A preparation method of lithium iron phosphate

A lithium iron phosphate and phosphorus source technology, applied in the field of lithium-ion batteries, can solve the problems of high overall energy consumption, cumbersome operation, and a large amount of solvents, and achieve the effects of low overall energy consumption, environmental friendliness, and improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

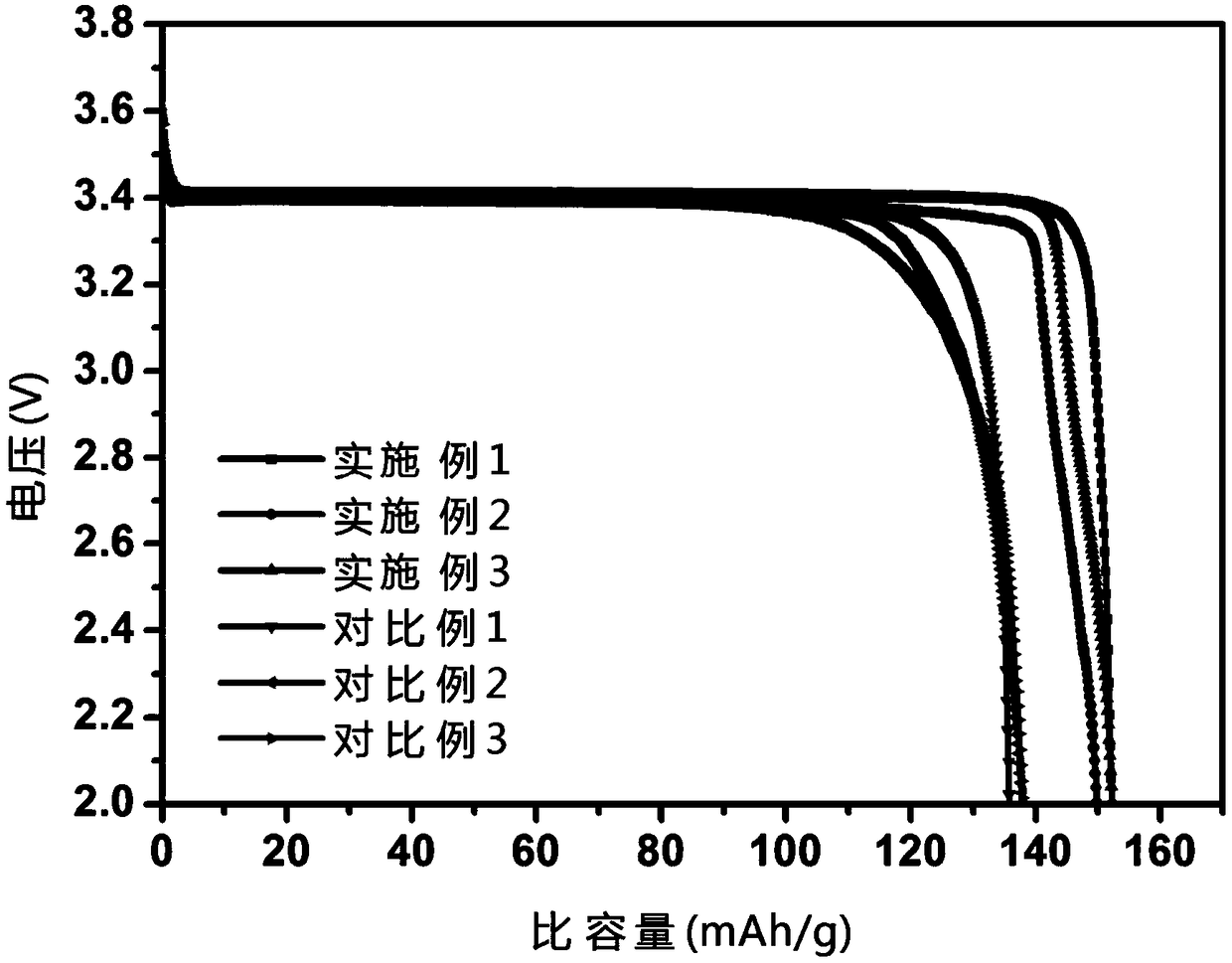

Embodiment 1

[0043] A preparation method of lithium iron phosphate cathode active material includes the following steps:

[0044] 723g of lithium carbonate (19.6mol), 1471.8g of iron oxide (18.4mol), and 14.9g of titanium dioxide (0.2mol) were added to the tank-type mixing and dispersing machine and mixed for 15 minutes, and then 2185.6g of ammonium dihydrogen phosphate ( 19 mol) and 240 g of glucose (added at 8 wt% of the theoretical mass of the produced lithium iron phosphate, here theoretically produced 3000 g of lithium iron phosphate), all the materials were mixed and dispersed for 15 minutes to obtain a mixture. Take out the mixed material in the trough-type mixing and dispersing machine and transfer it to the double-cone rotary vacuum dryer, vacuum the tank, adjust the vacuum in the tank to 0.08MPa, and mix and dry at a drying temperature of 150℃ 9h, get dry material. Then use a jet mill to crush and refine the obtained dry material, where the gas pressure in the jet mill is adjusted ...

Embodiment 2

[0048] A preparation method of lithium iron phosphate cathode active material includes the following steps:

[0049] Add 872.1g of lithium hydroxide (36.4mol), 2738.7g of iron oxide (34.3mol), and 93g of niobium oxide (0.7mol) into the tank-type mixing and dispersing machine for 30 minutes, and then add 4026g of ammonium dihydrogen phosphate in sequence (35 mol) and 552.2 g of glucose (added at 10 wt% of the theoretical mass of the produced lithium iron phosphate), all materials were mixed and dispersed for 20 minutes to obtain a mixture. Take out the mixed material in the trough-type mixing and dispersing machine and transfer it to the double-cone rotary vacuum dryer, vacuum the tank, adjust the vacuum in the tank to 0.06MPa, and mix and dry at a drying temperature of 200℃ 8h, get dry material. Then use a jet mill to crush and refine the obtained dry material, where the gas pressure in the jet mill is adjusted to 0.95MPa, the rotation frequency of the classification wheel is 35...

Embodiment 3

[0052] A preparation method of lithium iron phosphate cathode active material includes the following steps:

[0053] Add 1359.4g of lithium acetate (20.6mol), 3918.6g of iron sulfate (19.6mol), and 16.1g of magnesium oxide (0.4mol) into a tank-type mixing and dispersing machine for 30 minutes, and then add 2300.6g of dihydrogen phosphate in sequence Ammonium (20 mol) and 189.3 g of glucose (added at 6 wt% of the theoretical mass of the produced lithium iron phosphate), all materials are mixed and dispersed for 20 minutes to obtain a mixture. Take out the mixed material in the trough-type mixing and dispersing machine and transfer it to the double-cone rotary vacuum dryer, vacuum the tank body, adjust the vacuum degree in the tank to 0.07MPa, and mix and dry at 170℃ 8h, get dry material. Then use a jet mill to crush and refine the obtained dry material, where the gas pressure in the jet mill is adjusted to 0.9MPa, the rotation frequency of the classification wheel is 35Hz, the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com