Composite material of containing granule stuffing and polymer of thermotropic liquid crystal preparation method and application

A composite material and particle filler technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve problems such as poor melt fluidity, and achieve the effects of improving processing performance, reducing viscosity, excellent flow performance and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

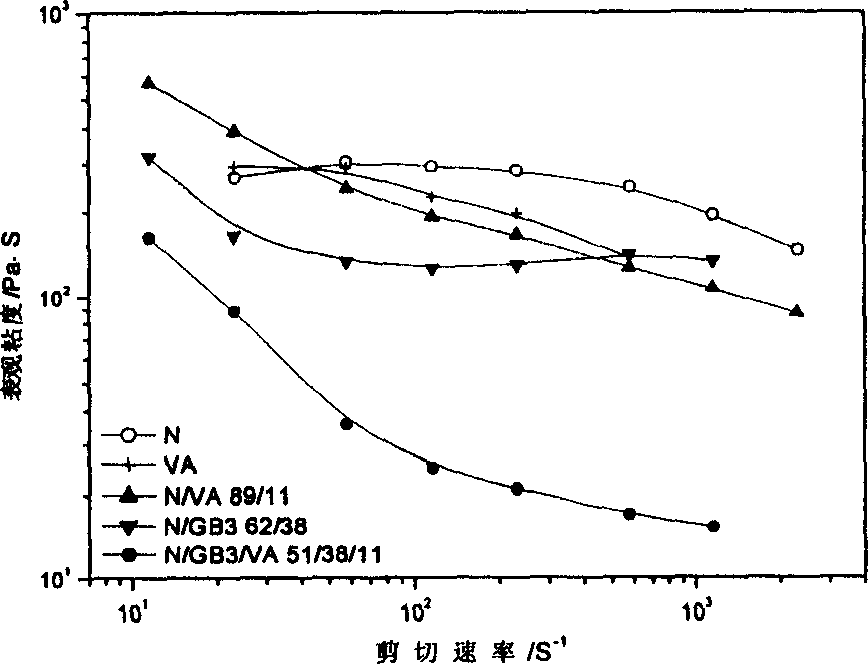

Embodiment 1

[0031] The raw materials are nylon 6 (relative viscosity 3.2), hollow glass beads with a diameter of 3 μm and thermotropic liquid crystal polymer (PHB / HNA 73 / 27, Vectra A950, Ticona Celanese Company, USA) in a weight ratio of 84:5:11 Melt blending on a Haake RC-90 twin-screw extruder, the temperature from the feeding port to the die is set to 260-280-280-280. The extruded bar was cooled and pelletized, and the resulting pellets were tested for rheological properties on a Goettfert Rheograph 2001 capillary rheometer. The inner diameter of the capillary used is 1mm, and the ratio of length to diameter is 30. The experiment temperature is 280°C, and the material is preheated for 4 minutes.

Embodiment 2

[0037] The weight ratio of nylon 6, glass beads and thermotropic liquid crystal polymer is 51 / 38 / 11, and other conditions are the same as in Example 1.

Embodiment 3

[0043] The weight ratio of nylon 6, glass microspheres and thermotropic liquid crystal polymer is 34:55:11, the specifications of hollow glass microspheres and thermotropic liquid crystal polymer are the same as in Example 1, and the preparation and testing methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com