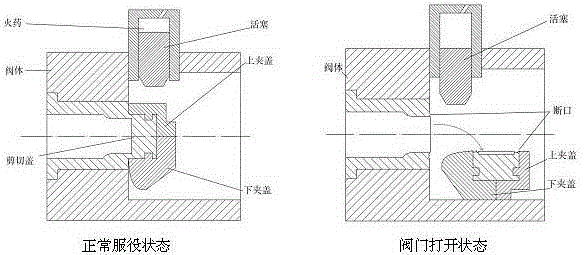

Crystalline grain control method for GH690 alloy shear cover of explosion valve

A technology of GH690 and control method, which is applied in the field of material processing, can solve problems such as uneven structure of forgings and grain growth, and achieve the effect of reducing forging times, deformation resistance and deformation cracking risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, further illustrate the details of the present invention:

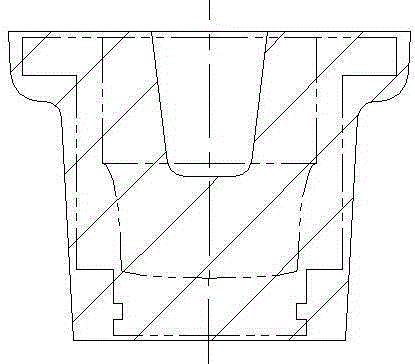

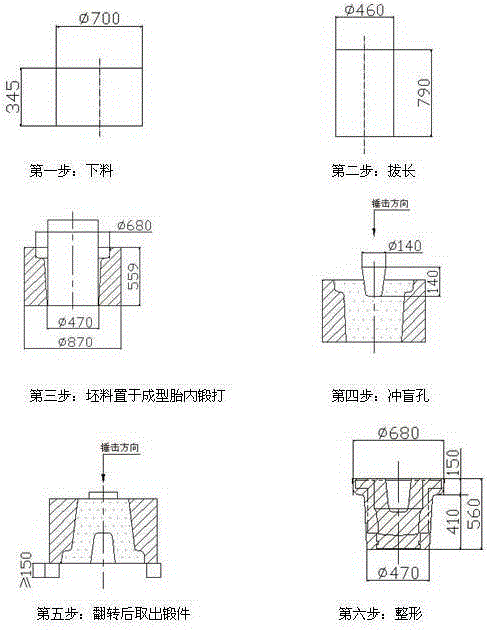

[0026] Taking the forging of DN450C shear cap as an example, its designed minimum cross-sectional diameter is 470 mm, and the purchased GH690 nickel-based alloy billet steel ingot with a grain grade of 4 and an average structure diameter of 700 mm (about 150% of the minimum cross-sectional diameter of the designed shear cap) ), use a sawing machine to cut the material, the length is about 345mm, heat the steel ingot in a heat treatment furnace at 1100°C, forge and draw the steel ingot on the forging press to a diameter of about 460mm (about 90% of the minimum cross-sectional diameter of the designed shear cover) %), about 790mm in length, water-cooled; the steel ingot was solid solution treated in a heat treatment furnace at 1050°C, and the grain boundary carbide M 23 C 6 Fully dissolved, Cr, Ti, C alloying elements are uniformly dissolved in the austenite matrix; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com