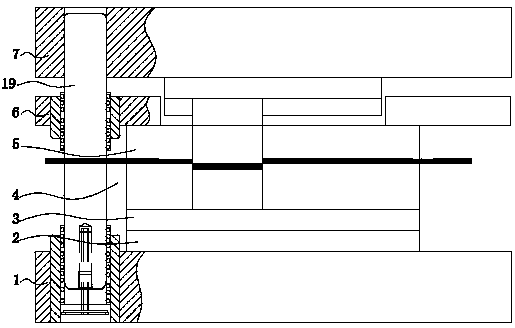

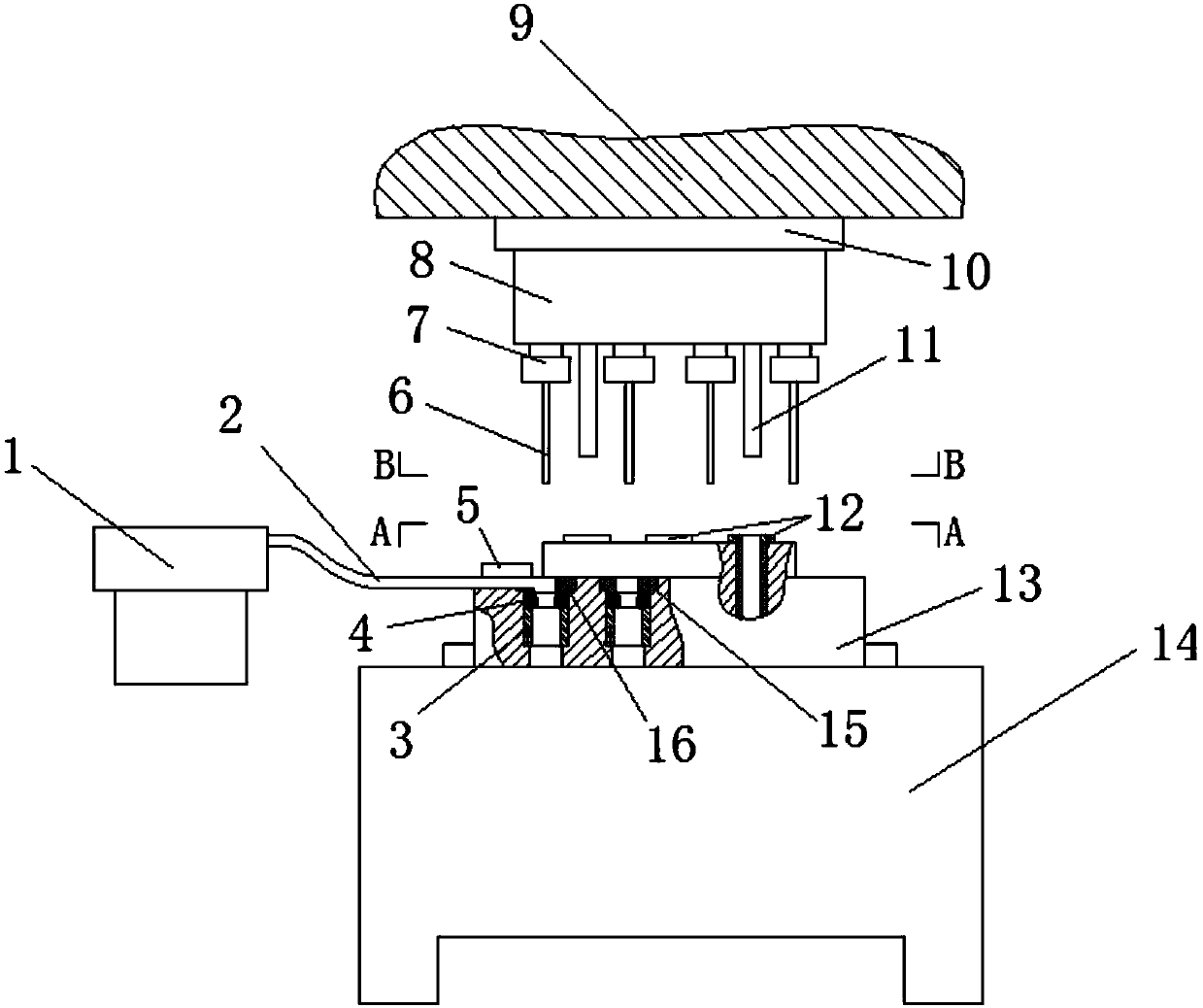

Fine stamping process method of compressor intermediate plate

PendingCN111375686AReduce consumptionImprove the level ofShaping toolsMaterials preparationStamping process

The invention discloses a fine stamping process method of a compressor intermediate plate blank. The method is characterized by comprising the following processes of material preparation, stamping, external circle turning, small hole drilling, double-face grinding, cleaning and full inspection packaging. The fine stamping process adopts a special composite die, the special composite die comprisesan upper die assembly and a lower die assembly which are oppositely arranged up and down, and the upper die assembly and the lower die assembly both adopt a relatively scientific and reasonable structure to realize synchronous machining of key holes and shapes. The method has the advantages that two processes of heating and correcting are saved, the machining amount of seven holes is reduced in the drilling process, the machining process is greatly reduced and simplified, the production cost is reduced, the efficiency is improved, and the product quality is improved; the key holes and the shapes are synchronously machined, secondary positioning is not needed, accumulated errors are avoided, the shape and position sizes are more stable, and the yield of products is greatly improved; the consumption of materials and energy is greatly reduced, energy is saved, and the environment is protected; and the problems that the edge distance of phi7 and phi 9 holes is small and forming is difficult are solved.

