Electro-plasticizing continuous extrusion molding processing technology of high-strength aluminum alloy

A technology of extrusion forming and processing method, which is applied in the field of continuous extrusion forming and processing of high-strength aluminum alloys by electroplasticization, and can solve the problem of inability to overcome the hot forming of high-strength aluminum alloys, reducing the service life of the cavity, and low plasticity of high-strength aluminum alloys. problems, to reduce the influence of residual stress and work hardening, improve performance, and reduce deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

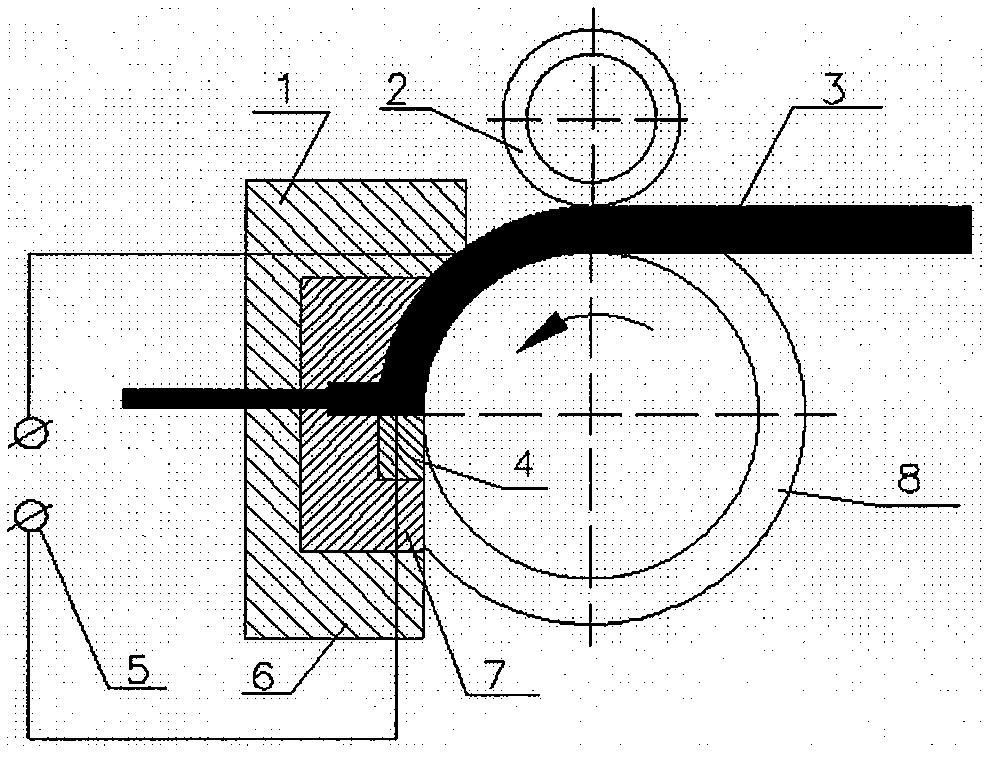

[0009] Such as figure 1 As shown, the extrusion wheel 8 is driven by power to perform circular rotation in the direction of the arrow, and there is an approximately U-shaped groove in the middle of the circumference of the extrusion wheel. Inside the boot seat 1, there is a The sealing block, the cavity 7, the material retaining block 4, the surface of the cavity 7 is processed into a surface with the same curvature as the extrusion wheel 8, so the sealing area is formed in the groove of the extrusion wheel. The blank 3 is pressed in the groove of the extrusion wheel 8 by the compaction wheel 2, and is continuously sent to the extrusion chamber 7 formed by the extrusion wheel 8 and the tool in the shoe seat 1 under the action of friction force. During the process, when the blank 3 enters the cavity 7 and reaches the block 4, the plastic deformation occurs, and the pulse current is passed into the blank 3 through the wire. When the blank 3 is doing circular motion, due to the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com