Owner:FOSHAN NUODI PRECISION MOLD CO LTD

Rotatable composite automatic stretching device

InactiveCN107639124AImproves wall thickness uniformityReduce cleaningMandrel separation arrangementsEngineeringHeat treating

The invention discloses a rotatable composite automatic stretching device which comprises a lower machine table, an upper machine table, a lower base and a servo motor linkage module, wherein the upper machine table is arranged above the lower machine table, the lower base is arranged on the lower machine table, and the servo motor linkage module is arranged on the upper machine table. A pluralityof female dies are uniformly and circumferentially distributed on the lower base, upper bases are uniformly and circumferentially distributed on servo motor linkage module, the number of the upper bases is as same as that of the female dies, the circumference positions of the upper bases are one-to-one correspondence to that of the female dies, core rods are arranged on the upper base, the core rods are matched with the female dies in the downward pressing process, so that tube blanks are stretched, the female dies are provided with cavities, and the inner diameter sizes of the female die cavities are sequentially reduced from the female dies correspondingly arranged below feeding blocks to the female dies correspondingly arranged below discharging blocks. According to the device, the processes such as cleaning and heat treatment in the original multi-pass stretching process are saved, a production period is greatly shortened, and production efficiency is improved.

Owner:ZHEJIANG GARDEN ELECTRONICS EQUIP

Electro-plasticizing continuous extrusion molding processing technology of high-strength aluminum alloy

InactiveCN102814349AReduce residual stressReduced processing performanceElectricityWorking environment

The invention relates to a new method for molding processing of a high-strength aluminum alloy, and belongs to the plasticity processing field. The method enables a pulse current to be applied to a deformation zone in the high-strength aluminum alloy extruding process to promote the improvement of the plasticity of the high-strength aluminum alloy and reduce the deformation resistance of the high-strength aluminum alloy to make the difficult-deformation high-strength aluminum alloy deform at normal temperature, so the heat treatment operations comprising device heating, annealing and the like are omitted. The pulse current can be directly applied to dislocation structures to promote the dislocation motion, so the affections of residual stress and processing hardening are reduced under the action of the pulse current, thereby the product surface quality is improved and the annealing operation is omitted. The reduction of the deformation resistance can effectively reduce the load acted on a die and reduce the temperature of the cavity material baffle block, so the service life and the production efficiency of the die are greatly improved, thereby the production cost is reduced. The surface quality and the mechanical performances of products are improved because of the pulse current, so rigorous performance requirements of the high-strength aluminum alloy of aerospace vehicles, high-speed trains and the like because of bad working environments are satisfied.

Owner:陶艳

A kind of aluminum-silicon-copper rare earth alloy material for metal mold casting and its preparation method and application

The invention discloses an aluminum, silicon, copper and rare earth alloy material for casting a dual-balance shaft shell of an automobile and a preparation method of the material. The aluminum, silicon, copper and rare earth alloy material comprises the following components (in percent by weight): 10-12 percent of silicon, 1.5-2.5 percent of copper, 0.3-0.9 percent of manganese, 0.1-0.3 percent of rare earth element, 0.18-0.2 percent of impurity element iron and the balance of aluminum. The dual-balance shaft shell of an automobile is made of the aluminum, silicon, copper and rare earth material. The aluminum, silicon, copper and rare earth alloy material has the beneficial effects that the dual-balance shaft shell of the automobile, which is made of the aluminum, silicon, copper and rare earth alloy material, is capable of lightening 2 / 3 of the weight of an existing dual-balance shaft of the automobile, the corrosion resistance is good, the hardness is high, the hardness (HBM (Brinell Hardness)) of the dual-balance shaft shell of the automobile reaches 80-85, and the tensile strength (theta b) reaches 230-240MPa; the casting yield of the dual-balance shaft shell of the automobile is increased to 90 percent from 80 percent, the thermal treatment procedure is saved, and the production cost is lowered to 5000RMB / ton.

Owner:济南润祥新材料科技有限公司

Preparation method of internal combustion engine tail gas purifier based on 3D printing technology

PendingCN112453397AUniform materialSimple processAdditive manufacturing apparatusIngot castingManufactured material

The invention discloses a preparation method of an internal combustion engine tail gas purifier based on a 3D printing technology. The preparation method comprises the following steps that S1, raw materials are prepared, specifically, ingot casting and melting are carried on required metal raw materials, and corresponding alloy is added into molten metal according to the actual requirements of a honeycomb carrier of the internal combustion engine tail gas purifier; S2, the raw materials are subjected to vacuum atomization powder preparation, specifically, the molten metal is prepared into metal powder through a vacuum atomization powder preparation method; S3, the honeycomb carrier of the internal combustion engine tail gas purifier is prepared; and S4, polishing finishing and acid pickling are conducted. Compared with an existing preparation method, the preparation method of the internal combustion engine tail gas purifier based on the 3D printing technology is simple in technologicalprocess, the finished product composition material is uniform, the product yield is high, the procedures of heat treatment, hot rolling, cold rolling and welding in an existing preparation method areomitted, the risk of product scrapping is reduced, short-process green and clean manufacturing is achieved, and energy is also saved.

Owner:安徽钢研新材料科技有限公司

Pouring flow inoculation feeding device

Owner:CHANGZHOU LANGRUI CASTING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com